Surface modification method for anode of polymer solar cell

A solar cell and surface modification technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion efficiency and low open circuit voltage, and achieve the goal of improving photoelectric conversion efficiency, increasing open circuit voltage, and increasing open circuit voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

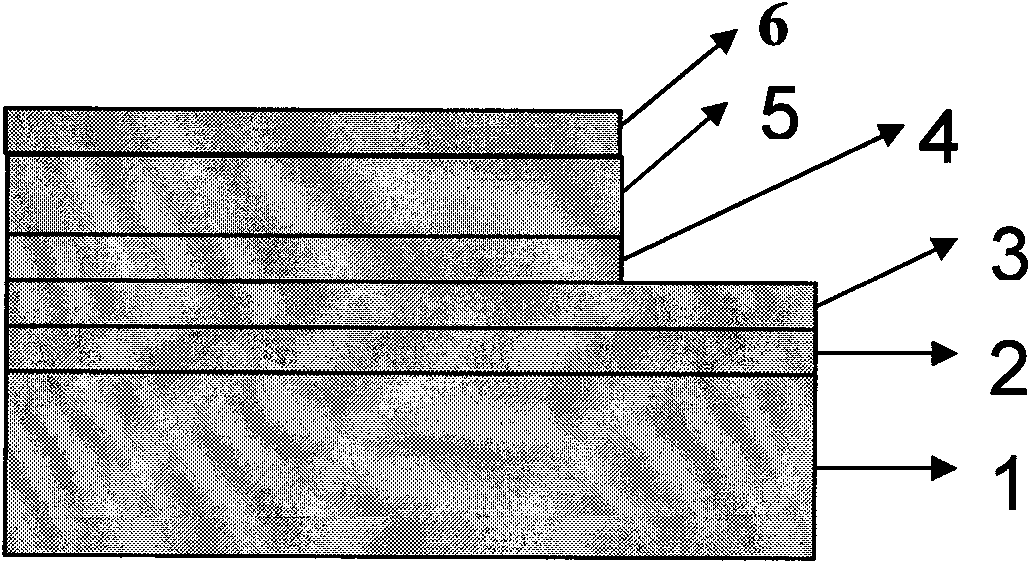

[0030] Example 1. Preparation of polymer solar cell I and performance testing

[0031] 1. Preparation of polymer solar cells

[0032] 1) Preparation of modified anode

[0033] First engrave the ITO on indium tin oxide (ITO) into 2mm wide and 15mm long electrodes, clean and dry the etched thin strips of ITO conductive glass with a certain width, and place the clean ITO conductive glass on the spinner. On the support of the coating machine, spin-coated a layer of polythiophene derivative-doped polystyrene sulfonic acid aqueous solution (PEDOT:PSS) on the ITO, and dried to obtain a PEDOT:PSS film with a thickness of 25nm; then on the PEDOT:PSS film Spin coating P3HT and C on 60 Mixed solution, P3HT and C in the mixed solution 60 The mass ratio is 1:1, the solvent is o-dichlorobenzene, and the photoelectric active layer P3HT / C with a thickness of 80nm is obtained. 60 .

