Patents

Literature

35results about How to "Overcome hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly processing technique of ultrathin high-gloss downproof chemical fiber fabric

ActiveCN103924411AOvercome hardeningSolve highFibre treatmentLiquid/gas/vapor textile treatmentEnvironmental resistanceFiber

The invention relates to an environment-friendly processing technique of an ultrathin high-gloss downproof chemical fiber fabric. The processing technique sequentially comprises the following steps: (1) performing dyeing drying on a grey fabric with the breadth of a and the normal calendaring temperature of T to lower the a to a-delta a1, wherein delta a1 is more than zero; (2) soaking the grey fabric into impregnation liquid containing functional assistants, fully absorbing the impregnation liquid, then shaping and drying, and drawing till the breadth is equal to a-delta a2, wherein delta a2 is more than or equal to zero and less than delta a1, and the functional assistants at least comprise a protective agent and a smoothing agent; and (3) calendaring the grey fabric at the temperature of T plus delta T and under the pressure of 6-10 MPa, wherein delta T is more than or equal to 0 and less than or equal to 30 DEG C, and the breadth of the grey fabric is reduced to a-delta a3, and delta a1 is less than or equal to delta a3. The prepared fabric solves the problems of hardening, thickening, weight increasing, and non-lasting downproof effect, and can achieve downproof, wind-resistant, breathable and moisture permeable effects under conditions of environment protection and no pollution; besides, the processing technique is simple in operation.

