Patents

Literature

77results about How to "Play a role in removing impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

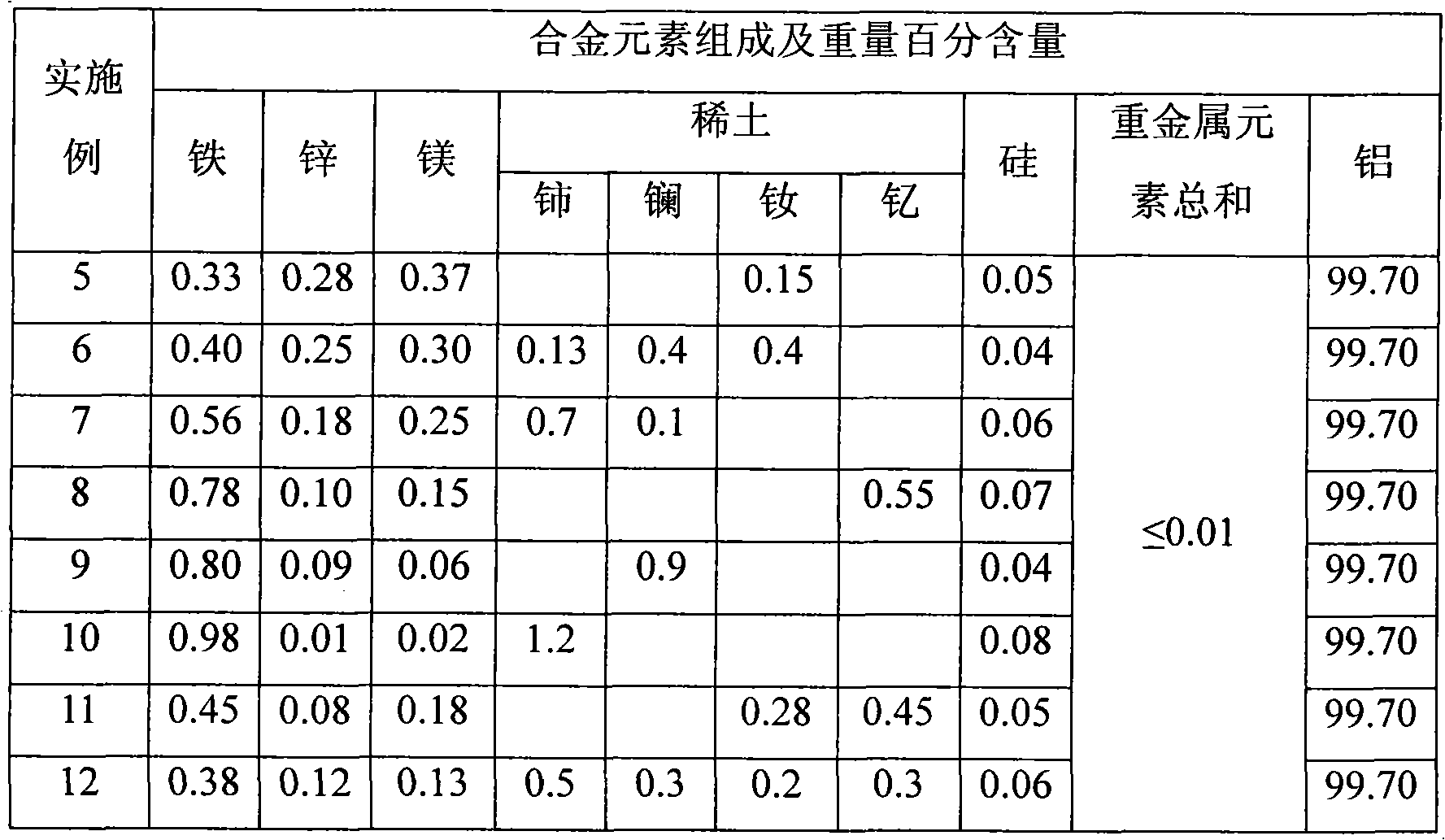

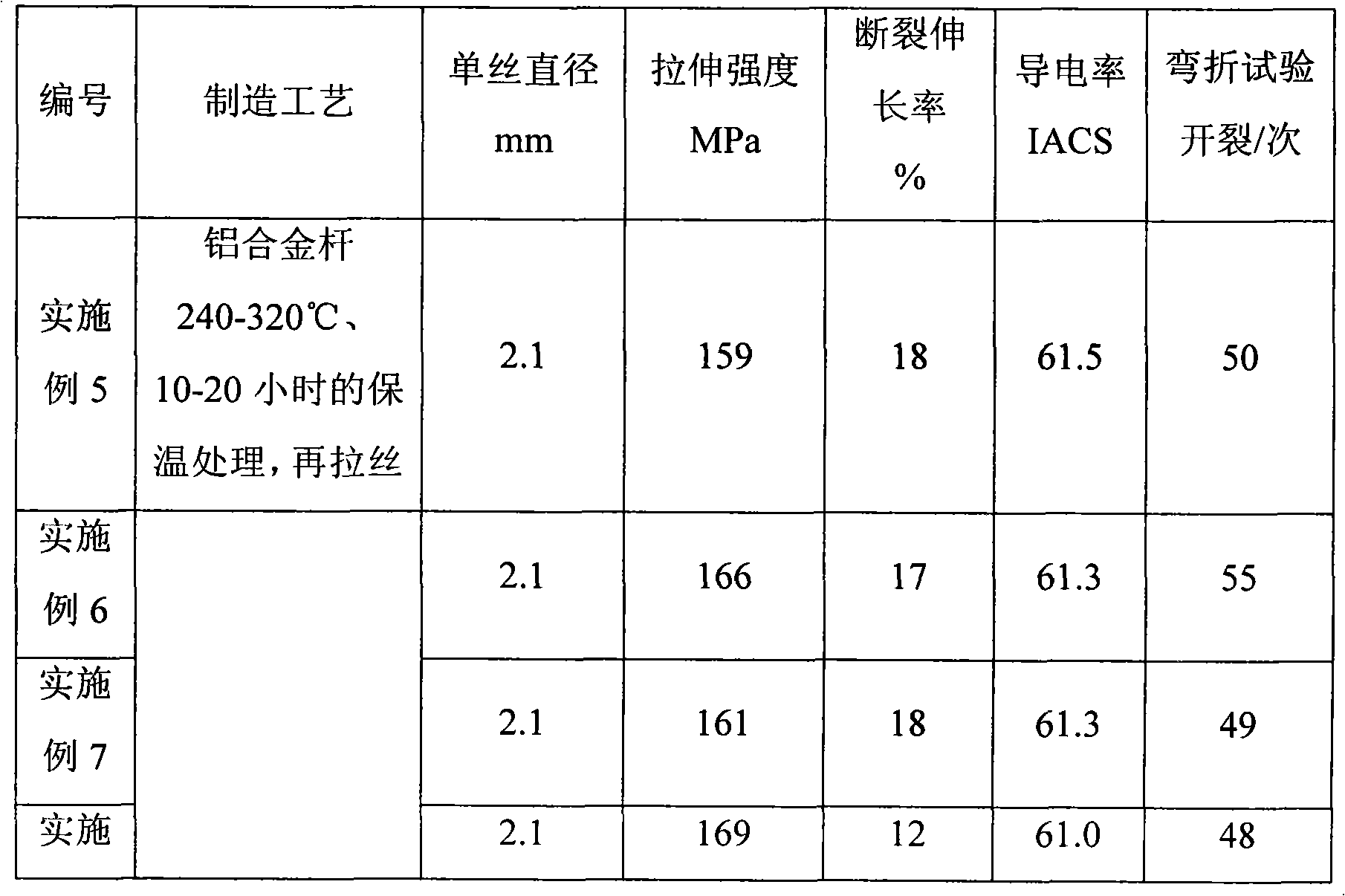

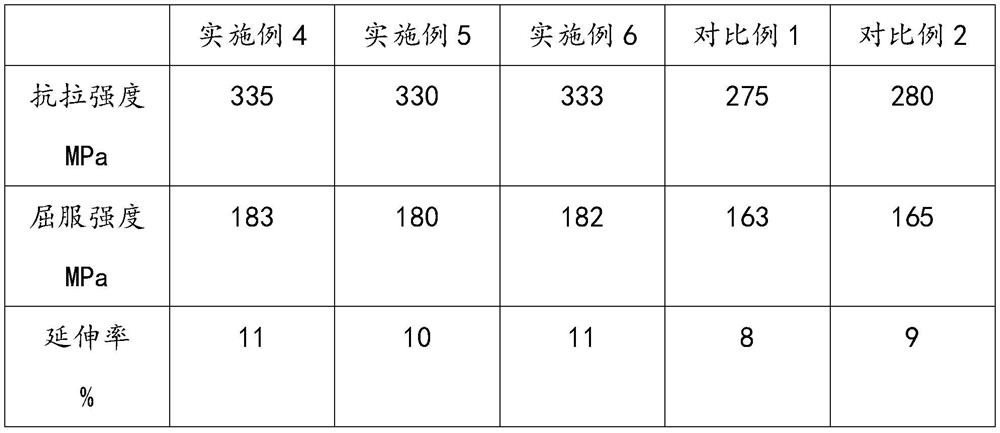

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

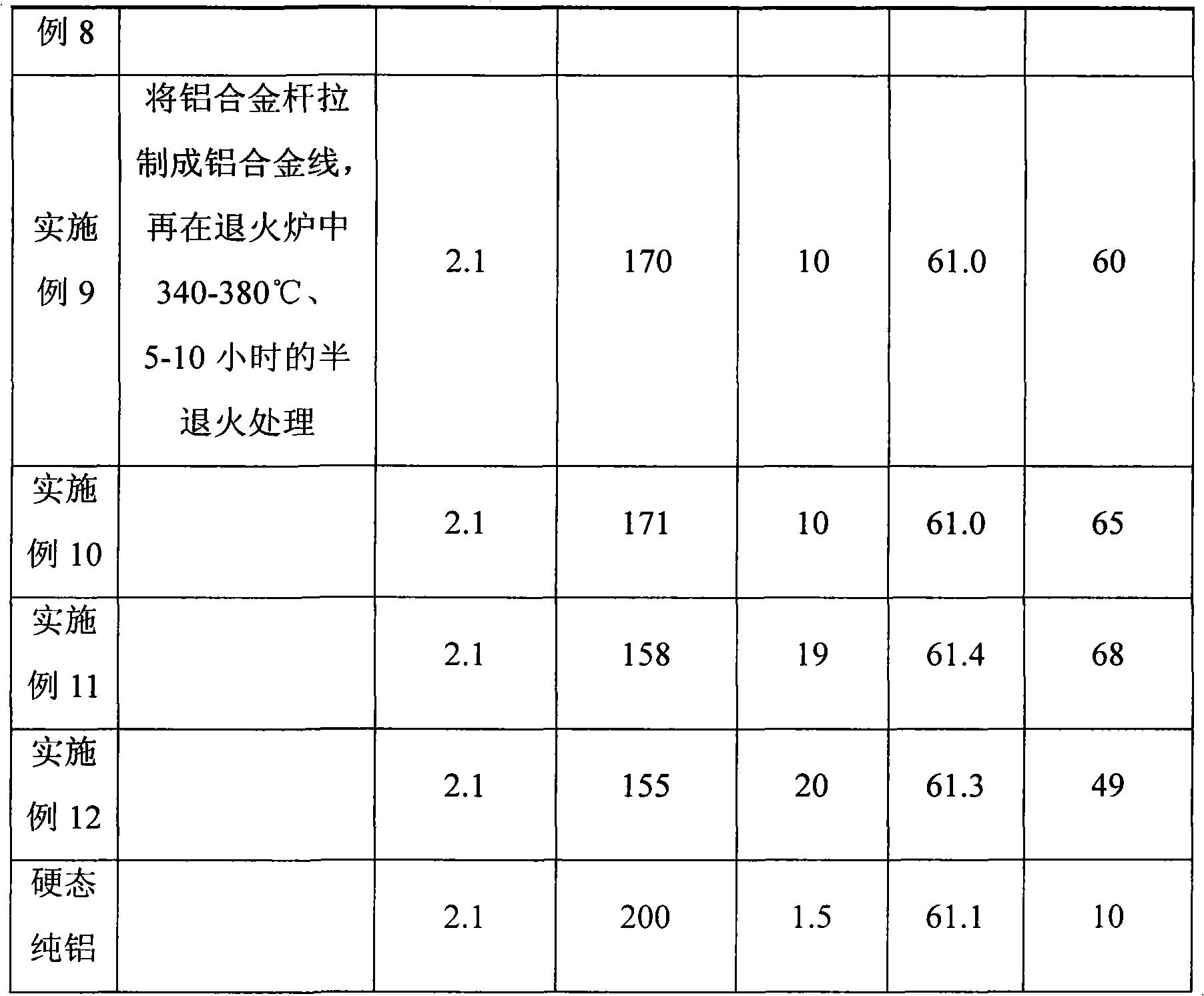

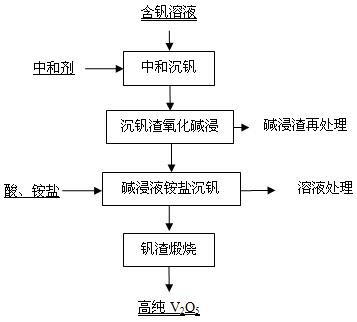

Method for preparing vanadium pentoxide

The invention relates to a method for preparing vanadium pentoxide, relates to a vanadium-containing acidic solution, in particular to a method for producing high purity vanadium pentoxide by treating the vanadium-containing acid leaching liquid of stone coal vanadium ore. The method is characterized in that the preparation process comprises the following steps: (1) adjusting the pH value of the vanadium-containing acidic solution to 4.0-4.5, precipitating, filtering; (2) performing oxidation and alkaline leaching to obtain alkaline leaching liquid and slag; (3) adjusting the pH value of the alkaline leaching liquid to 1.8-2.2, then adding ammonium salt to perform vanadium-precipitating reaction and prepare ammonium vanadate vanadium slag; and (4) calcining ammonium vanadate vanadium slag to prepare vanadium pentoxide. The method can be used to treat the stone coal vanadium ore leaching liquid with low vanadium concentration and the vanadium solution with high vanadium concentration; the flow is simple, the investment is lower than that of the traditional process; and impurities can be controlled well, high purity vanadium pentoxide can be obtained and the economic value of the product can be effectively increased.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

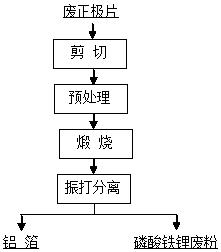

Method for separating and recycling positive plates of waste lithium iron phosphate batteries

ActiveCN110085939AIncrease recyclingSave resourcesWaste accumulators reclaimingProcess efficiency improvementLeaching rateAluminium

