Patents

Literature

82 results about "Ethylenesulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terpolymer dispersants and preparation technique and use thereof

InactiveCN101391194AGood dispersionImprove thermal stabilityTransportation and packagingMixingSolubilityDispersion stability

The invention discloses a terpolymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The terpolymer dispersing agent is prepared through free radical copolymerization of acrylic acid, sodium styrene sulfonate, hydroxypropyl acrylate or 2-hydroxyethyl methacrylate, the number average relative molecular weight of the terpolymer is between 2000 and 40000, and the dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to acid and alkali and good dispersion stability, and also has good dispersion effects to calcium carbonate, zinc oxide, barium sulfate, titanium dioxide and pesticide Atrazine water dispersible granules and fipronil water dispersible granule, and can be widely used in the pesticide, pigment, dyestuff, coal water slurry and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

Fabric softening laundry detergent

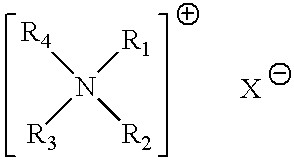

InactiveUS7994112B2Organic detergent compounding agentsNon-ionic surface-active compoundsMethacrylatePolymer science

Aqueous laundry detergent compositions containing surfactants and fatty acid, having a pH of from about 6 to about 11 and containing a polymer having a number average molecular weight of from about 700,000 to about 4,000,000 and comprising monomeric units including: nonionic monomers selected from acrylamide, N,N-dialkyl acrylamide, methacrylamide, N,N-dialkylmethacrylamide, hydroxyalkyl acrylate and vinyl pyrrolidone, vinyl acetate, vinyl alcohol, and mixtures thereof; cationic monomers selected from N,N-dialkylaminoalkyl methacrylate, N,N-dialkylaminoalkyl acrylate, N,N-dialkylaminoalkyl acrylamide, N,N-dialkylaminoalkylmethacrylamide, methacylamidoalkyl trialkylammonium chloride, acrylamidoalkylltrialkylammonium chloride, vinylamine, quaternized vinyl imidazole and diallyl dialkyl ammonium chloride, and mixtures thereof; and anionic monomers selected from acrylic acid, methacrylic acid, maleic acid, vinyl sulfonic acid, styrene sulfonic acid, acrylamidopropylmethane sulfonic acid (AMPS), salts thereof, and mixtures thereof; in a specified mole ratio.

Owner:THE PROCTER & GAMBLE COMPANY

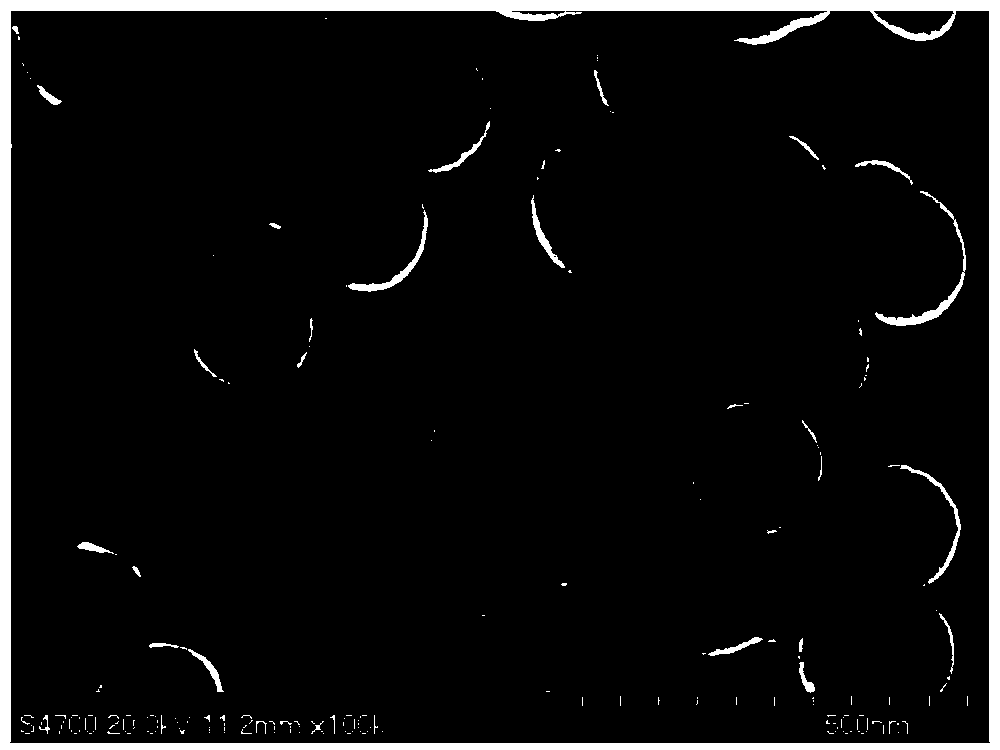

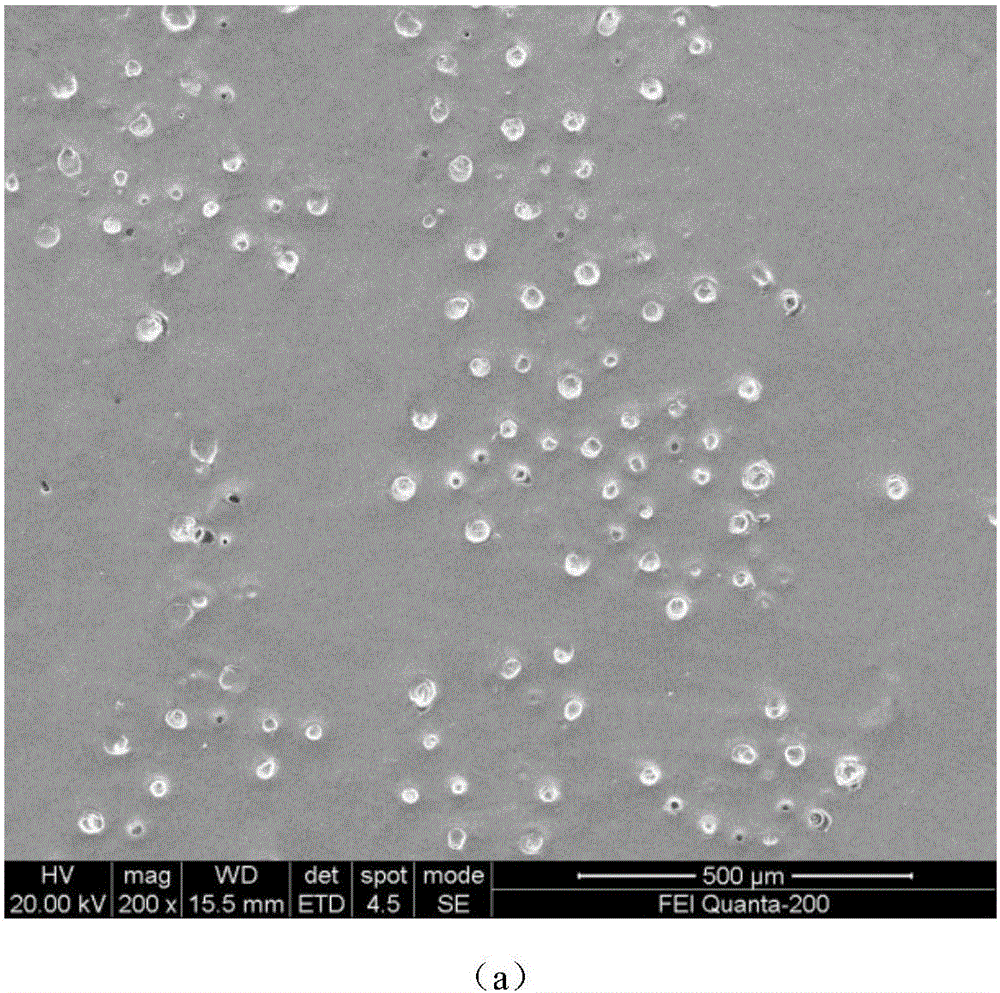

Method for preparing nonspherical, raspberry-shaped or hollow polymer microspheres through one-pot dispersion polymerization

The invention provides a method for preparing nonspherical, raspberry-shaped or hollow polymer microspheres through one-pot dispersion polymerization, and belongs to the technical field of dispersion polymerization. The method comprises the steps of stirring monomers styrene St and sodium styrenesulfonate NaSS and an initiator azodiisobutyronitrile AIBN, and dissolving the mixture in the mixed solution of an organic solvent and water to form a reaction solution; increasing the temperature of the reaction solution to the range from 75 to 80 DEG C and reacting for a certain of time; next, dropwise adding a cross-linking agent or the cross-linking and other reaction reagents to the reaction system, and further reacting for a while to obtain nonspherical, raspberry-shaped or hollow polymer microspheres. According to the invention, a method for directly preparing different types (nonspherical, raspberry-shaped or hollow) of polymer microspheres based on conventional dispersion polymerization and by controlling the cross-linking reaction process and adjusting reaction parameters is established.