Owner:SUZHOU TANGHUA NANO TECH

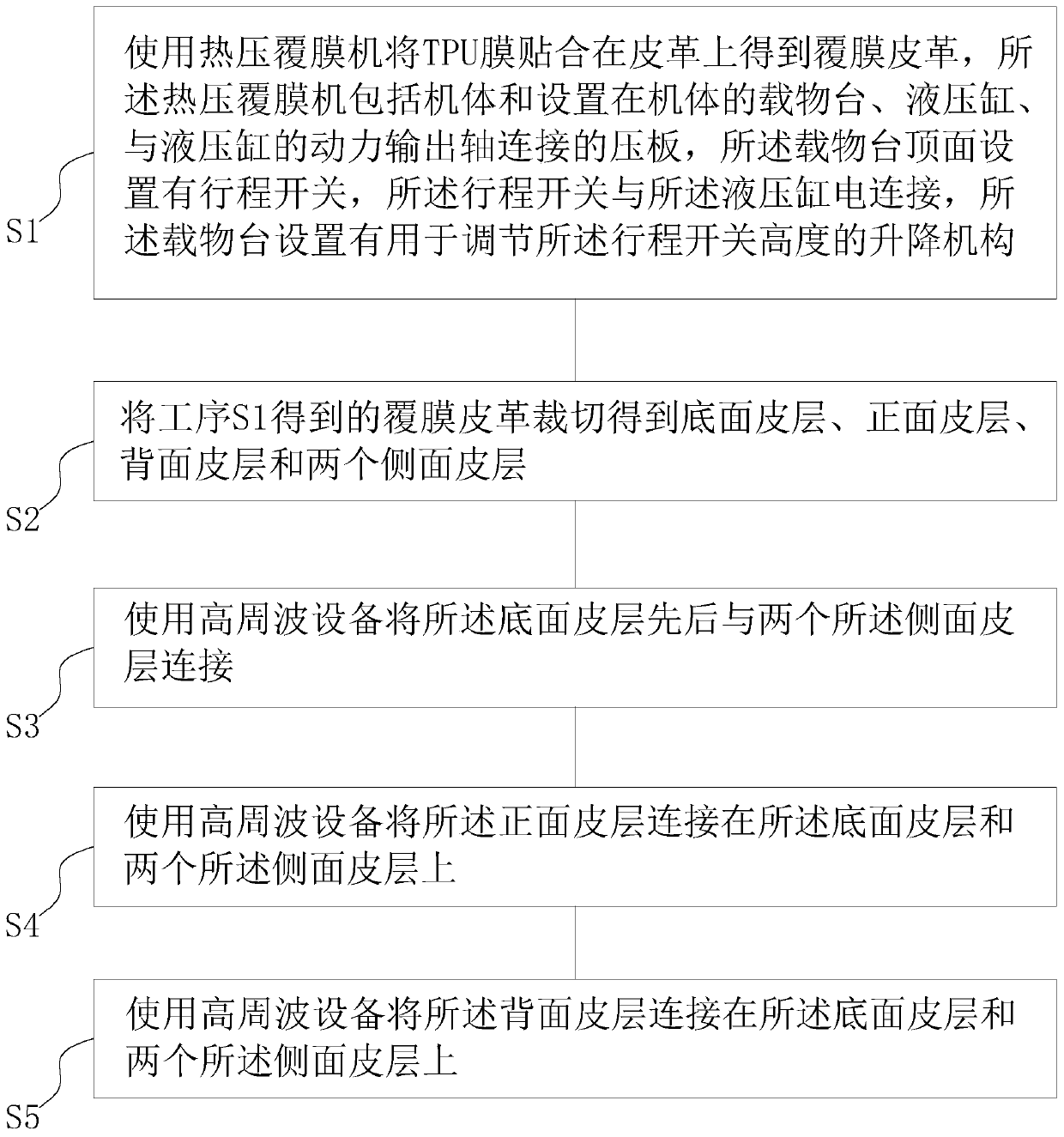

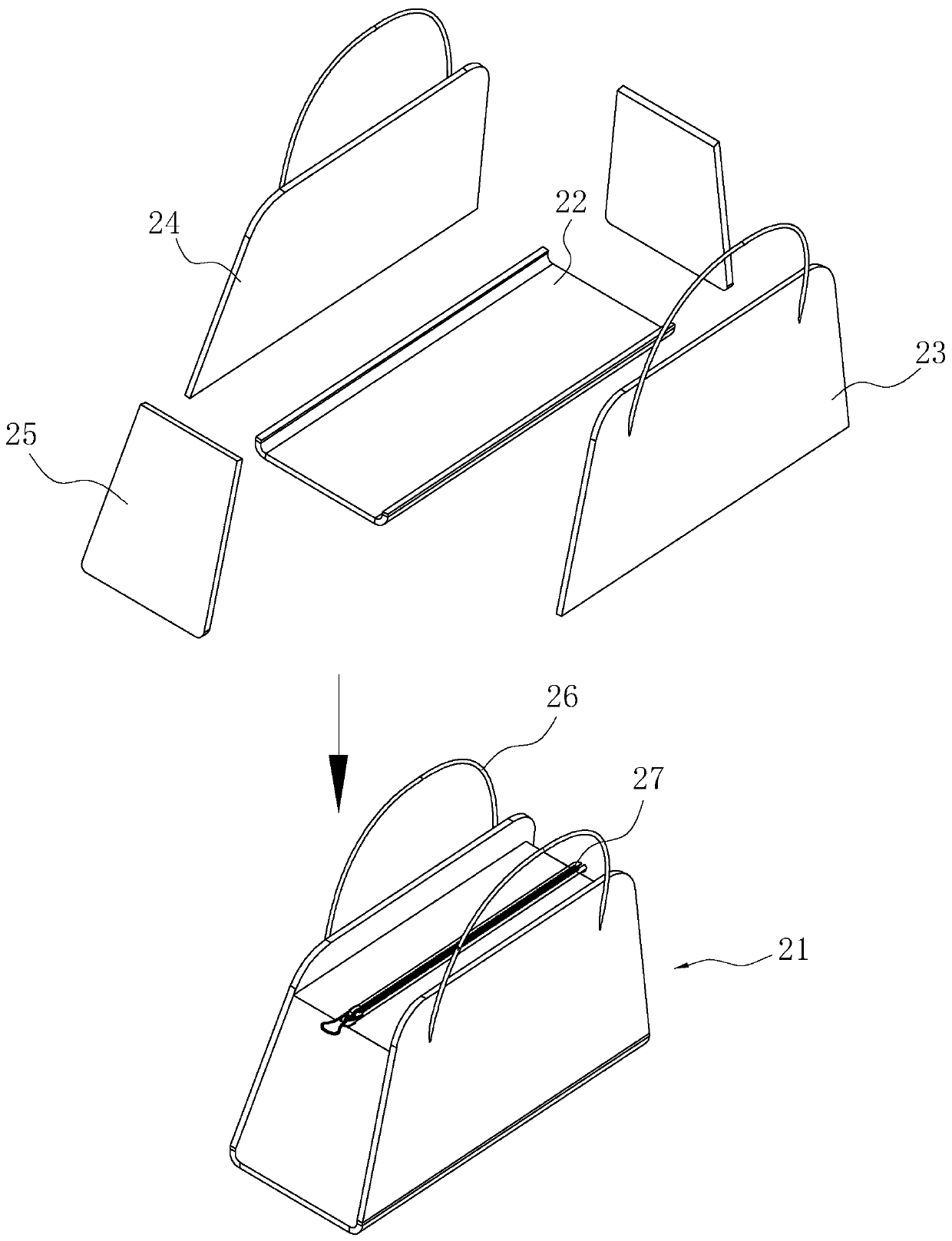

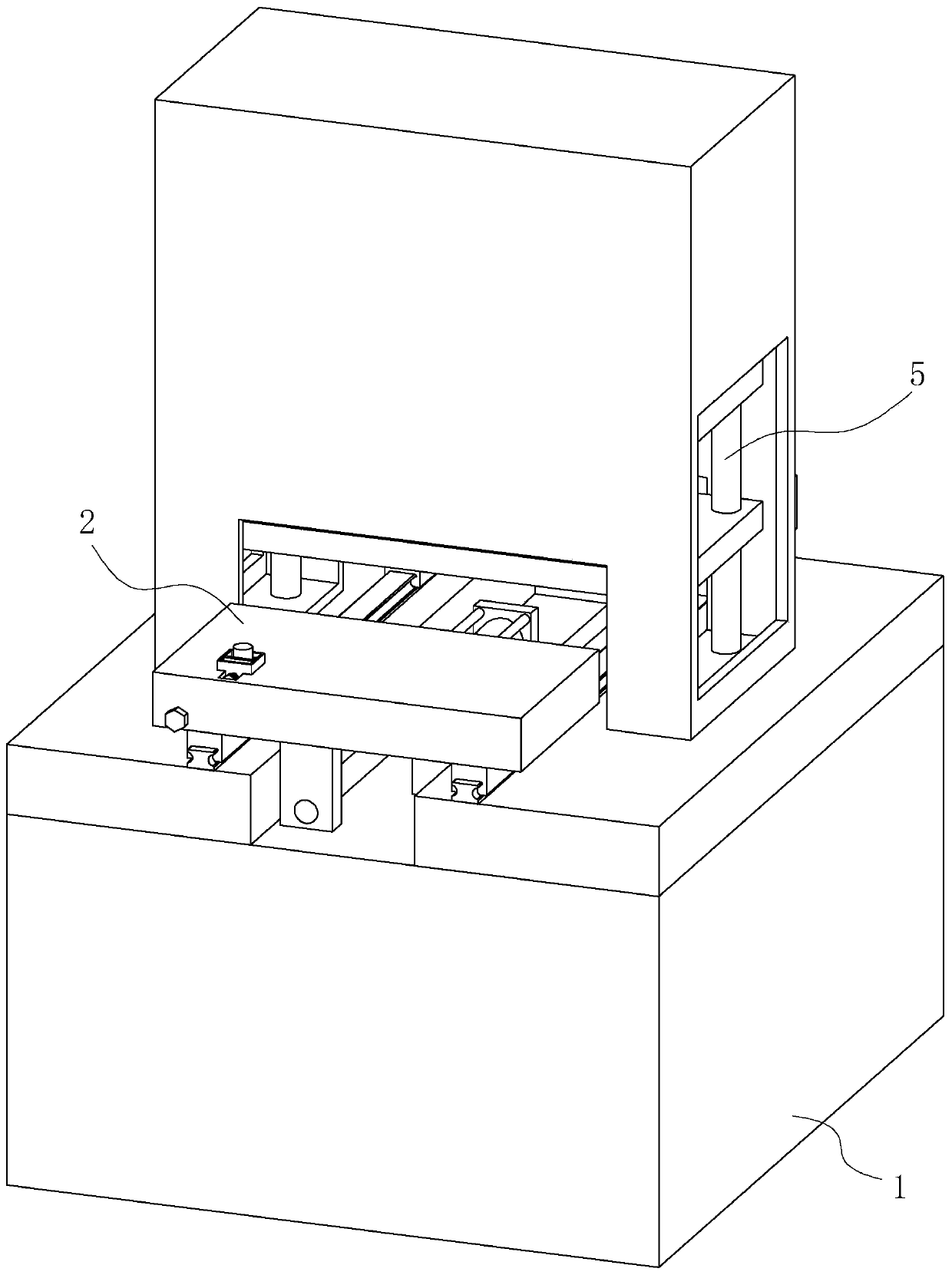

Leather bag processing technology and leather bag processed through technology

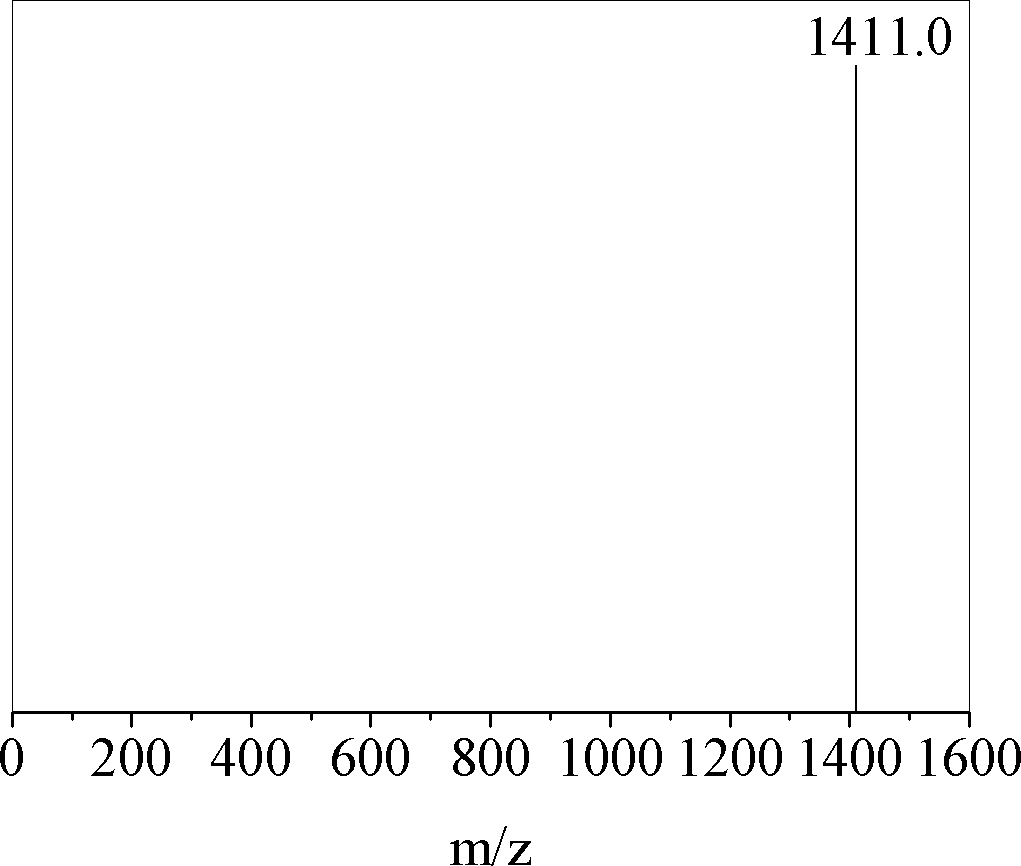

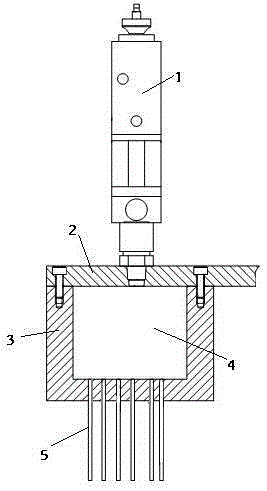

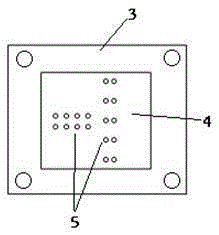

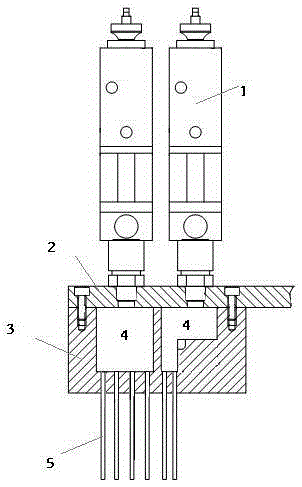

InactiveCN110123002AOvercome water resistanceOvercome wear resistanceSynthetic resin layered productsHandbagsHydraulic cylinderEngineering

The invention relates to a leather bag processing technology. The technology comprises the following steps that S1, a TPU film is attached to leather by using a hot-pressing film laminating machine toobtain the coated leather, wherein the hot-pressure laminating machine comprises a machine body, a carrying table arranged on the machine body, a hydraulic cylinder and a pressing plate connected with a power output shaft of the hydraulic cylinder, a travel switch is arranged on the top surface of the carrying table, the travel switch is electrically connected with the hydraulic cylinder, and thecarrying table is provided with a lifting mechanism used for adjusting the height of the travel switch; S2, the coated leather obtained in S1 is cut to obtain a bottom leather layer, a front leatherlayer, a back leather layer and two side leather layers; S3, the bottom leather layer is sequentially connected with the two side leather layers by using high-frequency equipment; S4, the high-frequency equipment is used for making the front leather layer connected to the bottom leather layer and the two side leather layers; S5,the back leather layer is connected to the bottom leather layer and the two side leather layers by using high-frequency equipment. Meanwhile, the invention provides a leather bag processed through the technology. The leather bag has the advantage of improving the strength and attractiveness.