The invention relates to a method for separating and recycling positive plates of waste lithium iron phosphate batteries, which comprises the steps of firstly cutting the positive plates of the wastelithium iron phosphate batteries into loose segments, putting the segments into a sintering furnace for calcination in an insert atmosphere to obtain calcined waste plates, and vibrating and sieving the waste plates so as to obtain aluminum foil on a vibrating sieve and lithium iron phosphate waste powder below the vibrating sieve. According to the invention, a binder is enabled to lose effectiveness through the calcination under the protection of an inert gas, the toughness and non-oxidation of the aluminum foil are maintained at the high temperature, and the high leaching rate of Li in the later wet recycling process and the difficulty of removing Al in the process are ensured at the same time.

Owner:ZHUZHOU SMELTER GRP

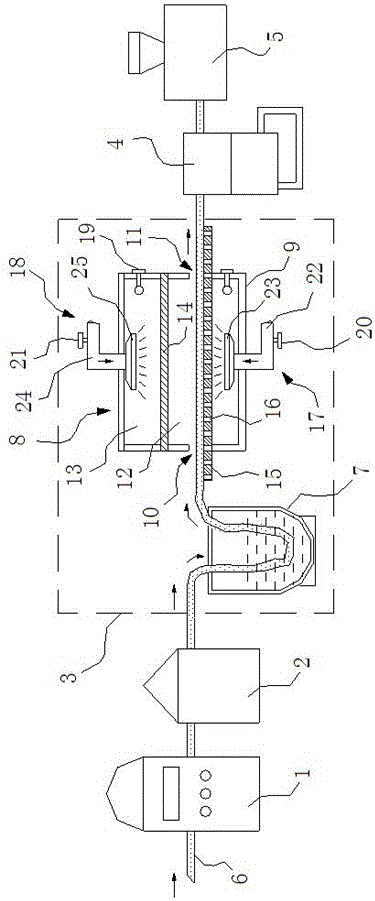

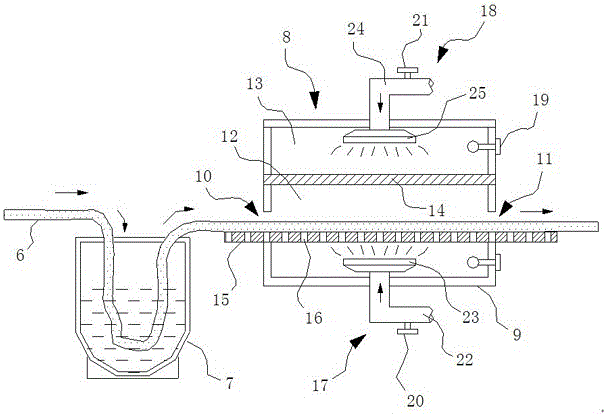

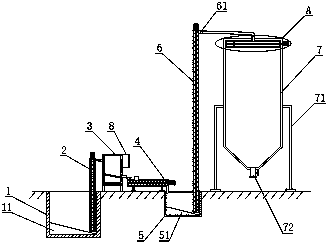

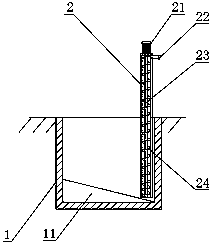

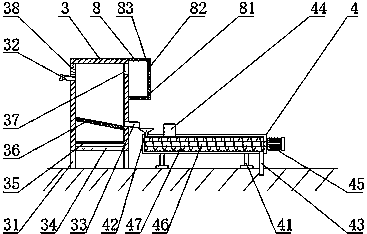

Long vehicle low-temperature steaming technology for fiber textiles and equipment

ActiveCN106637771AConserve waterSave energySucessive textile treatmentsTextile treatment machine arrangementsFiberEngineering

The invention discloses a long vehicle low-temperature steaming technology for fiber textiles and equipment. The technology comprises the following steps of (1) preparing gray cloth, (2) singeing, (3) desizing, (4) scouring, (5) rinsing and (6) drying. The invention further discloses long vehicle low-temperature steaming equipment for fiber textiles. The equipment comprises a scouring mechanism. The scouring mechanism has an immersion barrel and a steaming case connected with the immersion barrel, wherein the steaming case is provided with a case body equipped with an accommodating cavity; a steaming cavity steaming and heating textiles and a temperature balancing cavity preventing steam coagulation and on the upper part of the steaming cavity are disposed in the case body; the case body is equipped with a first steam supplying assembly and a second steam supplying assembly both providing high-temperature steam to the steaming cavity and the temperature balancing cavity. The steaming equipment can effectively reduce equipment energy consumption, save energy and improve production efficiency; and the long vehicle low-temperature steaming technology has short circulating, high efficiency, and can reduce water and energy use.