Owner:BEIJING UNIV OF CHEM TECH

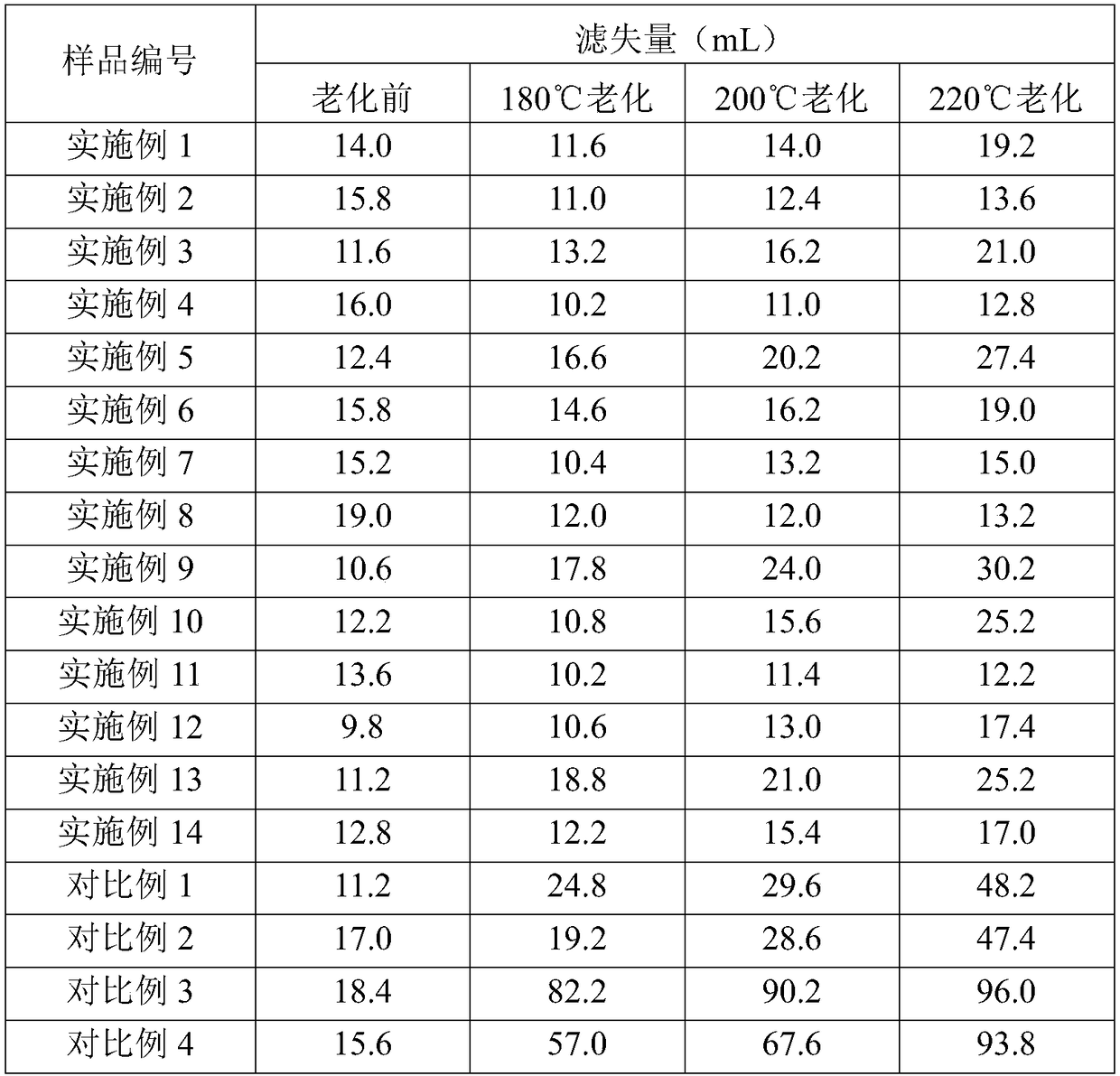

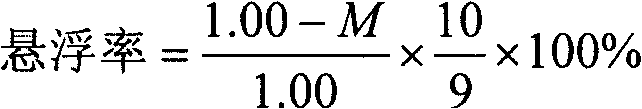

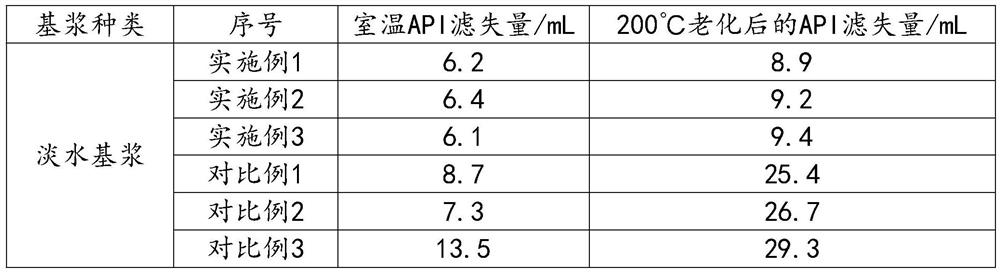

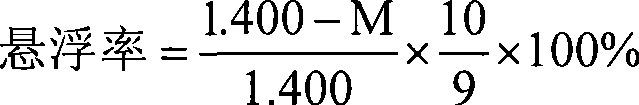

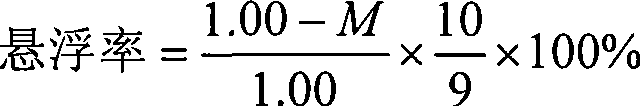

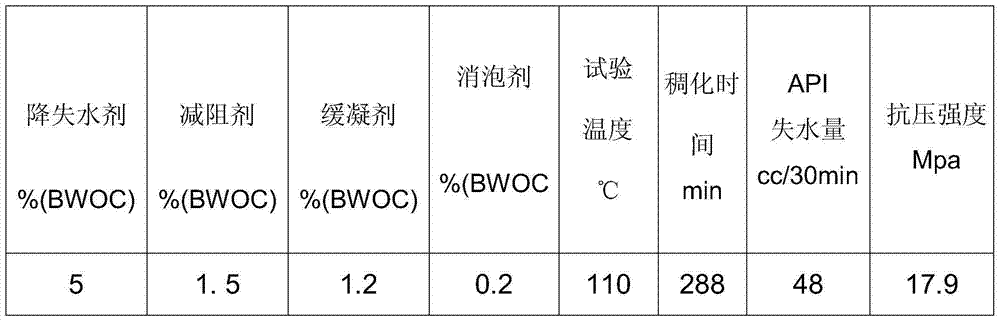

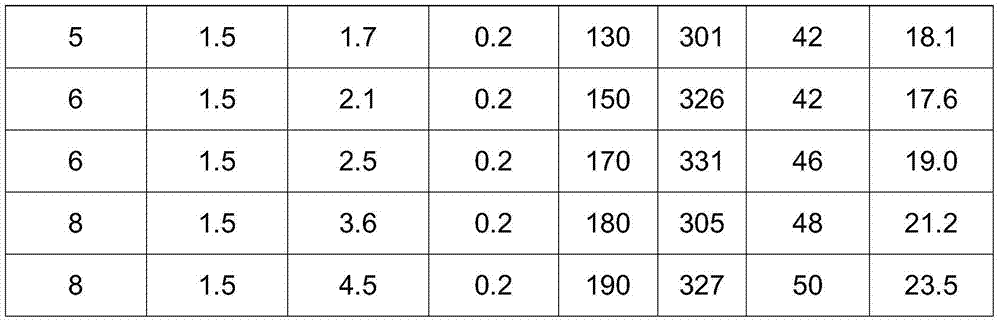

High-temperature-resistant oil well cement fluid loss agent and preparation method thereof

InactiveCN103881670AImprove high temperature resistanceDrilling composition(Hydroxyethyl)methacrylateOil well

The invention relates to a high-temperature-resistant oil well cement fluid loss agent which is prepared by acrylamide (AM), acrylic acid (AA) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS). The invention is characterized in that the fluid loss agent is also prepared from hydroxyethyl methacrylate (PEMA) and sodium styrene sulfonate (SS).

Owner:兰德(廊坊)石化环保设备有限公司

Acrylics polymeric dispersant and preparation technique and use thereof

InactiveCN101391193AGood water solubilityGood electrostatic repulsion stabilizationTransportation and packagingMixingImidaclopridIndustrial scale

The invention discloses an acrylic polymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The acrylic polymer dispersing agent is prepared through free radical copolymerization of acrylic acid, sodium styrene sulphonate and maleic anhydride, the number average relative molecular weight of the copolymer is between 2000 and 40000, and the dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to acid and alkali and good dispersion stability, and also has good dispersion effects to calcium carbonate, zinc oxide, barium sulfate, titanium dioxide and pesticide Atrazine water dispersible granules, imidacloprid water dispersible granules and Aatrex water dispersible granules, and can be widely used in the pesticide, pigment, dyestuff, coal water slurry and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

Rosin graft copolymer dispersant and preparation technique and use thereof

InactiveCN101391195AGood dispersionImprove thermal stabilityTransportation and packagingMixingSolubilityDispersion stability

The invention discloses a rosin graft polymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The rosin graft polymer dispersing agent is prepared through free radical polymerization of acrylic acid, sodium styrene sulfonate and rosin derivative, the number average relative molecular weight of the rosin graft polymer is between 12000 and 14000, wherein, the rosin derivative is a composition of maleopimaric acid acyl chloride and 2-hydroxyethyl methacrylate. The dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to alkali and good dispersion stability, and also has good dispersion effects to pesticide Aatrex water dispersible granules, and can be widely used in the pesticide, paint and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

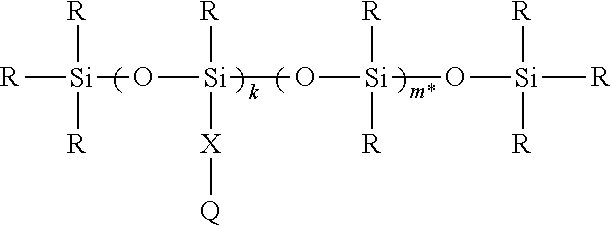

Fine-processing agent and fine-processing method

ActiveUS20120056126A1Reduce etch rateEliminate the effects ofSemiconductor/solid-state device manufacturingSurface treatment compositionsSilicon dioxidePolymer chemistry

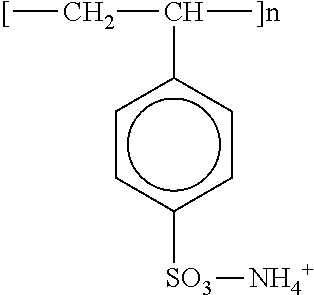

Provided is a fine-processing agent which, when fine-processing a laminated film stacked at least with a silicon dioxide film and a silicon nitride film, can selectively fine-process the silicon dioxide film. Also provided is a fine-processing method utilizing the fine-processing agent. The fine-processing agent is characterized by including: (a) 0.01-15.0 weight % hydrogen fluoride and / or 0.1-40.0 weight % ammonium fluoride, (b) water, and (c) 0.001-10.00 weight % water-soluble polymer selected from among a group consisting of acrylic acid, ammonium acrylate, acrylic acid ester, acrylamide, styrenesulfonic acid, ammonium styrenesulfonate, and styrenesulfonic acid ester.