Owner:上海全邯电子科技有限公司

Complex-calcium-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN103254965AExcellent overall performanceOvercome poor overall performanceThickenersDiamineIsocyanate

The invention relates to a complex-calcium-based tetrapolyurea lubricating grease and a preparation method thereof. The preparation method comprises the steps that: (1) under the existence of a lubricating base oil, calcium hydroxide, higher fatty acid, binary aromatic acid, and C1-C6 fatty acid are subjected to contact reaction; a mixture obtained after the reaction is subjected to heating dehydration, and is cooled to 50-80 DEG C, such that complex-calcium-based lubricating grease is obtained; (2) diisocyanate and diamine are sequentially added into the complex-calcium-based lubricating grease, and mixed contact is allowed for at least 5min; monoamine is added, and the mixture is heated to 90-120 DEG C, such that contact reaction is carried out; and a mixture obtained after the reaction is heated and refined. A dose molar ratio of diisocyanate to diamine to monoamine is (1.9-2.1):1:(1.9-2.1). The complex-calcium-based tetrapolyurea lubricating grease provided by the invention has excellent comprehensive performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite straw sheet and preparation method thereof

ActiveCN104098309APromote excitationMeet the hydration rateSolid waste managementAluminiumAlkaline water

The invention discloses a preparation method of a composite straw sheet. The method includes: increasing the content of sulphate aluminium cement clinker into common sulphate aluminium cement, adding hydraulic calcium oxide as an exciting agent, and conducting blending to form compound sulphoaluminate cement, and bonding the cement with crop straw to obtain the sheet. And the side effects of straw on cement setting and hardening can be overcome. In the method, the straw is not soaked by alkaline water, a chlorine-containing material is unnecessary for modification treatment on straw, wastewater discharge does not exist, heating is not needed, smoke dust and exhaust emission are absent. The advantages of light weight and abundant fiber of crop straw are utilized for low energy consumption and pollution-free preparation of the composite straw sheet.

Owner:四川什邡国正环保科技有限公司

Composite calcium-base octa-polyurea lubricating grease and preparation method thereof

The invention also relates to a composite calcium-base octa-polyurea lubricating grease and a preparation method thereof. The preparation method comprises the following steps: (1) in the presence of lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid, binary aromatic acid and C1-C6 fatty acid, heating to dehydrate the reaction mixture, and cooling to 50-70 DEG C to obtain a composite calcium-base lubricating grease; and (2) adding diisocyanate, diamine and monoamine into the composite calcium-base lubricating grease, carrying out contact reaction at 80-120 DEG C, and heating the reaction mixture for refinement, wherein the diisocyanate:diamine:monoamine mol ratio is (3.9-4.1):(2.9-3.1):2. The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

ActiveCN103289781AExcellent overall performanceOvercome poor overall performanceThickenersDiamineIsocyanate

The invention relates to a composite calcium-base hexa-polyurea lubricating grease which contains lubricating base oil, hexa-polyurea and composite calcium soap, wherein the composite calcium soap is a mixture of higher fatty acid calcium, binary aromatic acid calcium and C1-C6 fatty acid calcium. The invention also relates to a preparation method of the composite calcium-base hexa-polyurea lubricating grease, which comprises the following steps: (1) in the presence of the lubricating base oil, carrying out contact reaction on diisocyanate, diamine and monoamine in a mol ratio of (2.9-3.1):(1.9-2.1):2, and heating the reaction mixture for refinement; (2) in the presence of the lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid, binary aromatic acid and C1-C6 fatty acid, and heating to dehydrate the reaction mixture; and (3) mixing the product obtained in the step (1) with the product obtained in the step (2). The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base octa-polyurea lubricating grease and preparation method thereo

The invention also relates to a composite calcium-base octa-polyurea lubricating grease and a preparation method thereof. The preparation method comprises the following steps: (1) in the presence of lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid and binary aromatic acid, heating to dehydrate the reaction mixture, and cooling to 50-70 DEG C to obtain a composite calcium-base lubricating grease; and (2) adding diisocyanate, diamine and monoamine into the composite calcium-base lubricating grease, carrying out contact reaction at 80-120 DEG C, and heating the reaction mixture for refinement, wherein the diisocyanate:diamine:monoamine mol ratio is (3.9-4.1):(2.9-3.1):2. The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base hexa-polyurea lubricating grease and a preparation method thereof. The preparation method comprises the following steps: (1) in the presence of lubricating base oil, carrying out contact reaction on calcium hydroxide, higher fatty acid and binary aromatic acid, heating to dehydrate the reaction mixture, and cooling to 50-80 DEG C to obtain a composite calcium-base lubricating grease; and (2) adding diisocyanate, diamine and monoamine into the composite calcium-base lubricating grease, carrying out contact reaction at 80-120 DEG C, and heating the reaction mixture for refinement, wherein the diisocyanate:diamine:monoamine mol ratio is (2.9-3.1):(1.9-2.1):2. The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

