Leather bag processing technology and leather bag processed through technology

A processing technology and technology for leather bags, which are applied in small raw leather/large raw leather/leather/fur treatment, small raw leather/large raw leather/leather leather/fur chemical treatment, handbags, etc. It can solve the problem of reducing the value of noble leather bags and affecting leather bags. The overall appearance and the sutures are not strong enough to achieve the effect of improving the aesthetics, practicability and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

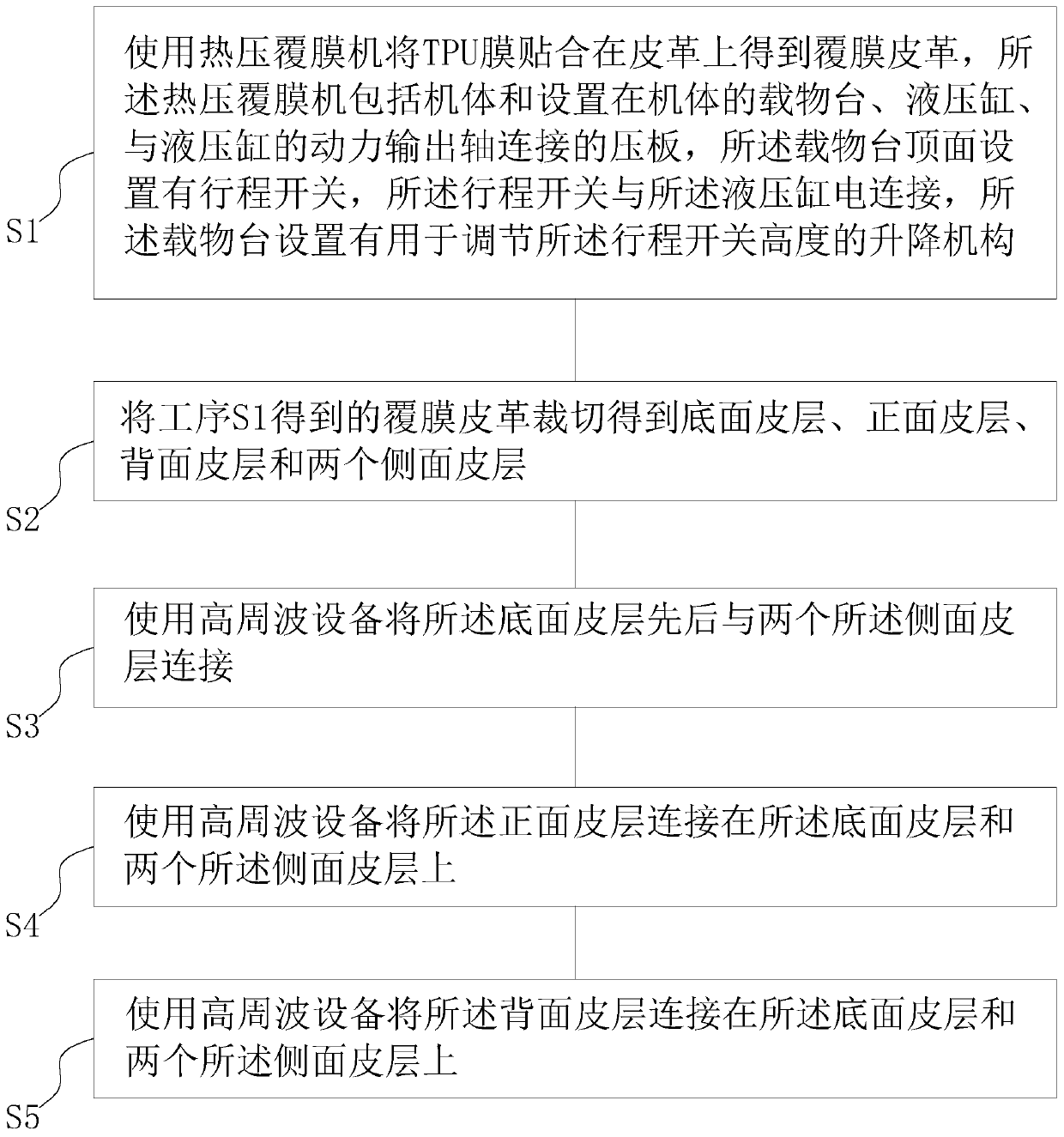

[0039] Such as figure 1 Shown, be a kind of leather bag processing technology that the present invention proposes, it comprises following operation:

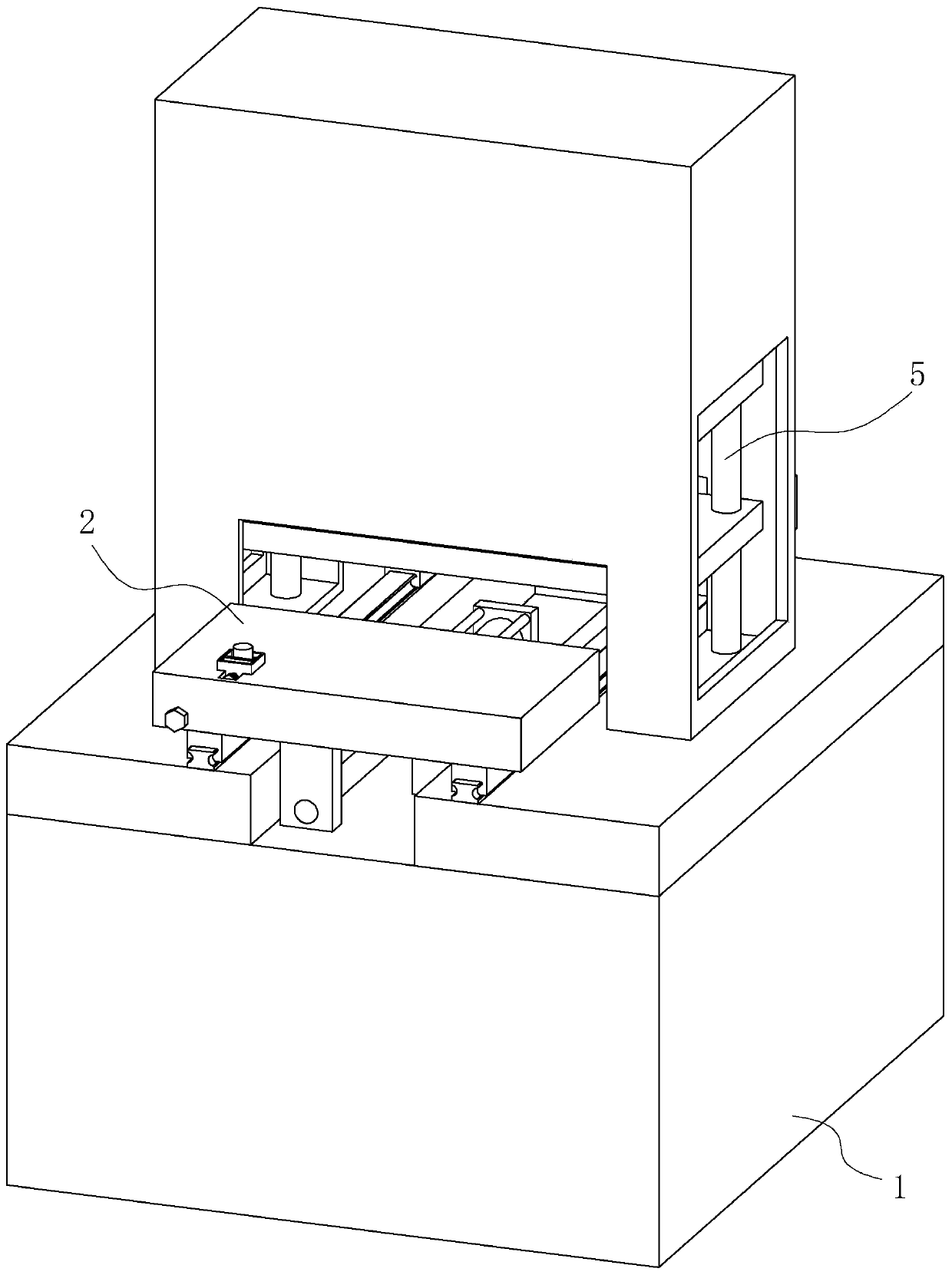

[0040] Process S1: Use a hot-press laminating machine to attach the TPU film to the leather to obtain coated leather. The hot-press laminating machine includes a body 1 and a stage 2 set on the body 1, a hydraulic cylinder 3, and a hydraulic cylinder 3. The pressure plate 4 connected to the power output shaft, and the top surface of the stage 2 are provided with a travel switch 6, and the travel switch 6 is electrically connected with the hydraulic cylinder 3, and the stage 2 is provided with a lifting mechanism for adjusting the height of the travel switch 6.