Owner:STELLA CHEMIFA CORP

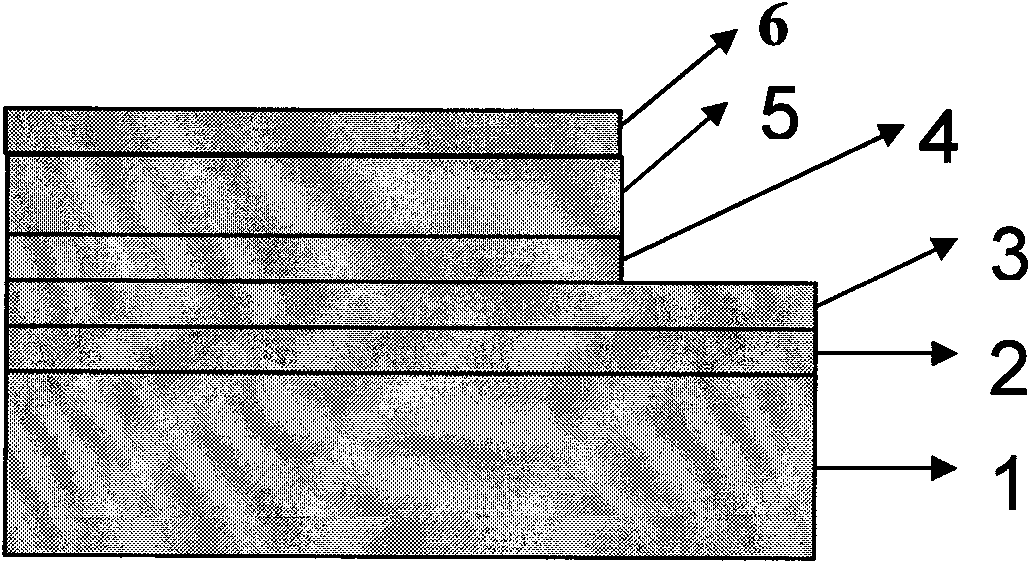

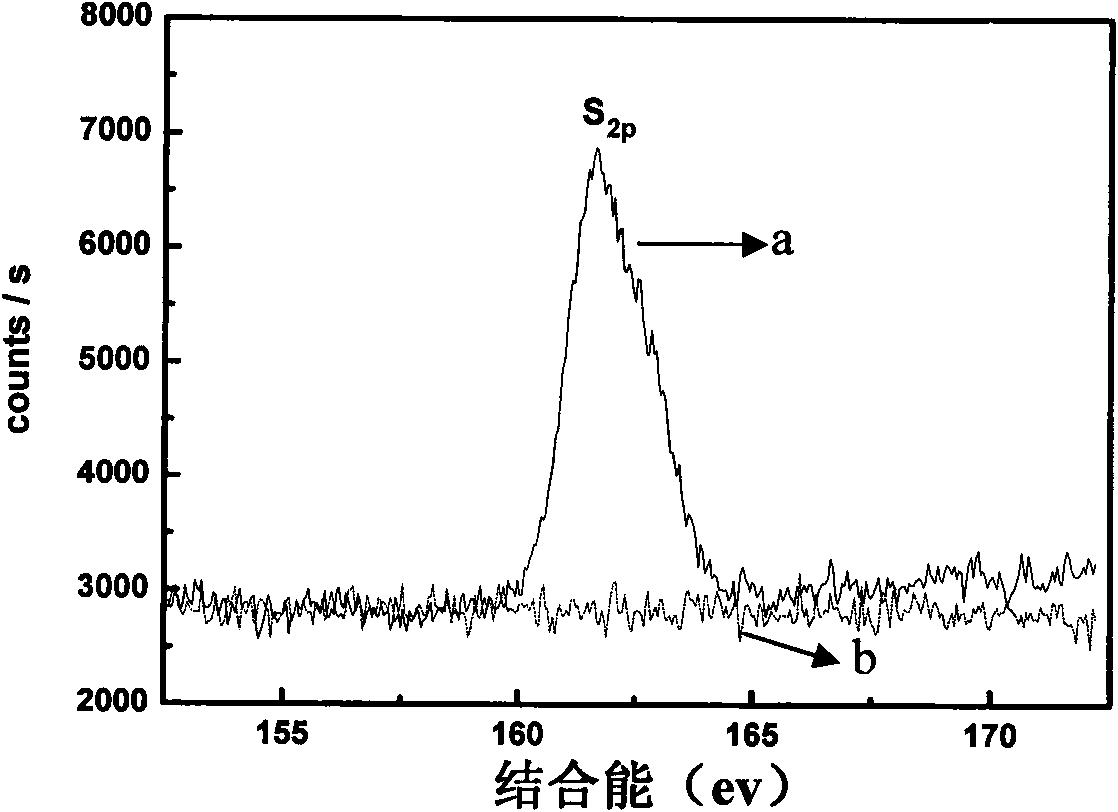

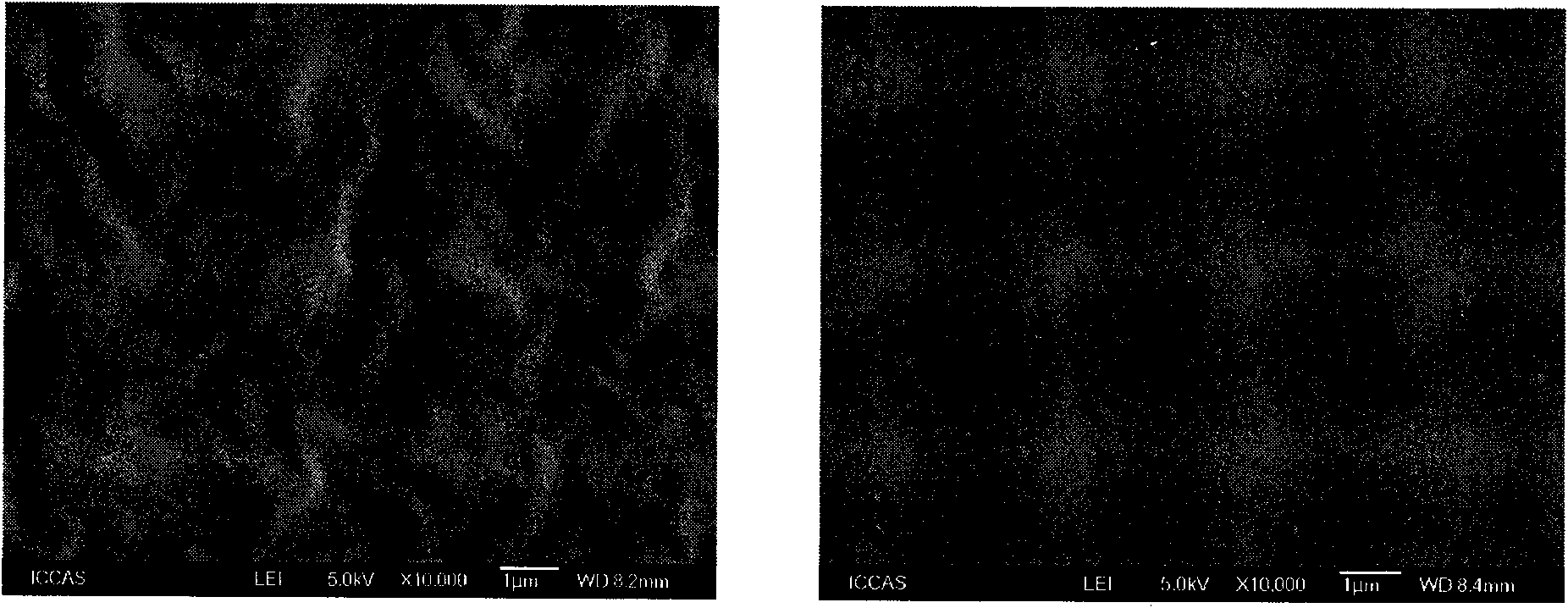

Surface modification method for anode of polymer solar cell

InactiveCN101901874AImprove work functionIncrease the open circuit voltageSolid-state devicesSemiconductor/solid-state device manufacturingIndiumMixed gas

Owner:INST OF CHEM CHINESE ACAD OF SCI

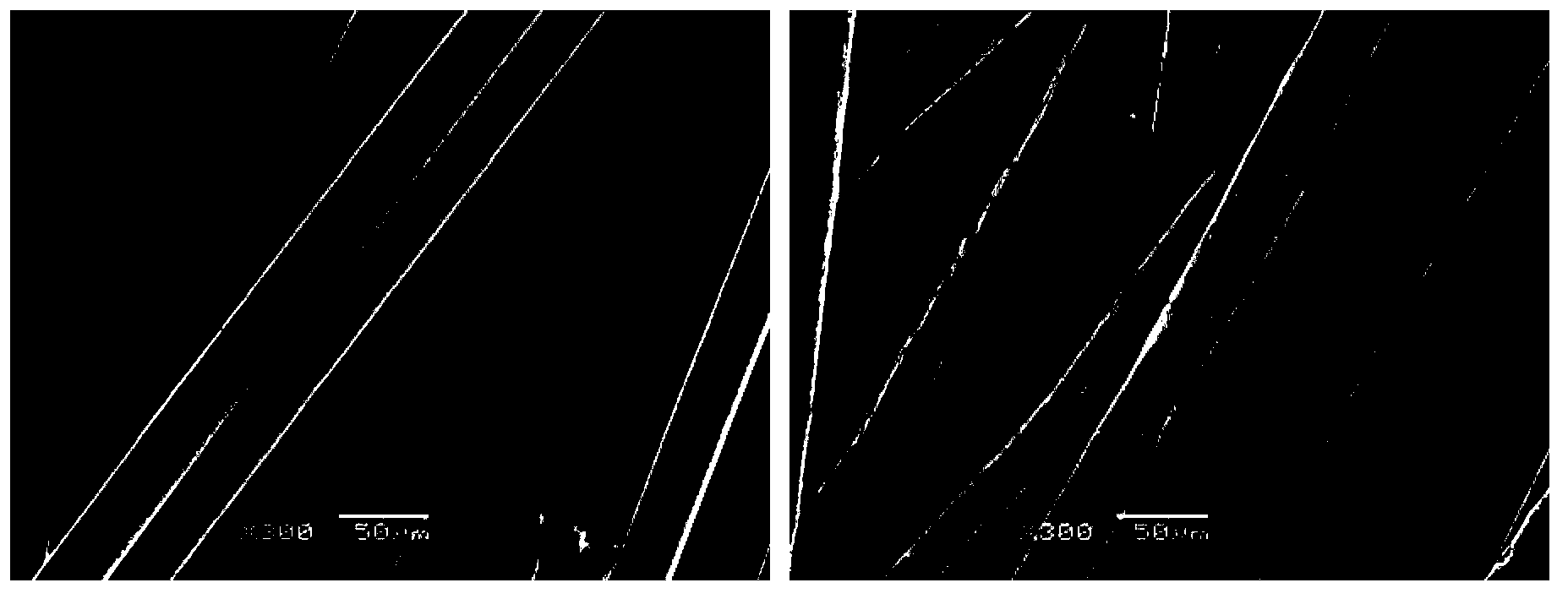

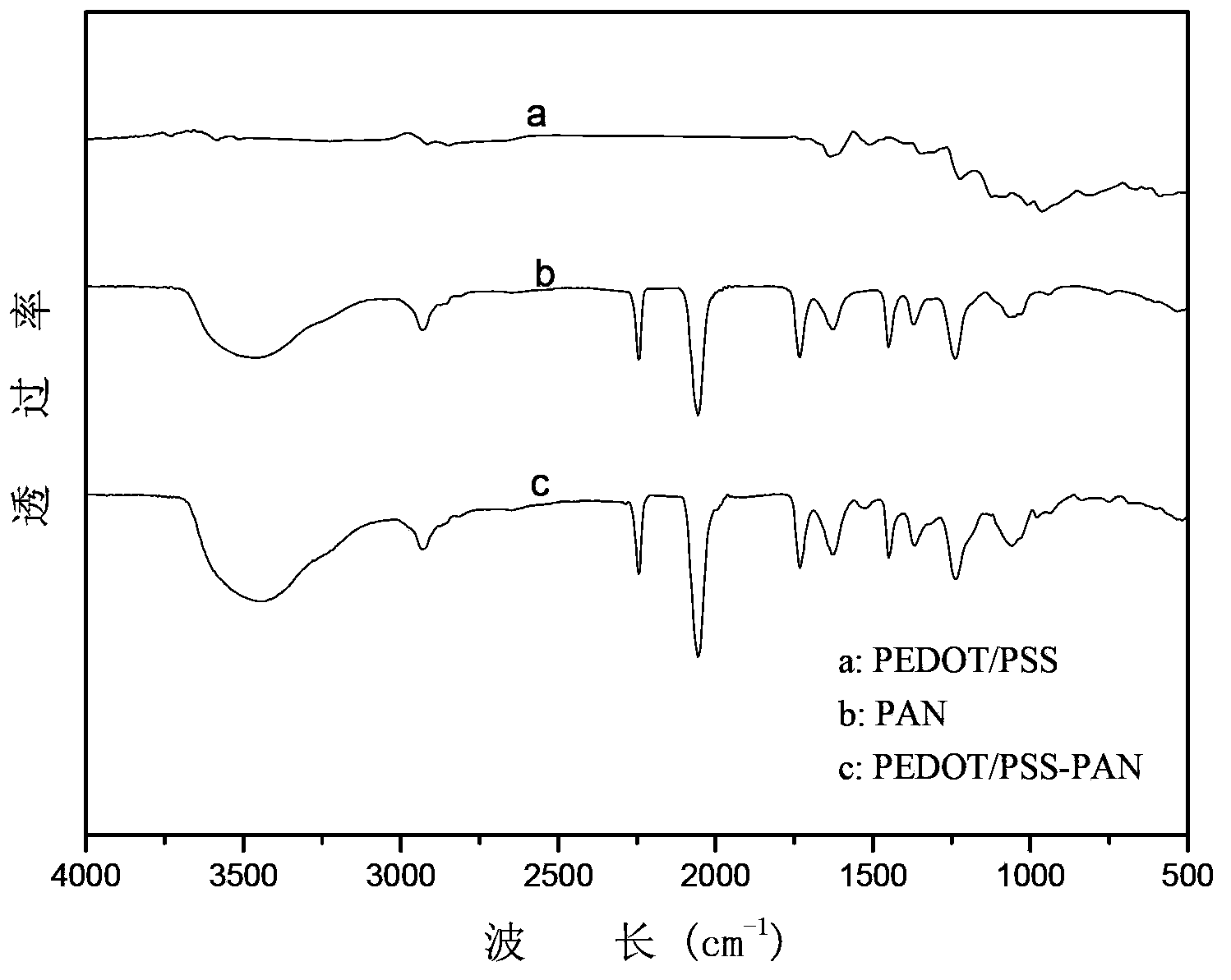

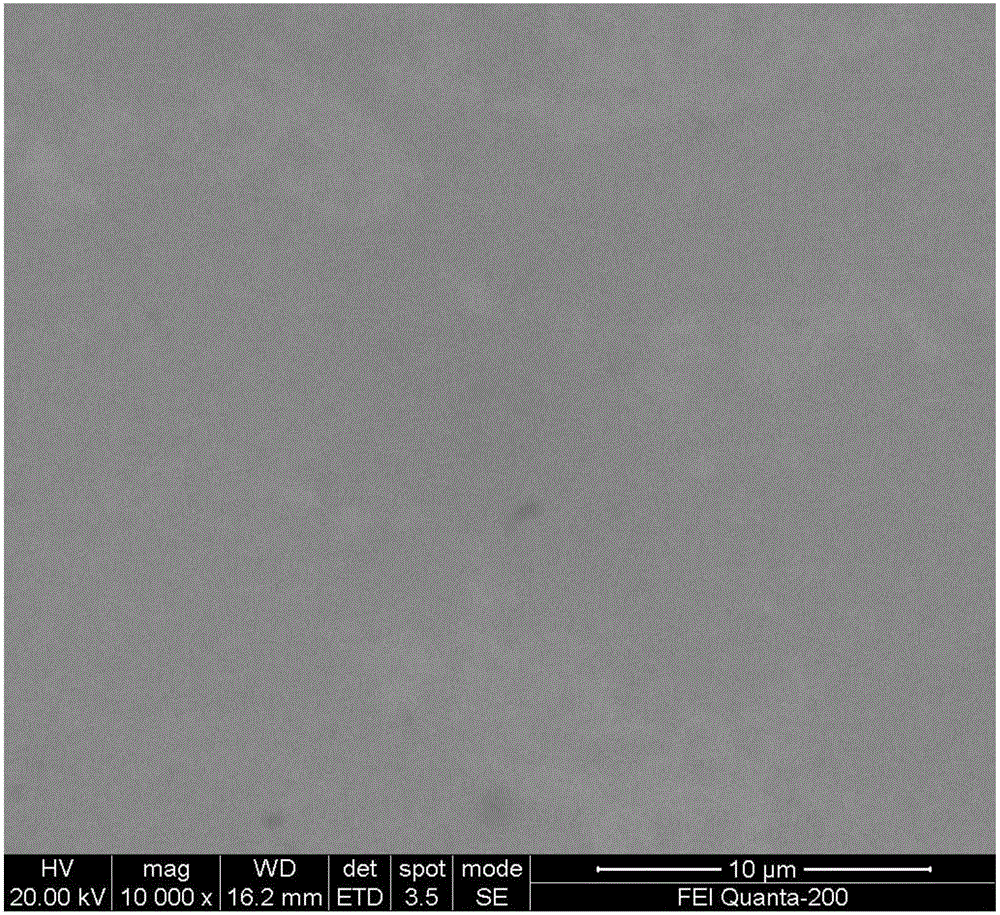

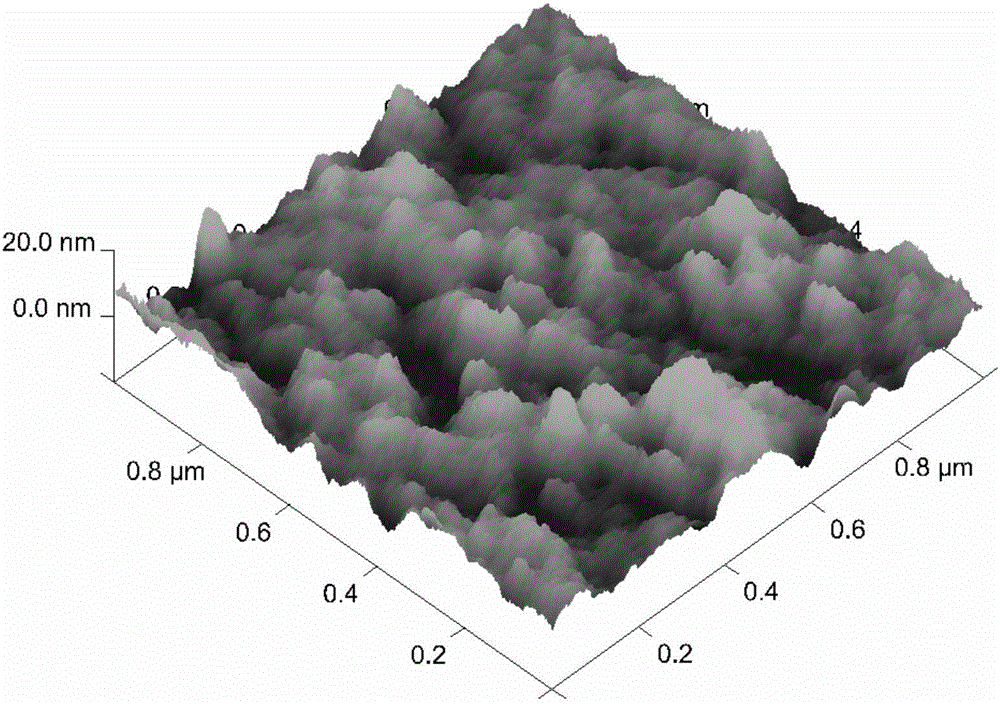

Method of preparing compound conductive fibers, compound conductive fibers obtained by method and application of compound conductive fibers