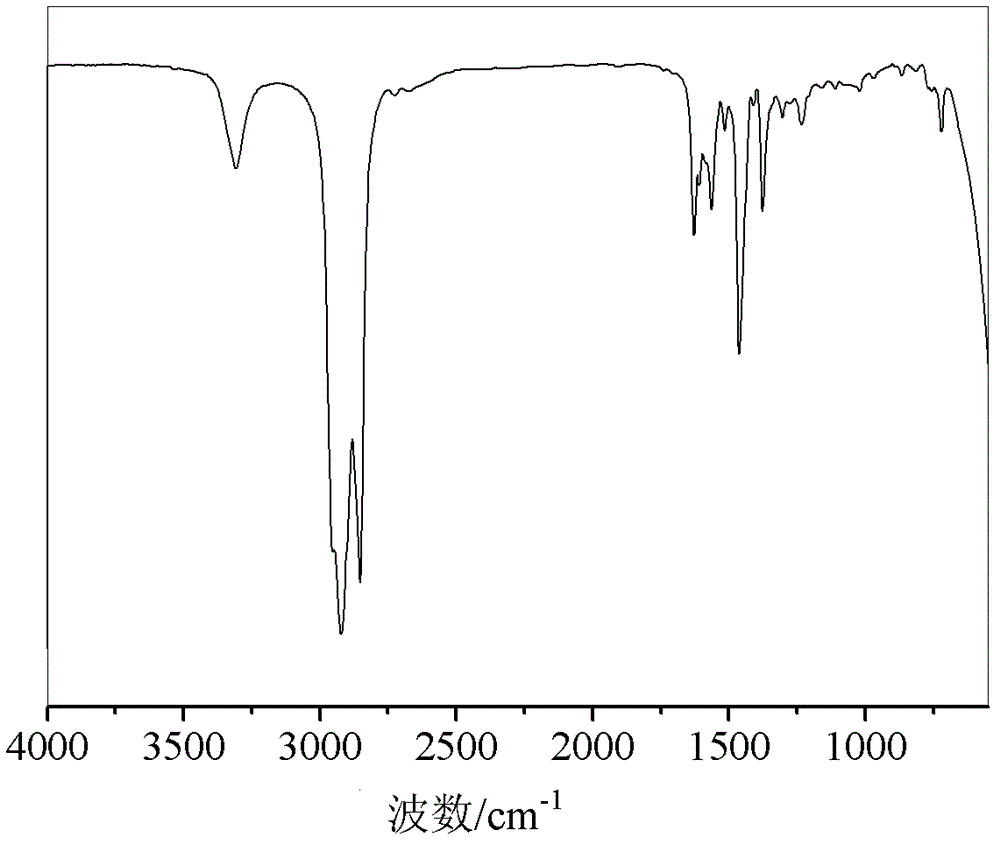

Euphausia superba oil gel capsule and preparation method thereof

PendingCN114224862AOvercome hardeningAvoid contactSenses disorderNervous disorderFood additiveCarboxyl radical

The invention relates to an euphausia superba oil gel capsule and a preparation method thereof, the method comprises the following steps: (1) mixing gelatin, a softener, water and a modifier, heating and uniformly stirring to obtain a gelatin solution, the modifier being a food additive with hydroxyl; and (2) taking gelatin liquid as a capsule wall material, taking euphausia superba oil as a capsule content, and wrapping the capsule content in the capsule wall material to form a soft capsule, thereby obtaining the euphausia superba oil soft capsule. By modifying the capsule wall material, when eicosapentaenoic acid and docosahexaenoic acid in the krill oil are in contact with the inner wall of the soft capsule, hydrophilic carboxyl groups on the eicosapentaenoic acid and docosahexaenoic acid can be combined with hydroxyl groups on the inner wall surface of the soft capsule to form ester groups, and the ester groups are hydrophobic groups; and equivalently, a barrier film layer is formed on the inner wall surface of the soft capsule, so that other krill oil in the capsule can be prevented from continuously contacting with the inner wall surface of the soft capsule, and the problems of hardening and embrittlement of the soft capsule caused by water absorption of the krill oil are well avoided.

Owner:QINGDAO BINHAI UNIV

Composite straw board and preparation method thereof

The invention discloses a preparation method of a composite straw sheet. The method includes: increasing the content of sulphate aluminium cement clinker into common sulphate aluminium cement, adding hydraulic calcium oxide as an exciting agent, and conducting blending to form compound sulphoaluminate cement, and bonding the cement with crop straw to obtain the sheet. And the side effects of straw on cement setting and hardening can be overcome. In the method, the straw is not soaked by alkaline water, a chlorine-containing material is unnecessary for modification treatment on straw, wastewater discharge does not exist, heating is not needed, smoke dust and exhaust emission are absent. The advantages of light weight and abundant fiber of crop straw are utilized for low energy consumption and pollution-free preparation of the composite straw sheet.

