Patents

Literature

499 results about "DHA - Docosahexaenoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

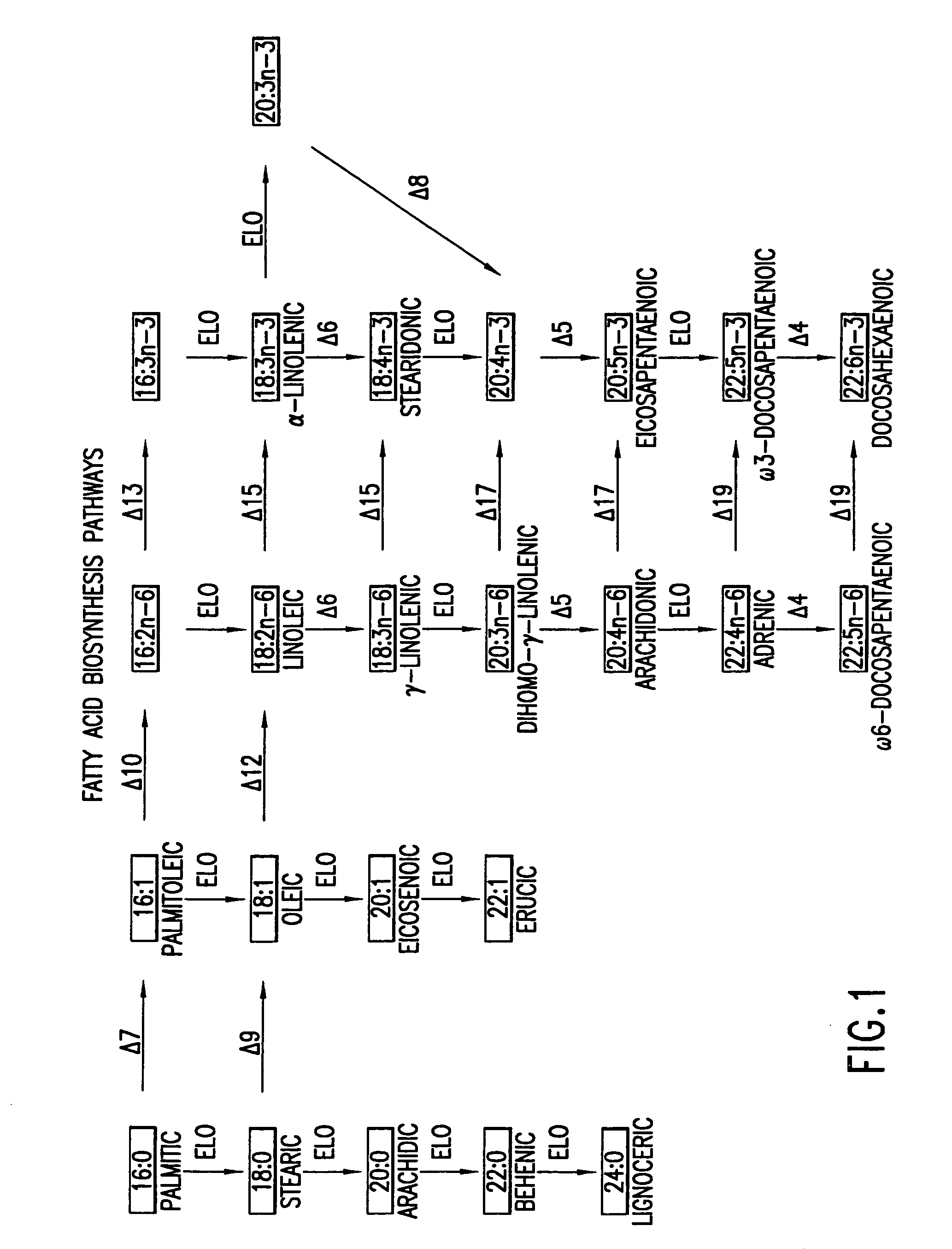

Docosahexaenoic acid (DHA) is an omega-3 fatty acid that is a primary structural component of the human brain, cerebral cortex, skin, and retina.

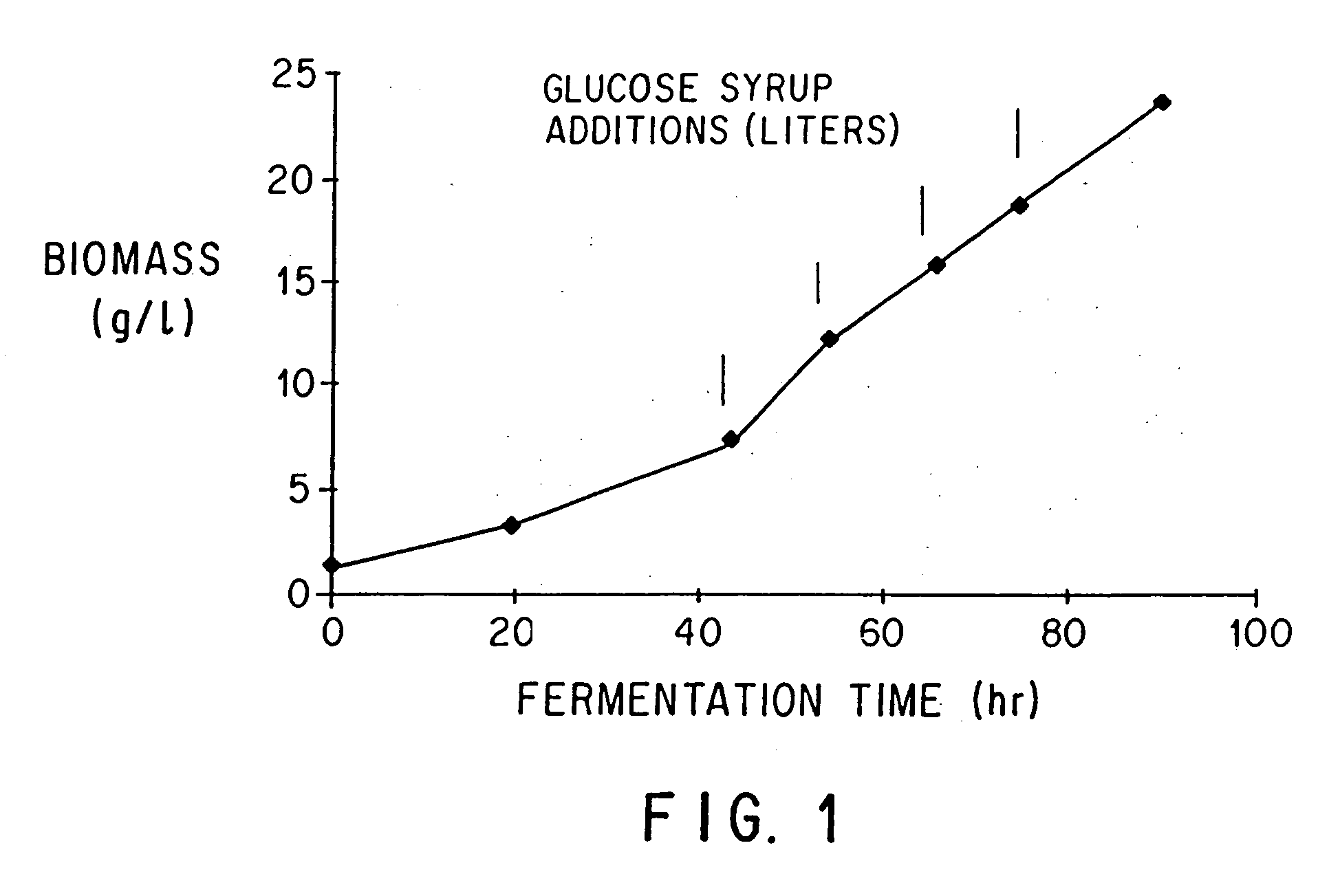

Process for preparing materials for extraction

InactiveUS20060122410A1Improve extraction efficiencyQuality improvementFungiUnicellular algaeArachidonic acid supplementationFermentation

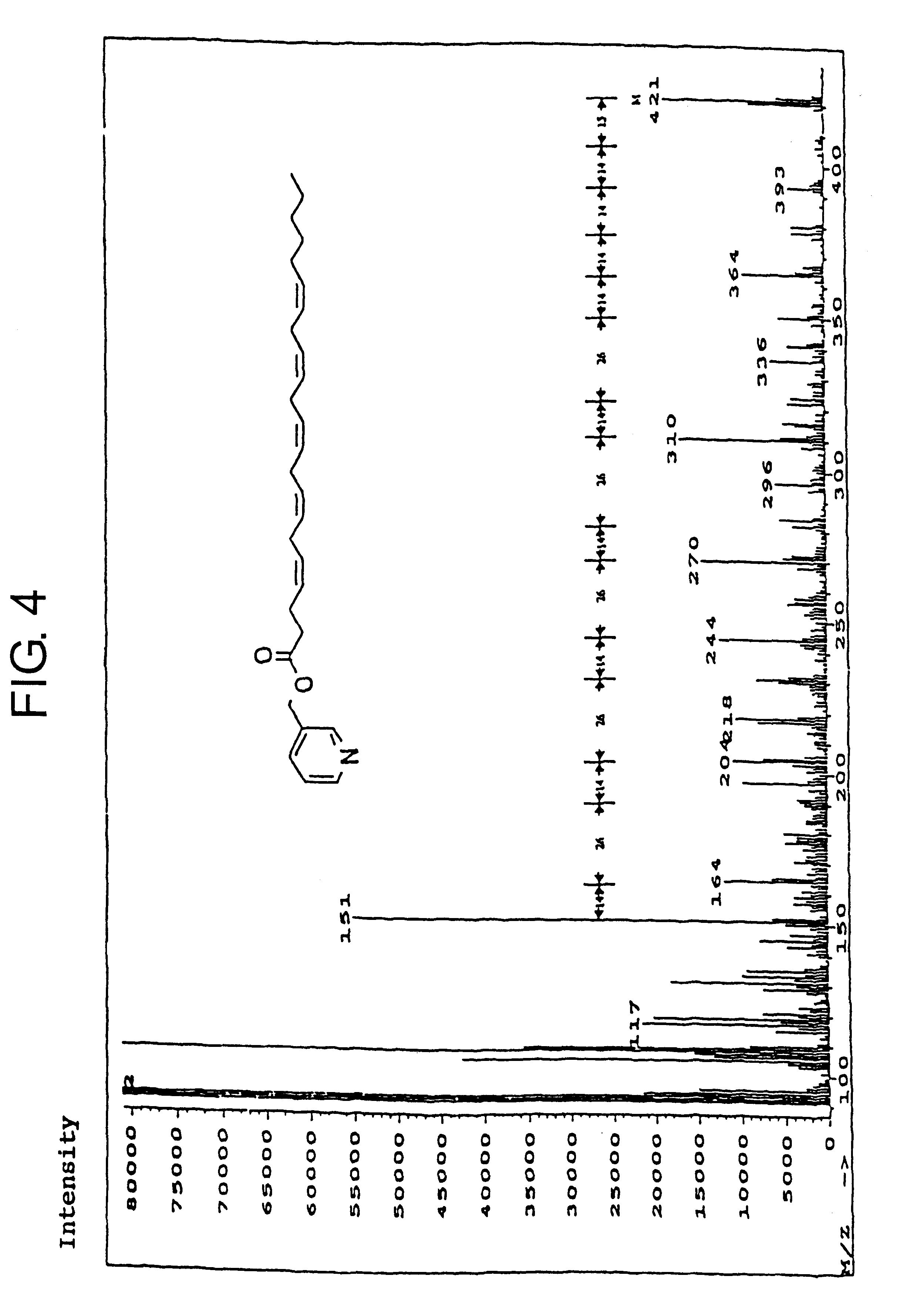

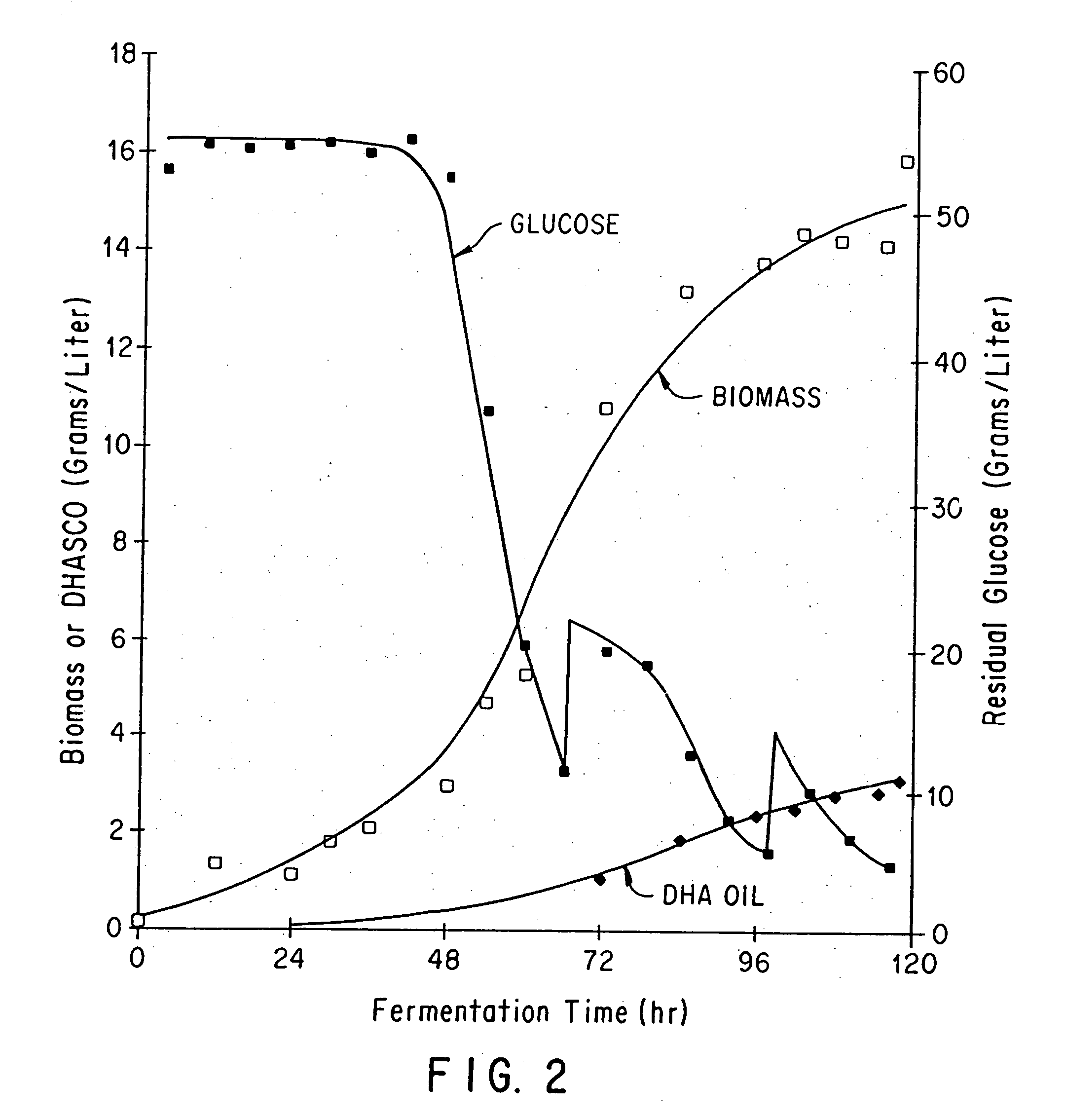

The present invention relates to a process for preparing a biomass, such as from a microbial fermentation, for an extraction process to separate desired chemicals, nutritional products, bioactive components, proteins, carbohydrates, and lipids, from the biomass. Particularly preferred substances to extract include docosahexaenoic acid, docosapentaenoic acid, and arachidonic acid. The present invention also includes extracting the prepared biomass. Biomasses to be treated in accordance with the methods of the invention include plant, animal, and microbial biomass, particularly a microorganism such as Crypthecodinium cohnii and a fungus such as Mortierella alpina.

Owner:MARTEK BIOSCIENCES CORP

Microorganisms capable of producing highly unsaturated fatty acids and process for producing highly unsaturated fatty acids by using the microorganisms

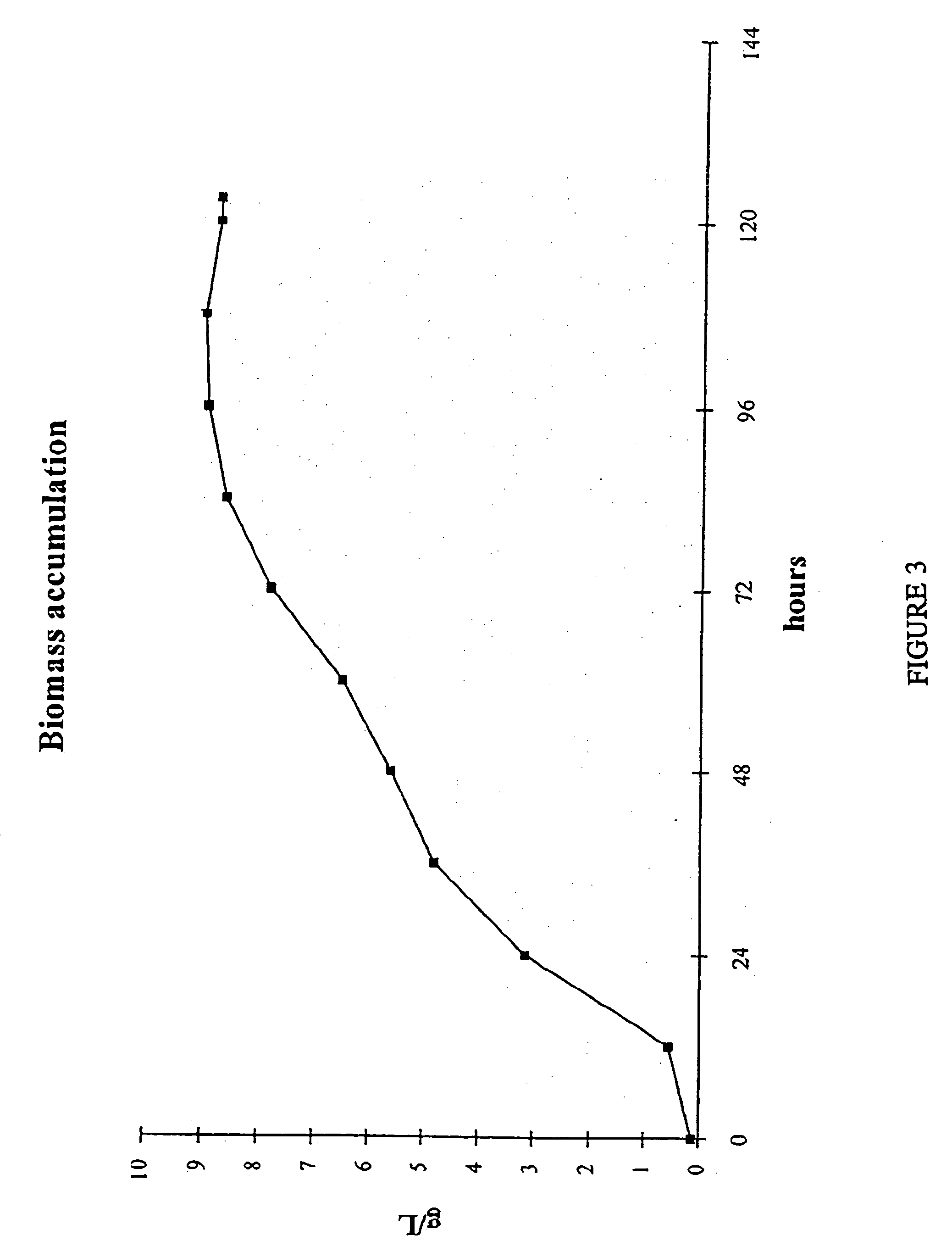

InactiveUS6582941B1High speedIncrease productionBiocideOrganic active ingredientsMicroorganismSchizochytrium

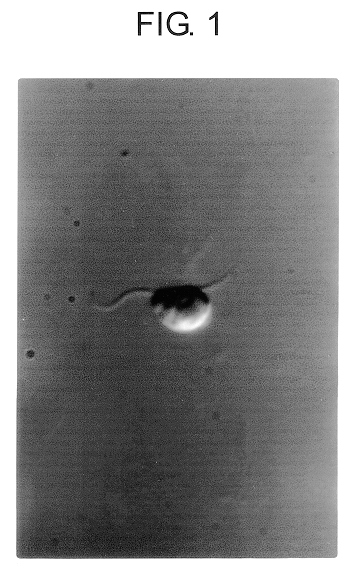

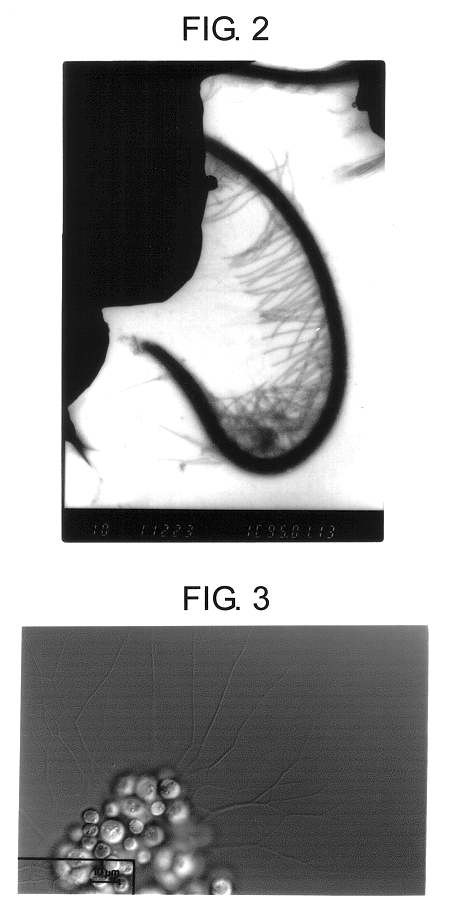

The present invention relates to the Schizochytrium genus SR21 strain and a microorganism belonging to the same species as does said SR21 strain or having substantially the same fungological properties as does said SR21 strain, the said SR21 strain and microorganism having the ability to produce the (n-3) series of docosahexaenoic acid (DHA) and the (n-6) series of docosapentaenoic acid (DPA), and the invention also relates to a process for preparing the (n-3) series of DHA and the (n-6) series of DPA utilizing said microorganisms. The microorganisms according to the present invention are superior in their proliferation character and their propensity to produce fat, and have the ability to produce the (n-3) series of DHA and the (n-6) series of DPA very well. Accordingly, it is possible to effectively produce the (n-3) series of DHA and / or the (n-6) series of DPA, which are useful in the fields of foods and pharmaceuticals, using the microorganisms according to the present invention. In addition, the present invention provides a fat obtained by culturing the present microorganisms. Since the fat composition contains the (n-6) series of DPA in addition to the (n-3) series of DHA having various physiological activities, it is possible to stably and effectively supply the (n-6) series of DPA and / or the (n-3) series of DHA to subjects in need of these highly unsaturated fatty acids by adding the fat composition to various feedstuffs or foods.

