Polymer material containing microencapsulated rare earth metal hypophosphite, and preparation method thereof

A polymer material and rare earth metal technology, which is applied in the field of polymer materials containing microencapsulated rare earth metal hypophosphite and its preparation, and can solve the problem that halogen-containing flame retardants are harmful to the environment and the addition amount of inorganic flame retardants is high. , poor thermal stability, etc., to overcome the environmental hazards, reduce the amount of addition, and improve compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

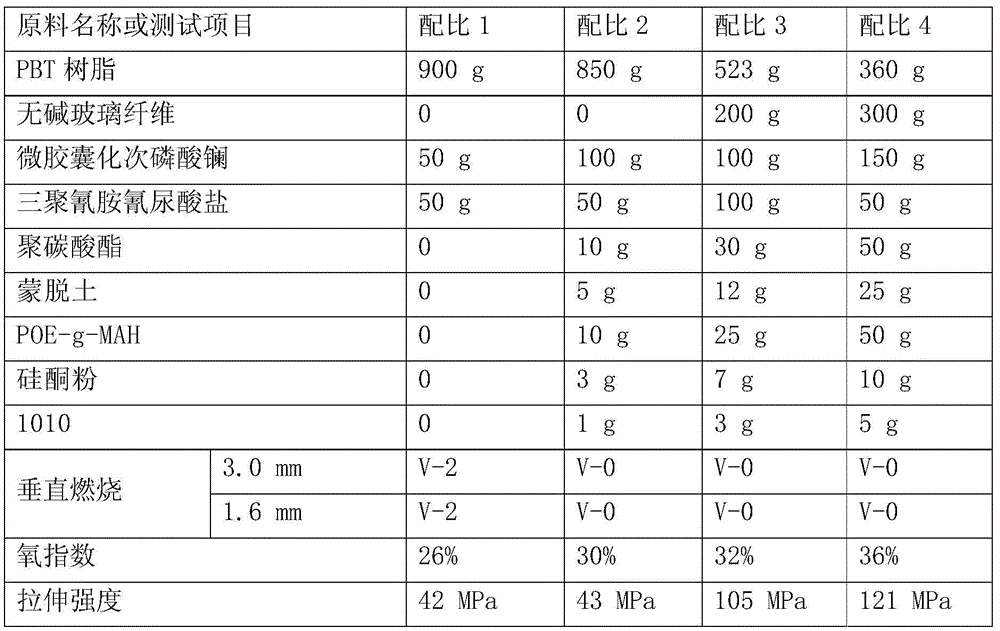

Embodiment 1

[0022] Prepare materials according to each formula of proportioning 1 to proportioning 4 given in table 1 respectively, dry polybutylene terephthalate (PBT) masterbatch, glass fiber, microencapsulated lanthanum hypophosphite, Melamine cyanurate, polycarbonate, montmorillonite, maleic anhydride grafted polyolefin elastomer (POE-g-MAH), silicone powder, tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester (1010) mixed uniformly, heated to 240°C in a twin-screw extruder, melted and blended, then extruded, drawn, cooled, pelletized and dried, that is A polymer material containing microencapsulated rare earth metal hypophosphite according to the invention is obtained. Then, the sample strips for oxygen index test, vertical combustion test and tensile strength test are injection molded by the injection molding machine, and the combustion performance and mechanical performance test are carried out. The oxygen index test is carried out according to the ...