Owner:青岛奥洛思新材料有限公司

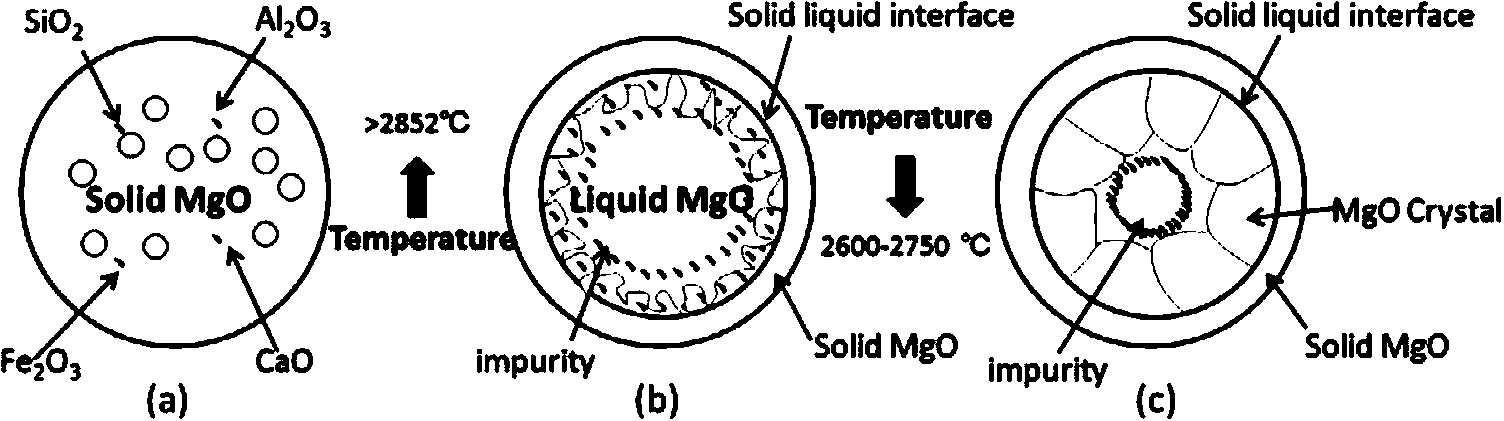

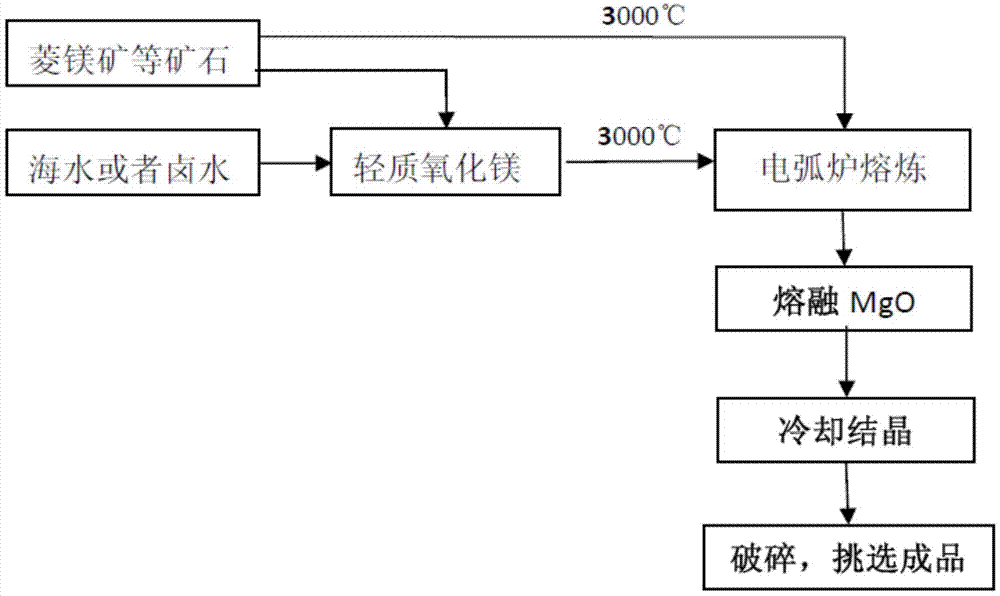

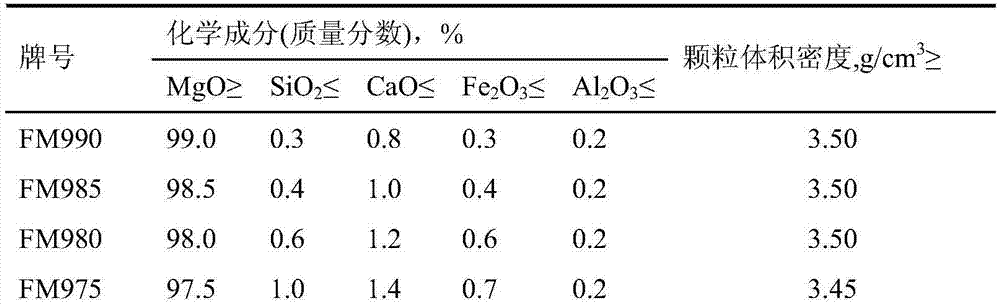

Additive for producing macrocrystalline fused magnesite

The invention relates to an additive for producing macrocrystalline fused magnesite. Main components of the additive are high purity graphite powder, rare earth oxide composition and zirconium oxide. The additive is characterized in that the addition mass of the high purity graphite powder accounts for 0.5-5% of the mass of magnesium oxide, the addition mass of the rare earth oxide accounts for 0.01-1.5% of the mass of magnesium oxide, and the addition mass of zirconium oxide accounts for 0.1-3% of the mass of magnesium oxide. The massive white transparent high purity fused magnesite is obtained by pointedly adding corresponding impurity removal materials according to the type and content of impurities in the magnesium oxide raw material in combination with an appropriate technological process; the technological process is simple; the dosage of the additive is small, but the additive has an obvious effect. Due to optimization of the additive and the technology, the melting power and time are reduced, the utilization rate of raw materials is increased, and the effects of energy conservation and emission reduction are achieved. The additive is easy to obtain, simple in process, low in cost and suitable for large-scale industrial production and application; requirements for required equipment are low.