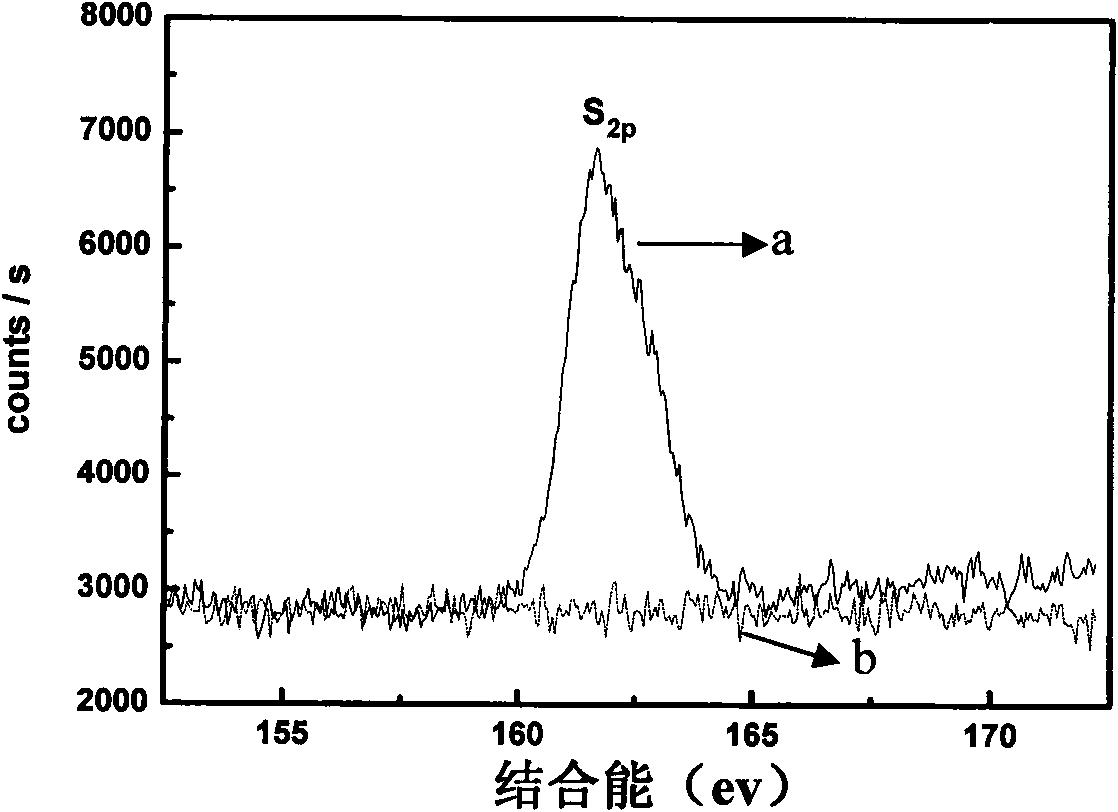

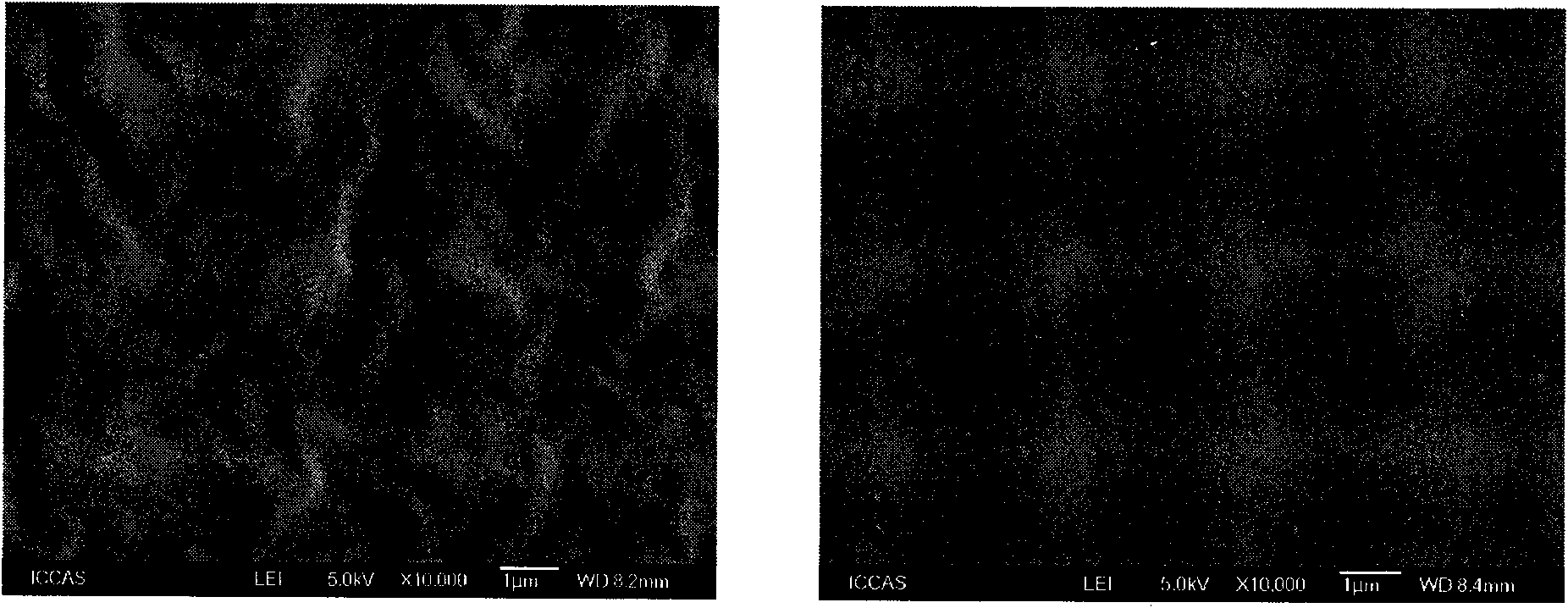

[0034] Then put the above sample in H 2 S, HCl, H 2 In the mixed gas of O, keep for 10 minutes, take it out, and dry i...

Embodiment 2

[0045] Example 2: Preparation and performance testing of polymer solar cell II

[0046] 1. Preparation of polymer solar cells

[0047] 1) Preparation of modified anode

[0048] First engrave the ITO on indium tin oxide (ITO) into 2mm wide and 15mm long electrodes, clean and dry the etched thin strips of ITO conductive glass with a certain width, and place the clean ITO conductive glass on the spinner. On the support of the coating machine, spin-coated a layer of polythiophene derivative-doped polystyrene sulfonic acid aqueous solution (PEDOT:PSS) on the ITO, and dried to obtain a PEDOT:PSS film with a thickness of 25nm; then on the PEDOT:PSS film Spin coating P3HT and C 60 P3HT and C in the mixed solution 60 The mass ratio is 1:1, the solvent is o-dichlorobenzene, and the photoelectric active layer P3HT / C with a thickness of 100 nm is obtained. 60 .

[0049] Then put the above sample in H 2 S, HCl, H 2 Keep it in the O mixed gas for 30 minutes, take it out, and vacuum dry.

[0050] Wh...

Embodiment 3

[0056] Example 3. Preparation of polymer solar cell III and performance testing

[0057] 1. Preparation of polymer solar cells

[0058] 1) Preparation of modified anode

[0059] First engrave the ITO on indium tin oxide (ITO) into 2mm wide and 15mm long electrodes, clean and dry the etched thin strips of ITO conductive glass with a certain width, and place the clean ITO conductive glass on the spinner. On the support of the coating machine, spin-coated a layer of polythiophene derivative-doped polystyrene sulfonic acid aqueous solution (PEDOT:PSS) on the ITO, and dried to obtain a PEDOT:PSS film with a thickness of 25nm; then on the PEDOT:PSS film Spin coating P3HT and C 60 P3HT and C in the mixed solution 60 The mass ratio is 1:1, the solvent is o-dichlorobenzene, and the photoelectric active layer P3HT / C with a thickness of 200nm is obtained. 60 .

[0060] Then put the above sample in H 2 S, HCl, H 2 Keep it in the O mixed gas for 60 minutes, take it out, and vacuum dry.

[0061] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com