InactiveCN103668529AImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceConductive polymer

The invention relates to a method of preparing polyacrylonitrile-based compound conductive fibers. The method comprises the following steps: a) carrying out chemical oxidative polymerization on liquor containing a conductive polymer monomer, an oxidant and a dopant at 0-50 DEG C to obtain a doped aqueous dispersion of the conductive polymer, wherein the conductive monomer is 3, 4-ethylene dioxothiophene, aniline, pyrrole or derivatives thereof, the oxidant is selected from sodium persulfate, ammonium persulfate, ferric sulfate, ferric trichloride and p-toluenesulfonic acid, and the dopant is selected from poly-p-styrenesulfonic acid, sodium poly-p-styrenesulfonate, polyethylene sulfonate and sodium polystyrene sulfonate; and b) mixing the aqueous dispersion of the conductive polymer obtained in the step a) with polyacrylonitrile in form of the aqueous dispersion and then spinning to obtain the polyacrylonitrile-based compound conductive fibers. The invention further relates to the compound conductive fibers obtained by the method, a conductive fabric prepared from the fibers and use of the conductive fibers and the conductive fabric. The conductive fibers obtained by the method provided by the invention have improved conductivity, and the method is simple in process and easy for industrialized production.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Preparation method and application of supercapacitor material

InactiveCN106935417AIncrease energy densityIncreased maximum power densityHybrid capacitor electrodesHybrid/EDL manufacturePhosphateCharge discharge

The invention discloses a preparation method and application of a supercapacitor material. The process comprises the steps of mixing and heating acetylene black, sulfuric acid and sodium p-styrenesulfonate, and performing a series of operation such as heat preservation, cooling, dilution, centrifugal separation and washing to obtain a modified carbon black compound; adding lithium dihydrogen phosphate and nickel chloride in a reaction kettle for reaction, and performing acid processing after drying; mixing the product and a reactant obtained through high-temperature reaction of acrylonitrile power, dimethyl sulfoxide and tetraethyl orthosilicate, and adding distilled water for ultrasonic dispersion, adding waterborne polyurethane emulsion, cobaltosic sulfide, stannous chloride, a triethanolamine salt and a silane coupling agent for high-temperature reaction; and finally, performing washing and vacuum drying to obtain a finished product. The supercapacitor material obtained by preparation is high in energy density, maximum power density and charge-discharge efficiency, and has relatively good application prospect. Meanwhile, the invention also discloses application of the supercapacitor material prepared by the process in preparation of a supercapacitor.

Owner:SUZHOU HAILINGDA EIECTRONIC TECH CO LTD

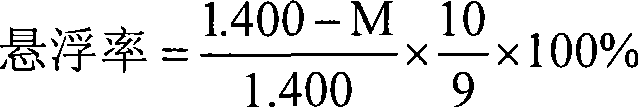

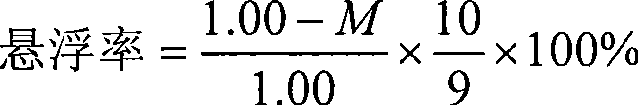

Composite brightener, nanocrystalline nickel electroplate liquid and method for nickel plating on surface of workpiece based on nanocrystalline electroplate liquid

The invention discloses a composite brightener, nanocrystalline nickel electroplate liquid and a method for nickel plating on the surface of a workpiece based on the nanocrystalline electroplate liquid. The composite brightener comprises saccharin sodium salt, diethyl propiolic amine, pyridinium propyl sulfobetaine, and an aqueous solution of ethylenesulfonic acid and S-carboxyethylisothiuronium betaine. The composite brightener is good in dispersing power and covering power in the electroplate liquid, the number of decomposition products in the nickel plating process is small, the brightening speed is high, stability of the electroplate liquid is good and the service life is long. The electroplate liquid added with the composite brightener has the advantages of being high in brightening speed, compact in clad layer structure, bright and uniform in appearance in the nickel plating process of the electroplate liquid. The average dimension of obtained nickel layer crystal grains reaches 8 nm, the appearance of the clad layer is bright and uniform, and the quality is stable.

Owner:CENT SOUTH UNIV

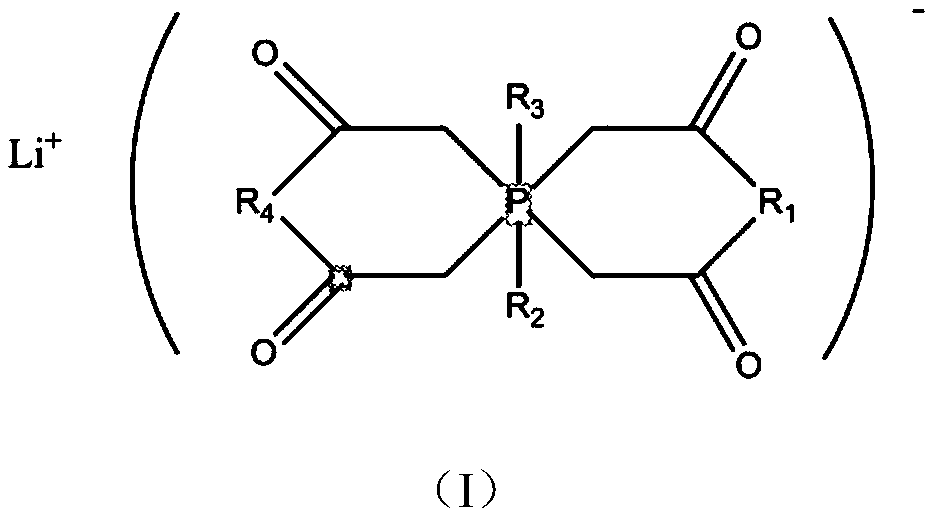

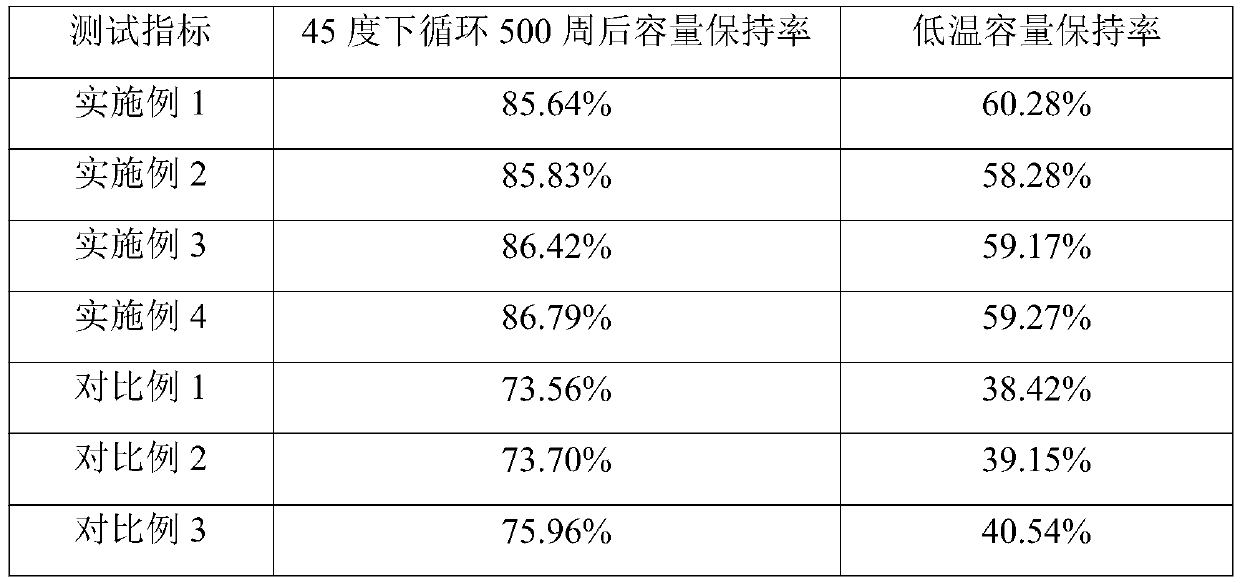

Non-aqueous electrolyte and lithium ion battery containing same

InactiveCN109818060AImprove cycle lifeHigh conductivity lithium ionSecondary cells servicing/maintenancePhosphatePhosphoric acid

The invention discloses a non-aqueous electrolyte and a lithium ion battery containing the non-aqueous electrolyte, and belongs to the technical field of lithium ion batteries. The non-aqueous electrolyte comprises a non-aqueous organic solvent, a conductive lithium salt and an additive. The additive includes at least one phosphate type lithium salt compound and at least one S=O-containing compound, wherein the phosphate type lithium salt compound is divinyl bis(malonic acid) lithium phosphate, diphenyl bis(malonic acid) lithium phosphate and difluoro bis(malonic acid) lithium phosphate. The S=O-containing compound is methylene methanedisulfonate, ethylene sulfate, propylene sulfate, 1,3-propane sultone, 1,4-butyl sultone, ethylene sultone and 1,3-propylene sultone or 1,4-butylene sultone.The preparation method has the advantages that through the synergistic effect of the phosphate lithium salt compound and the S=O-containing compound, a stable interface film with low impedance is formed, and the interface film has relatively good high-temperature cycling stability and low-temperature characteristic.

Owner:ZHUHAI COSMX BATTERY CO LTD

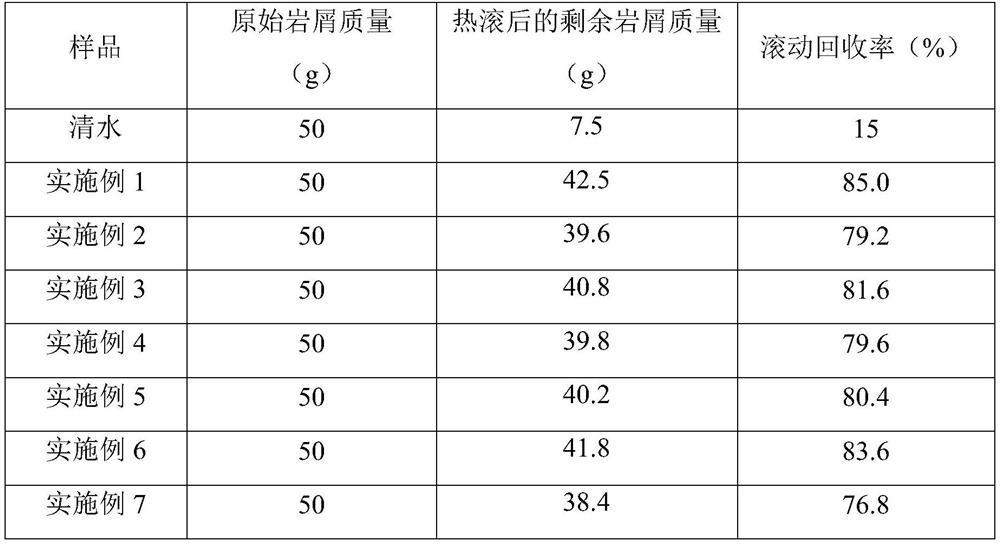

Hydrophobic membrane structure wall fixing agent as well as preparation method and application thereof