Owner:四川什邡国正环保科技有限公司

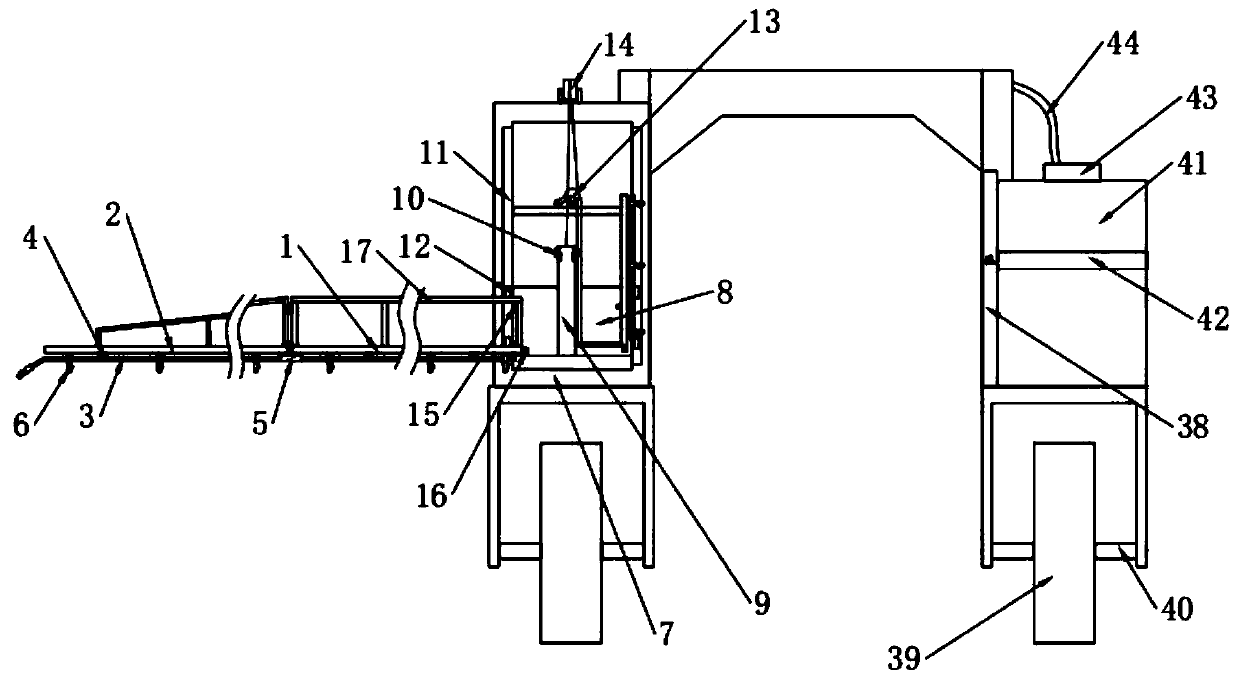

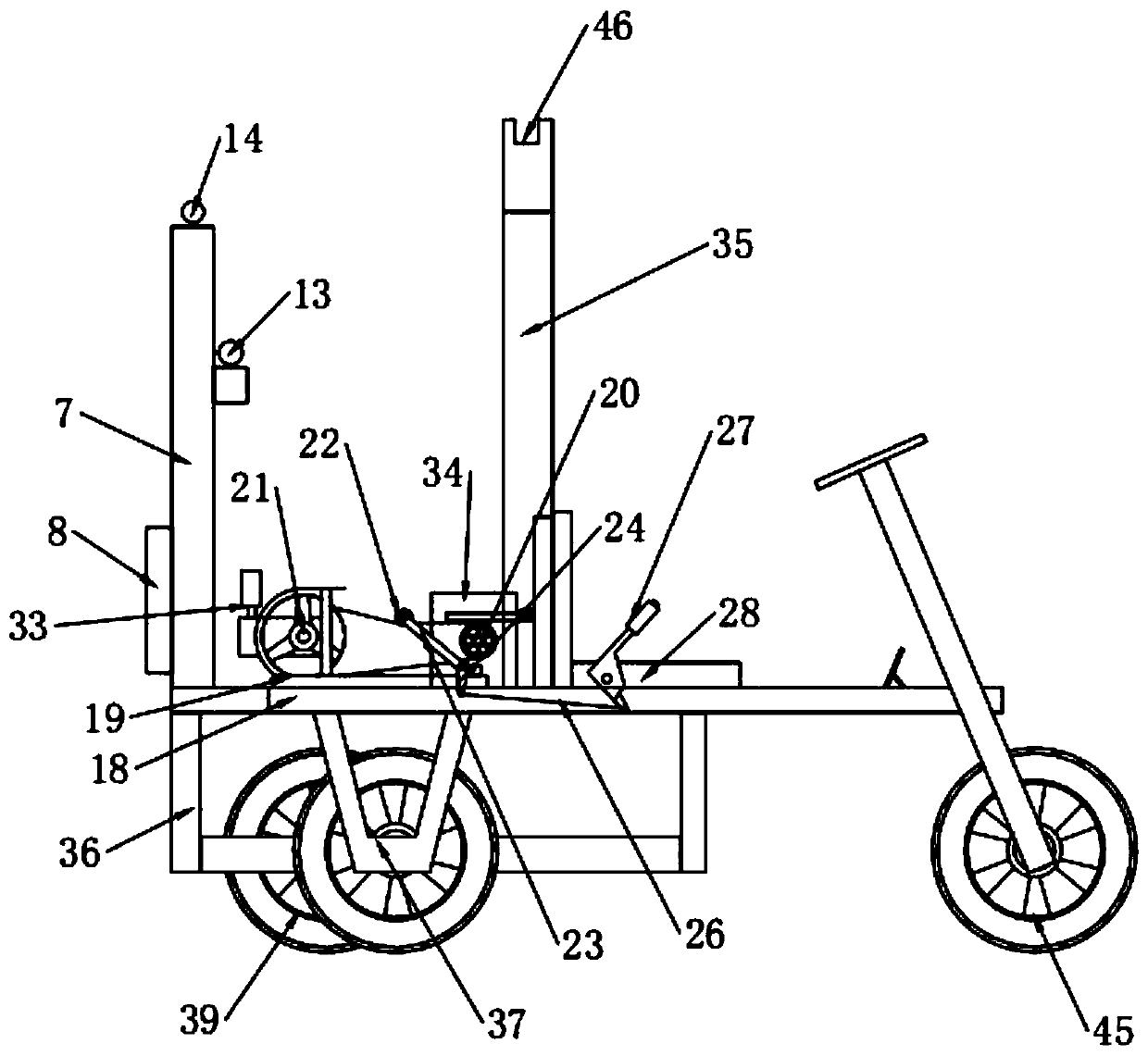

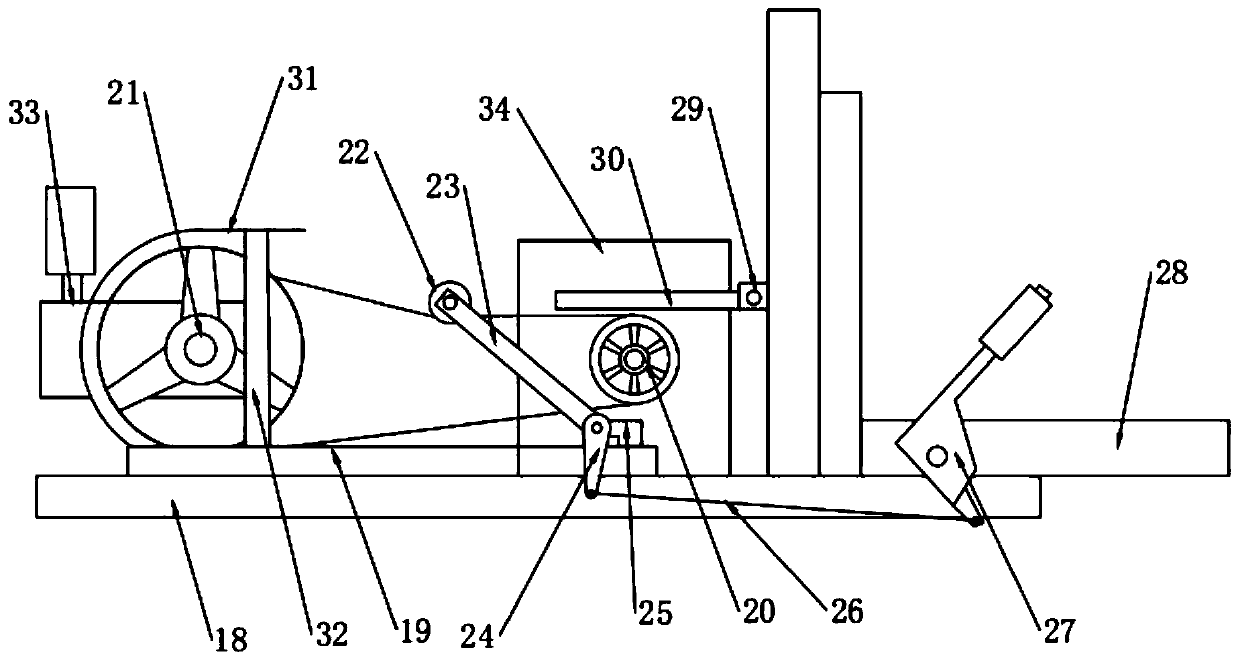

Pesticide spraying machine

InactiveCN110338174AAchieve rolling areaSmall turning radiusInsect catchers and killersSteering wheelMachine tool

