Method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil

A technology for unsaturated fatty acids and fatty acids, which is applied in the separation/purification of carboxylic acid compounds, fatty acid production, fatty acid preparation/refining, etc., and can solve problems such as the inability to achieve high purification, and the lack of research reports on the separation and purification of DHA and saturated fatty acids. , achieve considerable economic value, retain biological activity and nutrition, and avoid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

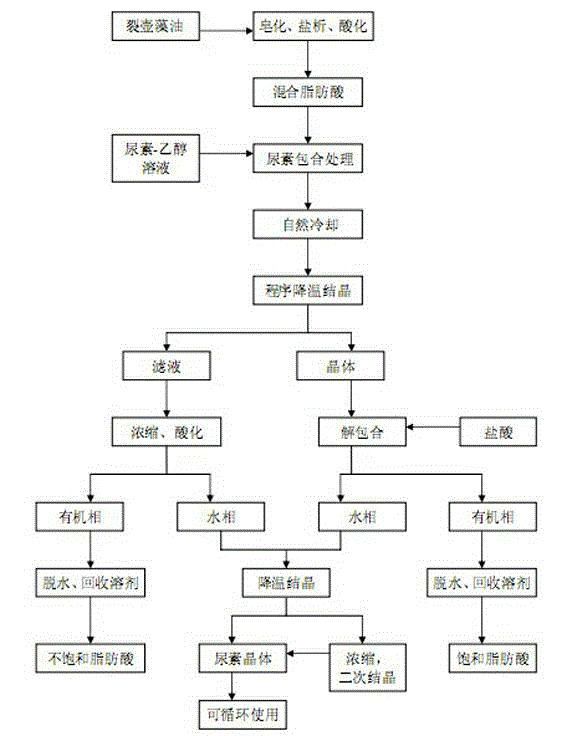

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of free mixed fatty acids

[0028] Take 100g of Schizochytrium algae oil into a flask, add 400mL of prepared 4% NaOH-95% ethanol solution, fill with nitrogen protection, stir and reflux in a water bath at 55°C for 1.5h, cool to room temperature, add 8g of chloride sodium, stirred, and stood for 15 minutes, filtered to obtain filtrate and solid, discarded the filtrate, added water and stirred the solid until it was completely dissolved, adjusted the pH to 2.5 with 10% hydrochloric acid, then added 2 times the volume of n-hexane to extract and separate with a separatory funnel, and obtained The oil in the upper organic phase was washed with distilled water to neutrality, added anhydrous sodium sulfate for dehydration, and suction filtered. The filtrate was concentrated under reduced pressure at 40°C and a vacuum of 0.08 MPa, and n-hexane was recovered to obtain 87g of free mixed fatty acids.

[0029] (2) Urea inclusion treatment

[0030] Weigh 174g of ure...

Embodiment 2

[0039] (1) Preparation of free mixed fatty acids

[0040] Put 100g of Schizochytrium oil into a flask, add 500mL of prepared 4% NaOH-95% ethanol solution, fill with nitrogen protection, stir and reflux in a water bath at 50°C for 1h, after cooling to room temperature, add 10g of sodium chloride , stirred, and stood still for 15 minutes, filtered to obtain the filtrate and solid, discarded the filtrate, added water and stirred the solid until it was completely dissolved, adjusted the pH to 2.6 with 10% hydrochloric acid, then added 2 times the volume of n-hexane to extract and separate with a separatory funnel, and took the upper layer The oil in the organic phase was washed with distilled water until neutral, dehydrated with anhydrous sodium sulfate, and suction filtered. The filtrate was concentrated under reduced pressure at 40°C and a vacuum of 0.08 MPa, and recovered n-hexane to obtain 85 g of free mixed fatty acids.

[0041] (2) Urea inclusion treatment

[0042]Weigh 170...

Embodiment 3

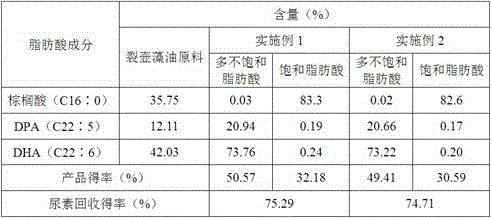

[0050] Schizochytrium oil raw material of the present invention and embodiment 1,2 gained product are carried out content analysis with gas chromatography, wherein the content of DHA, DPA, palmitic acid is shown in Table 1:

[0051] Table 1 Analysis of fatty acid content

[0052]

[0053] 1. Detection method of fatty acid composition:

[0054] The sample was first treated with the "boron trifluoride method" in GB / T 17376-2008 "Preparation of Fatty Acid Methyl Esters of Animal and Vegetable Oils", and then the content was analyzed by gas chromatography.

[0055] 2. Calculation formula:

[0056] Polyunsaturated fatty acid yield =

[0057] Saturated fatty acid yield =

[0058] 3. Conclusion:

[0059] (1) Polyunsaturated fatty acids and saturated fatty acids in Schizochytrium oil raw materials were effectively separated.

[0060] (2) The product has high purity. The content of DHA increased from 42.03% to 73%, the content of DPA increased from 12.11% to 20%, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com