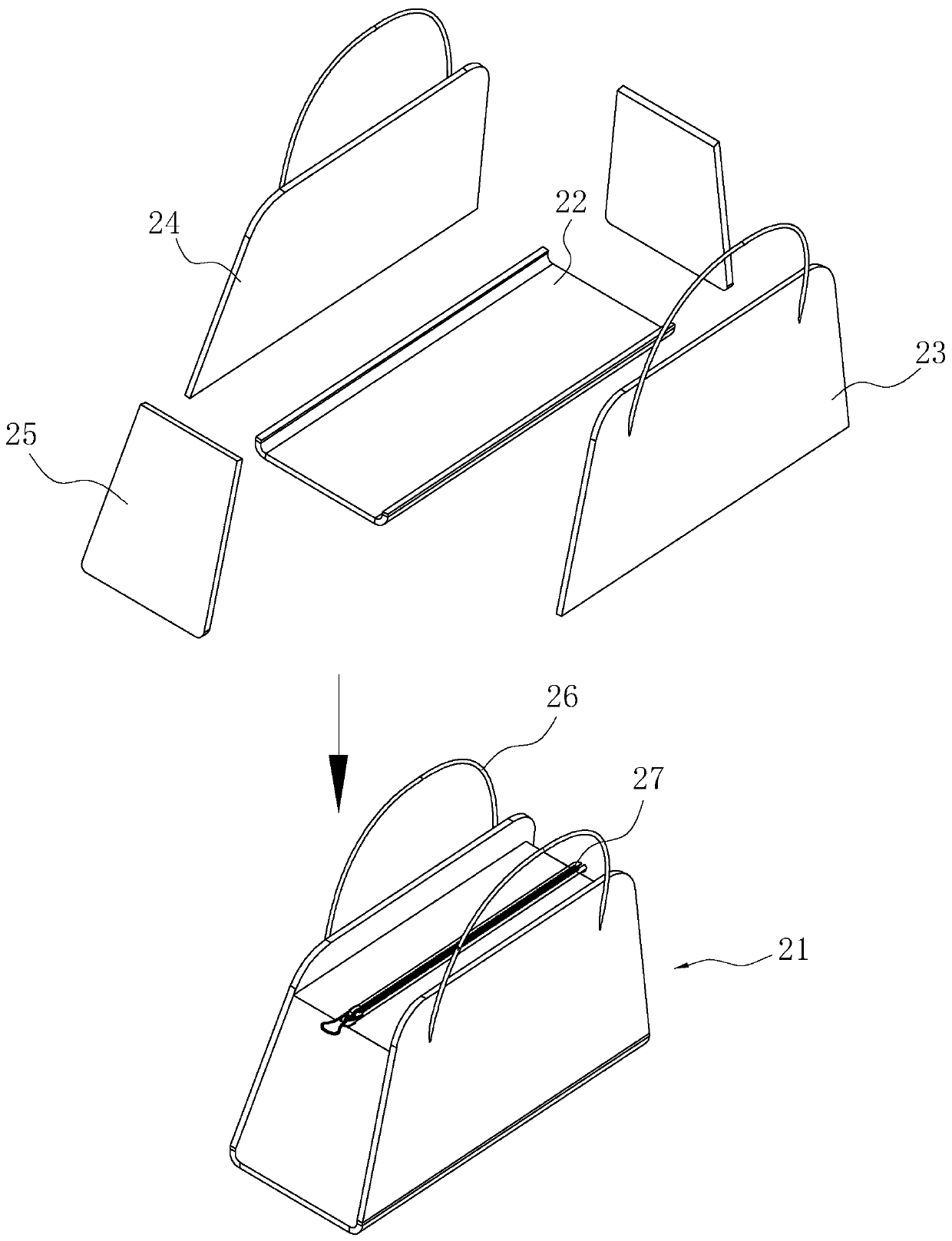

[0041] Step S2: cutting the coated leather obtained in step S1 to obtain a bottom leather layer 22 , a front leather layer 23 , a back leather layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com