Embodiment 2

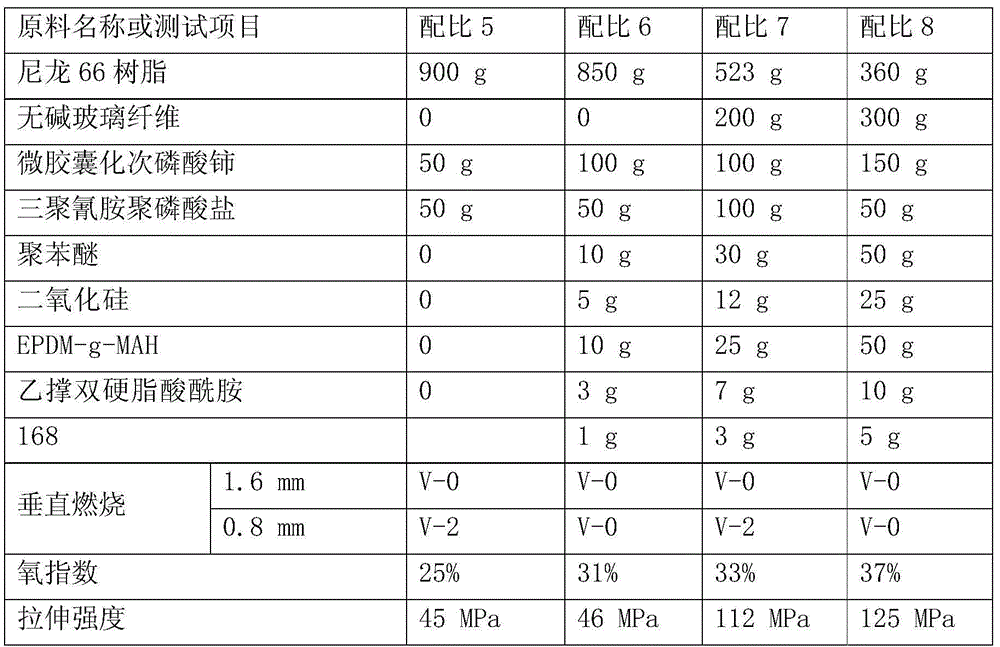

[0028] Prepare materials according to each formula of proportioning 5 to proportioning 8 given in Table 2 respectively, dry nylon 66 masterbatch, glass fiber, microencapsulated cerium hypophosphite, melamine polyphosphate, polyphenylene ether, di Silica, maleic anhydride grafted EPDM rubber (EPDM-g-MAH), ethylene bis stearic acid amide, tris (2,4-di-tert-butylphenyl) phosphite (168) mixed evenly , heated to 265 ° C in a twin-screw extruder, melted and blended, and then extruded, drawn, cooled, pelletized and dried to obtain the microencapsulated rare earth metal hypophosphite of the present invention. material. Then, the sample strips for oxygen index test, vertical combustion test and tensile strength test are injection molded by the injection molding machine, and the combustion performance and mechanical performance test are carried out. The oxygen index test is carried out according to the international standard ASTM D2863, the vertical burning test is carried out accordin...

Embodiment 3

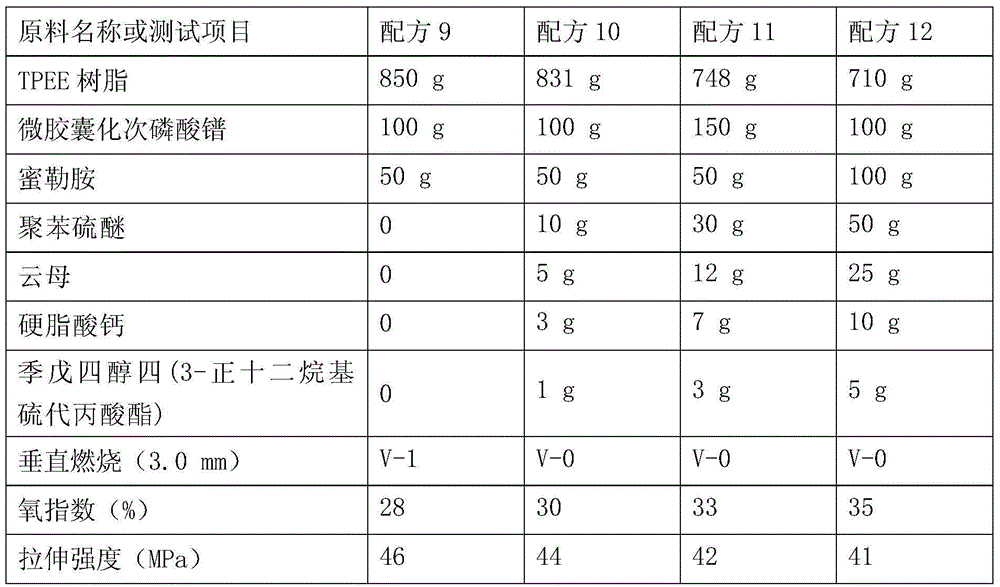

[0034] Prepare materials according to each formula of proportioning 9 to proportioning 12 given in Table 3 respectively, dry thermoplastic polyester elastomer (TPEE), microencapsulated praseodymium hypophosphite, melem, polyphenylene sulfide, Mix mica, calcium stearate and pentaerythritol tetrakis (3-n-dodecyl thiopropionate) evenly, heat to 225°C, melt blend, then extrude, draw, cool, pelletize and bake After drying, the polymer material containing microencapsulated rare earth metal hypophosphite of the present invention is obtained. Sample bars for oxygen index test, vertical combustion test and tensile strength test were injected by injection molding machine for combustion and mechanical performance tests. The oxygen index test is carried out according to the national standard ASTM D2863, the vertical burning test is carried out according to the American standard UL 94, and the tensile strength test is carried out according to the international standard ASTM D638.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com