The invention discloses a hydrophobic membrane structure wall fixing agent as well as a preparation method and application thereof. The wall fixing agent with the hydrophobic membrane structure is prepared by carrying out free radical polymerization on hydrophobic modified acrylamide, a high-temperature-resistant monomer and a cationic monomer under the action of a first initiator, the hydrophobic modified acrylamide is prepared by reacting acrylic acid long-chain alkyl ester with acrylamide; the high-temperature-resistant monomer is selected from one or a combination of more than two of sodium vinyl sulfonate, 2-acrylamido-2-methylpropanesulfonic acid, sodium p-styrenesulfonate, sodium allysulfonate and N-vinyl caprolactam; the cationic monomer is selected from one or a combination of more than two of 3-chloro-2-hydroxypropyl trimethyl ammonium chloride, dimethyl diallyl ammonium chloride and acryloyloxyethyl trimethyl ammonium chloride. The wall fixing agent disclosed by the invention has excellent temperature resistance and salt tolerance, and can form a hydrophobic membrane on the surface of rock, prevent water molecules from immersing, weaken the hydration effect and increase the strength of the rock.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

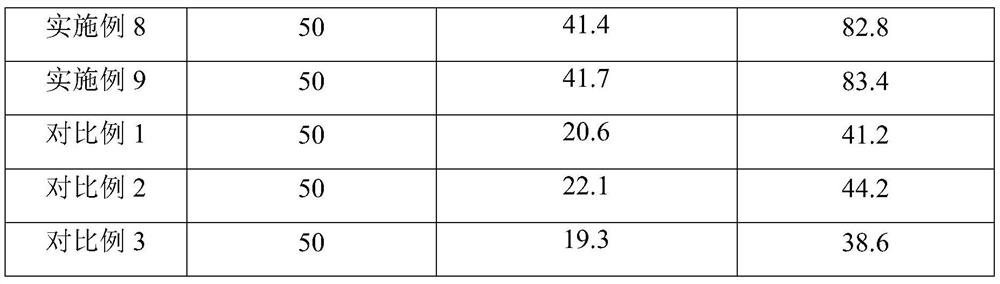

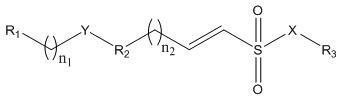

2-substituted vinylsulfonate compound and preparation method and use thereof

InactiveCN102408417APrevent diabetesPrevent obesityOrganic chemistryMetabolism disorderChemical industryDiabetes mellitus

The invention relates to a 2-substituted vinylsulfonate compound, and preparation method and use thereof in the field of chemical industry of drugs. The 2-substituted vinylsulfonate compound has the following structure formula: FORMULA, wherein R1 and R2 are substituted aromatic groups, R3 is alkyl substituted aromatic group, n1 is any one of integers of 1 to 4, n2 is 0, 1 or 2, X is O, substituted alkyl or aromatic group, and Y is any one of O, S, C and NH. The invention also relates to a preparation method of the compound and the use of the compound in preparing drug for inhibiting activity of PTPlB protein. The compound can be used for preparing drug for treating or preventing diabetes or obesity taking PTPlB as target point.

Owner:SHANGHAI JIAO TONG UNIV

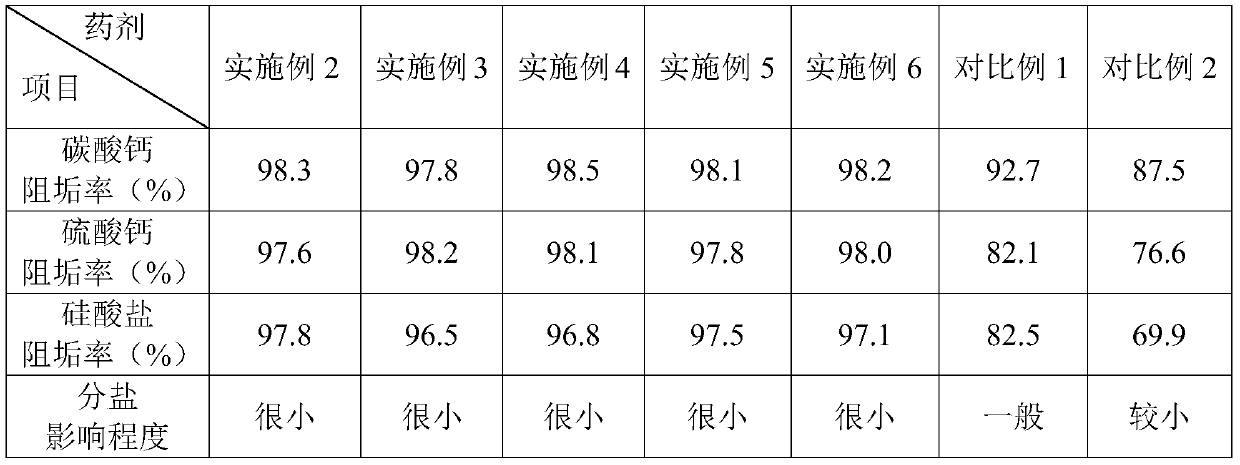

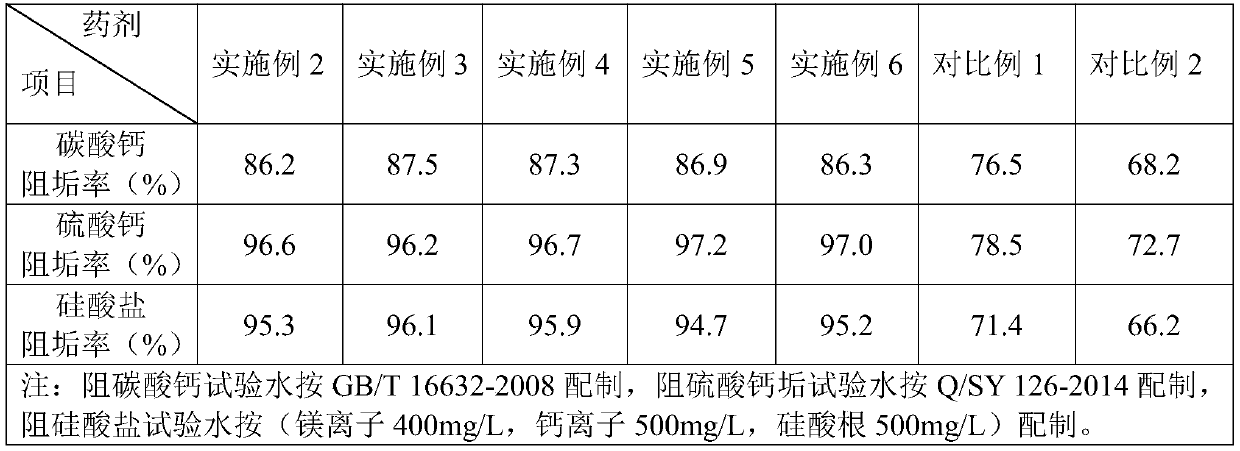

Special scale inhibitor for MVR system and preparation method thereof

InactiveCN110921857AGood scale inhibition and dispersibilityDoes not affect crystallizationScale removal and water softeningWater/sewage treatment by heatingPhosphoric Acid EstersMeth-

The invention discloses a special scale inhibitor for an MVR system. The special scale inhibitor for the MVR system is composed of the following raw materials: an acrylic acid-styrene sulfonate copolymer, organic phosphonic acid, an allyl polyoxyethylene polycarboxylic acid scale inhibitor, an acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-N-tert-butyl acrylamide terpolymer, an adipic acid-amine-terminated polyether-diethylenetriamine copolymer, an epoxysuccinic acid derivative, a phosphorus-containing polymer, phosphate starch and pure water. Aiming at researching the high-temperature, high-silicon and high-sulfate-radical water quality of the MVR system, the special scale inhibitor for the MVR system is prepared; the scale inhibitor has excellent scale inhibition dispersibility on sulfate, silicate and carbonate, does not influence later crystallization and salt separation, has excellent application effect and production value, and is beneficial to promoting energy conservation and emission reduction, waste salt utilization and zero emission development of enterprises.

Owner:SHANDONG TIANQING TECH DEV

Styrene-acrylic emulsion

InactiveCN111574657AGood weather resistanceImprove adhesion strengthCoatingsSodium bicarbonatePolymer science

The invention relates to the technical field of emulsion coatings, specifically to a styrene-acrylic emulsion. The styrene-acrylic emulsion comprises the following components in parts by weight: 85 to105 parts of acrylate monomer, 55 to 75 parts of styrene monomer, 1 to 5 parts of butyl acrylate, 4 to 10 parts of a weather-proof material, 1 to 8 parts of sodium bicarbonate, 1 to 4 parts of a silane coupling agent, 2 to 3 parts of an emulsifier, 1 to 3 parts of an initiator and 150 to 300 parts of deionized water. A water-resistant material is prepared from the following components in parts byweight: 15 to 30 parts of sodium fatty alcohol polyethylene sulfonate, 10 to 20 parts of silicon dioxide powder, 5 to 15 parts of silicone amide, 2 to 10 parts of hexamethylenediamine and 2 to 5 parts of triethylene tetramine. The styrene-acrylic emulsion prepared according to a formula disclosed by the invention has good weather resistance, and is applied to the coating industry so as to allow acoating to also have good weather resistance.

Owner:东联北方科技(北京)有限公司

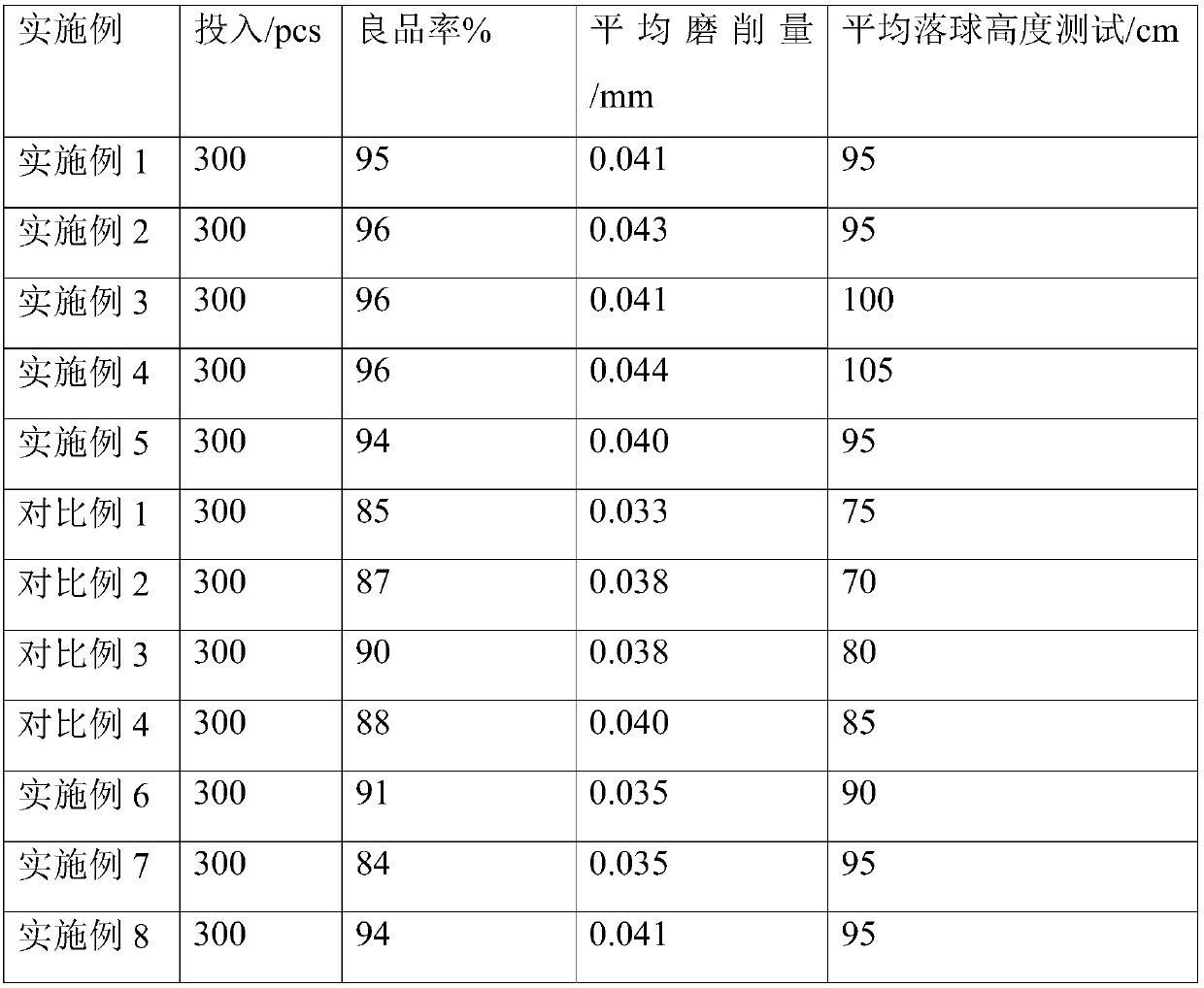

Cerium oxide polishing solution, preparation method and applications thereof

ActiveCN110872471AIncrease profitImprove dispersion stabilityPolishing compositions with abrasivesO-Phosphoric AcidLanthanum fluoride

The invention relates to the technical field of polishing solutions, and discloses a cerium oxide polishing solution, a preparation method and applications thereof, wherein the polishing solution contains a grinding agent, a dispersing agent, a defoaming agent and water, the grinding agent is a mixture of cerium oxide, lanthanum oxide, lanthanum fluoride, lanthanum oxyfluoride and titanium oxide,the dispersing agent is a mixture of allyl polyoxyethylene ether and / or polyoxyethylene octyl phenol ether, triethylhexyl phosphoric acid, vinyl bis stearamide and sodium p-styrenesulfonate, and the defoaming agent is a copolymer of polyoxyethylene polyoxypropylene alcohol amine ether and polyether dimethyl siloxane. With the application of the polishing solution to polish glass surface, the polishing efficiency is high, the dispersing capacity is strong, the lasting defoaming effect is good, and defoaming can be performed for a long time.

