Euphausia superba oil gel capsule and preparation method thereof

An Antarctic krill and oil gel technology, which is applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as deterioration, krill oil leakage, and difficult sealing of tablets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

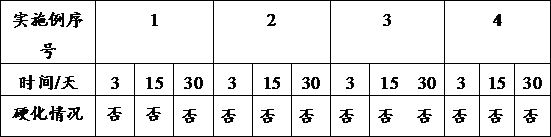

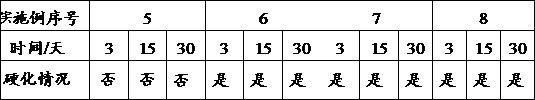

Examples

Embodiment 1

[0021] A preparation method of Antarctic krill oil gel capsule, comprising steps:

[0022] (1) Weigh gelatin, glycerin, water, and hydrophilic silica nanopowder according to the ratio of 1.0 parts by weight: 0.5 parts by weight: 1.0 parts by weight: 0.2 parts by weight; of silica nanopowder.

[0023] (2) Put the glycerin, water and hydrophilic silica nano-powder in step (1) in a plastic bucket, heat to 65°C and keep stirring for 35 minutes to disperse the silica nano-powder evenly, then add the gelatin, continue Stir to melt the gelatin completely to obtain gelatin glue, set aside.

[0024] (3) Use the gelatin solution prepared in step (2) as the capsule material, use Antarctic krill oil as the capsule content, and use the soft capsule machine (model HRS-250) to wrap the capsule content in the capsule material Soft capsules were formed in the process, the pilling temperature was 22°C, and the relative humidity was 50%. After completion, the obtained capsules were first dried...

Embodiment 2

[0026] A preparation method of Antarctic krill oil gel capsule, comprising steps:

[0027] (1) Weigh gelatin, composite softener, water, methyl p-hydroxybenzoate nanopowder according to the ratio of 1.0 parts by weight: 0.6 parts by weight: 1.07 parts by weight: 0.22 parts by weight; the composite softener is glycerin and D sorbic acid The mixture that alcohol forms, wherein, described D sorbitol is 8% of glycerin quality.

[0028] (2) Put the glycerin, water and methyl p-hydroxybenzoate nano-powder in step (1) in a rubber bucket, heat to 60°C and keep stirring for 40 minutes to disperse the methyl p-hydroxybenzoate nano-powder evenly, then add the Describe the gelatin, and continue to stir to melt the gelatin completely to obtain a gelatin glue solution, which is set aside.

[0029] (3) Use the gelatin solution prepared in step (2) as the capsule material, use Antarctic krill oil as the capsule content, and use the soft capsule machine (model HRS-250) to wrap the capsule con...

Embodiment 3

[0031] A preparation method of Antarctic krill oil gel capsule, comprising steps:

[0032] (1) Weigh gelatin, compound softener, water, and ethyl p-hydroxybenzoate nanopowder according to the ratio of 1.0 parts by weight: 0.4 parts by weight: 0.82 parts by weight: 0.13 parts by weight; the compound softener is glycerin and mannose The mixture that alcohol forms, wherein, described mannitol is 13% of glycerol quality.

[0033] (2) Put the glycerin, water and ethyl p-hydroxybenzoate nano-powder in step (1) in a rubber bucket, heat to 65°C and keep stirring for 40 minutes to disperse the ethyl p-hydroxybenzoate nano-powder evenly, then add the Describe the gelatin, and continue to stir to melt the gelatin completely to obtain a gelatin glue solution, which is set aside.

[0034] (3) Use the gelatin solution prepared in step (2) as the capsule material, use Antarctic krill oil as the capsule content, and use the soft capsule machine (model HRS-250) to wrap the capsule content in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com