Owner:EAST CHINA UNIV OF SCI & TECH

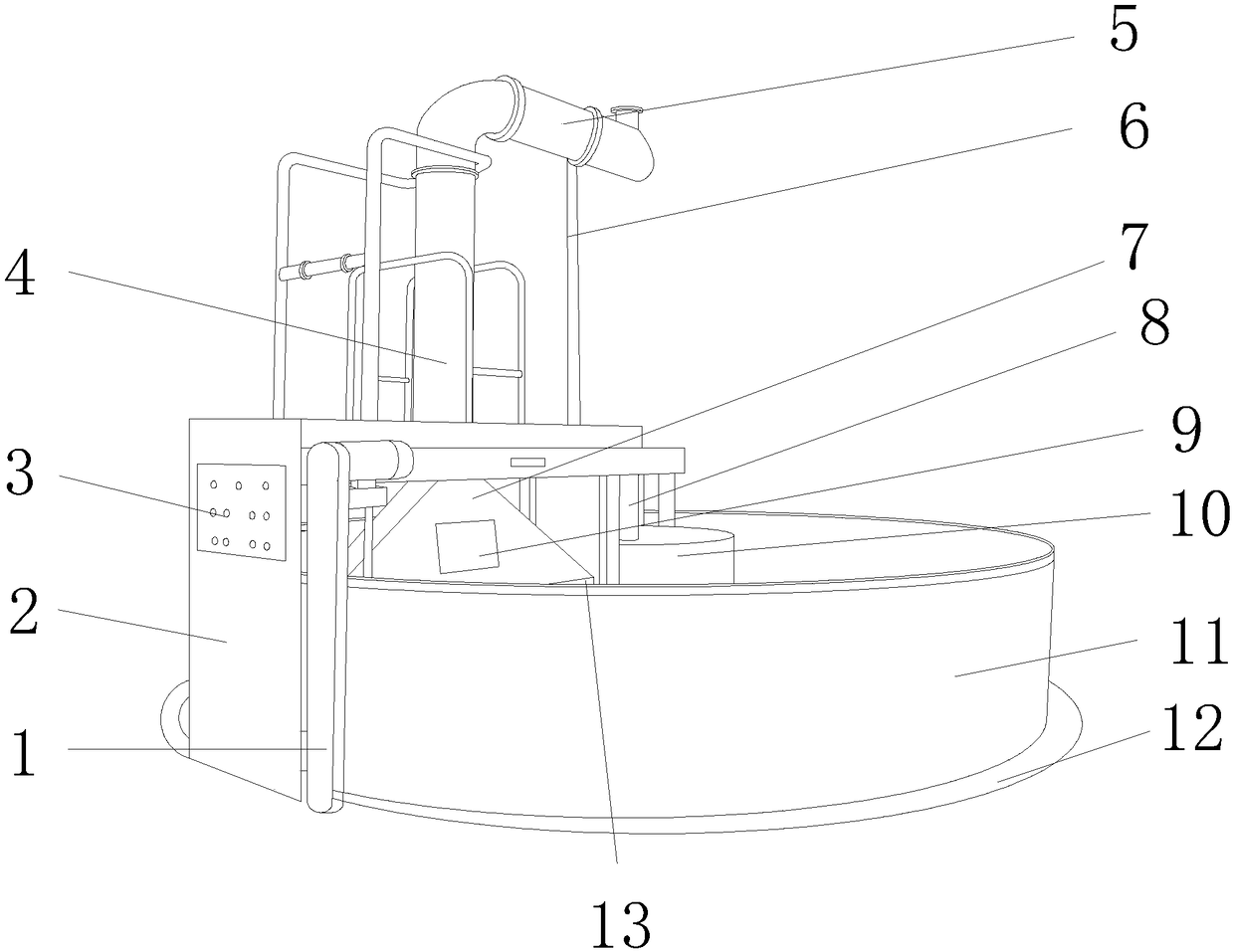

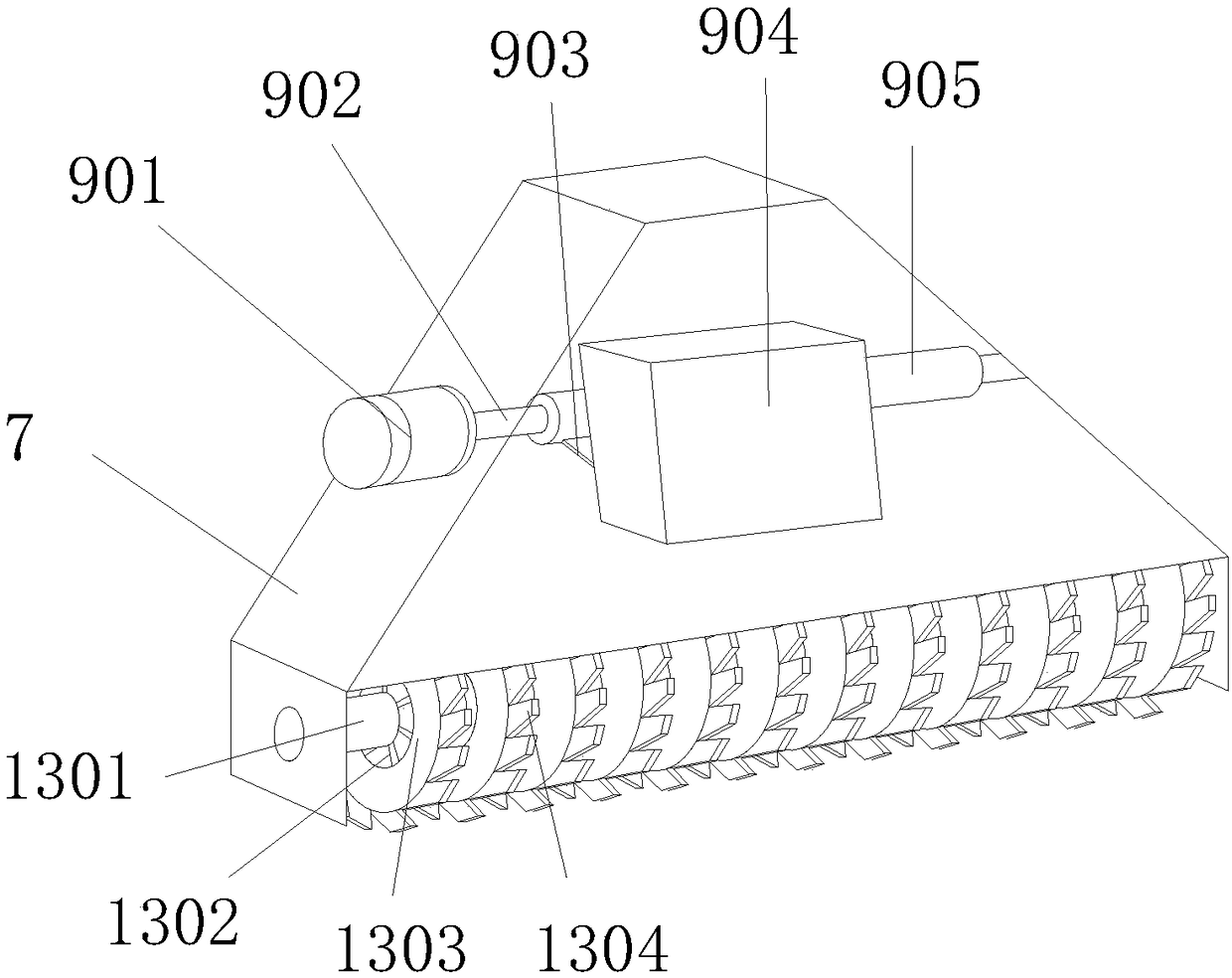

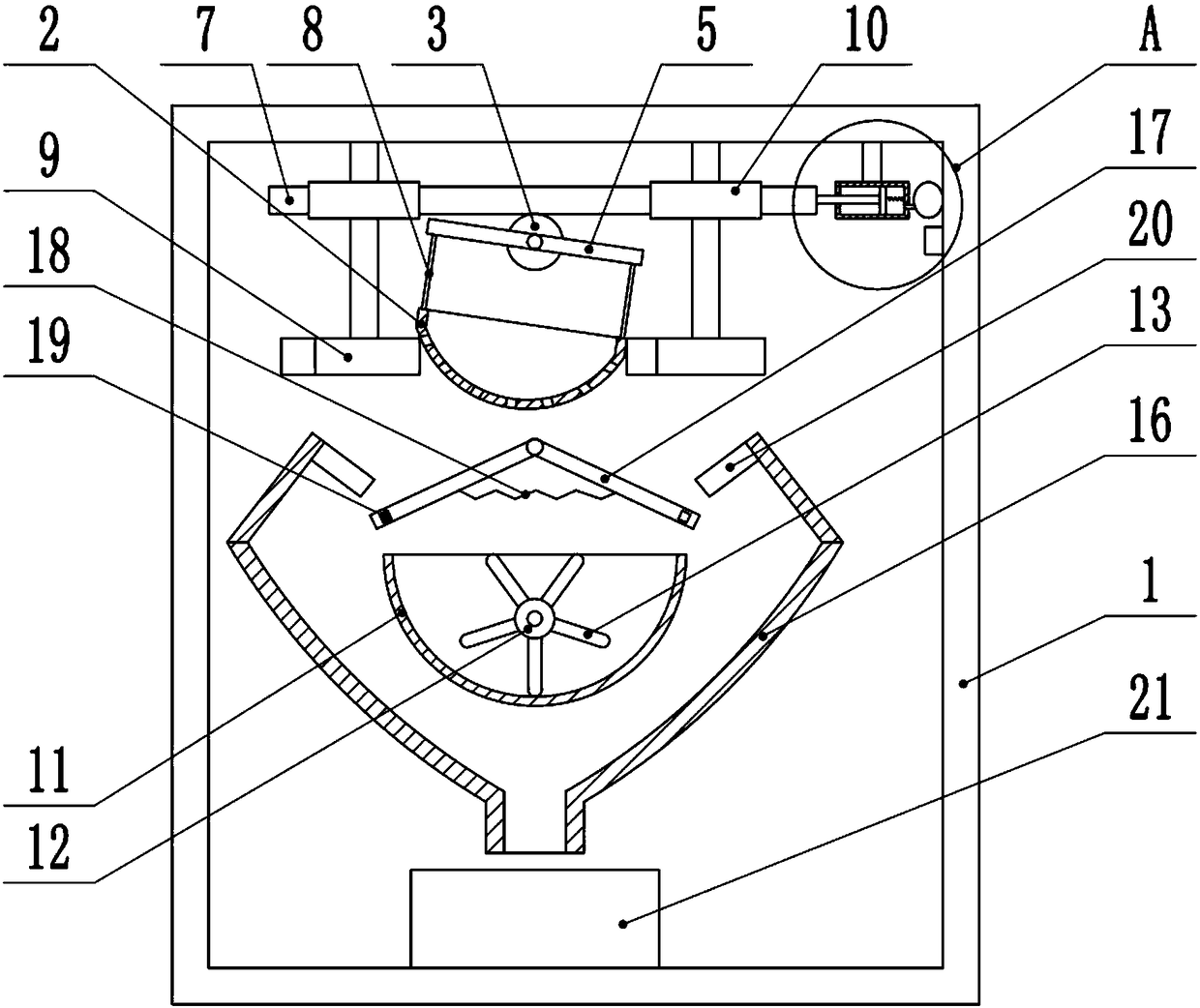

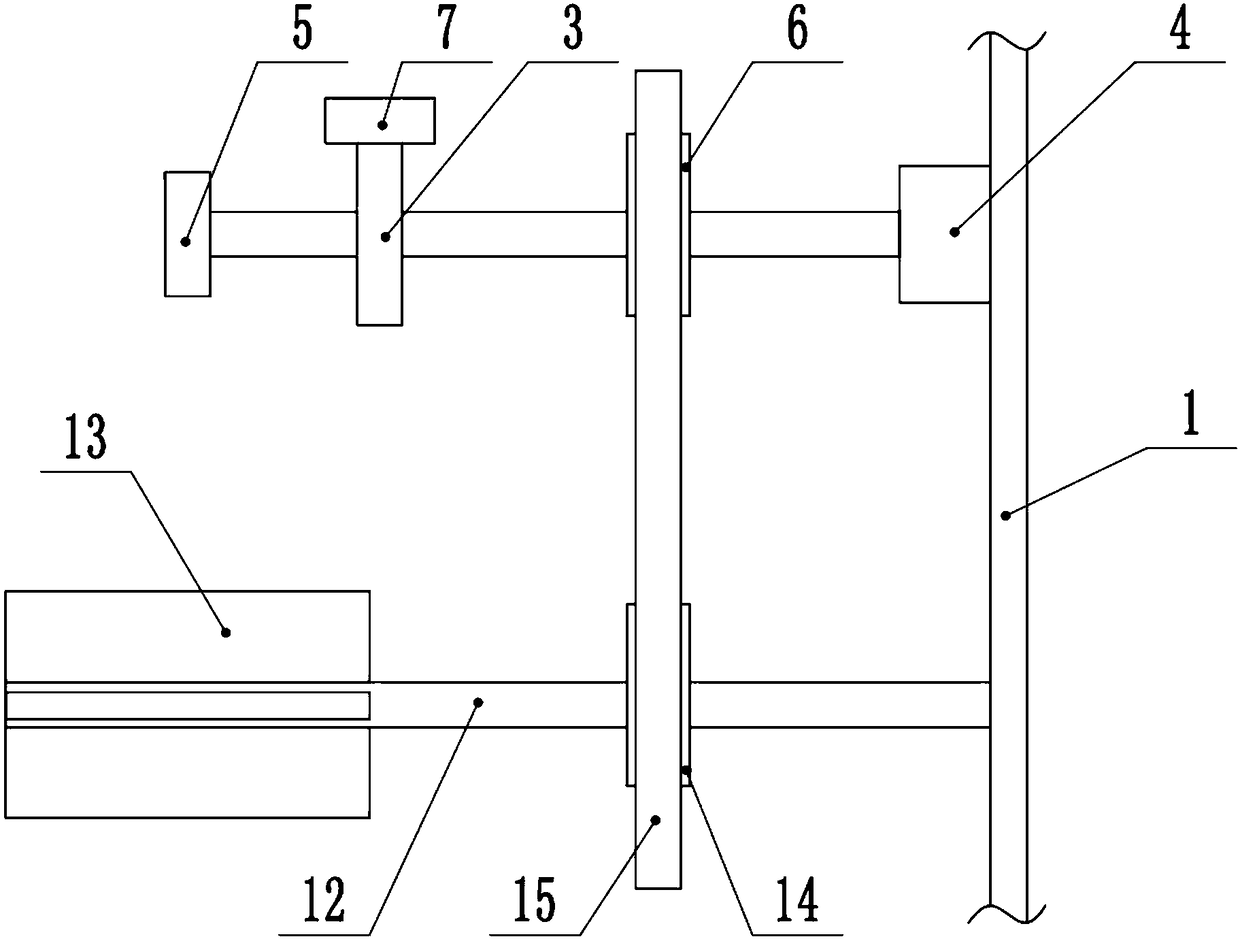

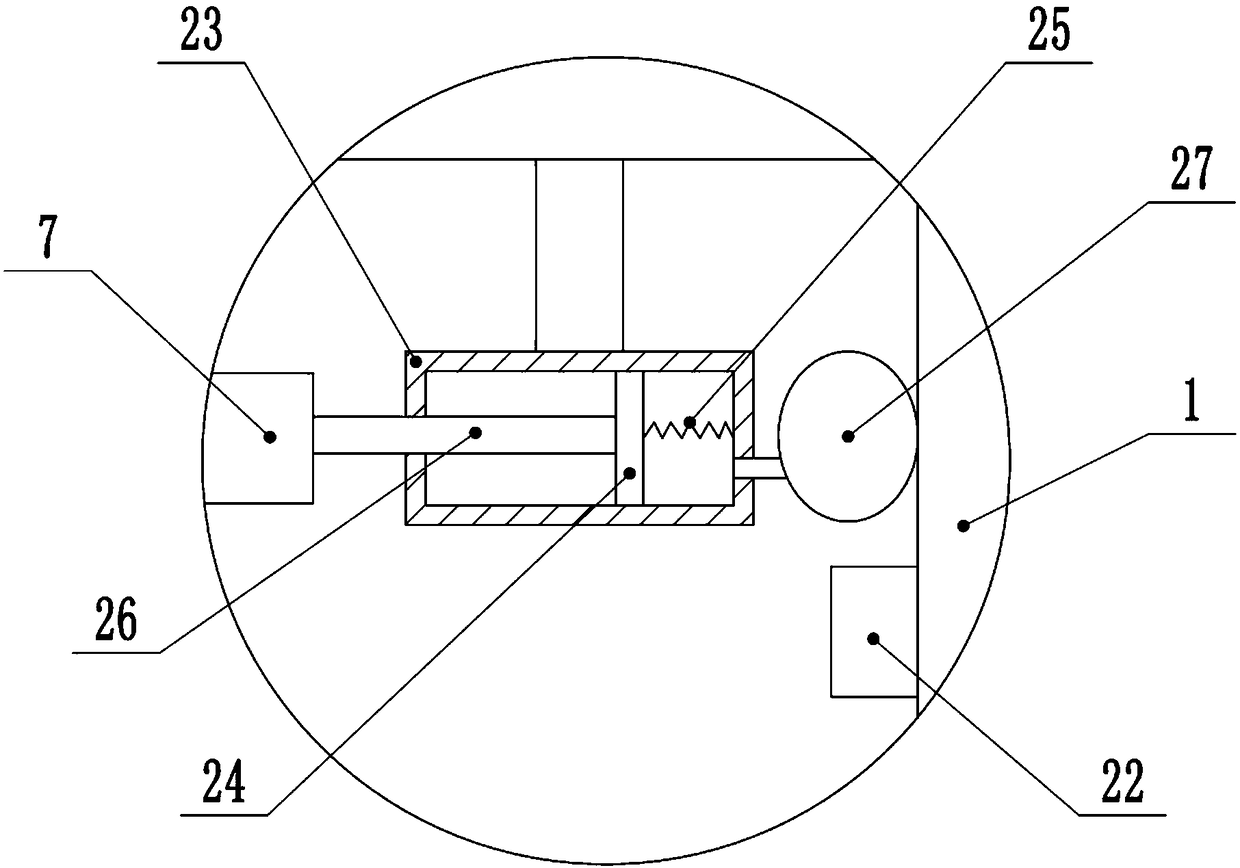

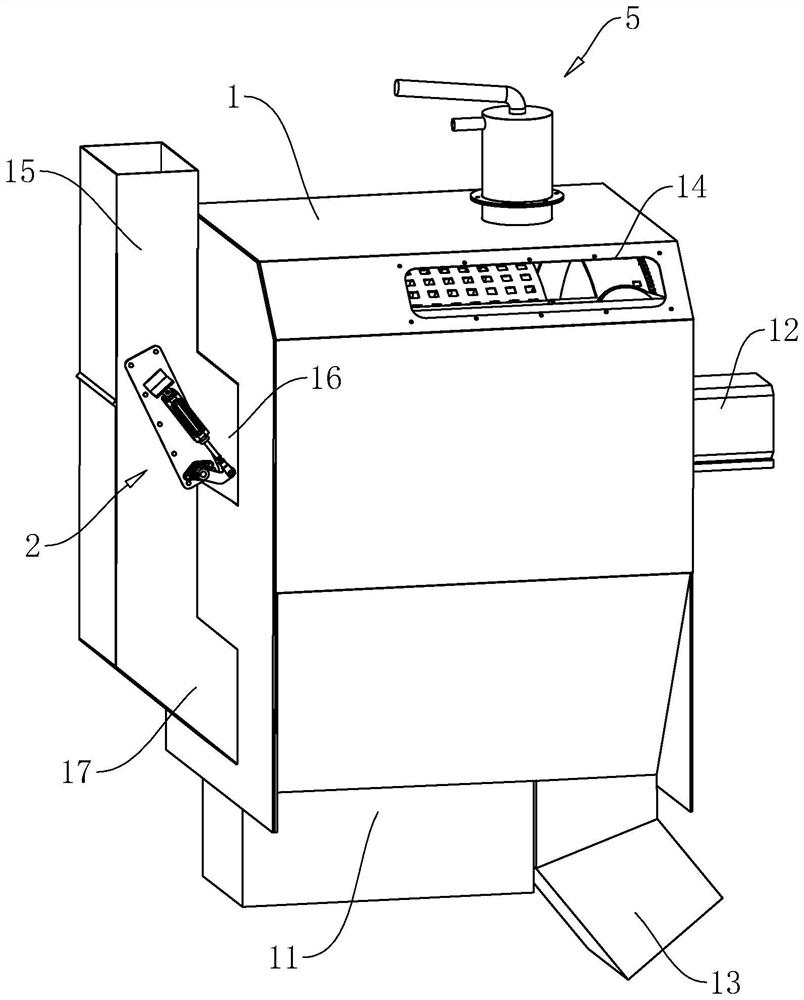

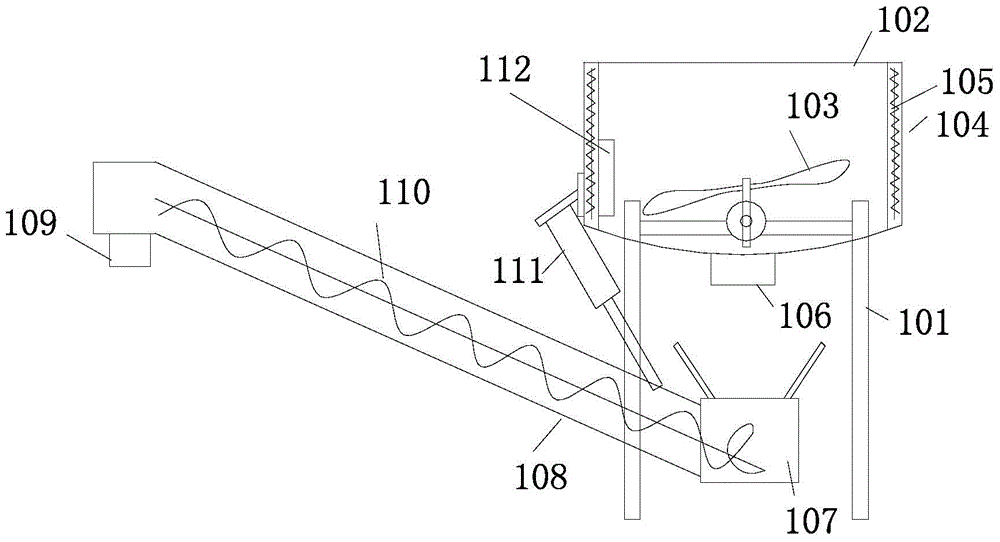

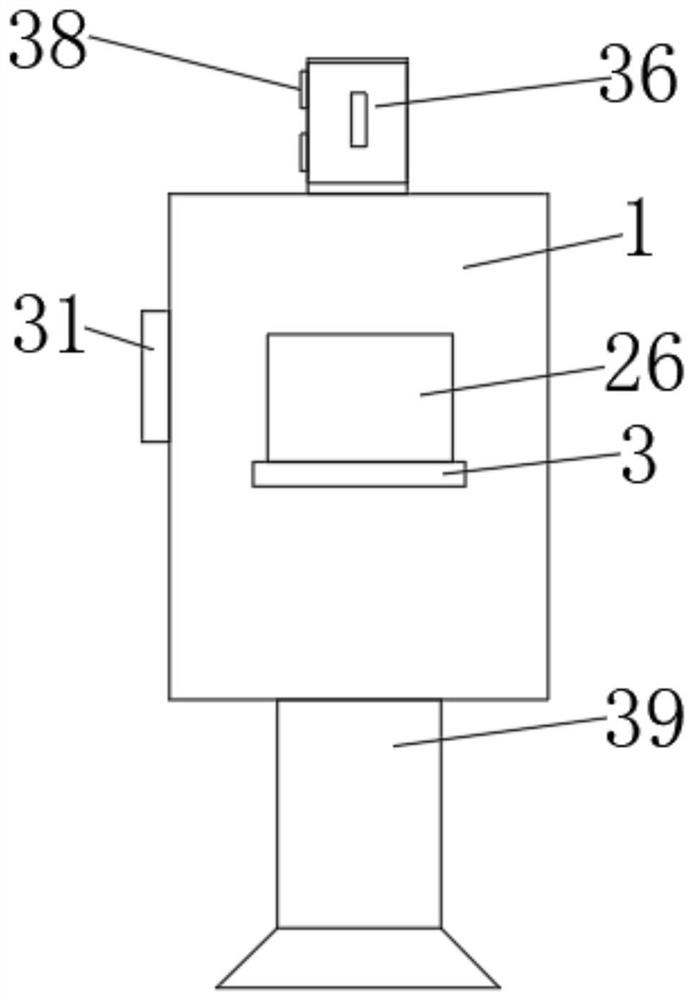

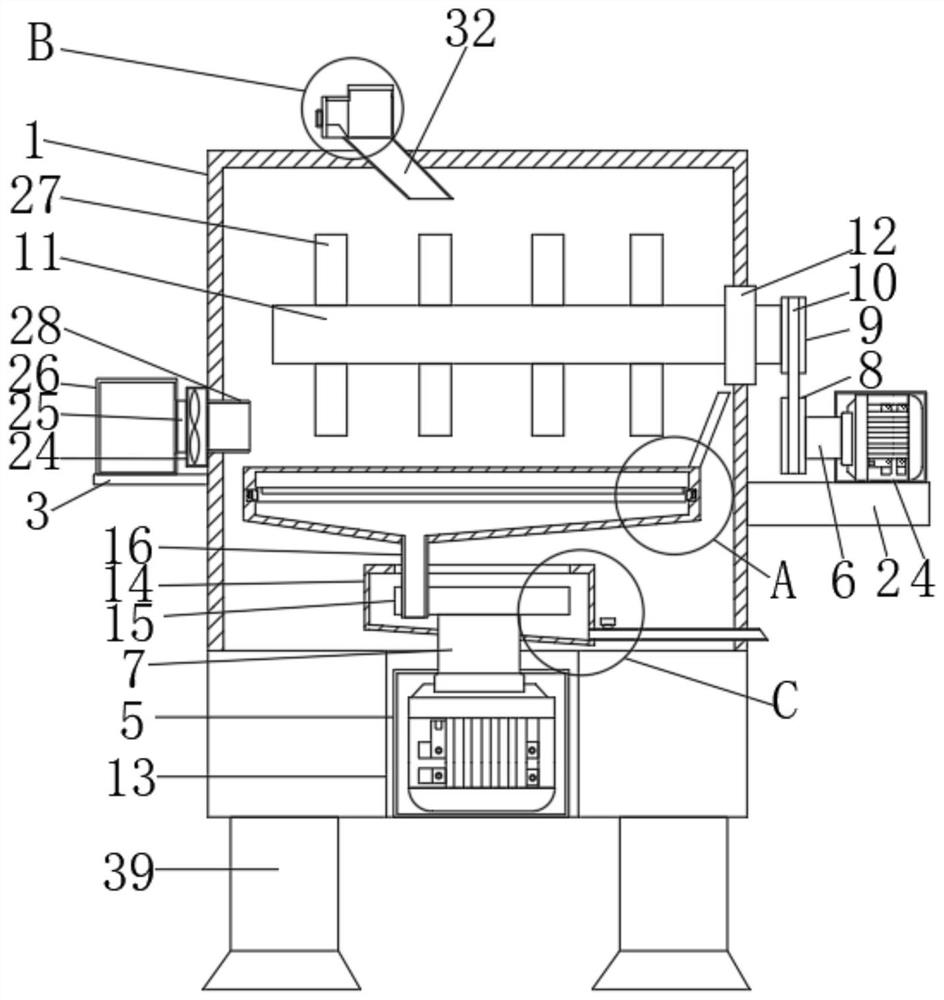

Spinning machine

InactiveCN108532031APlay a role in removing impuritiesImprove the quality of workFibre breaking machinesFibre breaking by beater armsEngineeringMagnet

The invention discloses a spinning machine. The spinning machine structurally comprises a phototube, a support, a control panel, a telescopic tube, a cotton delivery tube, a screw, a cart, a central shaft, an iron attracting device, inner-circle wall boards, outer-circle wall boards, a ground rail and a cotton grabbing beater, wherein the outer-circle wall boards are connected with the ground rail, the ground rail is movably connected with the support, the support is provided with the control panel, the control panel is connected with the phototube, the support is connected with the telescopictube, the bottom of the telescopic tube is