Fabricated vacuum heat insulation composite wallboard and production process thereof

A composite wallboard and vacuum insulation technology, which is applied in the direction of synthetic resin layered products, household walls, layered products, etc., can solve the problems of low heat conduction efficiency, achieve poor weather resistance, superior compression resistance, and reduce maintenance and repair workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

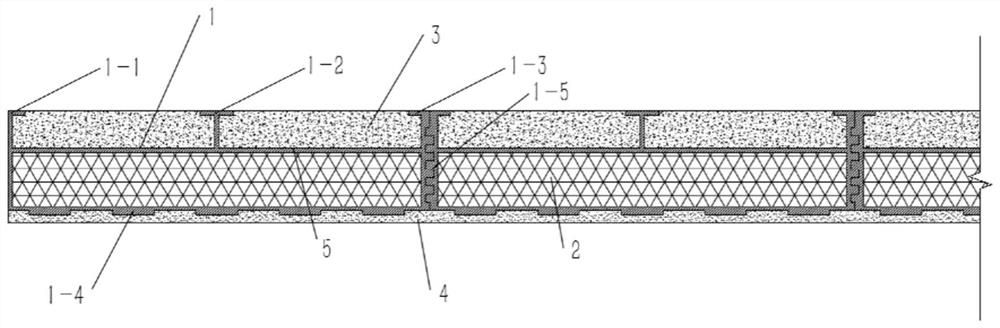

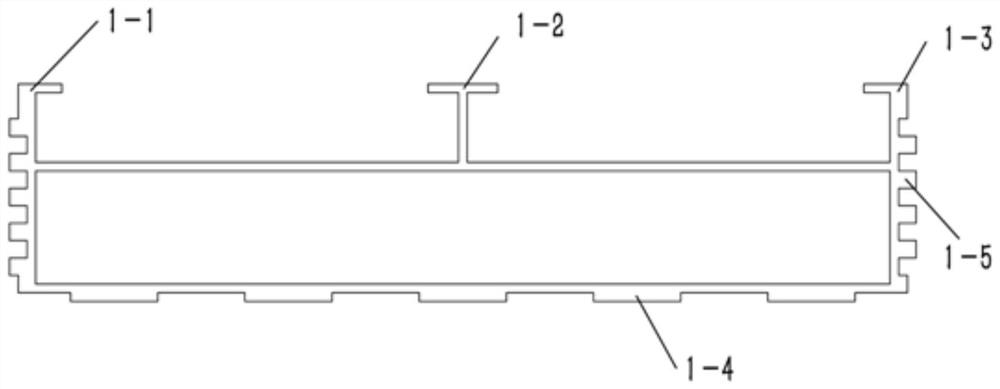

[0035] Such as Figure 1-Figure 8 As shown, a prefabricated vacuum heat insulation composite wall panel includes a GFRP profile plate 1. The GFRP profile plate 1 is a hollow square plate inside. The side of GFRP profile plate 1 is provided with male and female fasteners, and several GFRP profile plates 1 are connected by male and female fasteners 1-5 to form a whole as a skeleton, and the middle left and right sides of the upper end surface of GFRP profile plate 1 are distributed with Outer ribs 1-2, 1-1, 1-3, the upper end surface of GFRP profile plate 1 is poured with RPC concrete 3, the lower end surface of GFRP profile plate 1 is provided with inner ribs 1-4, the entire lower end surface of GFRP profile plate 1 The fine stone mortar leveling layer 4 is laid, bolt holes 6 are reserved on the upper end surface and the lower end surface of the GFRP pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com