Owner:DIRECTOR GENERAL OF THE AGENCY OF IND SCI & TECH +1

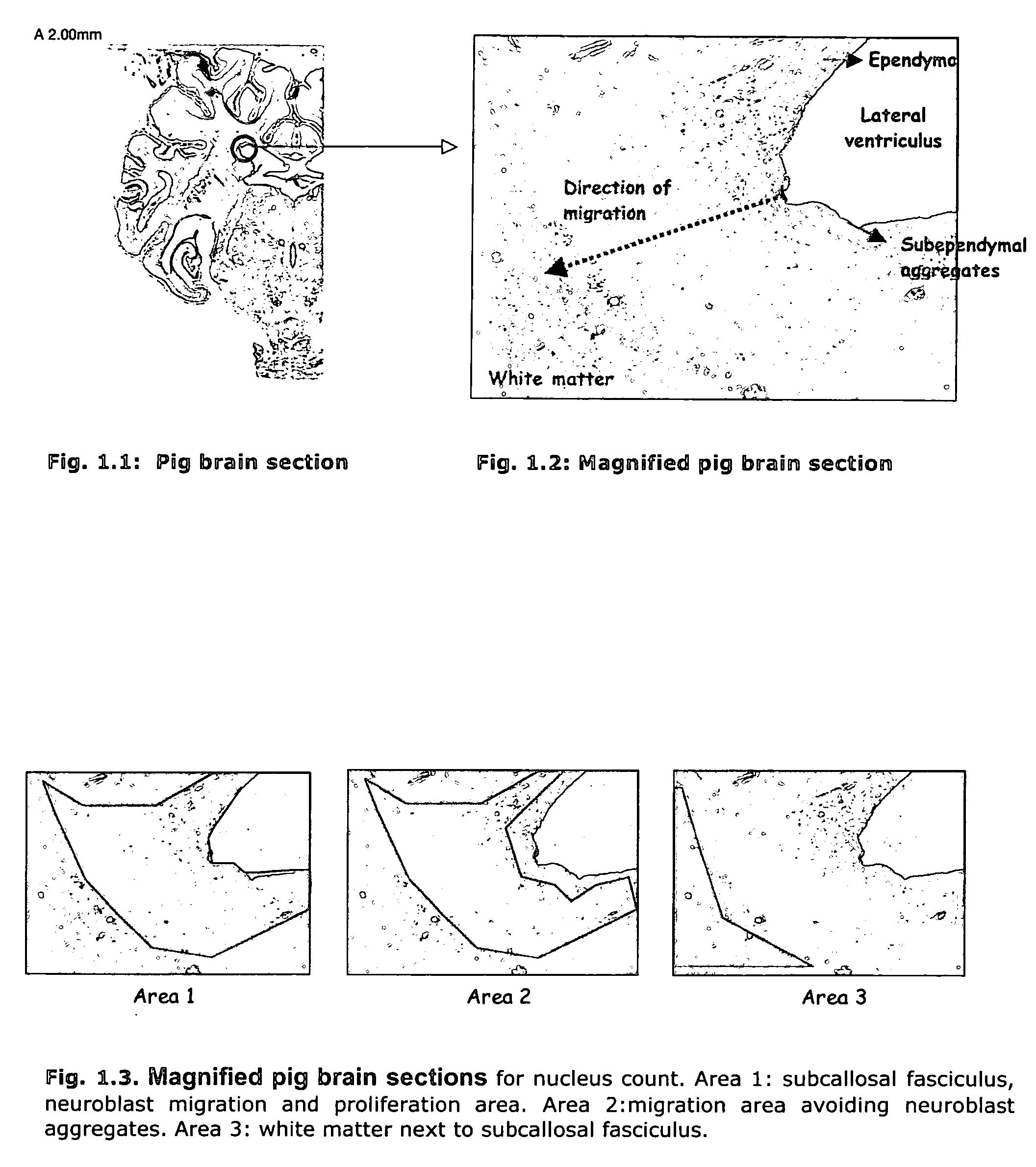

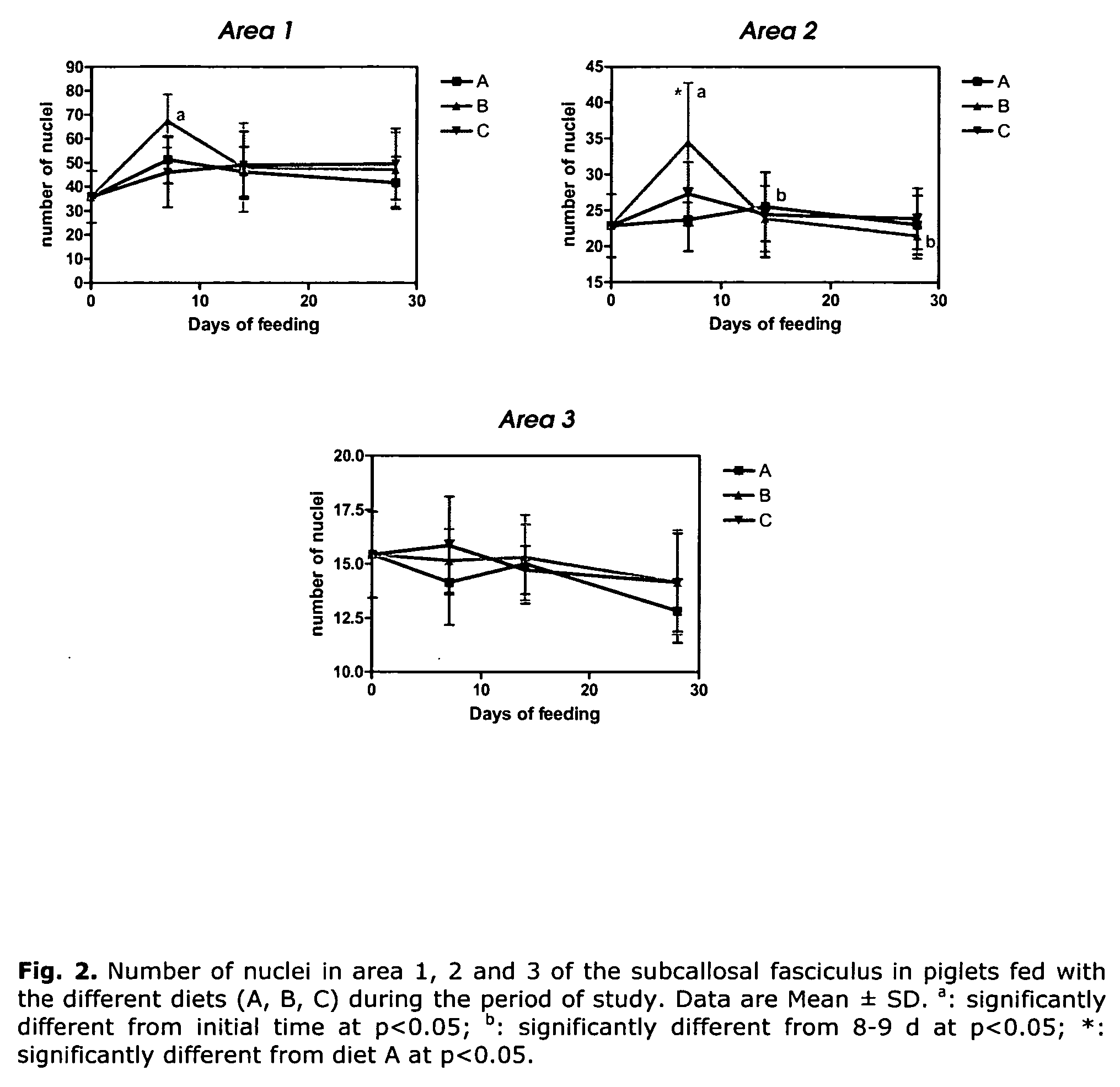

Infant formulas for early brain development

Disclosed are infant formulas comprising fat, protein, carbohydrate, vitamins, and minerals, including on an as-fed basis, at least about 5 mg / L of gangliosides, at least about 150 mg / L of phospholipids, at least about 70 mg / L of total sialic acid with at least about 2.5% as lipid-bound sialic acid, at least about 0.13% docosahexaenoic acid by weight of total fatty acids, and at least about 0.25% arachidonic acid by weight of total fatty acids. Also disclosed are methods of accelerating brain development, neural migration, and cognitive development in an infant by administering the infant formulas during the first 2-4 months of life, preferably as a sole source of nutrition.