Owner:HUIZHOU BYD IND

Method for producing high-purity electronic titanium dioxide

ActiveCN111439781APlay a role in removing impuritiesMeet the requirements of high-end electronic grade titanium dioxideTitanium dioxideAluminium chlorideHydrolysate

The invention discloses a method for producing high-purity electronic titanium dioxide. Panzhihua titanium concentrate with the concentration larger than or equal to 80% is selected as a raw material,sulfuric acid is used for acidolysis of the titanium concentrate, a flocculating agent composed of a maleic anhydride-styrene sulfonic acid copolymer, sodium lignin sulfonate and polyaluminum chloride is added for impurity removal treatment, standing and filter pressing are conducted for solid-liquid separation, filter-pressed liquid enters a vacuum crystallization system, secondary filter pressing is conducted, and refined titaniferous solution is obtained; water is added into the refined titaniferous solution to adjust the concentration to 95-200g / L, heating and stirring are performed, anda crystal form control agent is added to react to obtain a hydrolysate; the hydrolysate is washed until the iron ion content is below 150ppm, then sulfuric acid is added for bleaching and washed for the second time until the iron ion content is below 50ppm to obtain slurry; squeezing is performed by a filter press, a filter cake is calcined in a rotary kiln and crushed to obtain the electronic titanium dioxide. The purity of the titanium dioxide product prepared by the method reaches 99.5% or above, the particle size distribution is 200-400 nm, the particle size distribution is narrow, the particle size distribution is uniform, the powder whiteness reaches 90% or above, and the requirements of middle-high-end electronic-grade titanium dioxide can be met.

Owner:GUANGXI JINMAO TITANIUM

Graphene clothing material and production method thereof

InactiveCN108179627AEnhanced functions such as far infraredImprove breathabilityVegetal fibresUndergarmentsSulfonateTO-18

The invention discloses a graphene clothing material and a production method thereof. The production method comprises the following steps: preparing raw materials including 25 to 45 percent of a graphene nano raw material, 35 to 55 percent of a cotton fabric carrier, 6 to 10 percent of sodium p-styrene sulfonate powder, 10 to 18 percent of deacetylation degree, 8 to 13 percent of chitosan, 15 to 30 percent of negative ions, wherein the sum of the content of all components is 100 percent by weight; pre-treating the raw materials: mixing the raw materials in step (1) according to the ratio and stirring for 1 to 3h; after mixing the materials, putting a mixture into a pulping machine; absorbing slurry through a slurry groove and drying through a drying oven for 40 to 80min; collecting graphene clothing material raw powder with the size of 600 to 800 meshes; dissolving the graphene clothing material raw powder into de-ionized water until the concentration is 0.3mg / mL, so as to obtain electrolyte dissolved slurry. The graphene clothing material has the advantages of good clothing air permeability, strong antibacterial performance, good warm-keeping performance and static electricity prevention; meanwhile, the graphene clothing material can have the functions of releasing far infrared rays, absorbing moisture, eliminating the moisture and the like.

Owner:DET IND DESIGN

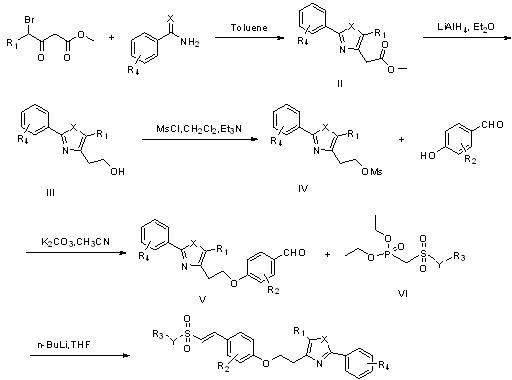

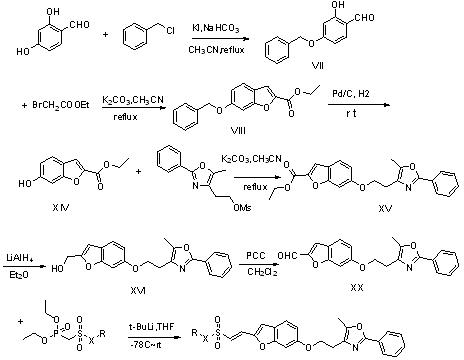

Oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof

ActiveCN113582949AStrong inhibitory activityOrganic chemistryAntineoplastic agentsFuranEstrogen receptor

The invention discloses oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof, and belongs to the technical field of targeted drugs. The structure of the compounds disclosed by the invention is shown as a general formula (I) or a general formula (II), and a furan derivative and a vinyl sulfonamide derivative or a vinyl sulfonate derivative containing different covalent warheads are subjected to Diels-Alder reaction to prepare the compounds disclosed by the invention. The compounds provided by the invention can be used for preparing anti-breast cancer medicines, medicines for degrading estrogen receptors and medicines for mutant estrogen receptors. Compared with the existing anti-breast cancer drug tamoxifen, the compounds provided by the invention have stronger inhibitory activity on MCF-7 cells and have the ability to down-regulate the level of an estrogen receptor, and the activity of the compounds on a mutant estrogen receptor is 5-10 times that of 4-hydroxytamoxifen.

Owner:WUHAN UNIV

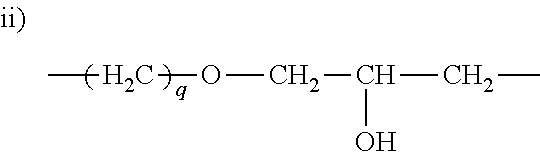

A kind of preparation method of micro-crosslinked water-based drilling fluid fluid loss reducer

ActiveCN108264890BImprove solubilityReduce fluid lossDrilling compositionPolymer scienceHalohydrocarbon

The invention relates to a preparation method of a fluid loss control agent for branched water-based drilling fluid, and belongs to the technical field of oil field chemistry. Polyethylene polyamine compounds containing multiple double bonds are prepared by reacting polyethylene polyamines with halogenated hydrocarbons containing double bonds, which are used as crosslinking agents, and non-ionic water-soluble monomers such as acrylamide and vinylpyrrolidone, And anionic water-soluble monomers such as 2-acrylamide-2-methylpropanesulfonic acid and sodium styrenesulfonate are used as polymerization raw materials to synthesize polymers with micro-crosslinked structures. This kind of polymer has excellent heat resistance and salt resistance, and its molecular structure has a variety of functional groups, which can significantly improve the dispersion stability of clay particles, and is suitable as a fluid loss control agent for water-based drilling fluids under harsh conditions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

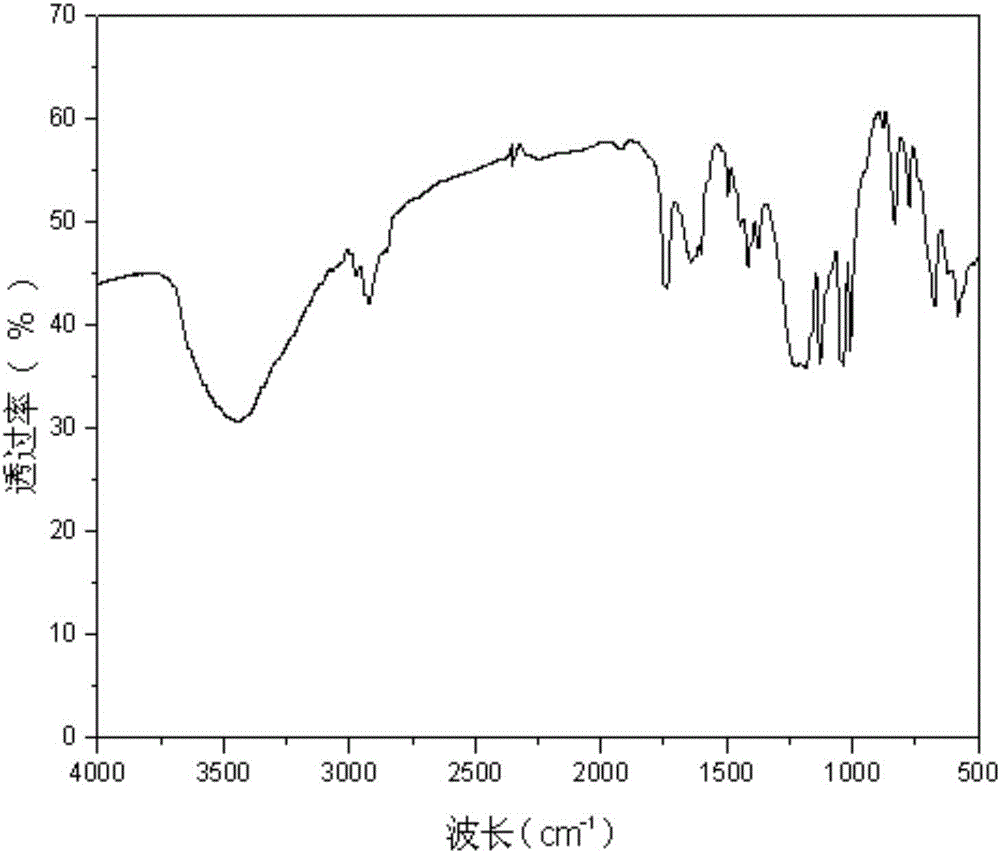

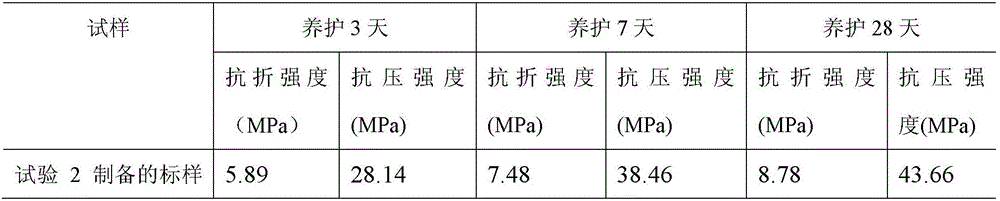

Additive used for increasing flexural and compressive strength of cement mortar, and preparation and application method thereof

The invention discloses an additive used for increasing flexural and compressive strength of cement mortar, and a preparation and application method thereof, and belongs to the field of cement additive. The additive is used for solving a technical problem of conventional polymer cement additives that strengthening effect is poor. The additive is a CMC-XYX type polymer emulsion, wherein CMC is used for representing carboxymethyl cellulose, X is used for representing styrene sulfonic acid group, and Y is used for representing acetic acid vinyl ester group. The preparation method comprises following steps: potassium persulphate and sodium p-styrene sulfonate are added into a carboxymethyl cellulose solution successively for graft copolymerization; potassium persulphate, and acetic acid vinyl ester are added successively for graft copolymerization; and potassium persulphate and sodium p-styrenesulfonate are added successively for graft copolymerization so as to obtain the additive. In applications, the additive is uniformly mixed with sodium lignosulfonate, water, sand, and cement, and then is uniformly mixed with tributyl phosphate. The preparation and application method is simple; and the additive can be used in building field.