The invention discloses a pesticide spraying machine and relates to the technical field of pesticide spraying machine tools in tobacco fields. The pesticide spraying machine comprises an arch-shaped rack, wherein a tobacco ridge avoiding space is formed through an arch-shaped area of the arch-shaped rack, two supporting arms relatively swing on the arch-shaped rack in the longitudinal direction, and the supporting arms perform vertical translational actions through lifting parts; the two side walls of the arch-shaped rack are respectively and horizontally provided with straightly going wheels,and one side of the arch-shaped rack is also provided with steering wheels horizontally arranged in parallel with the straightly going wheels on the side. The problems in the prior art are solved that a tobacco field pesticide spraying machine is large in tobacco rolling area when turning in a tobacco field and accordingly causes yield reduction; the machine is limited to a tobacco production period and easily scratches the surfaces of tobacco leaves; the pesticide spraying machine possibly rolls furrows with different intervals to influence the growth of tobacco; a pressure pump of the pesticide spraying machine applied to the tobacco field is frequently started and stopped, so that the abrasion is intensified, and the service life is shortened; and a pesticide spraying part influences the flow of incoming people and the driving space of vehicles when the machine runs on a road which is located in the tobacco field.

Owner:WEIFANG TOBACCO MONOPOLY BUREAU

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base hexa-polyurea lubricating grease which contains lubricating base oil, hexa-polyurea and composite calcium soap, wherein the composite calcium soap is a mixture of higher fatty acid calcium and binary aromatic acid calcium. The invention also relates to a preparation method of the composite calcium-base hexa-polyurea lubricating grease, which comprises the following steps: (1) in the presence of the lubricating base oil, carrying out contact reaction on diisocyanate, diamine and monoamine in a mol ratio of (2.9-3.1):(1.9-2.1):2, and heating the reaction mixture for refinement; (2) in the presence of the lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid and binary aromatic acid, and heating to dehydrate the reaction mixture; and (3) mixing the product obtained in the step (1) with the product obtained in the step (2). The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base octa-polyurea lubricating grease and preparation method thereo

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex-calcium-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN103254967AExcellent overall performanceOvercome poor overall performanceThickenersDiamineIsocyanate

The invention relates to a complex-calcium-based tetrapolyurea lubricating grease and a preparation method thereof. The preparation method comprises the steps that: (1) under the existence of a lubricating base oil, calcium hydroxide, higher fatty acid, and aromatic acid are subjected to contact reaction; a mixture obtained after the reaction is subjected to heating dehydration, and is cooled to 50-80 DEG C, such that complex-calcium-based lubricating grease is obtained; (2) diisocyanate and diamine are sequentially added into the complex-calcium-based lubricating grease, and mixed contact is allowed for at least 5min; monoamine is added, and the mixture is heated to 100-120 DEG C, such that contact reaction is carried out; and a mixture obtained after the reaction is heated and refined. A dose molar ratio of diisocyanate to diamine to monoamine is (1.9-2.1):1:(1.9-2.1). The complex-calcium-based tetrapolyurea lubricating grease provided by the invention has excellent comprehensive performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex-calcium-based tetrapolyurea lubricating grease and preparation method thereof

The invention relates to a complex-calcium-based tetrapolyurea lubricating grease and a preparation method thereof. The lubricating grease comprises lubricating base oil, tetrapolyurea, and composite calcium soap. The composite calcium soap is a mixture of higher fatty acid calcium, binary aromatic acid calcium, and C1-C6 fatty acid calcium. The invention also relates to a preparation method of the complex-calcium-based tetrapolyurea lubricating grease. The preparation method comprises the steps that: (1) under the existence of a lubricating base oil, diisocyanate, diamine and monoamine are subjected to a contact reaction; and the mixture obtained after the reaction is heated and refined; wherein a dose molar ratio of diisocyanate to diamine to monoamine is (1.9-2.1):1:(1.9-2.1); (2) under the existence of the lubricating base oil, calcium hydroxide, higher fatty acid, binary aromatic acid, and C1-C6 fatty acid calcium are subjected to a contact reaction; and the mixture obtained from the reaction is heated and dehydrated; and (3) the product obtained in the step (1) and the product obtained in the step (2) are mixed. The complex-calcium-based tetrapolyurea lubricating grease provided by the invention has excellent comprehensive performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base octa-polyurea lubricating grease and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base octa-polyurea lubricating grease and preparation method thereof

The invention also relates to a composite calcium-base octa-polyurea lubricating grease and a preparation method thereof. The preparation method comprises the following steps: (1) in the presence of lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid and aromatic acid, heating to dehydrate the reaction mixture, and cooling to 50-70 DEG C to obtain a composite calcium-base lubricating grease; and (2) adding diisocyanate, diamine and monoamine into the composite calcium-base lubricating grease, carrying out contact reaction at 80-120 DEG C, and heating the reaction mixture for refinement, wherein the diisocyanate:diamine:monoamine mol ratio is (3.9-4.1):(2.9-3.1):2. The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base hexa-polyurea lubricating grease which contains lubricating base oil, hexa-polyurea and composite calcium soap, wherein the composite calcium soap is a mixture of higher fatty acid calcium and aromatic acid calcium. The invention also relates to a preparation method of the composite calcium-base hexa-polyurea lubricating grease, which comprises the following steps: (1) in the presence of the lubricating base oil, carrying out contact reaction on diisocyanate, diamine and monoamine in a mol ratio of (2.9-3.1):(1.9-2.1):2, and heating the reaction mixture for refinement; (2) in the presence of the lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid and aromatic acid, and heating to dehydrate the reaction mixture; and (3) mixing the product obtained in the step (1) with the product obtained in the step (2). The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex-calcium-based tetrapolyurea lubricating grease and preparation method thereof