Owner:ABBOTT LAB INC

Docosahexaenoic acid producing strains of Yarrowia lipolytica

Owner:DUPONT US HLDG LLC

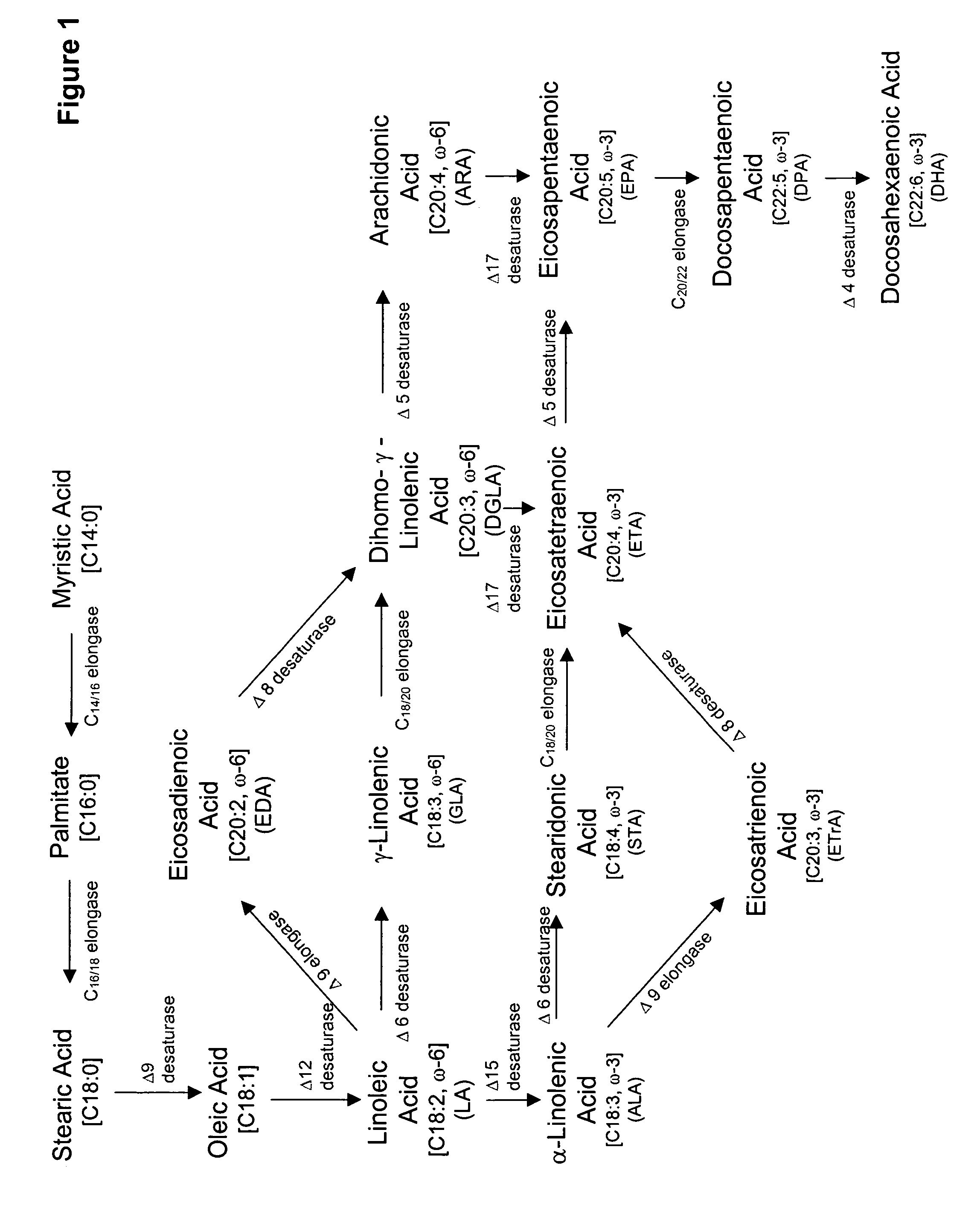

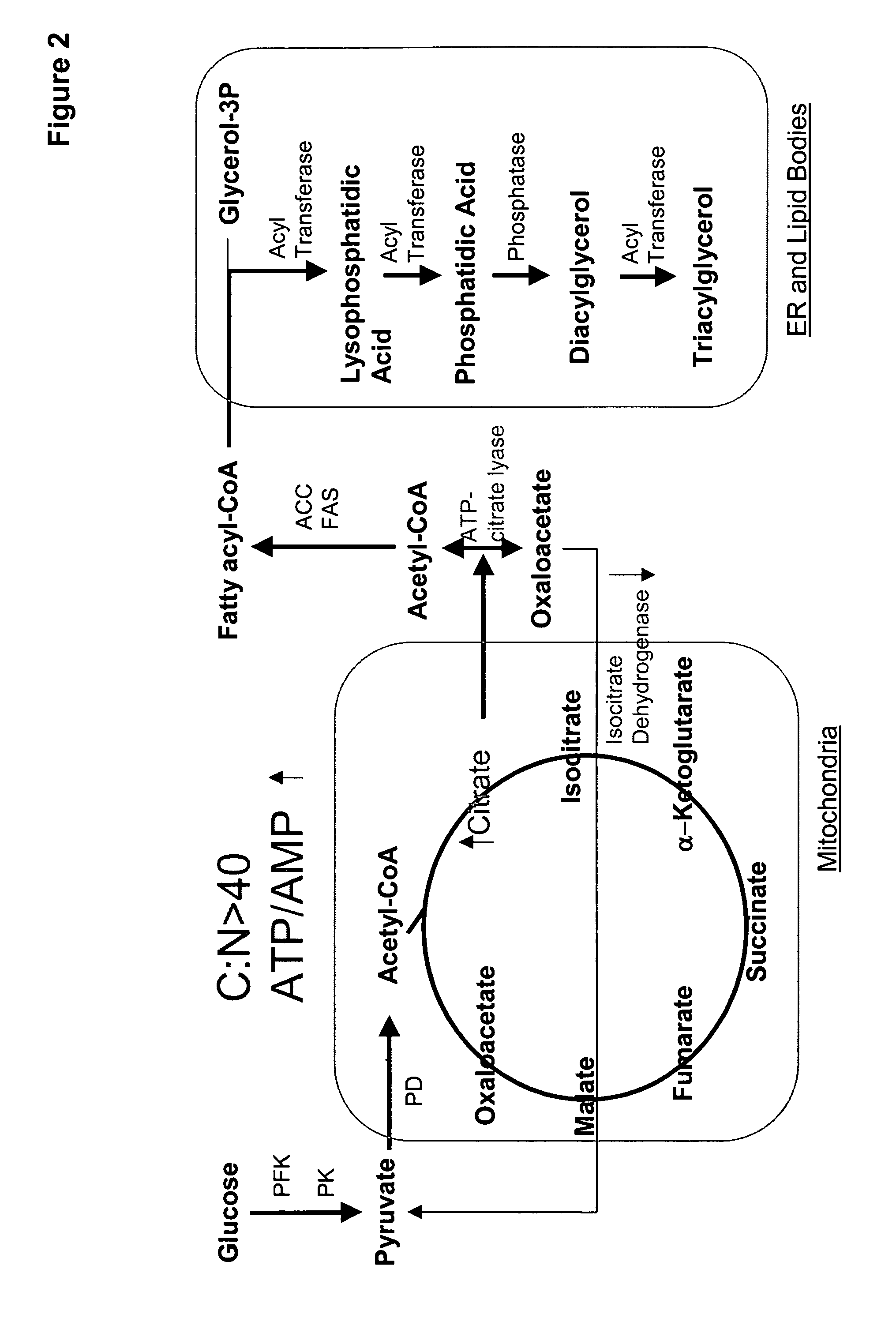

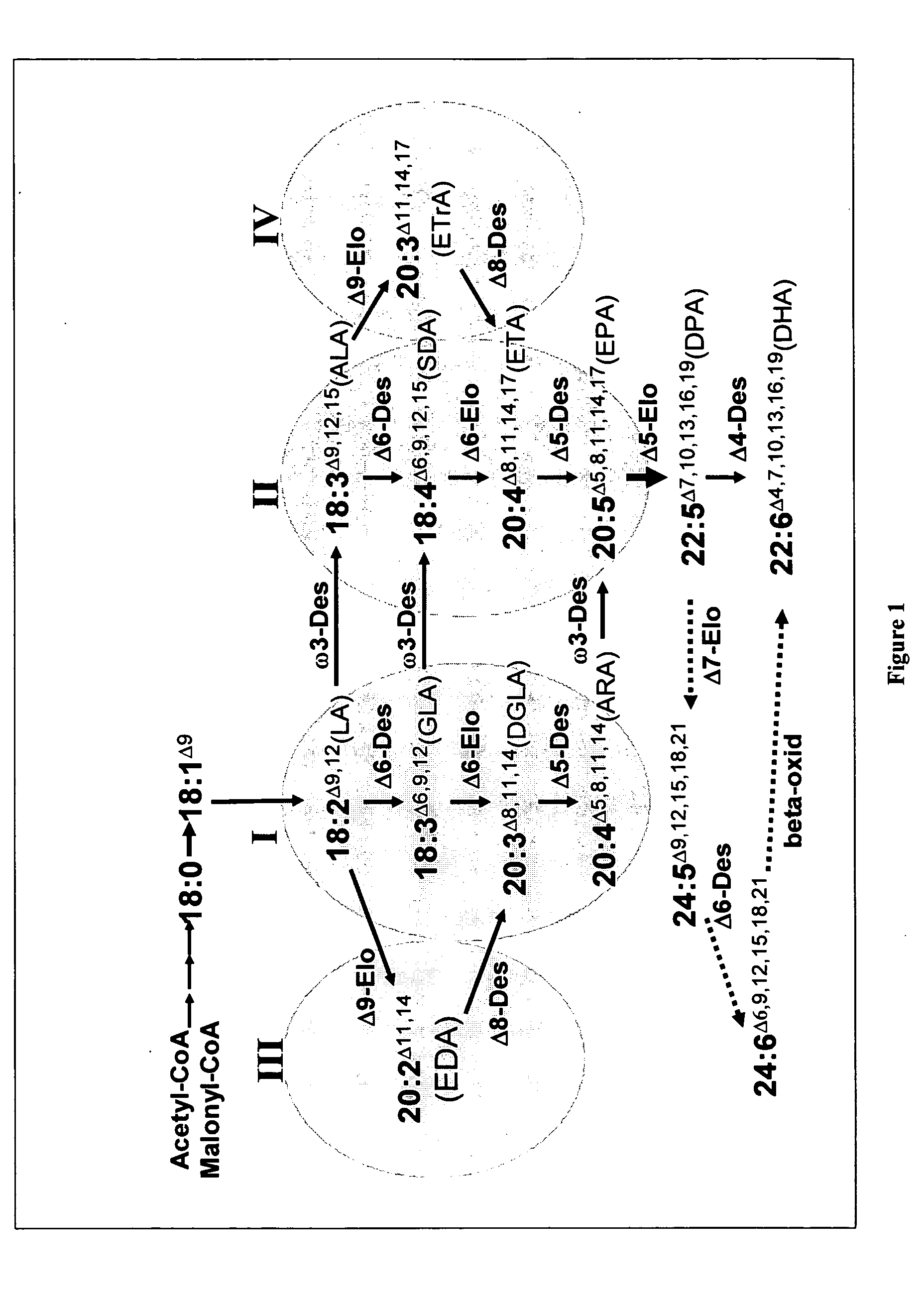

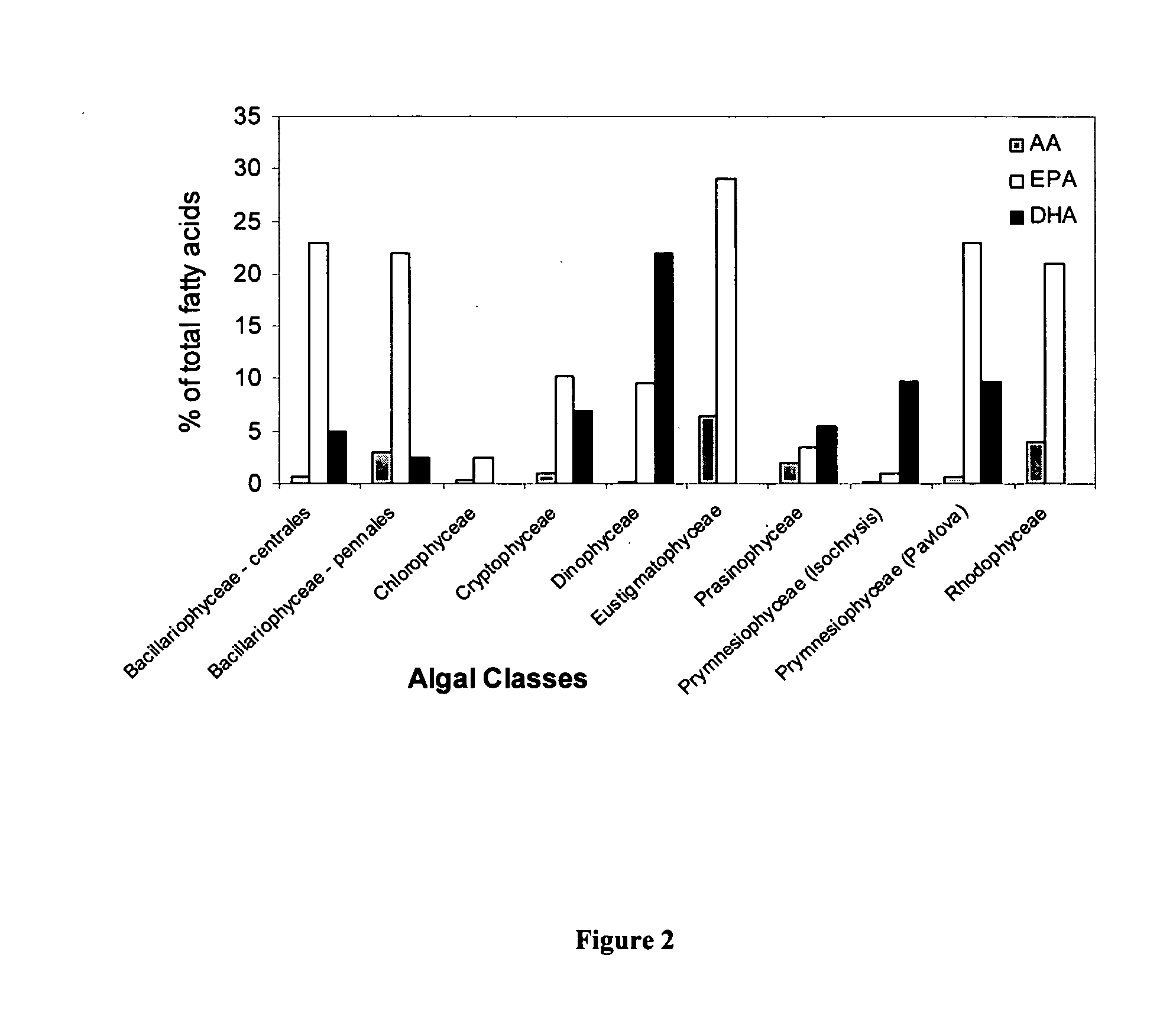

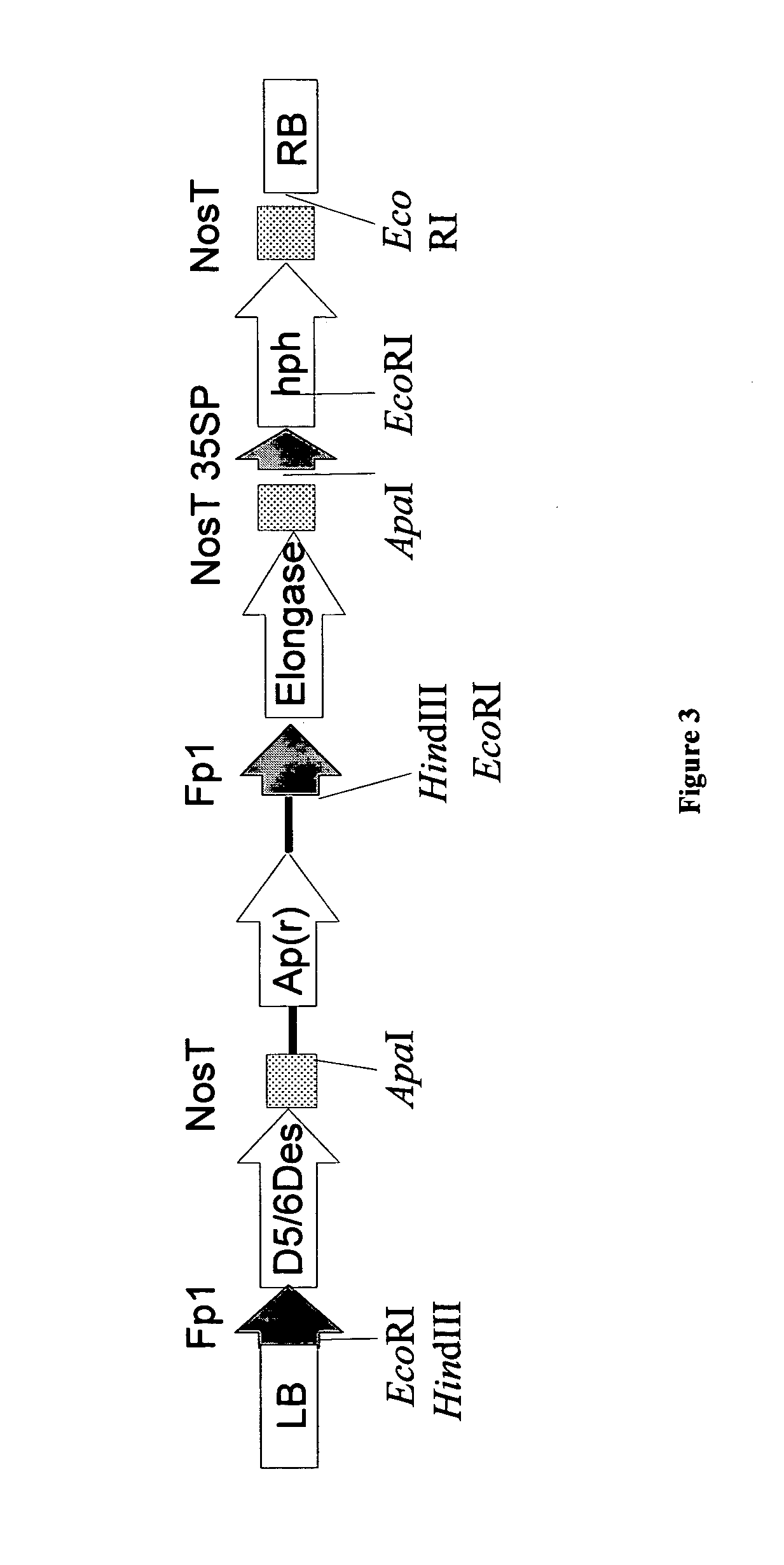

Synthesis of long-chain polyunsaturated fatty acids by recombinant cells

ActiveUS20050273885A1Reduce enzyme activityImprove efficiencyNervous disorderAntipyreticYeastPlant cell

The present invention relates to methods of synthesizing long-chain polyunsaturated fatty acids, especially eicosapentaenoic acid, docosapentaenoic acid and docosahexaenoic acid, in recombinant cells such as yeast or plant cells. Also provided are recombinant cells or plants which produce long-chain polyunsaturated fatty acids. Furthermore, the present invention relates to a group of new enzymes which possess desaturase or elongase activity that can be used in methods of synthesizing long-chain poly unsaturated fatty acids.

Owner:COMMONWEALTH SCI & IND RES ORG

Nutrition bar

InactiveUS20050181019A1Stable and goodExtended shelf lifeBiocideHeavy metal active ingredientsRice proteinIngested food

A nutrition bar comprising about 10% wt or more of soy and / or rice protein, at least one transition metal or transition metal compound, and about 2% wt or more of a humectant, and wherein the at least one transition metal or transition metal compound is in a substantially water insoluble form at 20° C. or the nutrition bar has an Aw of 0.45 or less or about 1% wt or more of the soy and / or rice protein is in the form of nuggets and the humectant is selected from polyols. The bars have elevated levels of soy and / or rice protein, yet do not suffer unacceptable from a deterioration in taste or other organoleptic properties over time. In other aspects, a nutrition bar or other food which incorporates pro-oxidants and / or polyunsaturated fatty acids or their sources in encapsulated form, especially as microcapsules. The pro-oxidants may be metal salts such as copper, manganese, iron and / or zinc salts. Sources of omega-3 fatty acids include fish oil. Processes for preparing the polyunsaturated fatty acid capsules are also disclosed. The polyunsaturated fatty acid capsules / microcapsules are prepared by forming an emulsion of the unsaturated fatty acid with a carrier, spray drying the emulsion to form a powder and encapsulating powder, especially with a fluid bed. The invention is especially useful for encapsulating polyunsaturated fatty acids, or oil sources thereof, most preferably omega-3 and omega-6 fatty acids, such as arachidonic acid, docosahexaenoic acid (DHA), eicosapentaenoic acid (EPA), lineoleic acid, linolenic acid (alpha linolenic acid), and gamma-linolenic acids, fish oil, and oil sources of C18:2 and C18:3 fatty acids such as canola oil, soybean oil or blends thereof.

Owner:SLIM FAST FOODS COMPANY A DIV OF CONOPCO

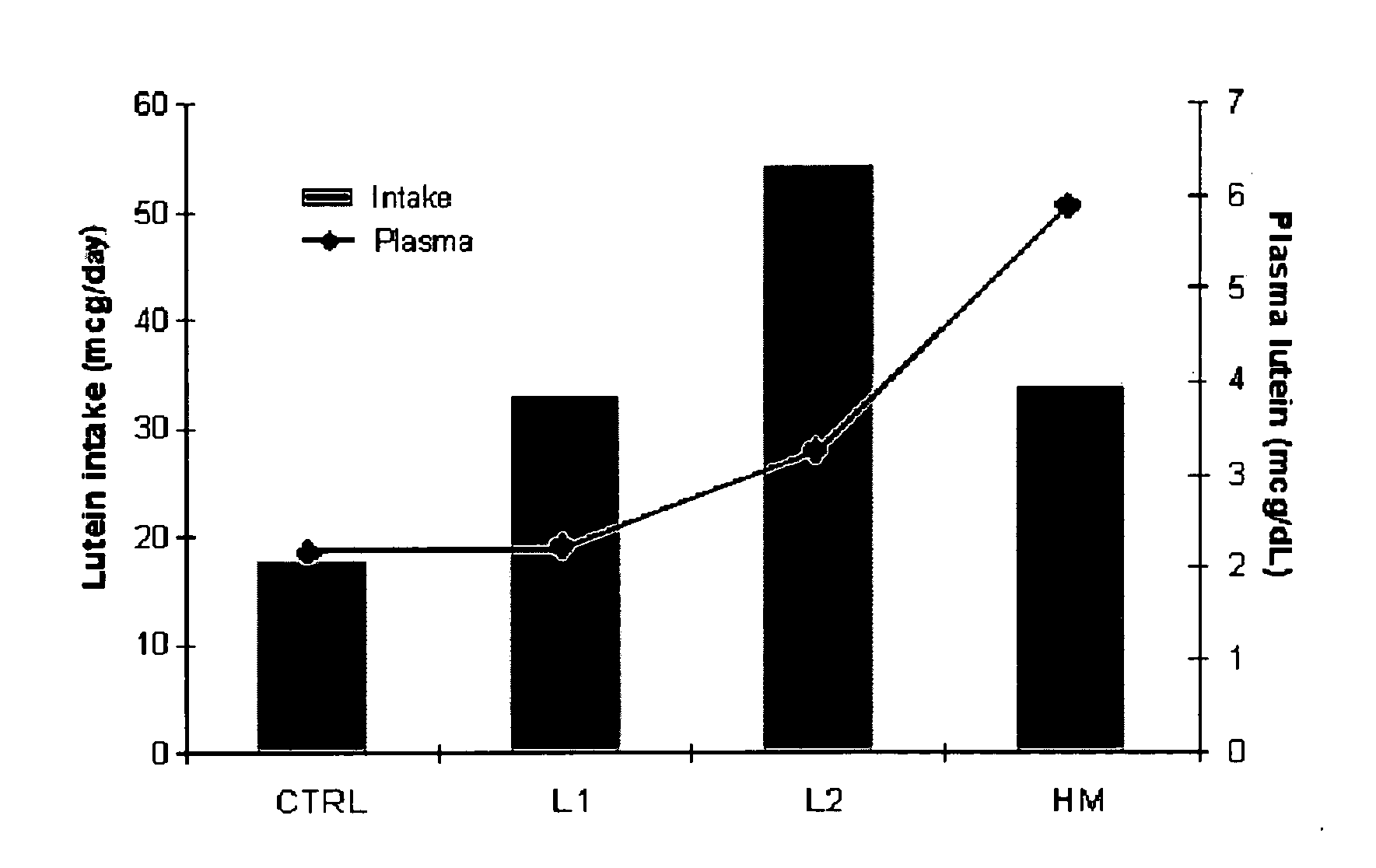

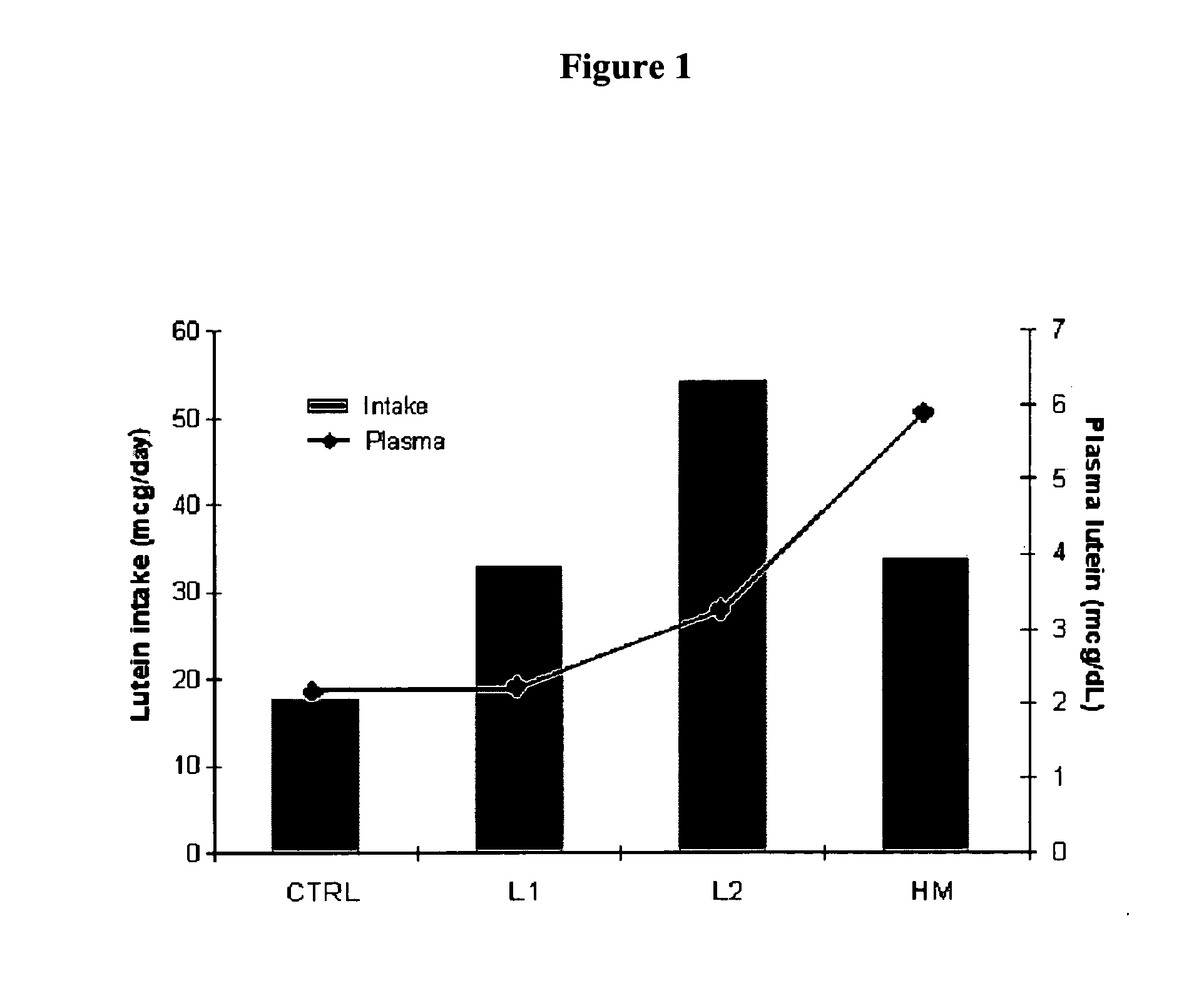

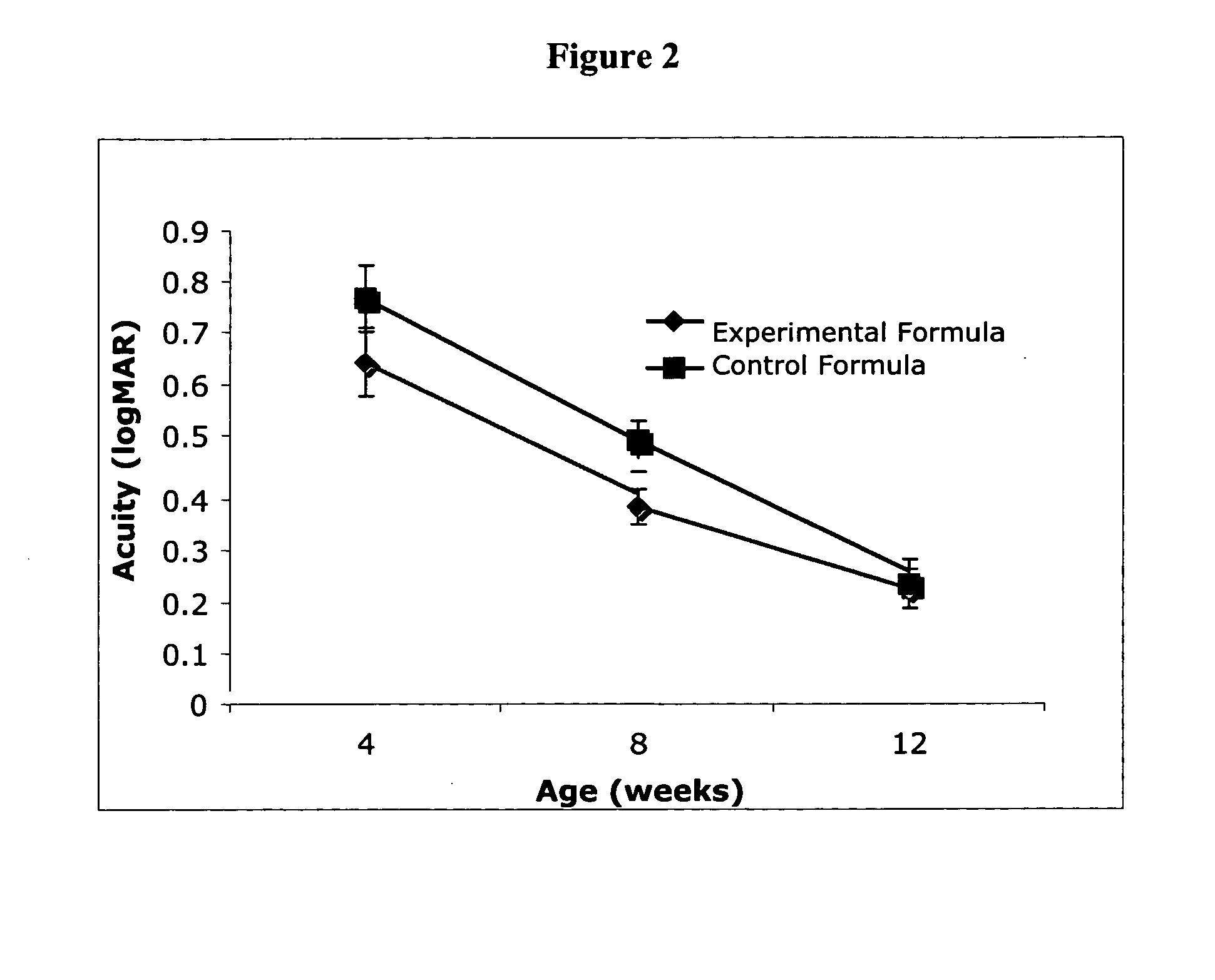

Infant formulas containing docosahexaenoic acid and lutein

ActiveUS20070098849A1Promote retinal healthPromote vision developmentBiocideHeavy metal active ingredientsLuteinDHA - Docosahexaenoic acid

Disclosed are infant formulas and corresponding methods of using them to promote retinal health and vision development in infants. The formulas, which are free of egg phospholipids and comprise fat, protein, carbohydrate, vitamins, and minerals, including docosahexaenoic acid and, on a ready-to-feed basis, at least about 50 mcg / liter of lutein, wherein the weight ratio of lutein (mcg) to docosahexaenoic acid (mg) is from about 1:2 to about 10:1. The formulas are also believed to be especially useful in reducing the risk of retinopathy of prematurity in preterm infants.