Owner:NORTHEAST FORESTRY UNIVERSITY

Thickening and tackifying agent for fracturing fluid

ActiveCN110964496AImprove suspension stabilitySmall preparation spaceDrilling compositionPolymer science(Hydroxyethyl)methacrylate

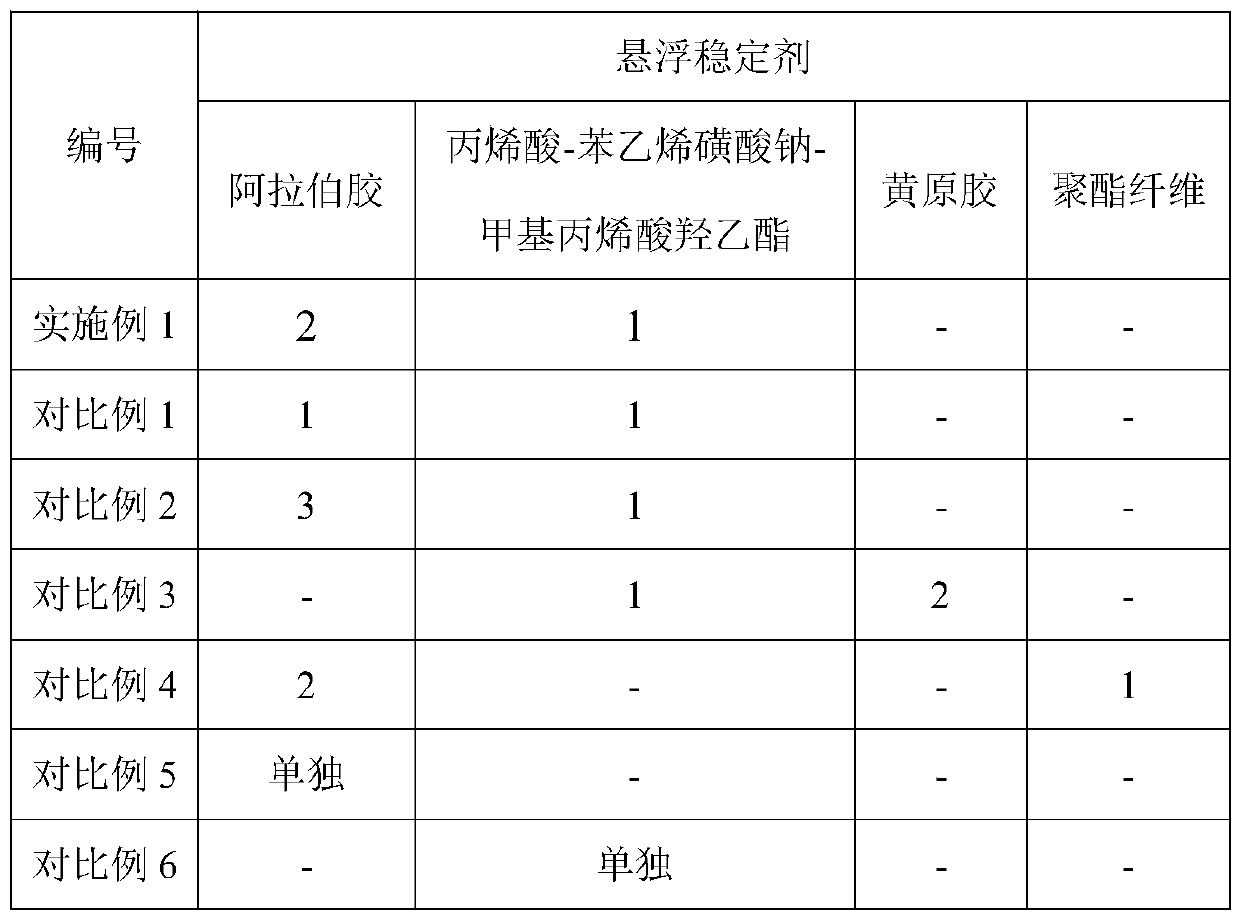

The invention relates to a thickening and tackifying agent for a fracturing fluid. The thickening and tackifying agent comprises 30 wt% of white oil, 50 wt% of an acrylamide monomer, 3 wt% of ethanol,1.5 wt% of sorbitan fatty acid ester, 0.5 wt% of hexadecyl trimethyl ammonium bromide, 0.5 wt% of a suspension stabilizer and 14.5 wt% of water, wherein the suspension stabilizer is prepared from Arabic gum and acrylic acid-sodium p-styrenesulfonate-hydroxyethyl methacrylate. The thickening and tackifying agent disclosed by the invention has the advantages of excellent suspension stability, smallrequired preparation space, low requirement on water quality, good tackifying effect, good sand suspending effect, long retention time, good shearing resistance, good high-temperature resistance, good salt resistance, wide application range, good compatibility, low construction cost, small influence on environment and wide application prospect.

Owner:东营江源化工有限公司

Synthetic method of potentiometric pesticide sensor

ActiveCN104677965ASpecific recognition selectivityExcellent binding affinityMaterial analysis by electric/magnetic meansPolysulfone membraneToxicology

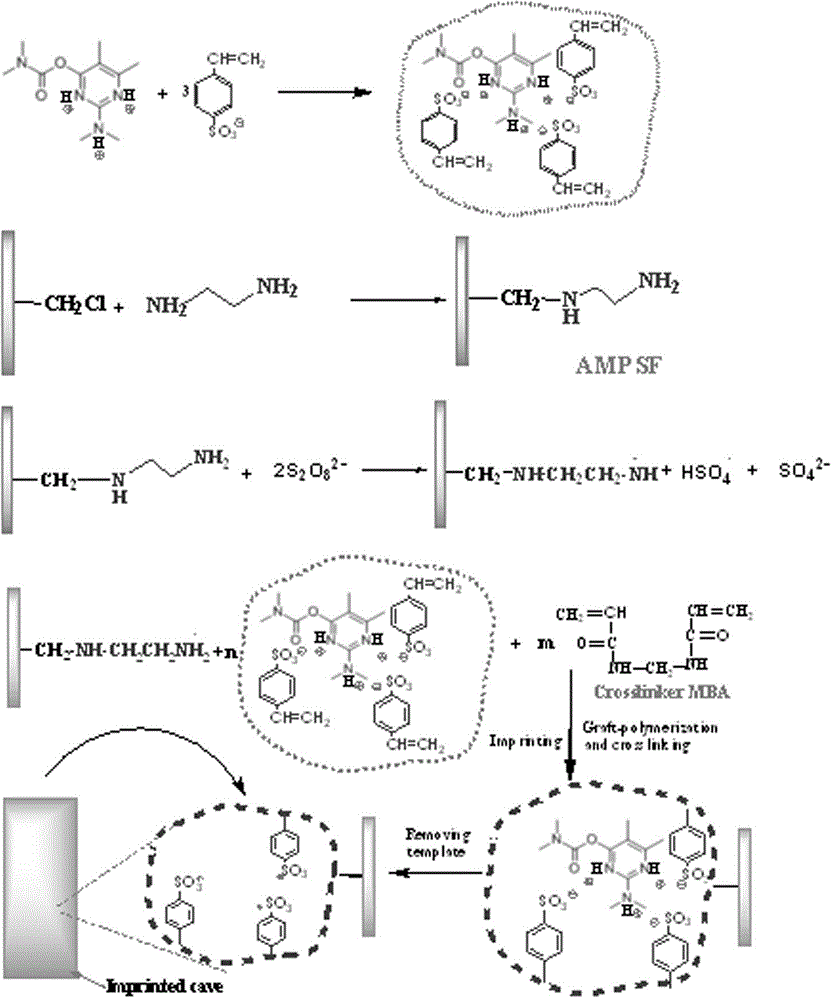

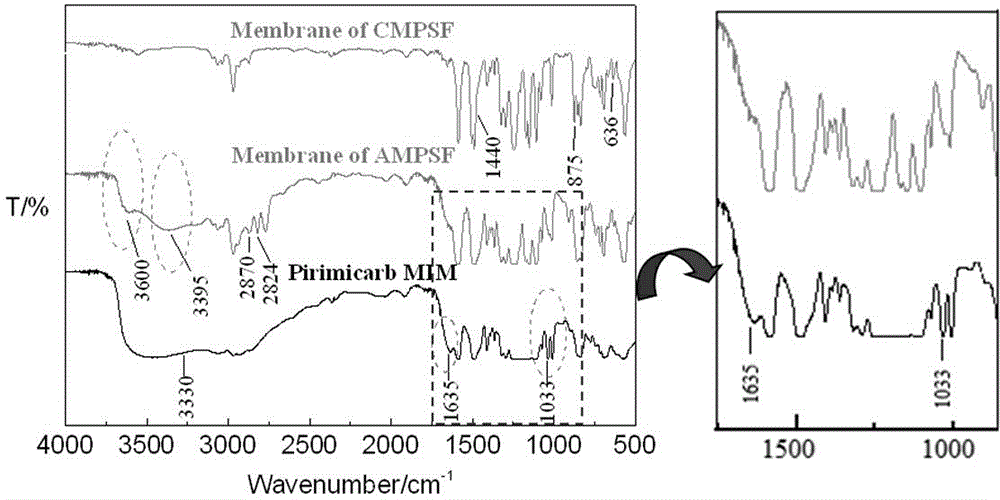

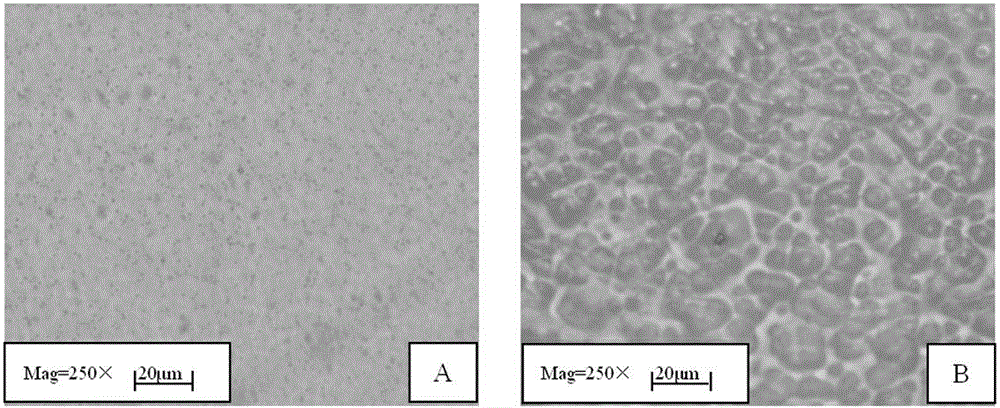

The invention discloses a synthetic method of a potentiometric pesticide sensor, and belongs to a molecular imprinting technology. The synthetic method comprises the following steps: (1) dissolving chloromethylated polysulfone (CMPSF) into dichloromethane, adding dimethylacetamide TDMAC, pouring into a glass culture dish, performing film casting, and immersing into ethidene diamine for amination to prepare an ammoniated polysulfone (AMPSF) membrane with amino on the surface; (2) dissolving absolute ethyl alcohol, sodium styrenesulfonate (SSS) and pirimicarb into water, and adding the AMPSF membrane, an initiator, namely ammonium persulfate and a crosslinking agent, namely bisacrylamide MBA to obtain a pirimicarb molecule-imprinted membrane MIM; (3) establishing the sensor. The grafting-type imprinted membrane has specific recognition selectivity and excellent binding affinity for pirimicarb template molecules, and has the binding capacity as high as 92 microgram / cm<2>; the potentiometric sensor established by using the pirimicarb molecule-imprinted membrane as a sensitive membrane is simple and quick in establishment process and sensitive and accurate in detection.

Owner:ZHONGBEI UNIV

Method for preparing rutile titanium dioxide with high tinctorial strength

InactiveCN111422902AUniform particle size distributionGood dispersionTitanium dioxideAluminium chlorideHydrolysate

The invention discloses a method for preparing rutile titanium dioxide with high tinctorial strength, which comprises the following steps: adding sulfuric acid into titanium concentrate for acidolysisto obtain a titanium suspension, and adding a flocculant composed of maleic anhydride-styrene sulfonic acid copolymer, sodium lignin sulfonate and polyaluminum chloride into the titanium suspension for impurity removal treatment to obtain a refined titanium solution; adding rutile seed crystals and a dispersing agent into the refined titanium solution for hydrolysis to obtain a hydrolysate; washing the hydrolysate with water, adding sulfuric acid for bleaching, and washing for a second time to obtain a slurry; adding a salt solution treating agent consisting of a phosphate solution, a zinc acetate solution and a yttrium nitrate solution into the slurry; and carrying out filter pressing on the slurry by using a filter press, calcining a filter cake in a rotary kiln, cooling, and crushing to obtain rutile titanium dioxide. The rutile content of the rutile titanium dioxide prepared through the method reaches 98.5% or above, the whiteness reaches 98% or above, the Tcs value reaches 2034 or above, the Scx value reaches 4.21 or above, and the product is uniform in particle size distribution and good in dispersity and is an excellent white pigment.