connected with the cart, the iron attracting device is arranged in the cart, the bottom of the cart is movably connected with the cotton grabbing beater, the top of the telescopic tube is connected with the cotton delivery tube, the support is movably connected with the central shaft, the central shaft is movably connected with the inner-circle wall boards, the iron attracting device consists of a motor, a rotary shaft, an iron scraping plate, an iron collecting box and a powerful magnet, the motor is movably connected with the rotary shaft, the rotary shaft is connected with the powerful magnet, and the powerful magnet is movably connected with the iron scraping plate. The spinning machine can attract irony impurities in cotton, play an impurityremoving effect and improve the working quality.

Owner:王振兴

Method for reclaiming metals from molybdenum-containing waste catalyst

ActiveCN102051483BPrevents the problem of easy leachingSolve pollutionProcess efficiency improvementFiltrationImpurity

The invention discloses a method for reclaiming metals from a molybdenum-containing waste catalyst, which comprises the following steps of: mixing the waste catalyst and a magnesium-containing compound, roasting, degreasing, removing carbon, then crushing, mixing the powder and sodium carbonate, roasting the mixture, and leaching the roasted materials by using aqueous solution, wherein ammonium salt or aqueous ammonia is added in the aqueous solution leaching step, the molybdenum in the waste catalyst enters the solution in a form of sodium molybdate or ammonium molybdate, the impurities suchas silicon, phosphorus and the like entering the aqueous solution form sediment, and the sediment is kept in solid residue in a filtration step; and after the solid is separated, performing acidification, extraction, re-extraction and the like to reclaim the molybdenum and other metals. The method solves the pollution problem caused by sulfur dioxide in the discharged gas in the roasting, degreasing and carbon removal processes; and the salts formed by the reclaimed sulfur and magnesium can play a role in removing impurities in the subsequent steps so as to save the consumption of chemical reagents in the metal reclaiming process and reduce the cost. In addition, the method reduces the operation steps, reduces equipment, improves the operation effect, and also can improve the molybdenum yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