Owner:ABBOTT LAB INC

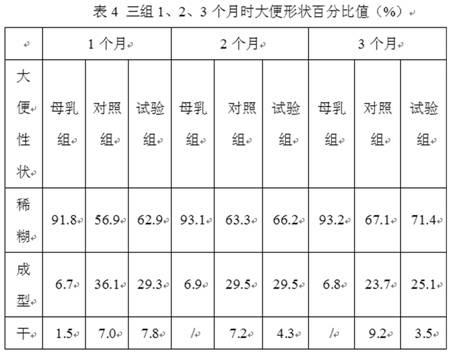

A kind of infant formula milk powder that does not get angry and its preparation process

ActiveCN102283289ANot ediblePromote digestion and absorptionMilk preparationVegetable oilFructooligosaccharide

The invention relates to an anti-inflaming infant formula milk powder and a preparation process thereof. The anti-inflaming infant formula milk powder comprises the following components in percentage by weight: 22%-50% of lactose, 10%-20% of goat milk whey protein concentrate, 9.8%-20% of structural grease 1,3-dioleoyl 2-palmitoyl triglyceride, 10%-13.5% of non-fat goat milk powder, 8%-10% of vegetable oil, 2%-8% of beta-casein, 0.8%-1.6% of fructooligosaccharides, 0.5%-1.5% of mineral premix, 0.3%-1% of galactooligosaccharide, 0.2%-1% of immunoglobulin G, 0.2%-0.5% of lactulose, 0.10%-0.45% of arachidonic acid, 0.1%-0.6% of docosahexaenoic acid, 0.06%-0.12% of vitamin premix, 0.04%-0.06% of lactoferrin, and 0.01%-0.06% of nucleotide. The invention also includes the preparation process ofthe infant formula milk powder. The nutrition constituents and the functions of the infant formula milk powder are close to those of breast milk, the infant formula milk powder is easy to assimilate,and infants do not get inflamed after eating the milk powder.

Owner:AUSNUTRIA DAIRY CHINA

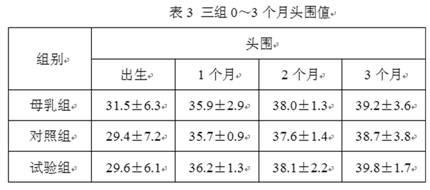

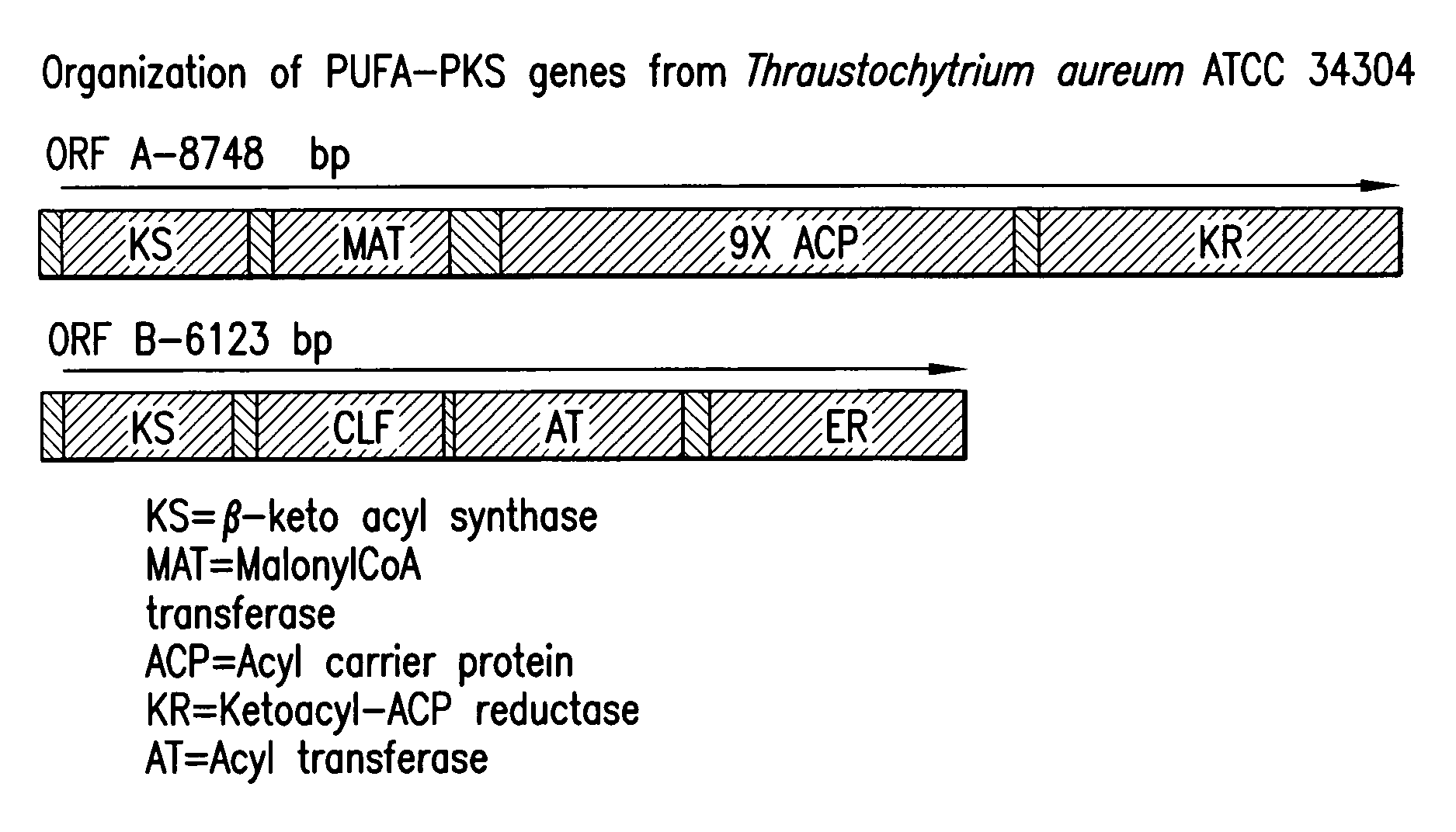

Genes involved in polyketide synthase pathways and uses thereof

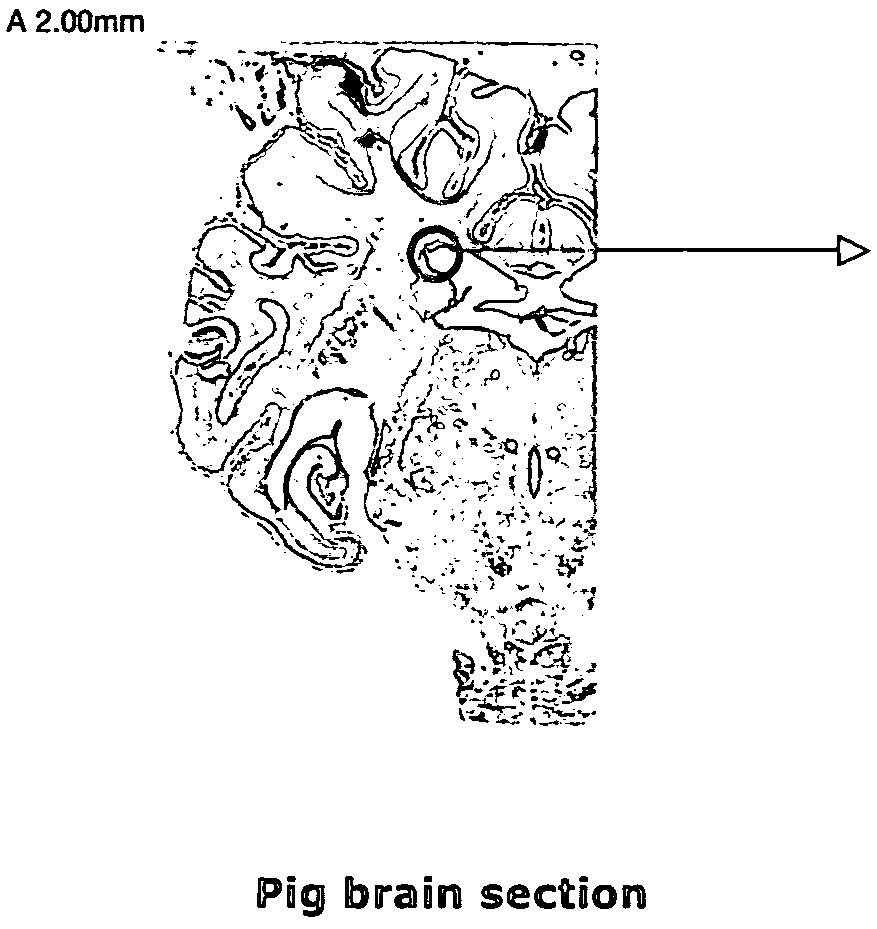

The subject invention relates to isolated nucleic acid sequences or genes involved in polyketide synthase (PKS) biosynthetic pathways. In particular, such pathways are involved in the production of polyunsaturated fatty acids (PUFAs) such as, for example, Eicosapentaenoic acid (EPA) and Docosahexaenoic acid (DHA). Specifically, the invention relates to isolating nucleic acid sequences encoding proteins involved in eukaryotic PUFA-PKS systems and to uses of these genes and encoded proteins in PUFA-PKS systems, in heterologous hosts, for the production of PUFAs such as EPA and DHA.