The invention relates to a complex-calcium-based tetrapolyurea lubricating grease and a preparation method thereof. The lubricating grease comprises lubricating base oil, tetrapolyurea, and composite calcium soap. The composite calcium soap is a mixture of higher fatty acid calcium and binary aromatic acid calcium. The invention also relates to a preparation method of the complex-calcium-based tetrapolyurea lubricating grease. The preparation method comprises the steps that: (1) under the existence of a lubricating base oil, diisocyanate, diamine and monoamine are subjected to a contact reaction; and the mixture obtained after the reaction is heated and refined; wherein a dose molar ratio of diisocyanate to diamine to monoamine is (1.9-2.1):1:(1.9-2.1); (2) under the existence of the lubricating base oil, calcium hydroxide, higher fatty acid and binary aromatic acid are subjected to a contact reaction; and the mixture obtained from the reaction is heated and dehydrated; and (3) the product obtained in the step (1) and the product obtained in the step (2) are mixed. The complex-calcium-based tetrapolyurea lubricating grease provided by the invention has excellent comprehensive performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base hexa-polyurea lubricating grease and a preparation method thereof. The preparation method comprises the following steps: (1) in the presence of lubricating base oil, carrying out contact reaction on calcium hydroxide, higher fatty acid and aromatic acid, heating to dehydrate the reaction mixture, and cooling to 50-80 DEG C to obtain a composite calcium-base lubricating grease; and (2) adding diisocyanate, diamine and monoamine into the composite calcium-base lubricating grease, carrying out contact reaction at 80-120 DEG C, and heating the reaction mixture for refinement, wherein the diisocyanate:diamine:monoamine mol ratio is (2.9-3.1):(1.9-2.1):2. The composite calcium-base hexa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base octa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base octa-polyurea lubricating grease which contains lubricating base oil, octa-polyurea and composite calcium soap, wherein the composite calcium soap is a mixture of higher fatty acid calcium, binary aromatic acid calcium and C1-C6 fatty acid calcium. The invention also relates to a preparation method of the composite calcium-base octa-polyurea lubricating grease, which comprises the following steps: (1) in the presence of the lubricating base oil, carrying out contact reaction on diisocyanate, diamine and monoamine in a mol ratio of (3.9-4.1):(2.9-3.1):2, and heating the reaction mixture for refinement; (2) in the presence of the lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid, binary aromatic acid and C1-C6 fatty acid, and heating to dehydrate the reaction mixture; and (3) mixing the product obtained in the step (1) with the product obtained in the step (2). The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex-calcium-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN103254968BImprove performanceOvercome the defects of poor comprehensive performanceThickenersCalcium hydroxideBase oil

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex-calcium-based tetrapolyurea lubricating grease and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex-calcium-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN103254968AImprove performanceOvercome the defects of poor comprehensive performanceThickenersCalcium hydroxideBase oil

The invention relates to a complex-calcium-based tetrapolyurea lubricating grease and a preparation method thereof. The preparation method comprises the steps that: (1) under the existence of a lubricating base oil, calcium hydroxide, higher fatty acid, and binary aromatic acid are subjected to contact reaction; a mixture obtained after the reaction is subjected to heating dehydration, and is cooled to 70-80 DEG C, such that complex-calcium-based lubricating grease is obtained; (2) diisocyanate and diamine are sequentially added into the complex-calcium-based lubricating grease, and mixed contact is allowed for at least 5min; monoamine is added, and the mixture is heated to 100-120 DEG C, such that contact reaction is carried out; and a mixture obtained after the reaction is heated and refined. A dose molar ratio of diisocyanate to diamine to monoamine is (1.9-2.1):1:(1.9-2.1). The complex-calcium-based tetrapolyurea lubricating grease provided by the invention has excellent comprehensive performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

ActiveCN103289787BImprove performanceOvercome the defects of poor comprehensive performanceThickenersCalcium hydroxideBase oil

Owner:CHINA PETROLEUM & CHEM CORP +1

oiling machine oiling device

InactiveCN102921600BControl oiling qualityReduce in quantityLiquid surface applicatorsCoatingsOil and greaseLarge distance

Owner:GUIZHOU GUIHANG AUTOMOTIVE COMPONENTS

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base hexa-polyurea lubricating grease which contains lubricating base oil, hexa-polyurea and composite calcium soap, wherein the composite calcium soap is a mixture of higher fatty acid calcium, binary aromatic acid calcium and C1-C6 fatty acid calcium. The invention also relates to a preparation method of the composite calcium-base hexa-polyurea lubricating grease, which comprises the following steps: (1) in the presence of the lubricating base oil, carrying out contact reaction on diisocyanate, diamine and monoamine in a mol ratio of (2.9-3.1):(1.9-2.1):2, and heating the reaction mixture for refinement; (2) in the presence of the lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid, binary aromatic acid and C1-C6 fatty acid, and heating to dehydrate the reaction mixture; and (3) mixing the product obtained in the step (1) with the product obtained in the step (2). The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base hexa-polyurea lubricating grease and a preparation method thereof. The preparation method comprises the following steps: (1) in the presence of lubricating base oil, carrying out contact reaction on calcium hydroxide, higher fatty acid and binary aromatic acid, heating to dehydrate the reaction mixture, and cooling to 50-80 DEG C to obtain a composite calcium-base lubricating grease; and (2) adding diisocyanate, diamine and monoamine into the composite calcium-base lubricating grease, carrying out contact reaction at 80-120 DEG C, and heating the reaction mixture for refinement, wherein the diisocyanate:diamine:monoamine mol ratio is (2.9-3.1):(1.9-2.1):2. The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base octa-polyurea lubricating grease and preparation method thereof

The invention relates to a composite calcium-base octa-polyurea lubricating grease which contains lubricating base oil, octa-polyurea and composite calcium soap, wherein the composite calcium soap is a mixture of higher fatty acid calcium, binary aromatic acid calcium and C1-C6 fatty acid calcium. The invention also relates to a preparation method of the composite calcium-base octa-polyurea lubricating grease, which comprises the following steps: (1) in the presence of the lubricating base oil, carrying out contact reaction on diisocyanate, diamine and monoamine in a mol ratio of (3.9-4.1):(2.9-3.1):2, and heating the reaction mixture for refinement; (2) in the presence of the lubricating base oil, carrying out contact reaction on the calcium hydroxide, higher fatty acid, binary aromatic acid and C1-C6 fatty acid, and heating to dehydrate the reaction mixture; and (3) mixing the product obtained in the step (1) with the product obtained in the step (2). The composite calcium-base octa-polyurea lubricating grease provided by the invention has excellent comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite calcium-base hexa-polyurea lubricating grease and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com