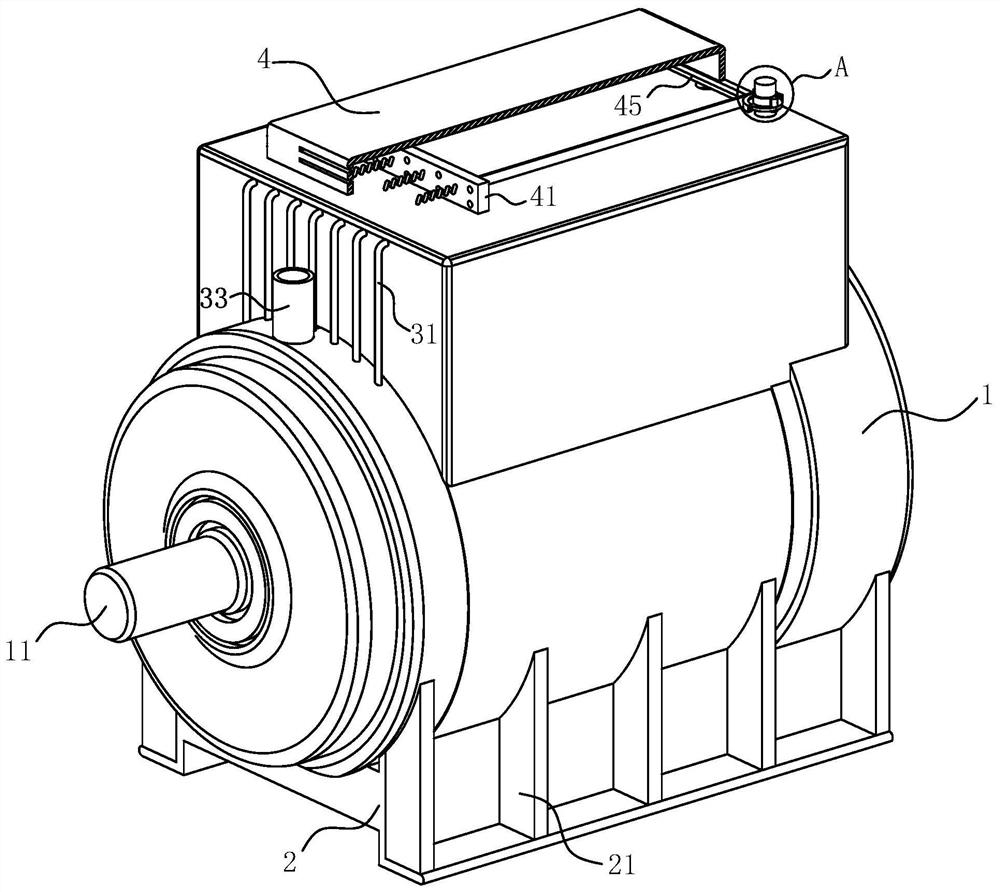

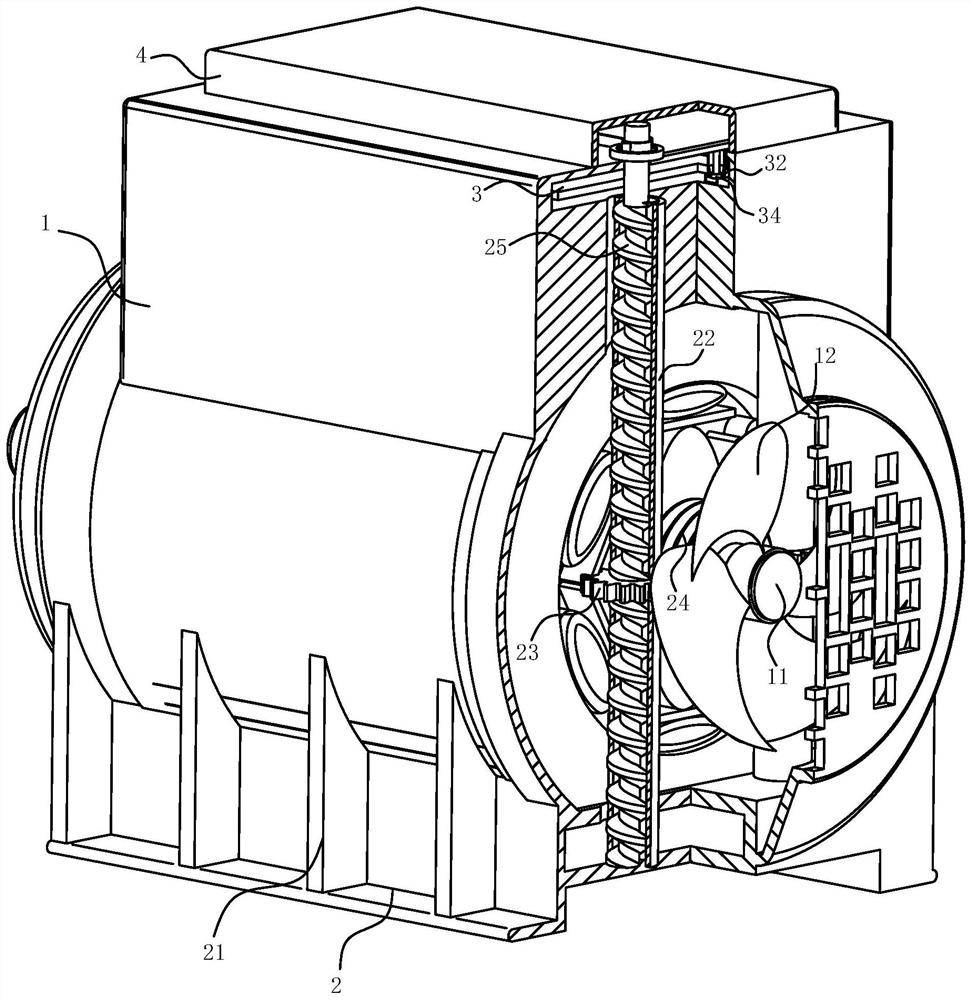

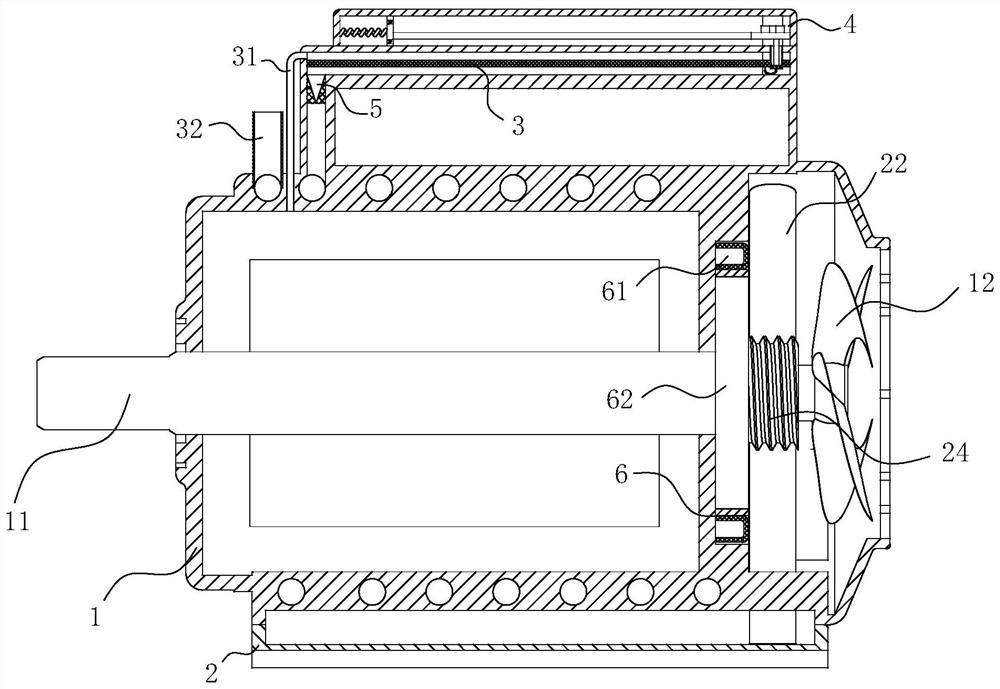

3300V high-voltage permanent magnet variable frequency motor all-in-one machine

ActiveCN111969760AFast heat conductionAvoid enteringAssociation with control/drive circuitsUsing liquid separation agentFrequency changerElectric machine

The invention belongs to the technical field of variable frequency motors, and particularly relates to a 3300V high-voltage permanent magnet variable frequency motor all-in-one machine which comprisesa machine shell, a frequency converter assembly and a permanent magnet synchronous motor assembly. The permanent magnet synchronous motor assembly comprises a stator, a rotor and a rotating shaft. Amotor cavity and a frequency conversion cavity are formed in the machine shell. The permanent magnet synchronous motor assembly and the motor cavity jointly form a permanent magnet synchronous motor.The frequency converter assembly is installed in the frequency conversion cavity. A heat dissipation cavity is formed in the end, located in the motor cavity, of the machine shell. A rotating shaft inthe permanent magnet synchronous motor assembly extends into the heat dissipation cavity. By arranging a water storage cavity and a circulating cavity and utilizing rotation of the rotating shaft, water flow in the lower water storage cavity is pumped into the circulating cavity through the water pumping pipe, after the water flow makes contact with the pumped outside air, the water flow flows into the heat exchange cavity, the air flow enters the motor cavity, and heat conduction between the permanent magnet synchronous motor assembly and the machine shell is effectively accelerated and enhanced.