Owner:ABBOTT LAB INC

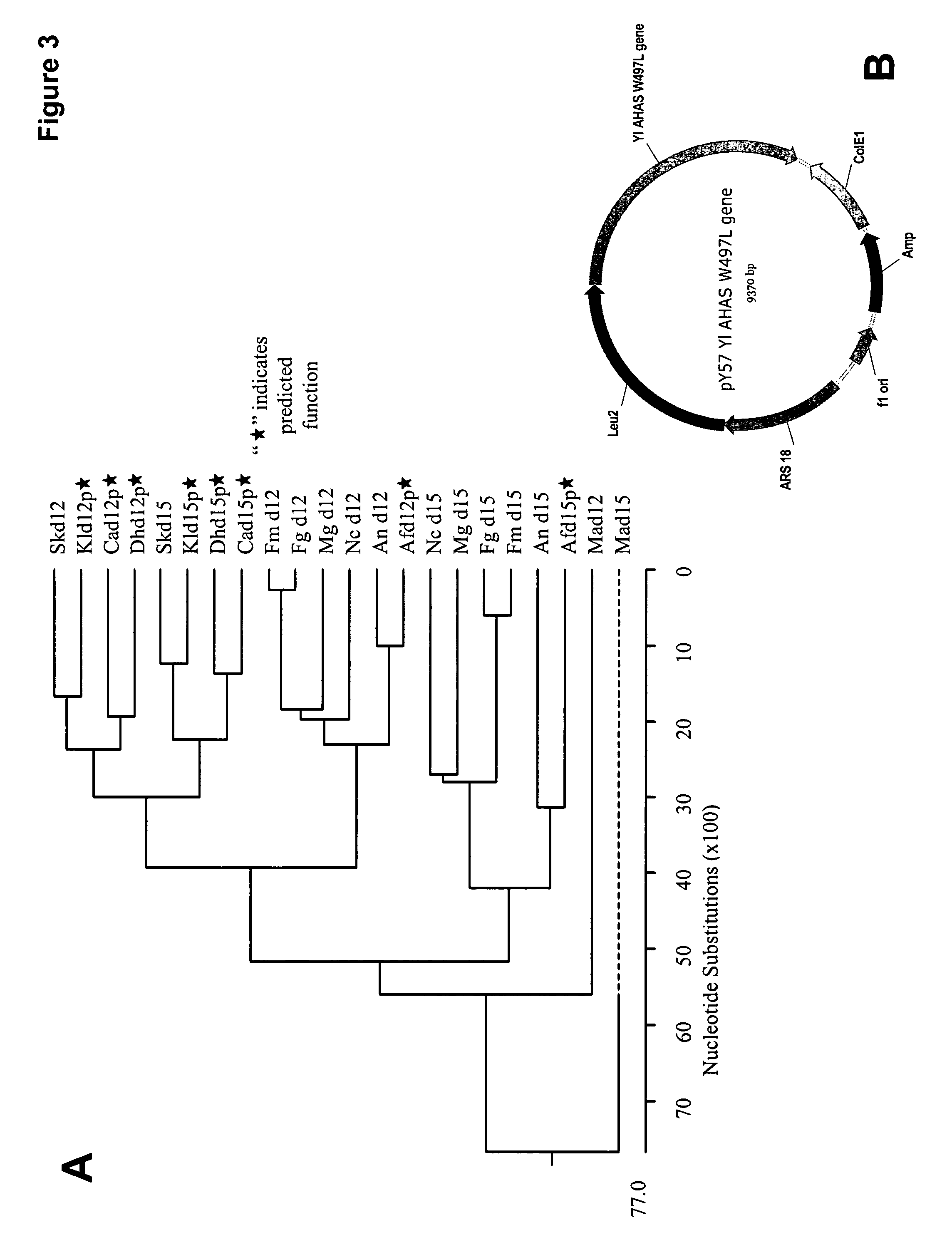

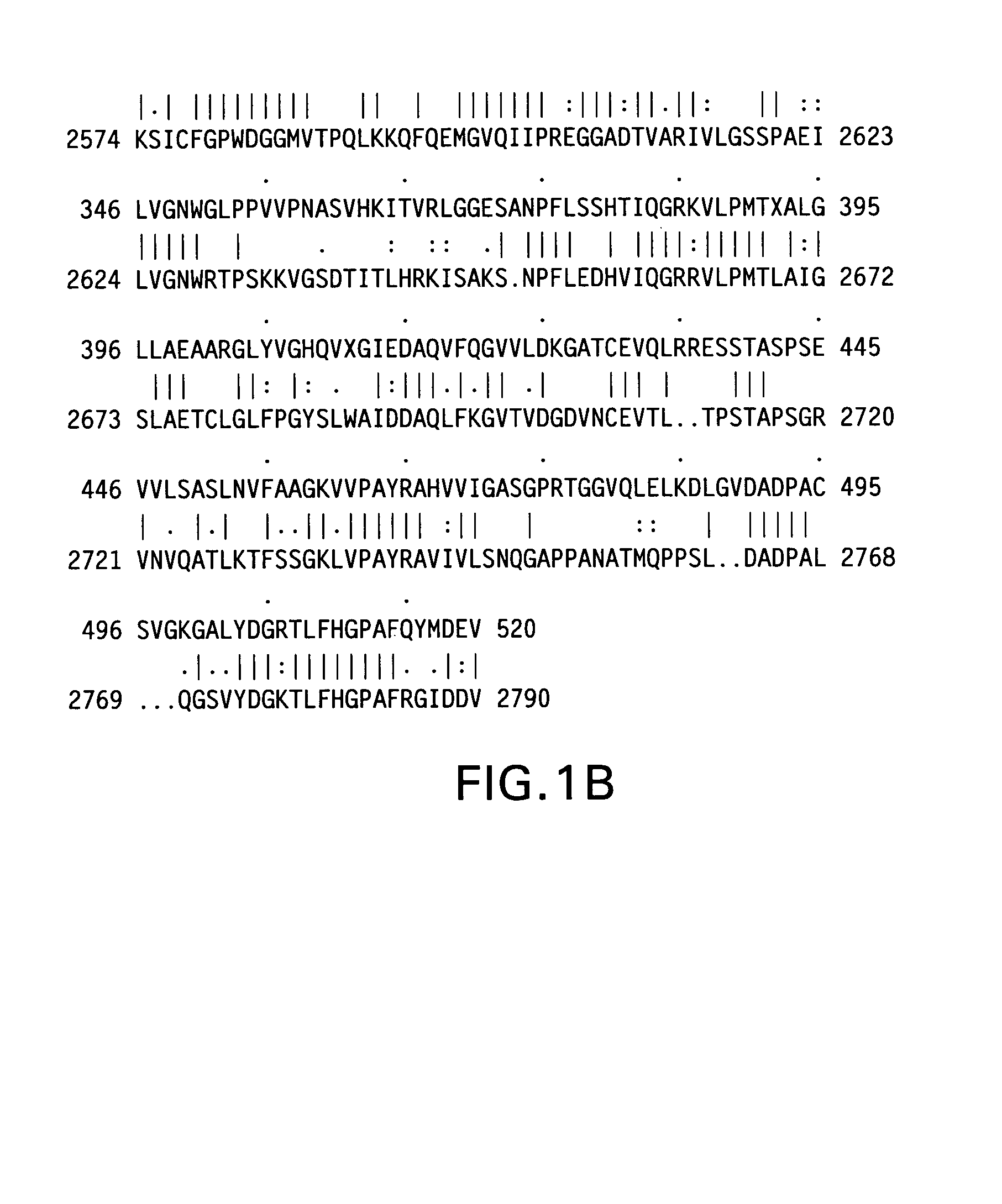

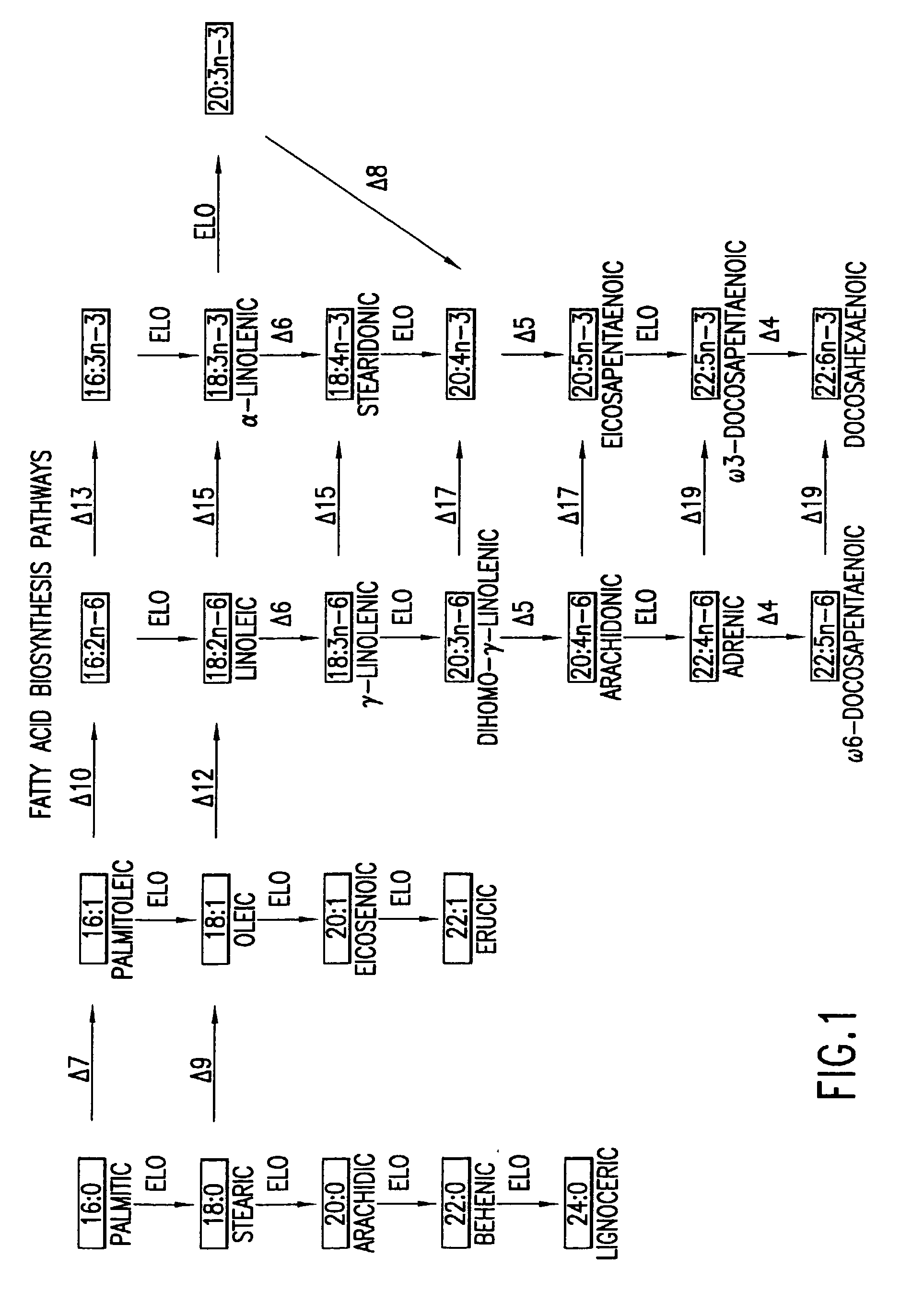

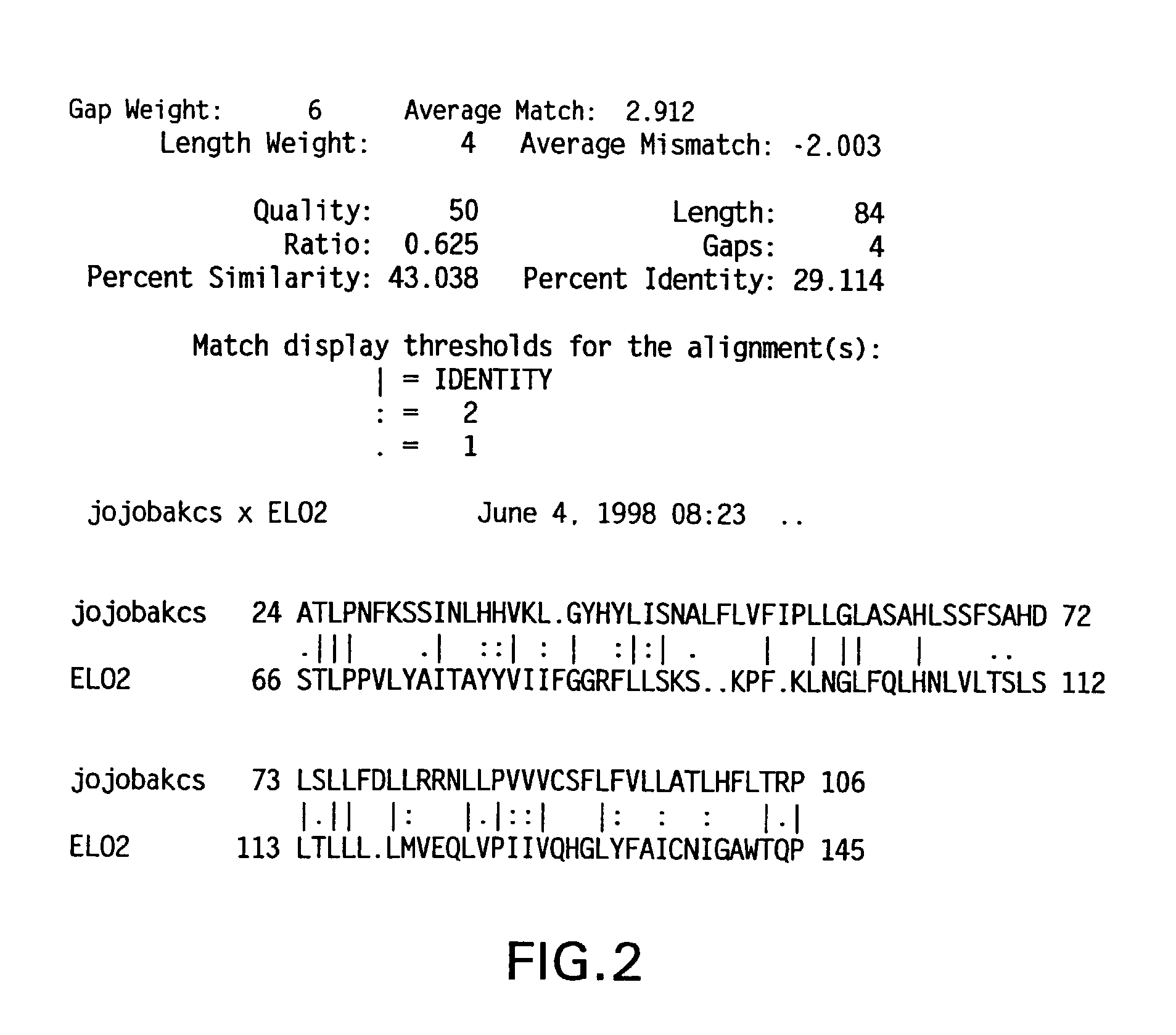

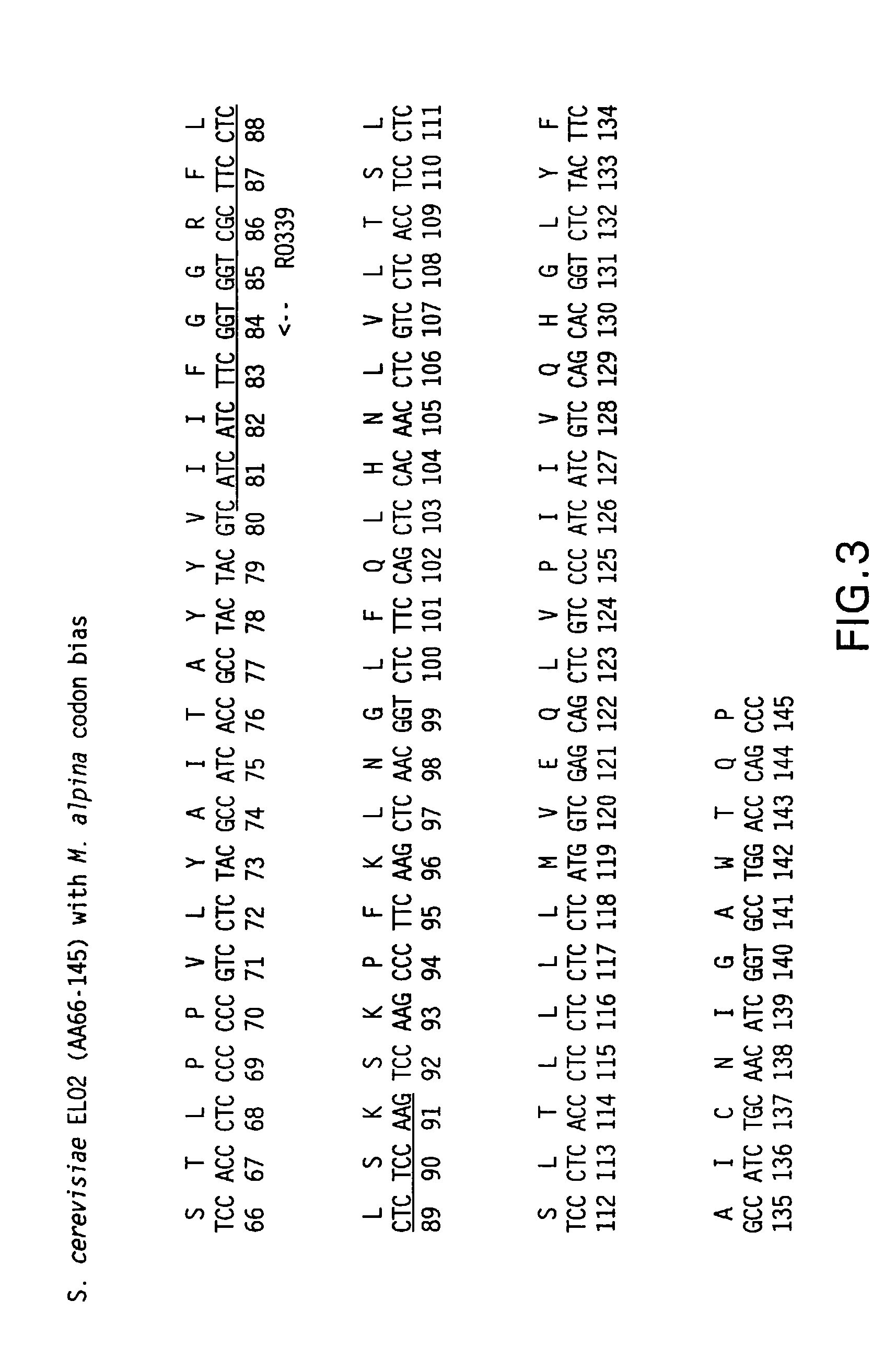

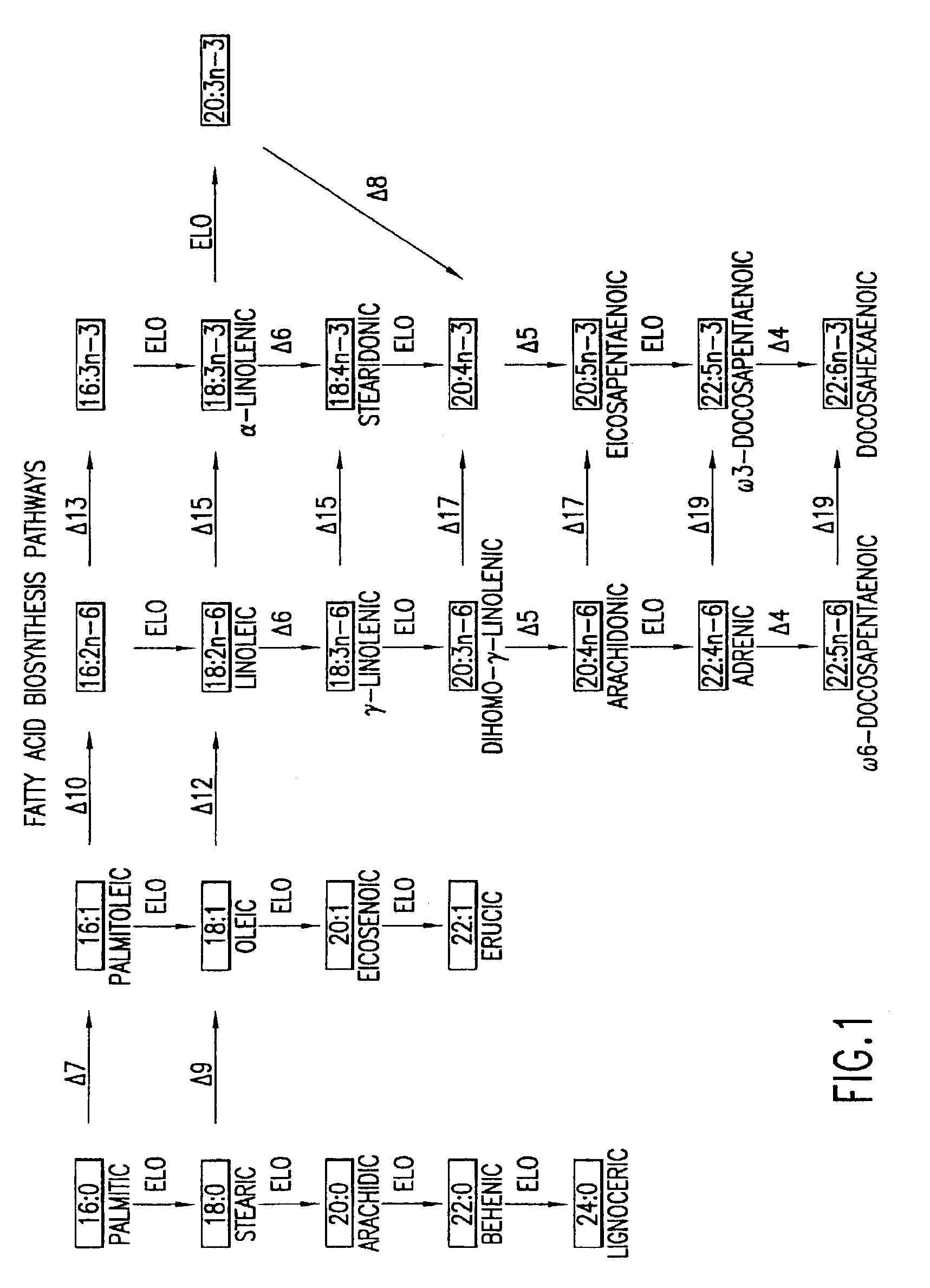

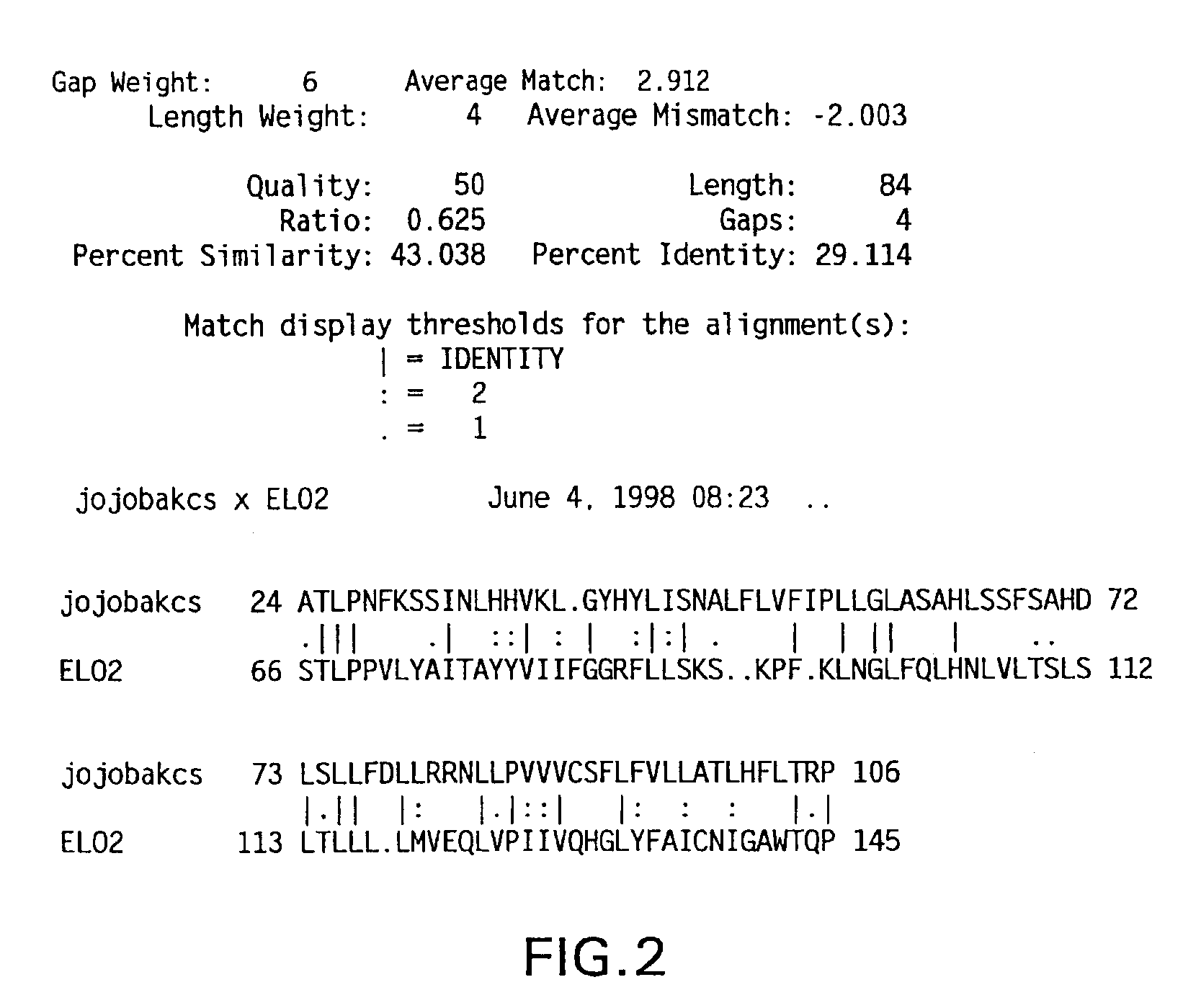

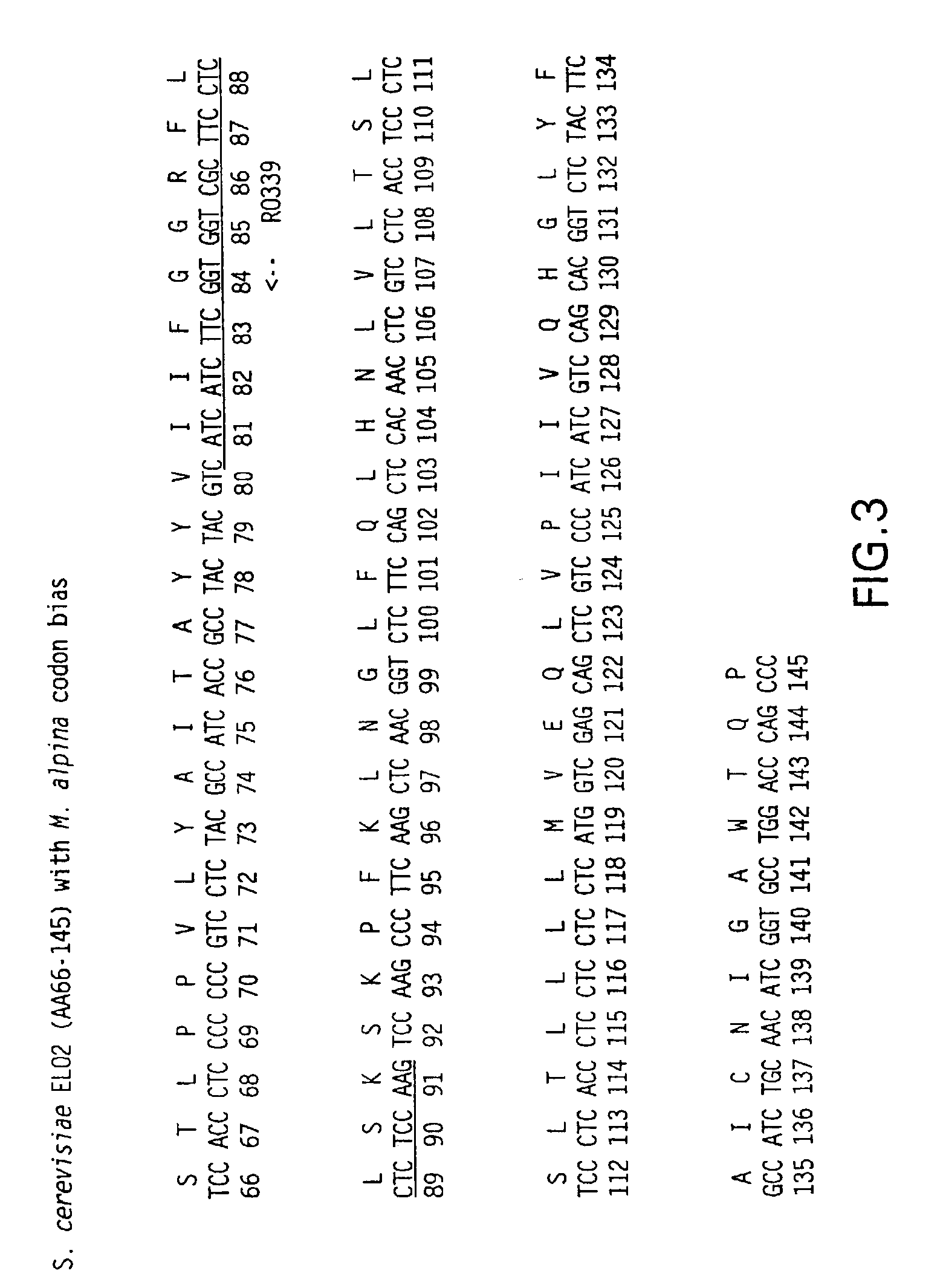

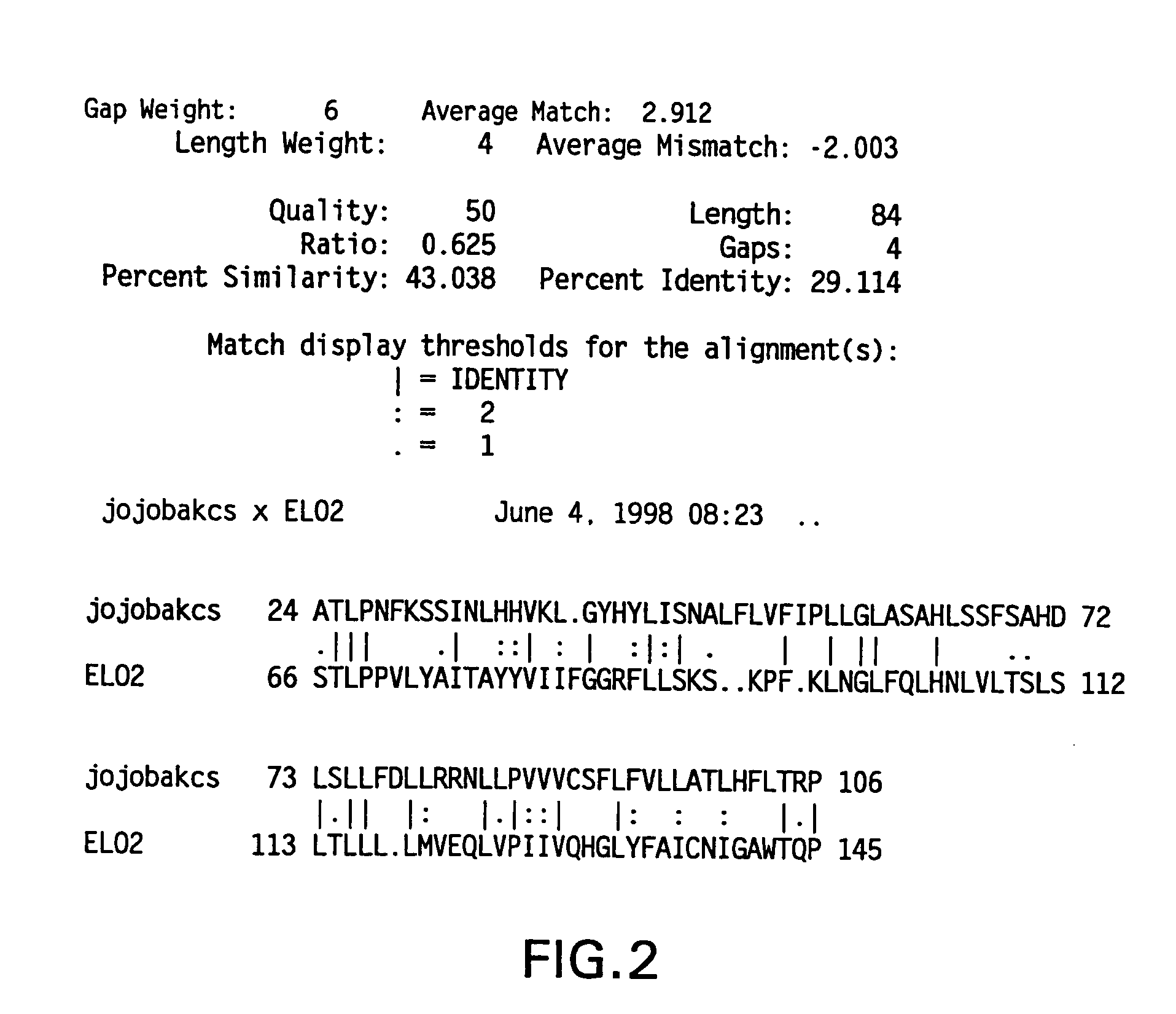

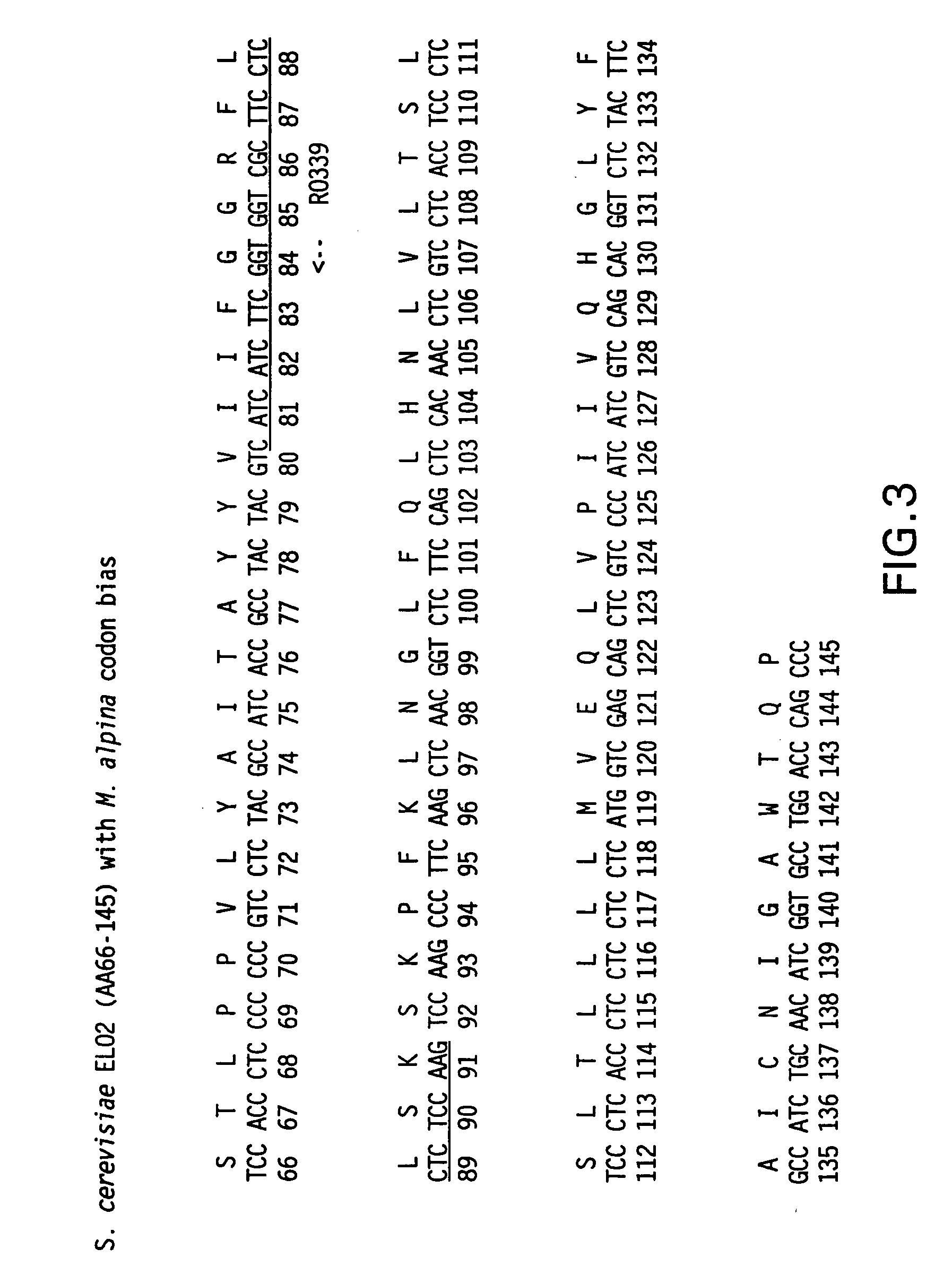

Elongase genes and uses thereof

The subject invention relates to the identification of several genes involved in the elongation of polyunsaturated acids (i.e., "elongases") and to uses thereof. At least two of these genes are also involved in the elongation of monounsaturated fatty acids. In particular, elongase is utilized in the conversion of gamma linolenic acid (GLA) to dihomogamma linolenic acid (DGLA) and in the conversion of AA to adrenic acid (ADA), or eicosapentaenoic acid (EPA) to omega3-docosapentaenoic acid (DPA). DGLA may be utilized in the production of polyunsaturated fatty acids, such as arachidonic acid (AA), docosahexaenoic acid (DHA), EPA, adrenic acid, omega6-docosapentaenoic acid or omega3-docosapentaenoic acid which may be added to pharmaceutical compositions, nutritional compositions, animal feeds, as well as other products such as cosmetics.

Owner:ABBOTT LAB INC

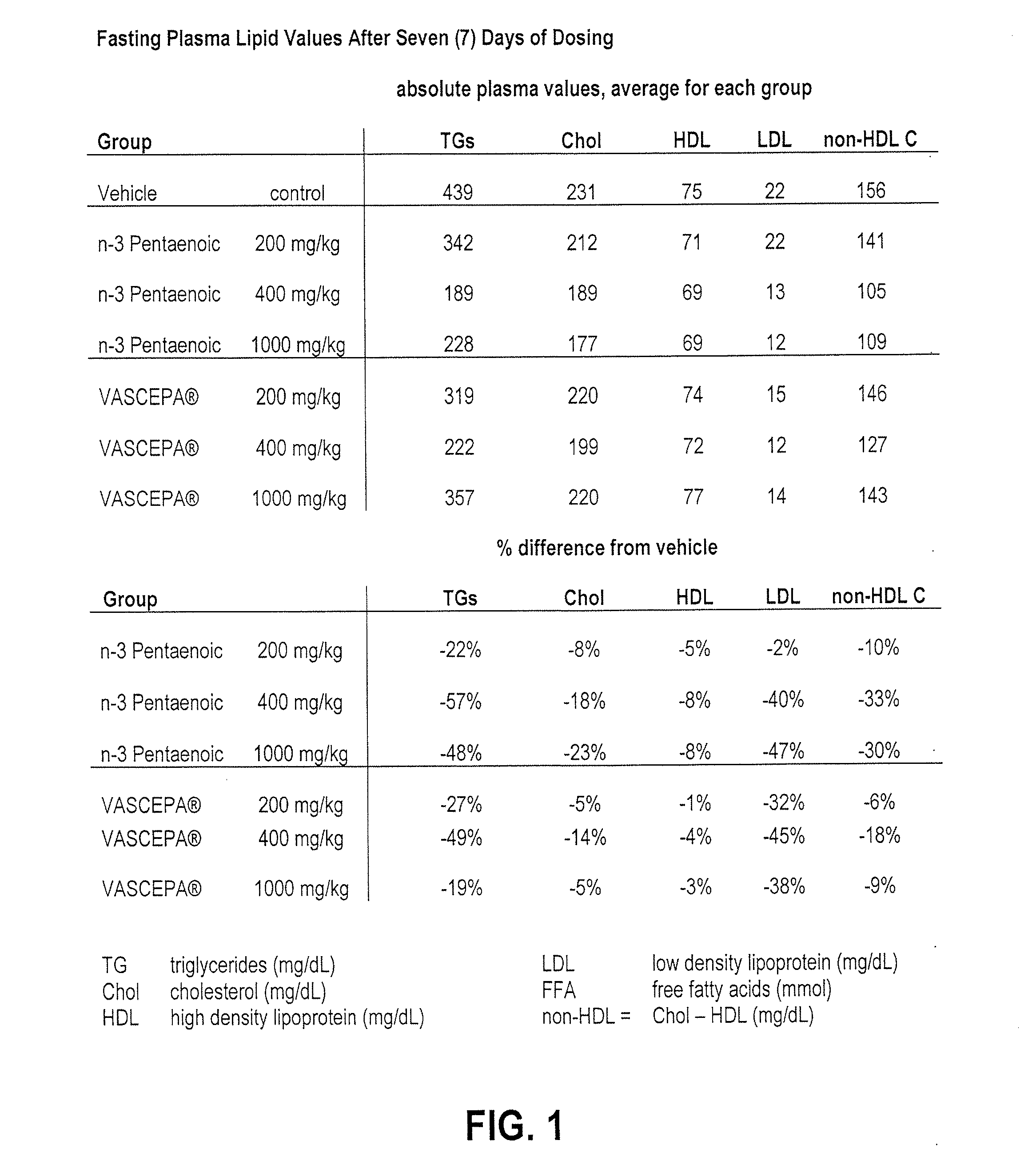

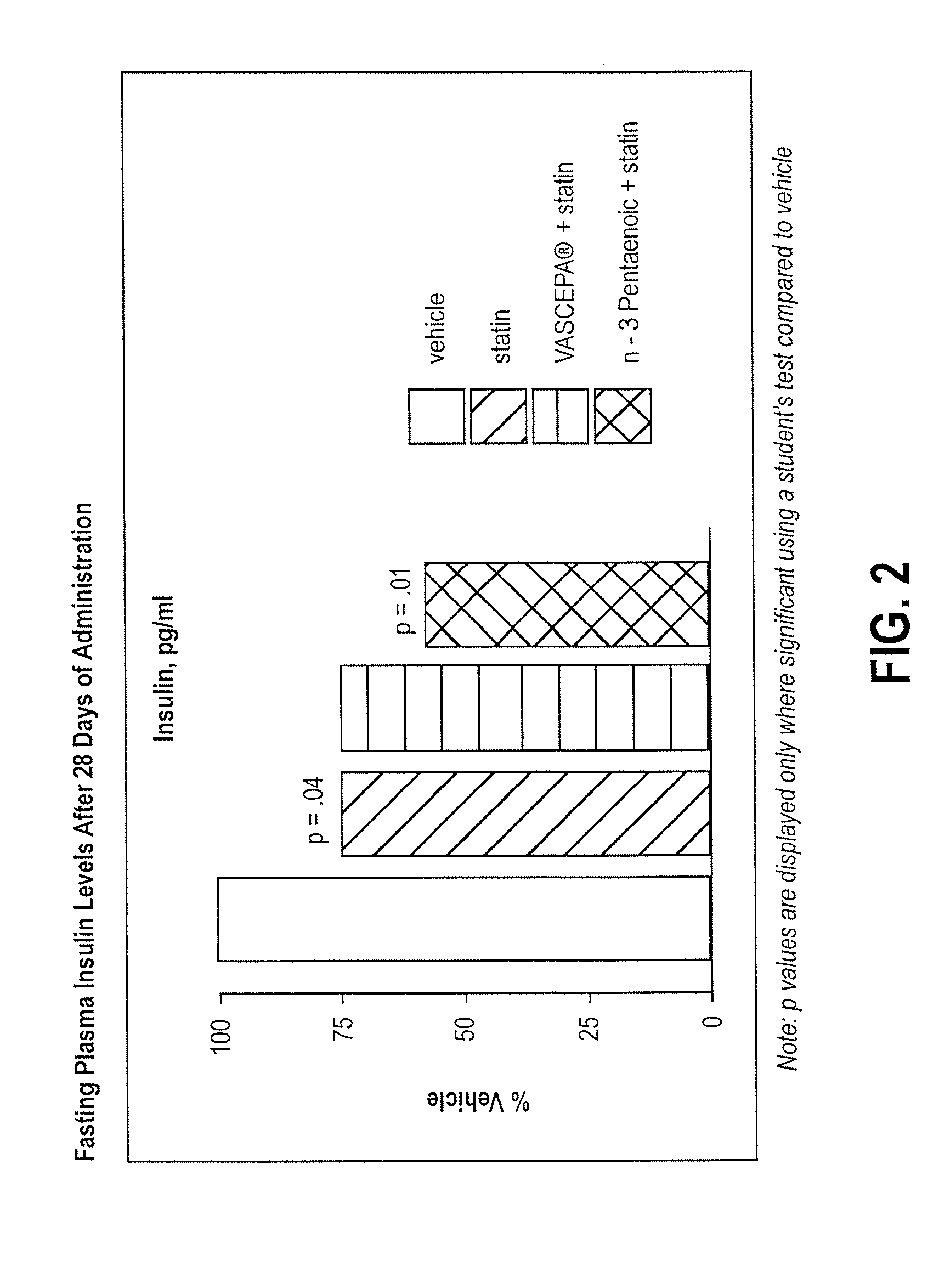

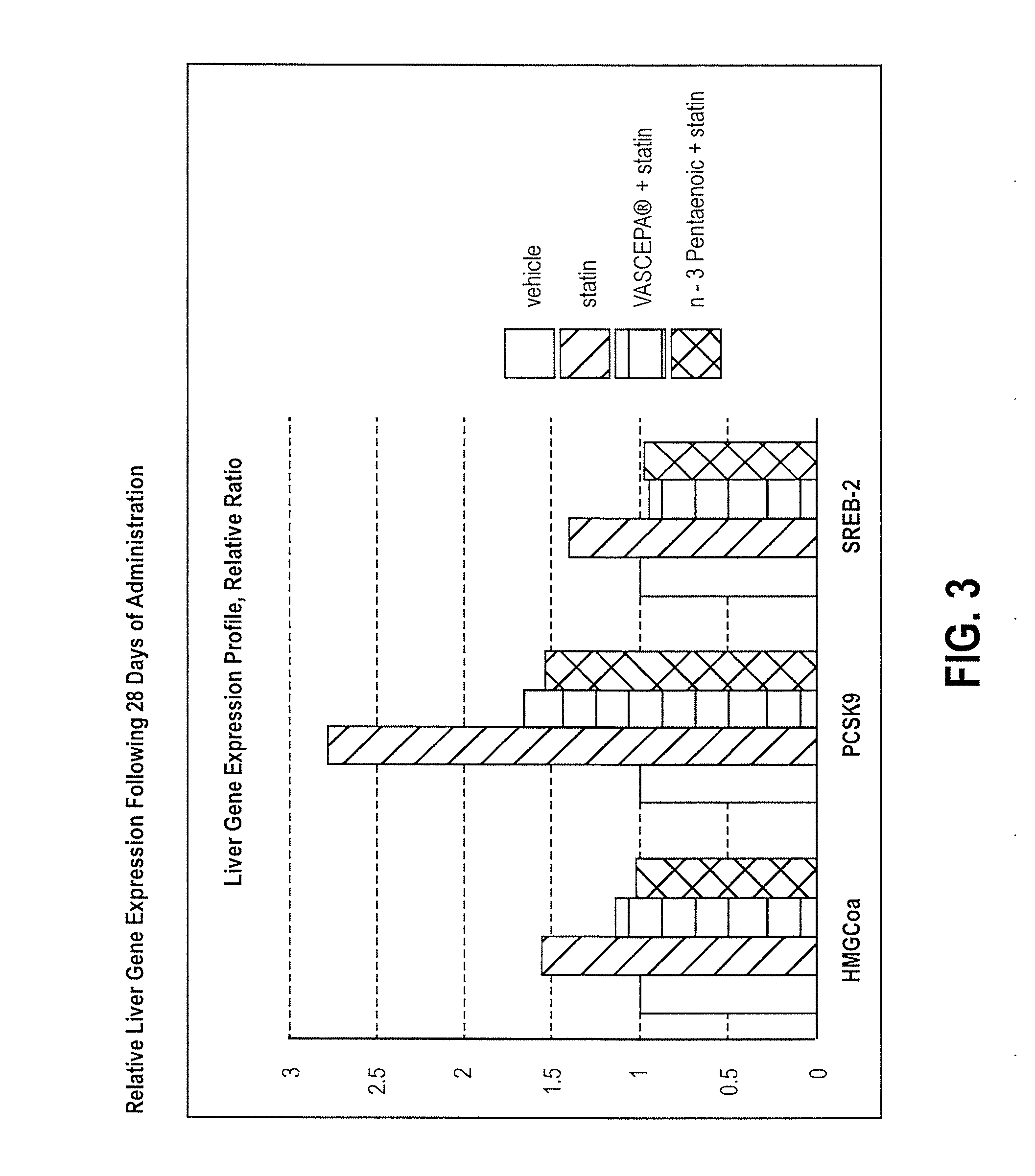

Omega-3 pentaenoic acid compositions and methods of use

Orally administrable composition comprising fatty acids, wherein at least 50% by weight of the fatty acids comprise omega-3-fatty acids, salts or derivatives thereof, wherein the omega-3 fatty acids comprise eicosapentaenoic acid (EPA; C20:5-n3), docosapentaenoic acid (DPA; C22:5-n3), and docosahexaenoic