Owner:GUANGXI JINMAO TITANIUM

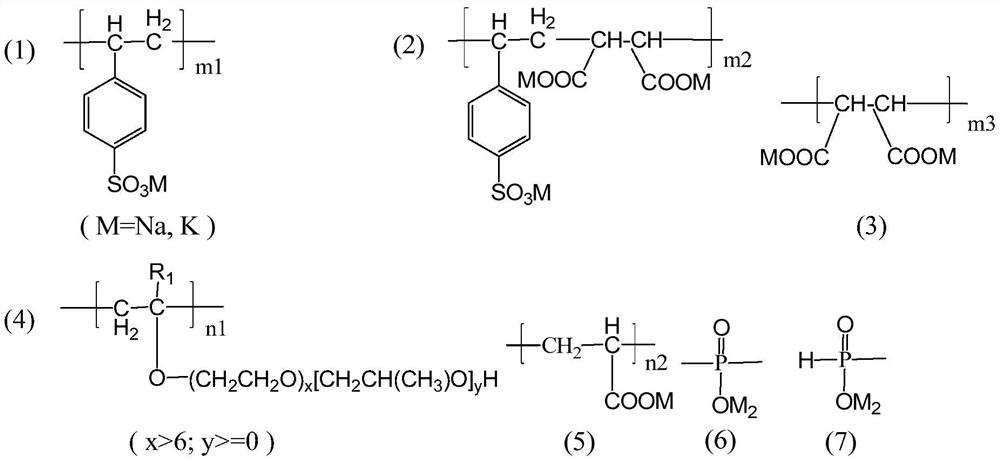

Multi-copolymer composite dispersant for ceramic phenol water coal water slurry and preparation method of multi-copolymer composite dispersant

ActiveCN113549478AGood pulpingHigh solid contentLiquid carbonaceous fuelsTotal solid contentPolymer solution

The invention discloses a multi-copolymer composite dispersant for ceramic phenolic water coal water slurry and a preparation method of the multi-copolymer composite dispersant, wherein the preparation method comprises the following steps: (1) mixing monomer styrene sulfonate, maleic anhydride, acrylic acid, vinyl polyether, water and a phosphorus-containing reducing agent, completely dissolving, dropwise adding a persulfate aqueous solution, and dropwise adding and reacting at the temperature of 70-90 DEG C; (2) then dropwise adding a mixed solution of acrylic acid, water and the persulfate aqueous solution, reacting at the temperature of 90-95 DEG C for 2-1 hour, adding a chain terminator solution, uniformly stirring, and cooling; (3) adjusting the pH value of the solution to 8-10 to obtain a polymer solution with the concentration of 30-45 wt%; and (4) finally adding an inorganic water glass water reducing agent, and enabling the content of the water reducing agent to be 10-40 wt% of the total solid content to obtain the composite dispersant. The composite dispersant significantly improves the dispersibility, fluidity and stability of the ceramic phenol water coal water slurry, and is beneficial to energy conservation and emission reduction in the ceramic industry.

Owner:肇庆市欧陶新型材料有限公司

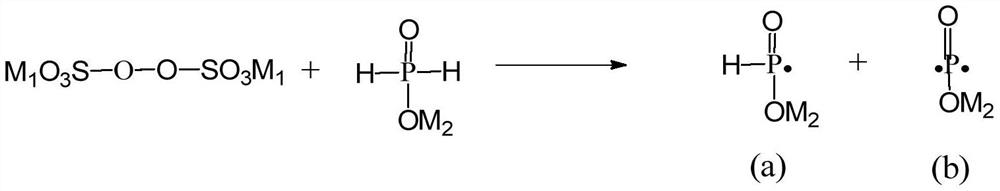

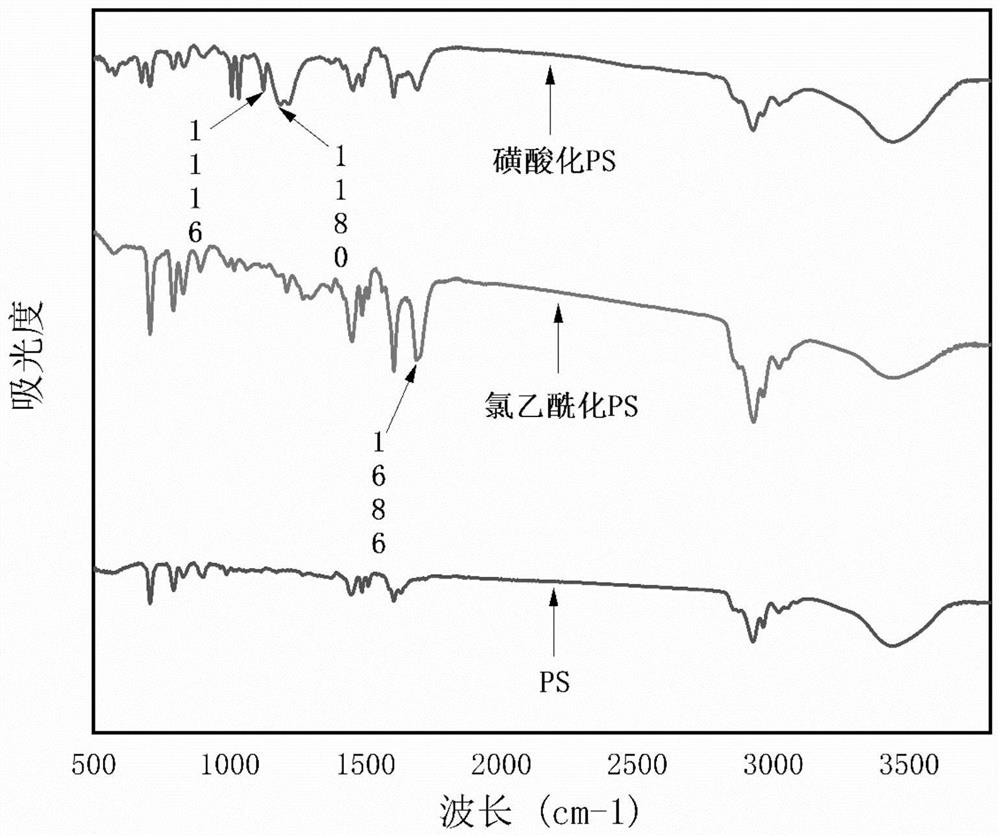

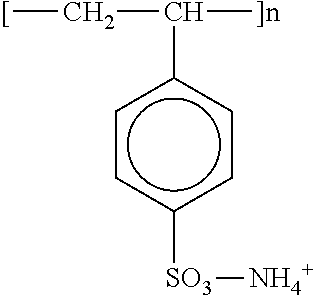

Preparation method of highly sulfonated polystyrene resin

ActiveCN112321756ALow number of solutionsSolve the difficulty of controlling the sulfonation processPolymer scienceResin microsphere

The invention provides a preparation method of highly sulfonated polystyrene resin. In the preparation method, adopted unmodified resin is large-particle polystyrene resin microspheres, and ananionicmonomer for modification adopts sodium p-styrenesulfonate. The preparation methodcomprises the following steps: swelling polystyrene resin microspheres by using dichloromethane, sequentially conducting washing and filtering by using tetrahydrofuran, ultrapure water, absolute ethyl alcohol and methanol for multiple times, and finally performing vacuum drying; then grafting an acylation reagent chloroacetyl chloride on the surfaces of the pretreated microspheres by utilizing a Friedel-Crafts acylation reaction to obtain an acylated polystyrene resin macromolecular initiator; and finally, initiating monomer sodium p-styrenesulfonate to polymerize on the surface of the polystyrene resin by utilizing an atom transfer radical polymerization method, taking cuprous bromide as a catalyst and takingpentamethyldiethylenetriamine as a ligand. The preparation method solves the problems that the amount of sulfonic acid groups is small, the reaction process is not easy to control, the strength of the resin microspheres is low and the cost is high due to the steric hindrance effect when the surfaces of the existing large-particle-size polystyrene resin microspheres are sulfonated.

Owner:FUJIAN AGRI & FORESTRY UNIV

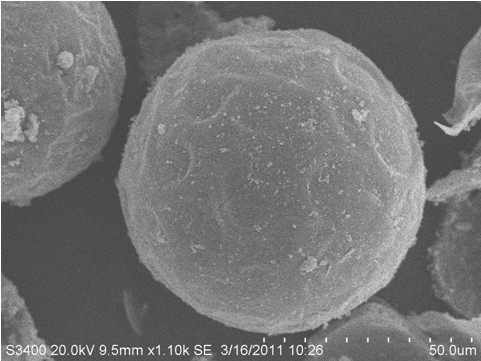

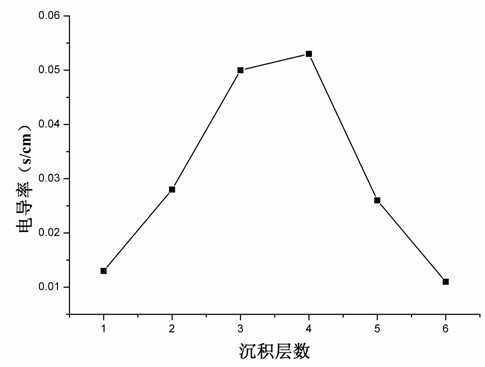

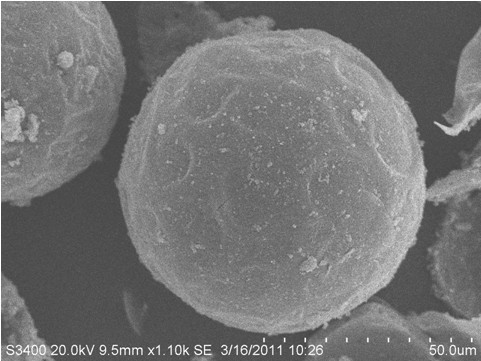

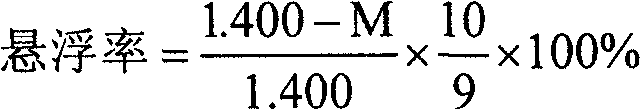

Floating bead based polypyrrole conductive composite with adjustable conductivity and preparation method thereof

The invention discloses a floating bead based polypyrrole conductive composite with adjustable conductivity and a preparation method thereof. In the composite, a floating bead is used as a carrier, and polypyrrole is loaded on the floating bead in a controllable film layer form. The preparation method comprises the following steps that: the pretreatment of the floating bead is achieved through repeated and multiple depositions of polycation diallyldimethyl ammonium chloride and polyanion sodium styrene sulfonate on the surface of the floating bead by using an electrostatic self-assembly method, i.e., homogenization of surface charge is achieved; and the controllable load of polypyrrole on the surface of the floating bead is achieved by using a chemical in suit polymerization method. The load amount of polypyrrole on the surface of the floating bead can be controlled through regulating the deposition layer number of a polyelectrolyte on the surface of the floating bead, thus changing the conductivity of the composite and being in favor of meeting the difference requirement of different fields on the conductivity of the material; and simultaneously, the defect that the topography of polypyrrole is not controlled in the preparation process is improved by introducing a floating bead template, thereby increasing the industrial application value of the composite.

Owner:NANJING UNIV

Terpolymer dispersants and preparation technique and use thereof

InactiveCN101391194BGood water solubilityGood electrostatic repulsion stabilizationTransportation and packagingMixingFipronilWater dispersible

The invention discloses a terpolymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The terpolymer dispersing agent is prepared through free radical copolymerization of acrylic acid, sodium styrene sulfonate, hydroxypropyl acrylate or 2-hydroxyethyl methacrylate, the number average relative molecular weight of the terpolymer is between 2000 and 40000, and the dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to acid and alkali and good dispersion stability, and also has good dispersion effects to calcium carbonate, zinc oxide, barium sulfate, titanium dioxide and pesticide Atrazine water dispersible granules and fipronil water dispersible granule, and can be widely used in the pesticide, pigment, dyestuff, coal water slurry and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

Filtrate reducer zwitterionic polymer for drilling fluid

The invention discloses a filtrate reducer zwitterionic polymer for a drilling fluid. The filtrate reducer zwitterionic polymer is prepared from the following raw materials: polyacrylamide, 2-acrylamide-2-methylpropanesulfonic acid, dimethyl propyl ammonium chloride, sodium p-styrenesulfonate, an initiator, deionized water, a sodium hydroxide solution with the mass fraction of 40%, modified cassava starch, modified shellfish shell powder and ethylene glycol. A hydration group and an adsorption group are arranged on a molecular chain of the acrylamide copolymer, so that the adsorption capacityis high; 2-acrylamide-2-methylpropanesulfonic acid contains sulfonate radicals of ionizable groups, the hydration effect with clay particles is improved, and the tolerance to salt and calcium can be improved, so that the drilling fluid is stabilized; a cationic group is introduced into a molecular chain of dimethyl propyl ammonium chloride, so that the improvement of the blocking inhibition effectwith clay particles is facilitated. The filtrate reducer provided by the invention has good temperature resistance and salt resistance, is suitable for fresh water and saline water drilling fluid systems with various concentrations, is biodegradable, and has no pollution to the environment.

Owner:ANHUI LUHAI PETROLEUM AUX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof Oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof](https://images-eureka.patsnap.com/patent_img/15856aa0-f473-4930-bcfd-d8325cc505f6/HDA0003219710980000011.png)

![Oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof Oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof](https://images-eureka.patsnap.com/patent_img/15856aa0-f473-4930-bcfd-d8325cc505f6/HDA0003219710980000012.png)

![Oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof Oxygen-bridged bicyclo-[2.2. 1]-heptene compounds containing different covalent warhead structures and preparation and application thereof](https://images-eureka.patsnap.com/patent_img/15856aa0-f473-4930-bcfd-d8325cc505f6/FDA0003219710960000011.png)