oiling machine oiling device

An oiling device and oiling machine technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uneven oiling, easy hardening of grease, etc. oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

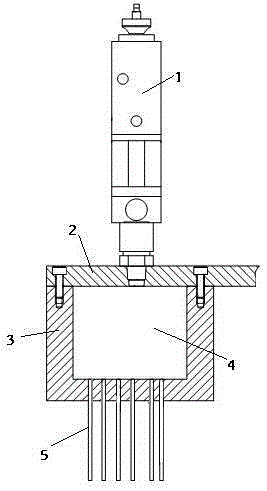

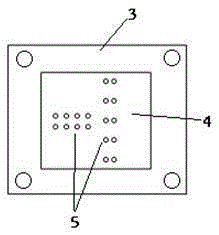

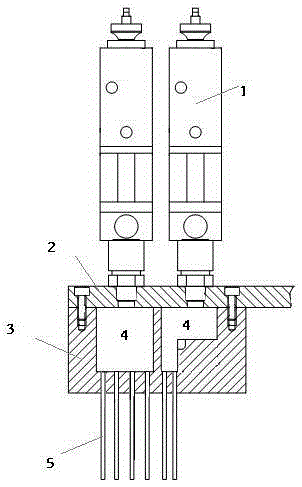

[0019] Such as image 3 and Figure 4 As shown, the oiling device of the oiling machine includes two oil controllers 1, the oil controller 1 is connected with the oiling connecting plate 2, the oiling connecting plate 2 is fixed on the oil chamber plate 3 by four screws, and the oiling connecting plate 2 The space formed between the oil chamber plate 3 contains two disconnected oil chambers 4, one left and one right, and there is an oiling pipe 5 in the oil chamber 4. Each oil controller 1 corresponds to an oil chamber 4 , the transition in the oil chamber 4 is rounded, and the volume of the chamber is smaller than the oil storage capacity of the oil controller 1 . The distribution, shape and arrangement direction of the oil chamber 4 are determined according to the needs, Figure 4 The middle is a rounded rectangle, arranged vertically and horizontally. The arrangement and quantity of the oiling pipes 5 in the oil chamber 4 can be adjusted according to the oiling situation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com