acid (DHA; C22:6-n3), wherein the ratio of DHA to EPA (DHA:EPA) is less than 1:20, and wherein the ratio of DHA to DPA (DHA:DPA) is less than 2:1 are provided. These compositions can be used for the treatment or prophylaxis of dyslipidemic, cardiovascular, CNS, inflammatory, and other diseases / conditions or risk factors therefore.

Owner:MATINAS BIOPHARMA

Methods of treating senile dementia and Alzheimer's diseases using docosahexaenoic acid and arachidonic acid compositions

InactiveUS20050027004A1Lower triglyceride levelsCorrecting lipid imbalanceBiocideNervous disorderMicrobial oilMedicine

A method of treating a neurological disorder comprises administering to a person affected from such a disorder a microbial oil comprising DHA, a microbial oil comprising ARA or a combination of DHA and ARA oils in an amount sufficient to elevate the levels of circulating DHA and / or ARA in the person's blood to at least normal levels.

Owner:MARTEK BIOSCIENCES CORP

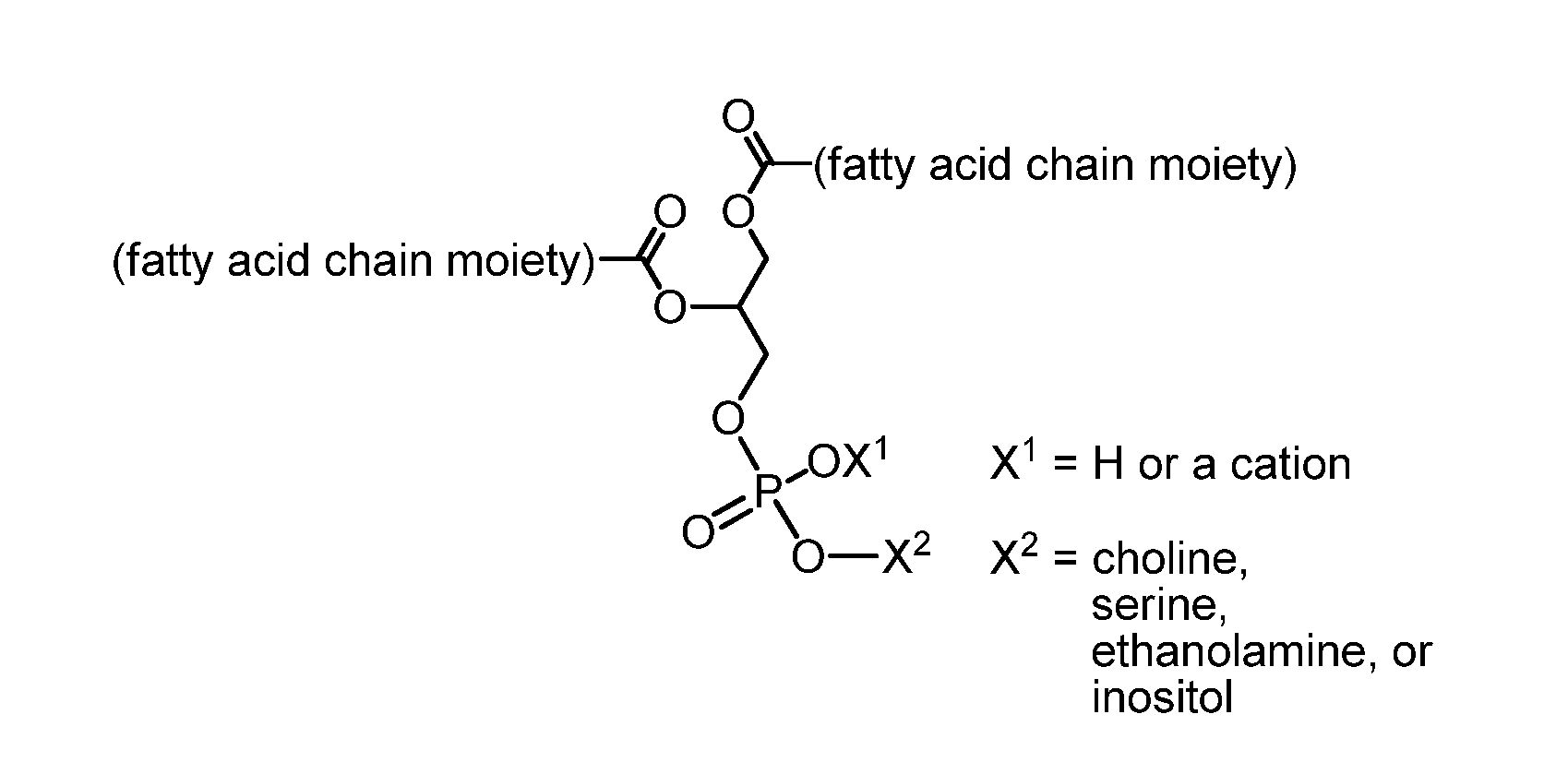

Production and use of a polar lipid-rich fraction containing omega-3 and/or omega-6 highly unsaturated fatty acids from microbes, genetically modified plant seeds and marine organisms

InactiveUS20050129739A1Speed up the processAntibacterial agentsCosmetic preparationsPlanting seedAdemetionine

The production and use, and in particular, the extraction, separation, synthesis and recovery of polar lipid-rich fractions containing eicosapentaenoic acid (EPA), docosahexaenoic acid (DHA), docosapentaenoic acid (DPA(n-3) or DPA(n-6)), arachidonic acid (ARA), and eicosatetraneonoic acid (C20:4n-3) from microorganisms, genetically modified seeds and marine organisms (including fish and squid) and their use in human food applications, animal feed, pharmaceutical applications and cosmetic applications.

