Environment-friendly polyvinyl chloride ultraviolet-resistant sheath material and preparation method thereof

A polyvinyl chloride and polyvinyl chloride resin technology, applied in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of extravasation of inorganic fillers, prone to phase separation, affecting stability, etc. The effect of good high and low temperature performance, good environmental protection performance and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

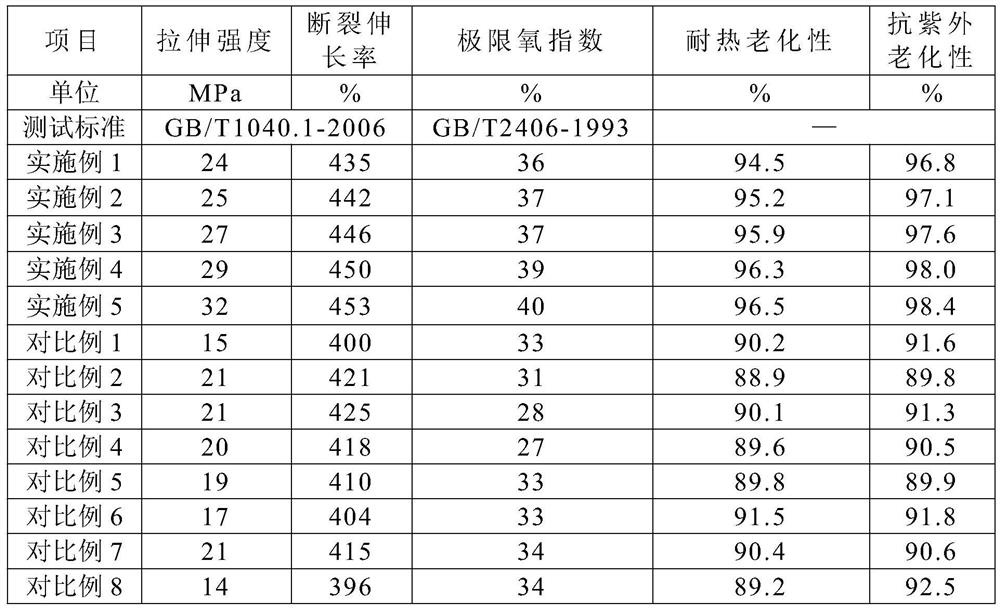

Examples

Embodiment 1

[0034] An environment-friendly polyvinyl chloride anti-ultraviolet sheath material is characterized in that it comprises the following components in parts by weight: 20 parts of polyvinyl chloride resin, 5 parts of hyperbranched polyethylene functionalized with terminal hydroxyl groups, 2-trimethyl Silyloxy-4-allyloxydiphenyl ketone / 2,3,4,5,6-pentafluoro-1-ethylenesulfonic acid phenyl ester / 3,5-diamino-1H-pyrazole-4 - 6 parts of allyl carboxylate / 1-allyl benzotriazole copolymer, 30 parts of epoxy SBS resin, 0.2 part of carbazole-based modified graphene quantum dots, 0.3 part of benzophenone hydrazone, filler 3 parts, 1 part of coupling agent. The coupling agent is silane coupling agent KH550; the filler is nano boron fiber.

[0035] The preparation method of described carbazole-based modified graphene quantum dots, comprises the steps:

[0036] Step D1: Add carbazole, 4-(chloromethyl)phenyltrimethoxysilane, and basic catalyst to N-methylpyrrolidone, stir and react at 40°C fo...

Embodiment 2

[0045] An environment-friendly polyvinyl chloride anti-ultraviolet sheathing material is characterized in that it comprises the following components in parts by weight: 22 parts of polyvinyl chloride resin, 6 parts of hyperbranched polyethylene functionalized with terminal hydroxyl groups, 2-trimethyl Silyloxy-4-allyloxydiphenyl ketone / 2,3,4,5,6-pentafluoro-1-ethylenesulfonic acid phenyl ester / 3,5-diamino-1H-pyrazole-4 -7 parts of allyl carboxylate / 1-allyl benzotriazole copolymer, 32 parts of epoxy SBS resin, 0.3 parts of carbazole-based modified graphene quantum dots, 0.4 parts of benzophenone hydrazone, filler 4 parts, 1.2 parts of coupling agent; the coupling agent is silane coupling agent KH560; the filler is nano titanium dioxide.

[0046] The preparation method of described carbazole-based modified graphene quantum dots, comprises the steps:

[0047] Step D1: Add carbazole, 4-(chloromethyl)phenyltrimethoxysilane, and a basic catalyst to N-methylpyrrolidone, stir and rea...

Embodiment 3

[0056] An environment-friendly polyvinyl chloride anti-ultraviolet sheath material is characterized in that it comprises the following components in parts by weight: 25 parts of polyvinyl chloride resin, 8 parts of hyperbranched polyethylene functionalized with terminal hydroxyl groups, 2-trimethyl Silyloxy-4-allyloxydiphenyl ketone / 2,3,4,5,6-pentafluoro-1-ethylenesulfonic acid phenyl ester / 3,5-diamino-1H-pyrazole-4 - 9 parts of allyl carboxylate / 1-allyl benzotriazole copolymer, 35 parts of epoxy SBS resin, 0.6 part of carbazole-based modified graphene quantum dots, 0.45 parts of benzophenone hydrazone, filler 4.5 parts, 1.5 parts of coupling agent; the coupling agent is silane coupling agent KH570; the filler is nano-zinc oxide.

[0057] The preparation method of described carbazole-based modified graphene quantum dots, comprises the steps:

[0058] Step D1: Add carbazole, 4-(chloromethyl)phenyltrimethoxysilane, and basic catalyst to N-methylpyrrolidone, stir and react at 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com