Owner:DSM IP ASSETS BV

Elongase genes and uses thereof

The subject invention relates to the identification of four genes involved in the elongation of polyunsaturated acids (i.e., “elongases”) and to uses thereof. Two of these genes are also involved in the elongation of monounsaturated fatty acids. In particular, elongase is utilized in the conversion of gamma linolenic acid (GLA) to dihomogamma linolenic acid (DGLA) and in the conversion of DGLA or 20:4n-3 to eicosapentaenoic acid (EPA). DGLA may be utilized in the production of polyunsaturated fatty acids, such as arachidonic acid (AA), docosahexaenoic acid (DHA), EPA, adrenic acid, ω6-docosapentaenoic acid or ω3-docosapentaenoic acid which may be added to pharmaceutical compositions, nutritional compositions, animal feeds, as well as other products such as cosmetics.

Owner:ABBOTT LAB INC

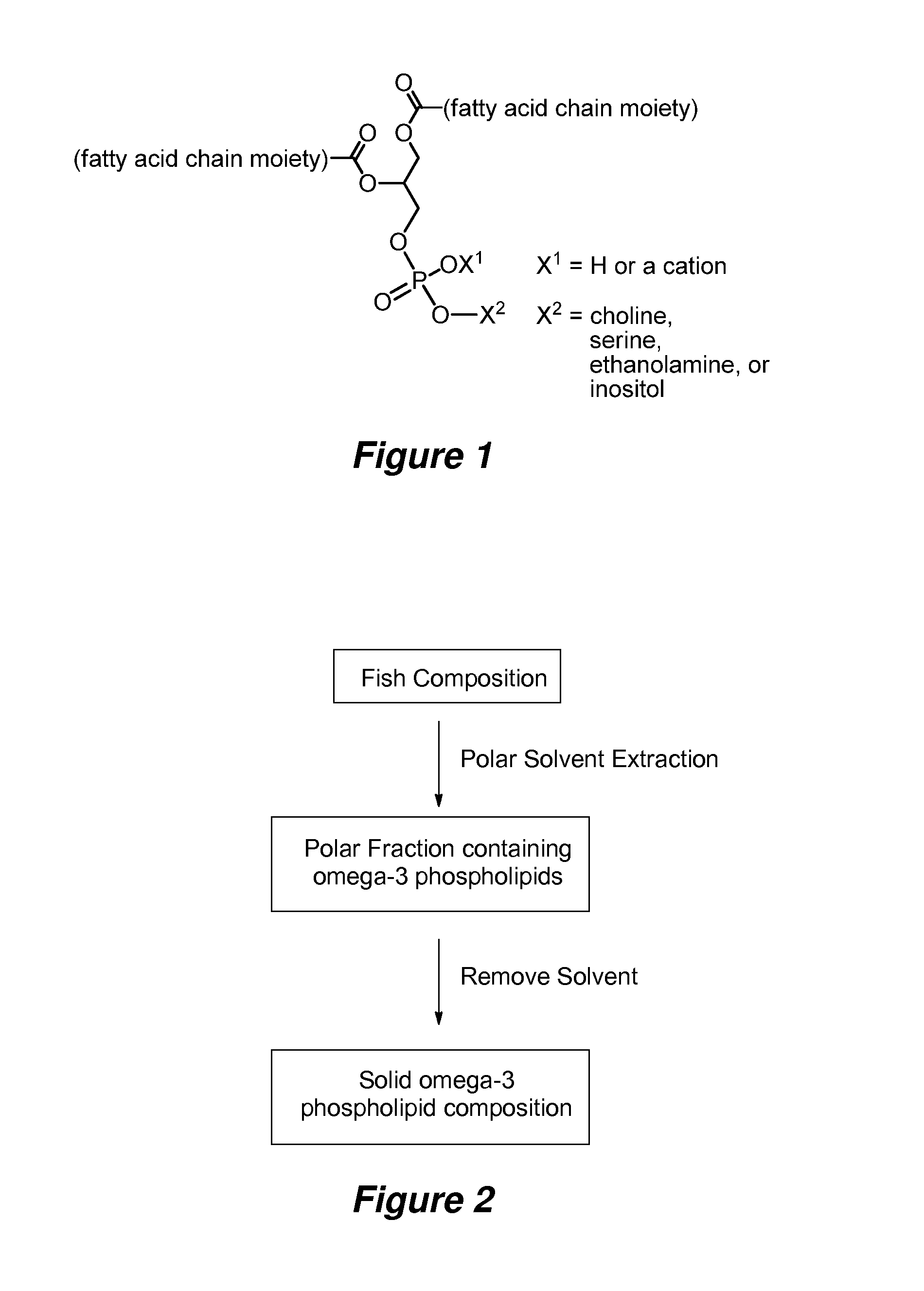

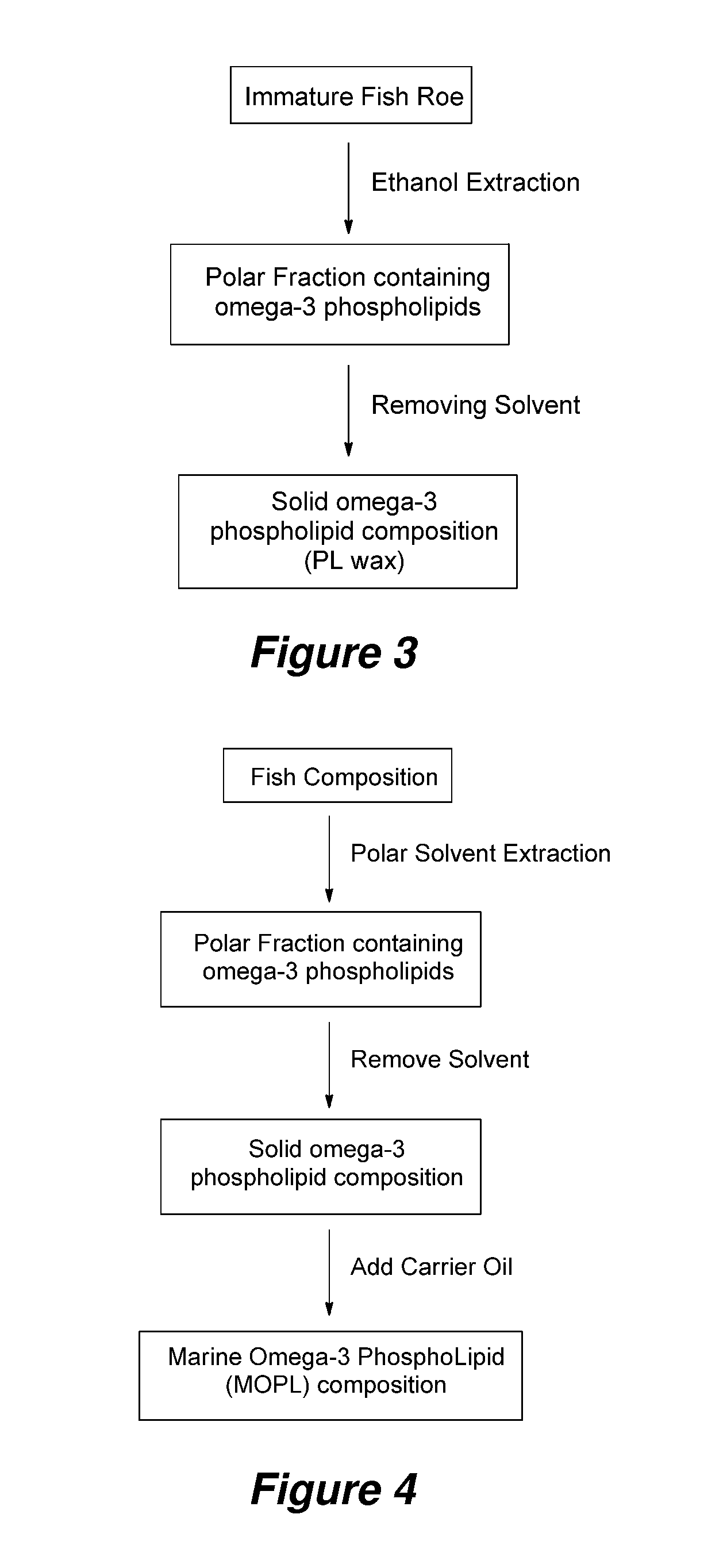

Lipid compositions with high DHA content

ActiveUS20130059768A1Oxidation stabilityEfficiently provideBiocidePeptide/protein ingredientsNatural sourceLipid formation

The invention provides lipid compositions comprising phospholipids having a high docosahexaenoic acid (DHA) content, which compositions are preferably extracted from natural sources. The lipid compositions are excellent sources of highly bioavailable DHA and they can be used in oral delivery vehicles, dietary supplements, functional foods, and the like.

Owner:ARCTIC NUTRITION

Elongase genes and uses thereof

The subject invention relates to the identification of several genes involved in the elongation of polyunsaturated acids (i.e., "elongases") and to uses thereof. At least two of these genes are also involved in the elongation of monounsaturated fatty acids. In particular, elongase is utilized in the conversion of gamma linolenic acid (GLA) to dihomogamma linolenic acid (DGLA) and in the conversion of AA to adrenic acid (ADA), or eicosapentaenoic acid (EPA) to omega3-docosapentaenoic acid (DPA). DGLA may be utilized in the production of polyunsaturated fatty acids, such as arachidonic acid (AA), docosahexaenoic acid (DHA), EPA, adrenic acid, omega6-docosapentaenoic acid or omega3-docosapentaenoic acid which may be added to pharmaceutical compositions, nutritional compositions, animal feeds, as well as other products such as cosmetics.

Owner:ABBOTT LAB INC

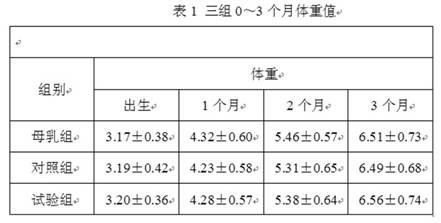

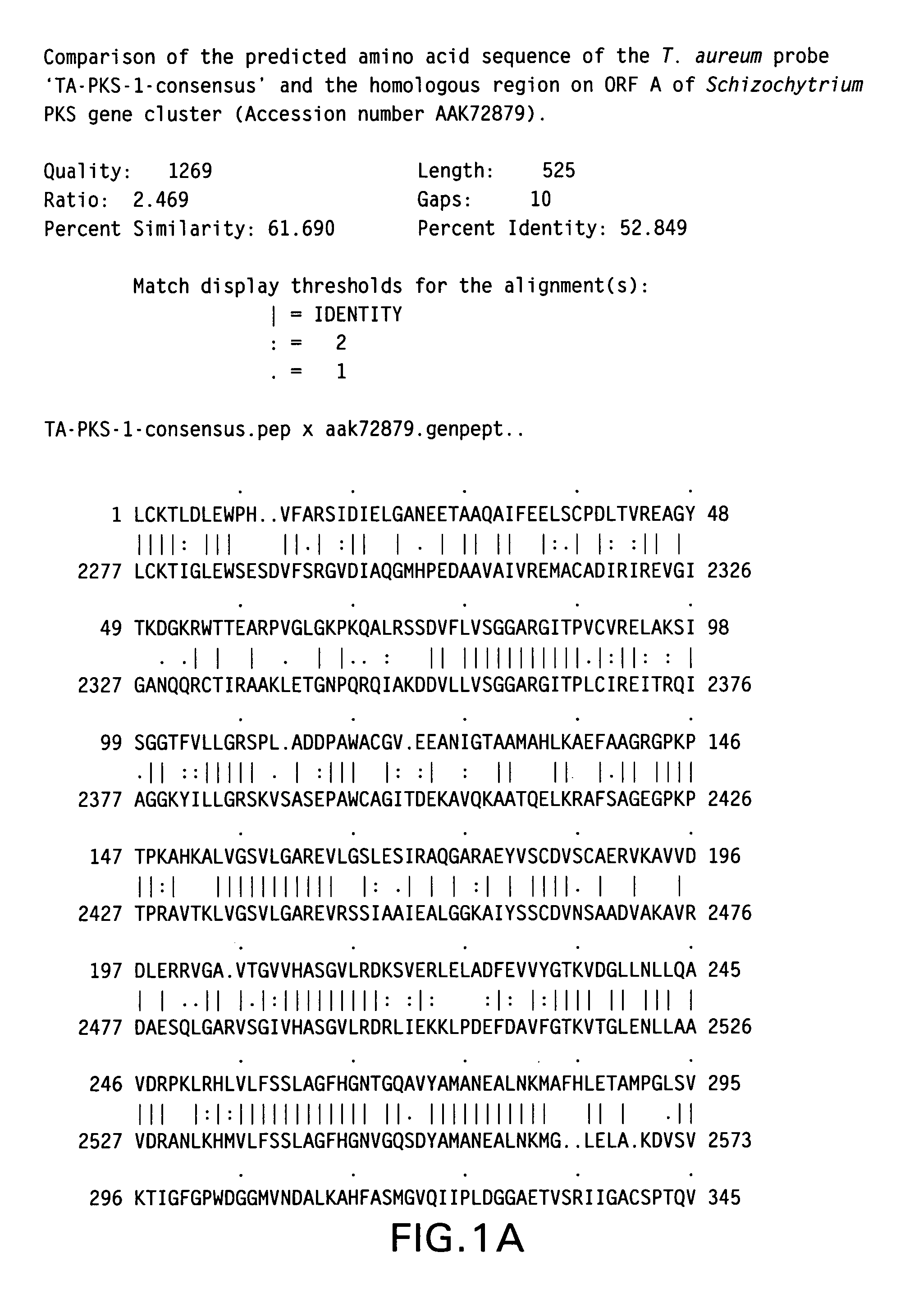

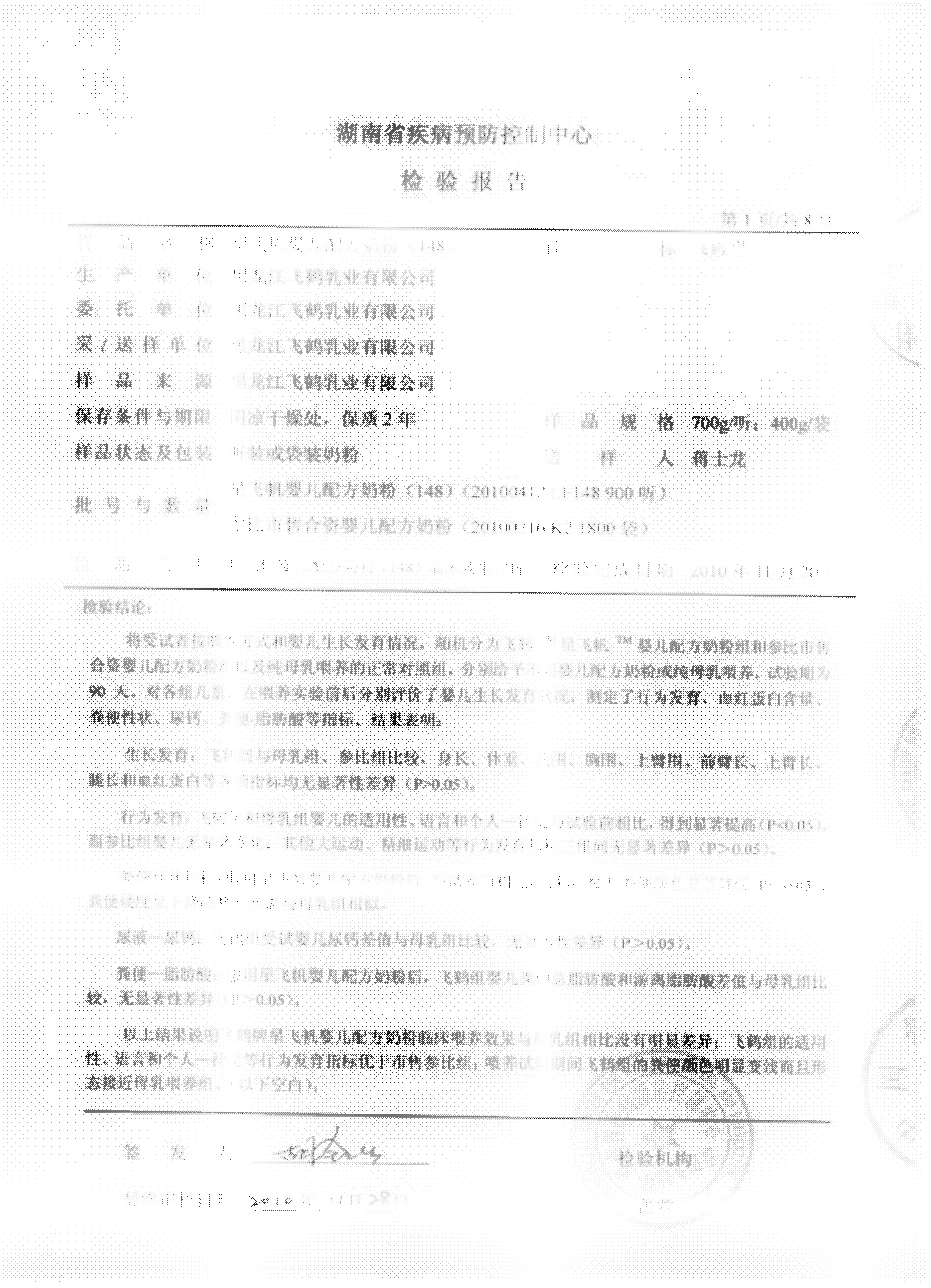

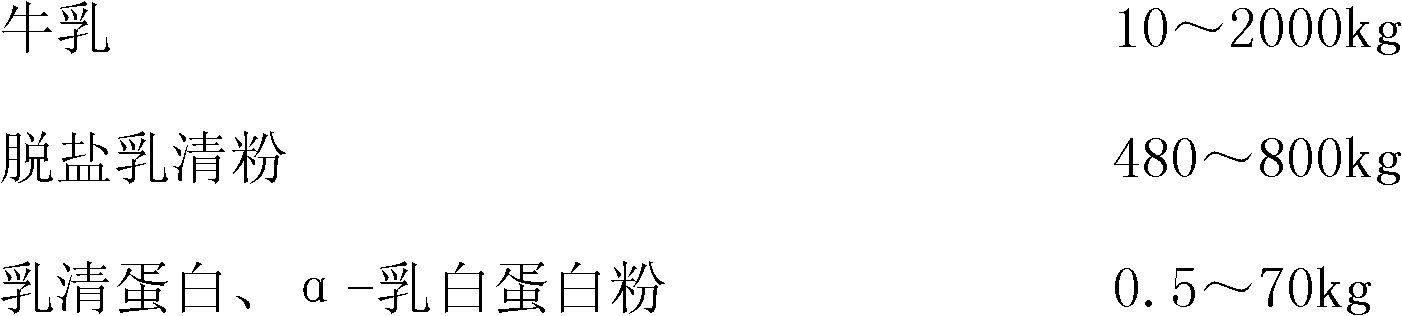

Formula milk powder for promoting absorption of fatty acid and calcium and preparation method thereof

The invention discloses a formula milk powder for promoting the absorption of fatty acid and calcium and a preparation method thereof. Raw cow milk, lactose, 1,3-Dioleoyl 2-palmitoyl triglyceride and demineralized whey powder as main materials are added with concentrated whey albumen powder, Alpha-lactalbumin powder, oligosaccharide, walnut oil, casein phosphopeptide, docosahexaenoic acid, arachidonic acid, nucleotide, lutein, inositol, carnitine and the like as well as vitamins, mineral substances and other nutrients needed for strengthening infants, and fat humanization, protein humanization and carbohydrate humanization are realized. The powdery product is produced by the processes of blending, homogenization, concentration, spray-drying, packaging and the like. According to the physiological characteristics and nutritional demand of the infants, the invention reinforces the calcium, the 1,3-Dioleoyl 2-palmitoyl triglyceride, other nutrient ingredients and the like, and aiming at the oversea clinical test conclusion of the 1,3-Dioleoyl 2-palmitoyl triglyceride, the final test conclusion of comparison with breast milk and infant formula milk powder sold on the market in the process of a clinical feeding test is that the feeding result of the designed formula approximates the feeding result of the breast milk and is better than the feeding result of an infant formula milk powder group sold on the market.

Owner:HEILONGJIANG FEIHE DAIRY

Omega-3 Fatty Acids Encapsulated In Zein Coatings and Food Products Incorporating the Same

Disclosed are processes for stabilizing omega-3 fatty acids for use in food products. The processes permit creation of a variety of food forms and food ingredients that contain omega-3 fatty acids like docosahexaenoic acid and eicosapentaenoic acid wherein these foods and food forms are stable for months without developing fishy aromas or tastes. This stability enables the incorporation of omega-3 fatty acids into food forms such as ready to eat cereals, trail mixes, chips, granola bars, toaster pastries, baked goods, cookies, crackers, fruit pieces and fruit leathers. The processes utilize a zein coating to protect and stabilize the omega-3 fatty acids.

Owner:KELLOGG CO

Method for enrichment of n-3 polyunsaturated fatty acid glyceride from fish oil

InactiveCN101348807AAchieve enrichmentImprove app targetingFermentationCarboxylic compound separation/purificationDocosahexaenoic acidEicosapentaenoic acid

The invention relates to a method for enriching n-3 polyunsaturated fatty acid (n-3PUFA) from fish oil, which belongs to the food organism and functional health product technical field. The method takes the fish oil as a raw material, uses the chemical hydrolysis method to hydrolyze the fish oil, respectively obtains high-purity eicosapentaenoic acid (EPA) and high-purity docosahexaenoic acid (DHA) from the hydrolyzed fish oil through separation and purification, uses glycerol and the purified EPA or DHA as raw materials and utilizes lipase to respectively catalyze and synthesize an EPA glyceride product or a DHA glyceride product in an organic phase. The products are mainly n-3PUFA triglyceride; the purity of the products is high; and the concentration of EPA triglyceride in the EPA glyceride is between 90 and 95 percent, and the concentration of DHA triglyceride in the DHA glyceride is between 92 and 94 percent. The high-purity EPA triglyceride product and the high-purity DHA triglyceride product prepared by the method well improve the application pertinence of different health care efficacies of natural fish oil products and improve the functional health care value of the fish oil products.

Owner:JIANGNAN UNIV

Compositions for improving mental performance

ActiveUS20050244510A1Improved mental performanceElimination of mental fatigueHeavy metal active ingredientsBiocidePoor focusAntioxidant

The present invention provides formulas for producing compositions for the structural / functional nutritional support for those who struggle with poor focus, concentration and / or memory. In addition, the present invention provides compositions comprising nutritional / botanical factors helpful to those who subjectively experience transient mental fatigue or poor cognitive function. The compositions of this invention consist primarily of the following ingredients B-complex vitamins, antioxidants, minerals, phosphatidyl serine (PS), choline, dimenthyl-aminoethanol (DMAE), docosahexaenoic acid (DHA), L-pyroglutamic acid, as well as herbal extracts from Bacopa monniera, Vinca minor, and Huperzia serrata. The present invention also relates to the administration of these compounds to alleviate mental fatigue or poor cognitive function.

Owner:SYNERGY STRIPS CORP

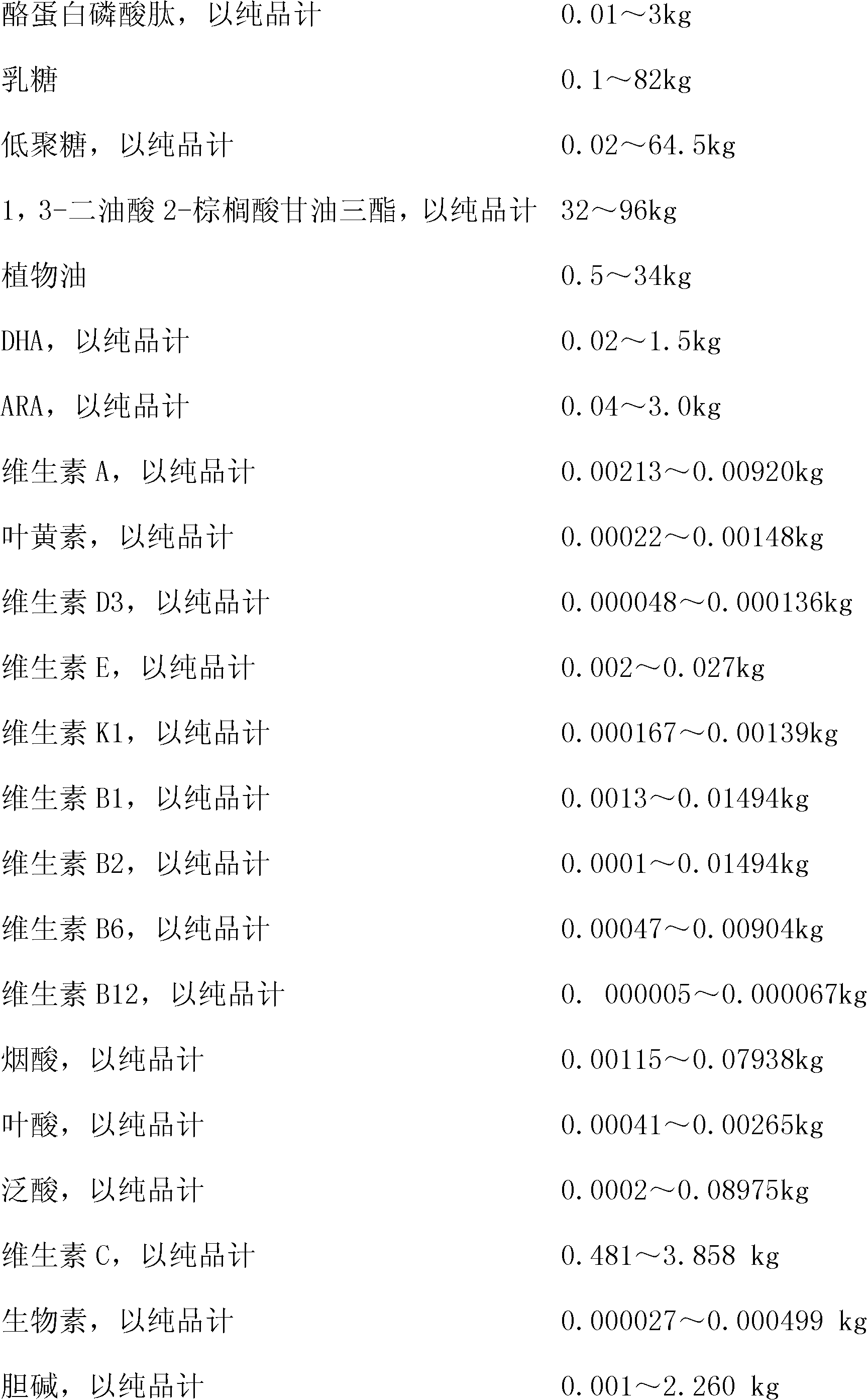

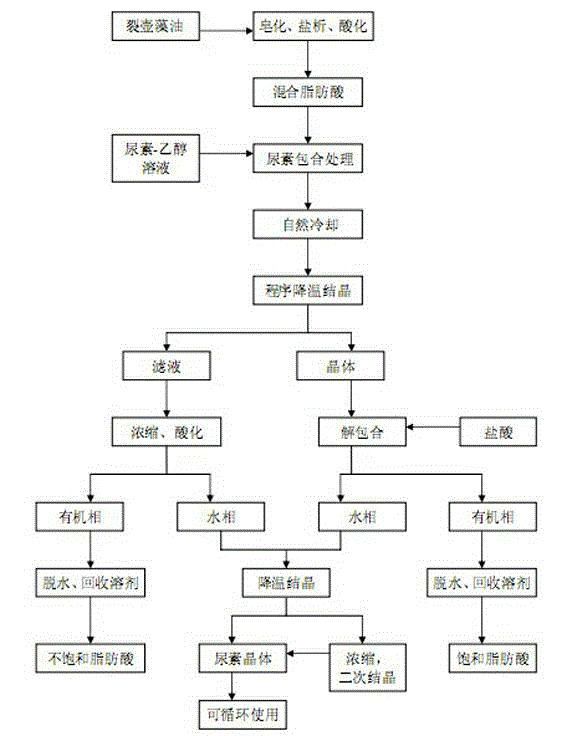

Method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil

ActiveCN102746947AIncrease contentPrevent oxidationPreparation from carboxylic acid saltsFatty acids production/refiningMixed fatty acidSalting out

The invention discloses a method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil. The method includes: firstly, saponifying, salting out and acidizing the schizochytrium limacinum oil under protection of nitrogen so as to obtain free mixed fatty acid, and separating the fatty acid different in degree of saturation by urea adduction fractionation so as to obtain filtrate and solids after filtration; concentrating and extracting the filtrate so as to obtain polyunsaturated fatty acid rich in DHA and DPA (docosapentenoic acid); and allowing the solids to leach by means of acidolysis, extracting the saturated fatty acid (mainly comprising palmic acid) and recovering urea, wherein the urea is recyclable. The method is performedat a low temperature, oxidization of the unsaturated fatty acid is avoided, biological activity and nutrition of the unsaturated fatty acid are kept intact, and the problem of residual solvent is avoided. Products are high in purity, and the obtained polyunsaturated fatty acid mainly comprises the DHA and the DPA and hardly comprises EPA (eicosapentaenoic acid), the content of the DHA and the DPAis higher than 93%, and the content of the palmic acid of the saturated fatty acid is higher than 82%.

Owner:福建华尔康生物科技有限公司

Oil or fat composition

ActiveUS20050129830A1Edible oils/fats with fatty acid estersAnimal feeding stuffMonoglycerideEicosapentaenoic acid

The present invention relates to an oil or fat composition containing the following components (A) and (B): (A) from 80 to 99.9 wt. % of a monoglyceride containing 20 to 75 wt. % of docosahexaenoic acid (DHA) and 0.1 to 25 wt. % of icosapentaenoic acid (IPA), as the constituent fatty acids thereof, wherein the weight ratio of DHA / IPA being 2 or more; and (B) from 0.1 to 20 wt. % of a diglyceride.

Owner:KAO CORP

Nutritional composition for supporting brain development and function of children

InactiveUS20120171178A1Contributes to orImprove abilitiesBiocideNervous disorderBrain developmentBiology

The present invention relates to a nutritional composition, in particular directed to children of 3-6 years, said nutritional composition comprising a protein source, a source of available carbohydrates, a lipid source, at least one probiotic microorganism, and prebiotics, wherein said lipid source comprises DHA (docosahexaenoic acid) and / or ARA (arachidonic acid). The nutritional composition improves cognitive performance, in particular memory, learning comprehension, alertness, attention, concentration, processing speed, conceptual thinking, abstract thinking, verbal abilities, language comprehension, psychomotor skills, curiosity, and confident interaction with the environment. Preferably, the composition comprises one, a combination of several or all selected of the group of DHA, ARA, LA, ALA, choline, iron, iodine and folic acid.

Owner:NESTEC SA

Long chain fatty acids for reducing off-taste of non-nutritive sweeteners

InactiveUS20080226790A1Food ingredient as taste affecting agentFood preparationArachidic acidAdipic acid

Aspects of the invention relate to beverage compositions, including, for example, concentrated and ready-to-drink formulations sweetened with at least one non-nutritive sweetener and further including a long chain fatty acid compound in an amount sufficient to reduce the off-note taste of the non-nutritive sweetener. In certain embodiments, the long chain fatty acid may be one or more of the following: lauric acid, myristic acid, palmitic acid, stearic acid, arachidic acid, behenic acid, oleic acid, linoleic acid, alpha-linolenic acid, arachidonic acid, eicosapentaenoic acid, docosahexaenoic acid, erucic acid, adipic acid, and palmitic acid. In certain exemplary embodiments, a plurality of different long chain fatty acids are utilized. In another embodiments, the long chain fatty acids comprise both natural and synthetic fatty acids.

Owner:CONCENTRATE MFG OF IRELAND

Novel Strain of Schizochytrium limacinum useful in the production of lipids and Extracellular Polysaccharides and process thereof

The present disclosure provides a novel mutant strain of Schizochytrium limacinum having the Accession No. MTCC 5249, which produces lipids and extracellular polysaccharide (EPS) simultaneously. The disclosure further provides a process for simultaneous production of lipids and extracellular polysaccharide (EPS) from the novel mutant strain of Schizochytrium limacinum. The lipids produced from the novel mutant strain of Schizochytrium limacinum comprises docosahexaenoic acid (DHA). The disclosure also provides a food, feed, cosmetic, nutritional or therapeutic supplement for humans or animals comprising the cell biomass and extracellular polysaccharides (EPS) of the mutant strain of Schizochytrium limacinum. A cosmetic composition comprising the extracellular polysaccharides (EPS) of Schizochytrium limacinum is also provided that is useful as a base for cosmetics for topical application. The present disclosure further provides a pickle composition and a fat product having improved nutritive value.

Owner:ABL BIOTECH

Lutein ester health care product for protecting eyesight and preparation method thereof

InactiveCN102144780AFree from destructionStrengthen the immune systemSenses disorderSulfur/selenium/tellurium inorganic active ingredientsDiseaseAlpha-Lipoic Acid

The invention discloses a lutein ester health care product for protecting eyesight. The lutein ester health care product is prepared by taking lutein ester as a main material, and adding any one or more materials including taurine, selenium, zinc, alpha-lipoic acid, docosahexaenoic acid (DHA), vitamin A, vitamin E, vitamin B1, vitamin B2 and bilberry extract, and pharmaceutically acceptable formulation accessories. The outstanding innovation of the invention is the implementation of the method for preparing a functional eye health care product with the lutein ester instead of lutein, so that the bioavailability, the stability and the health care effect of the product are improved, and production cost can be greatly reduced. The health care product can be prepared into common dosage forms, such as tablets, capsula, granules and soft capsules. The lutein ester health care product is mainly used for the treatment on diseases, such as myopia, amblyopia, hyperopia, presbyopia, cataract, vitreous opacity, retinal pigment degeneration, macular degeneration, asthenopia, and retinopathy caused by diabetes, and the like. The lutein ester health care product adopts a unique formulation of multiple constituents, measures and mechanisms, and has significant treatment effects and excellent social and economic benefits.

Owner:崔晓廷

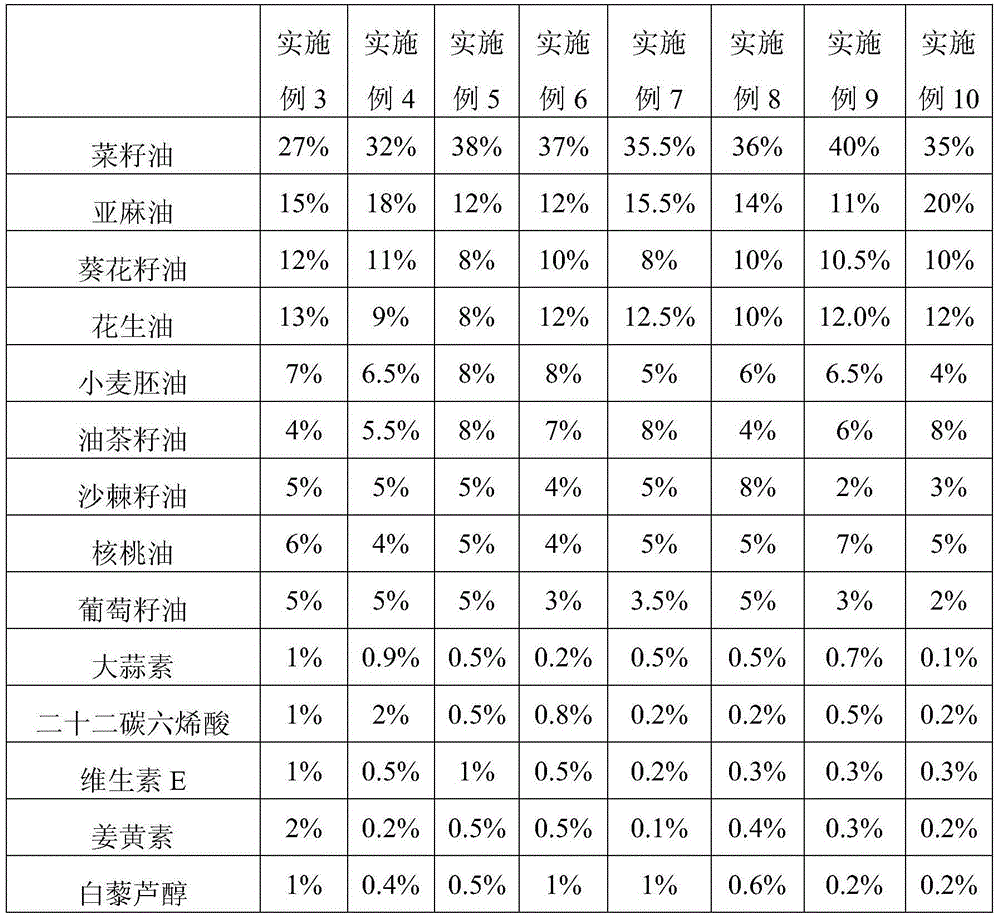

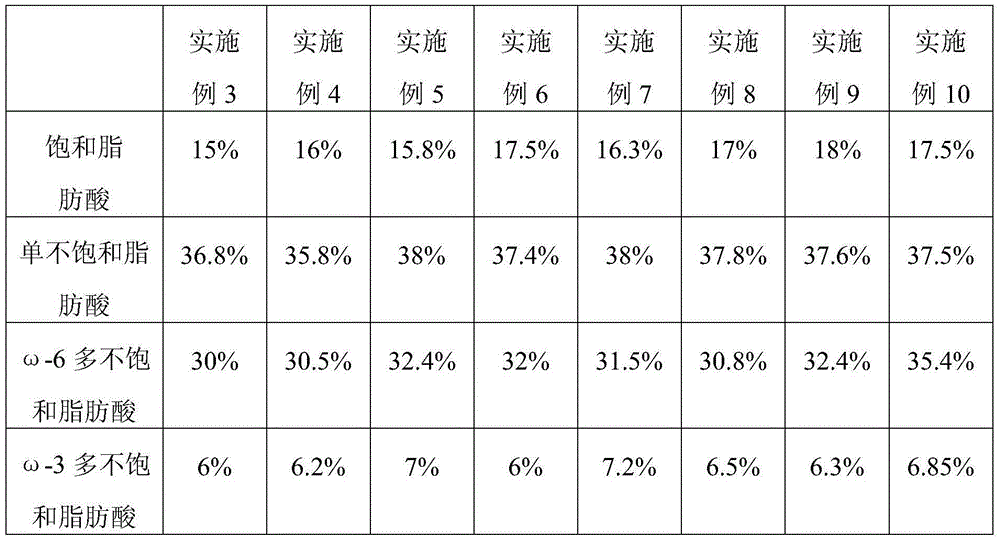

Nutrient plant blending oil and production method thereof

The invention provides nutrient plant blending oil. The nutrient plant blending oil comprises components in percentage by weight as follows: 20%-40% of rapeseed oil, 10%-20% of linseed oil, 6%-12% of sunflower seed oil, 5%-15% of peanut oil, 4%-8% of wheat germ oil, 2%-10% of camellia seed oil, 1%-5% of seabuckthorn seed oil, 3%-8% of walnut oil, 2%-5% of grape seed oil, 0.1%-2% of allicin, 0.1%-2% of docosahexaenoic acid, 0.1%-2% of vitamin E, 0.1%-2% of curcumin and 0.1%-1% of resvaritrol. The production method of the blending oil comprises steps as follows: the raw materials are weighed in the proportion and then added to a mixing vessel, nitrogen is injected at the temperature of 40-60 DEG C, so that pressure in the mixing vessel can keep 0.1-0.5 Mpa, vibration and blending are performed through ultrasonic waves for 60-120min and then are left to stand for 3-5 hours, and primary blending oil is obtained; then bentonite and activated carbon in the weight ratio of 1:(2-4) are added to the primary blending oil, the mixture is stirred for 30-60min at a rotation speed of 80-100 r / min, then solid impurities are filtered out, and the nutrient plant blending oil is obtained. The blending oil integrates edible and health-care functions of various kinds of plant oil, and the nutrient plant blending oil has more nutrition and health-care functions due to addition of functional additives.

Owner:SICHUAN CHAOFENG GRAIN & OIL

Co-beadlet of dha and rosemary and methods of use

InactiveUS20050106272A1Increase nutritionPromotes eye healthBiocideSenses disorderMedicineDietary supplement

The present invention provides improved beadlet formulations useful for inclusion in dietary supplements customized for improving and maintaining ocular nutrition. In particular, the improved beadlets comprise DHA (docosahexaenoic acid); rosemary and / or its components; and excipients.

Owner:BIO DAR +1

Baby-food compositions enhancing cognitive ability and methods therefor

InactiveUS20050053713A1Improve cognitive abilityIncrease in MDI scoreBiocideAlgae medical ingredientsYolkMedicine

Methods for enhancing cognitive ability in infants are disclosed. The methods comprise feeding infants baby-food compositions containing docosahexaenoic acid (DHA) in an amount of at least about 0.5 mg per gram of the composition. Infants fed a composition containing DHA from an age of about 6 months to about one year exhibit improved problem solving ability compared to infants fed a composition containing DHA in an amount less than about 5 mg per 100 grams total composition over the same period. The source of the DHA can be DHA-enriched coagulated egg yolk solids present in an amount of from about 5% to about 25% (grams / 100 grams). Also disclosed are methods of making the DHA-enriched baby-food compositions, and methods of providing the compositions to a consumer.

Owner:BEECH NUT NUTRITION

Method of extracting Euphausia superba oil by using supercritical carbon dioxide

InactiveCN102358865AReduce dosageReduce the degree of nutrient denaturationFatty-oils/fats productionAnhydrous ethanolDocosahexaenoic acid

The invention discloses a method of extracting Euphausia superba oil by using supercritical carbon dioxide. The method is as follows: freeze drying or heat drying is carried out on Euphausia superba, anhydrous ethanol is sprinkled after Euphausia superba is crushed and ground, uniform stirring is carried out, and supercritical carbon dioxide extraction is carried out after Euphausia superba is immersed for 1 to 2 h; flow for supercritical carbon dioxide extraction comprises the steps of standing and infiltrating Euphausia superba, carrying out static extraction for 20 to 40 m, heating an obtained extract to a temperature of 40 to 50 DEG C and carrying out dynamic extraction for 1 to 2 h. Yield of the Euphausia superba oil is 12 to 18%, and the obtained Euphausia superba oil mainly comprises, by weight, 37 to 43% of phosphatide, 13 to 18% of EPA (eicosapntemacnioc acid), 8 to 12% of DHA (docosahexaenoic acid) and 0.12 to 0.13% of astaxanthin. The method has the advantages of simple flow, stable quality, no harmful influence on environment in the process of extraction, safety and utility.

Owner:SHANDONG KERUIER BIOLOGICAL PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com