Owner:浙江开泰新能源科技有限公司

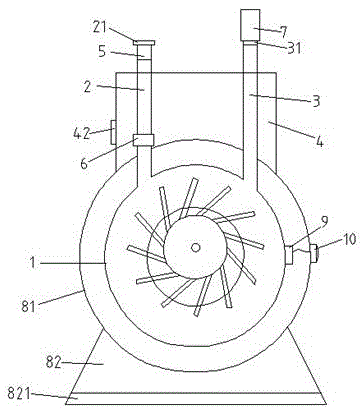

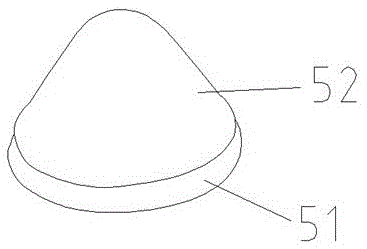

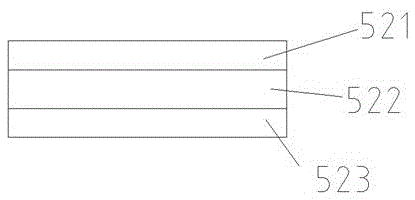

Vacuum pump

InactiveCN105422452APlay a role in removing impuritiesImprove cleanlinessRotary piston pumpsRotary/oscillating piston pump componentsImpellerRubber ring

The invention particularly relates to a vacuum pump. The vacuum pump comprises a vacuum pump body and an impeller. The top of the vacuum pump body is connected with an air inlet pipe and an air outlet pipe. The top of the air inlet pipe is provided with an air inlet. The top of the air outlet pipe is provided with an air outlet. A pipe sleeve is arranged on the periphery of the air inlet pipe and the air outlet pipe in a sleeving mode. The lower end of the air inlet is connected with the upper end of a filtering mechanism. The filtering mechanism comprises a rubber ring and a filtering assembly. The filtering assembly comprises a first metal net layer, a phenolic paper element and a second metal net layer. A check valve is arranged at the lower end, close to the vacuum pump body, of the inlet pipe. A silencing mechanism is connected with the upper portion of the air outlet. The silencing mechanism sequentially comprises a pipe, silencing cotton and a metal plate from outside to inside. An outer shell is arranged on the periphery of the vacuum pump body in a sleeving mode. The pipe sleeve is provided with an opened plate. The outer wall of the vacuum pump body is connected with a thermometer. The thermometer is connected with an alarming device which is arranged on the outer side wall of the outer shell. The service life of the vacuum pump is greatly prolonged through the reasonable structural design.

Owner:CHONGQING YUNHAI MACHINERY MFG

Additive for producing high-purity fused magnesite

The invention relates to an additive for producing high-purity fused magnesite. The main components of the additive are high-purity graphite powder, rare earth oxide and titanium oxide. The additive is characterized in that the adding dosage of the high-purity graphite powder is 0.5-5% of the mass of magnesium oxide; the adding dosage of the rare earth oxide is 0.01-0.5% of the mass of magnesium oxide; the adding dosage of titanium oxide is 0.1-5% of the mass of magnesium oxide. In the additive provided by the invention, the chemical form oxides are used for replacing an expensive rear earth alloy material, the main components of the additive are high-purity graphite powder, such rare earth oxide combinations as lanthanum oxide, cerium oxide and the like and titanium oxide, and the components are added in the raw material in different smelting stages; impurity removal and purification are performed by means of the excellent properties of the rare earth oxide and titanium oxide, and massive white transparent high-purity fused magnesia is obtained by appropriate process flows.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing high-purity xylooligosaccharide

ActiveCN109796508APlay a role in removing impuritiesHigh puritySugar derivativesDisaccharidesActivated carbonBlack liquor

The invention relates to a method for preparing high-purity xylooligosaccharide. The method includes subjecting a solution, obtained by removing lignin from black liquor or plant extract, to adsorption treatment by activated carbon, and performing solid-liquid separation to obtain purified liquid I; adsorbing monosaccharide in the purification liquid I by strong acidic cation exchange resin; mixing purified liquid II obtained after absorption with an organic solvent, removing impurities through purification and extraction, and concentrating and crystallizing a xylooligosaccharide solution obtained after impurity removal to obtain the high-purity xylooligosaccharide. The method has the advantages that the solution obtained by removing the lignin from the black liquor or the plant extract isused as a raw material, and is sequentially subjected to the steps of decolorization and adsorption by the activated carbon, adsorption by the strong acid cation exchange resin, purification and extraction by the organic solvent, and the like to obtain the high-purity xylooligosaccharide of which the purity is higher than 95%; resources are fully utilized, and the method has good economic benefits and application prospect.

Owner:GUANGZHOU YINNOVATOR BIOTECH CO LTD

Tea stir-frying device with screening function

InactiveCN108522671AStir wellSpeed up sievingSievingPre-extraction tea treatmentAgricultural engineeringCam

The invention relates to the technical field of tea processing and discloses a tea stir-frying device with a screening function. The tea stir-frying device comprises a machine frame, wherein a screening mechanism, a material guiding mechanism and a tea stir-frying mechanism are arranged on the machine frame; the screening mechanism comprises a screening basket and a first gear; the first gear is coaxially connected with a swing rod and a second gear; the first gear is meshed with a first gear rack; a connecting piece is connected between the screening basket and the swing rod; the machine frame is rotationally connected with a cam; the cam is coaxially connected with a third gear; a discharge door is arranged on the screening basket; the tea stir-frying mechanism comprises a wok; the inside of the wok is rotationally connected with a rotating shaft; a stirring plate is arranged on the rotating shaft; the rotating shaft is coaxially connected with a fourth gear; the second gear is meshed with a second gear rack; the material guiding mechanism comprises a waste material channel and two material guiding plates; a first spring is connected between the two material guiding plates; a first electromagnet is arranged on each material guiding plate; and the waste material channel is fixedly connected with a second electromagnet. The tea stir-frying device with a screening function can perform screening and fixation on tea, thereby reducing the invested cost and improving the processing efficiency.

Owner:贵州省凤冈县翠巅香生态茶业有限公司

Method for producing high-purity electronic titanium dioxide

ActiveCN111439781APlay a role in removing impuritiesMeet the requirements of high-end electronic grade titanium dioxideTitanium dioxideAluminium chlorideHydrolysate

The invention discloses a method for producing high-purity electronic titanium dioxide. Panzhihua titanium concentrate with the concentration larger than or equal to 80% is selected as a raw material,sulfuric acid is used for acidolysis of the titanium concentrate, a flocculating agent composed of a maleic anhydride-styrene sulfonic acid copolymer, sodium lignin sulfonate and polyaluminum chloride is added for impurity removal treatment, standing and filter pressing are conducted for solid-liquid separation, filter-pressed liquid enters a vacuum crystallization system, secondary filter pressing is conducted, and refined titaniferous solution is obtained; water is added into the refined titaniferous solution to adjust the concentration to 95-200g / L, heating and stirring are performed, anda crystal form control agent is added to react to obtain a hydrolysate; the hydrolysate is washed until the iron ion content is below 150ppm, then sulfuric acid is added for bleaching and washed for the second time until the iron ion content is below 50ppm to obtain slurry; squeezing is performed by a filter press, a filter cake is calcined in a rotary kiln and crushed to obtain the electronic titanium dioxide. The purity of the titanium dioxide product prepared by the method reaches 99.5% or above, the particle size distribution is 200-400 nm, the particle size distribution is narrow, the particle size distribution is uniform, the powder whiteness reaches 90% or above, and the requirements of middle-high-end electronic-grade titanium dioxide can be met.

Owner:GUANGXI JINMAO TITANIUM

Method for manufacturing fused magnesia and pig iron by using waste magnesia carbon bricks and rolled steel sheets

The invention relates to a method for manufacturing fused magnesia and pig iron by using waste magnesia carbon bricks and rolled steel sheets. The method comprises the steps that (1) the waste magnesia carbon bricks and the rolled steel sheets are broken to form magnesia carbon brick powder and rolled steel sheet powder respectively; (2) the magnesia carbon brick powder is mixed with the rolled steel sheet powder after water is added to the magnesia carbon brick powder to enable the magnesia carbon brick powder to be wet; (3) adhesion agents are added to enable mixed materials to be pressed so as to form iron carbon magnesium pellets; (4) the iron carbon magnesium pellets containing water are dried; (5) the iron carbon magnesium pellets and magnesite are fed into a high-capacity magnesium electrofusion furnace in a layered material distribution mode, and the iron carbon magnesium pellets serve as the first layer of raw materials; (6) the iron carbon magnesium pellets are distributed in the central region of the magnesium electrofusion furnace, and the magnesite is distributed on the periphery of the iron carbon magnesium pellets, so that the second layer of raw materials is formed by the iron carbon magnesium pellets and the magnesite together; and (7) the step (5) and the step (6) are repeatedly conducted, various layers of raw materials are distributed in sequence, refining and precipitation are conducted, and finally the fused magnesia and the pig iron are obtained. The method for manufacturing the fused magnesia and the pig iron by using the waste magnesia carbon bricks and the rolled steel sheets achieves comprehensive and efficient utilization of the industrial waste.

Owner:鞍山澳海耐火材料有限公司

Oxygen-free copper, preparation method and application

ActiveCN112322924AReduce contentImprove heat resistanceProcess efficiency improvementHeat resistanceIngot

The invention provides oxygen-free copper, a preparation method and application. Four alloy elements of Zr, Sr, Ce and Yb are added into the oxygen-free copper. The preparation method comprises the following steps: S1, uniformly mixing electrolytic copper, Zr, Sr, Ce and Yb; adding a covering agent and a refining agent; smelting in a reducing atmosphere; S2, casting a melt with uniform componentsobtained in the step S1 in a protective atmosphere; S3, performing homogenization treatment on a cast ingot obtained in the step S2 under the protective atmosphere; and S4, circularly carrying out a cold deformation recrystallization air cooling process on the homogenized cast ingot in a protective atmosphere. The oxygen-free copper provided by the invention has good heat resistance; and after high-temperature treatment at 900 DEG C, the grain size is not obviously increased.

Owner:CENT SOUTH UNIV

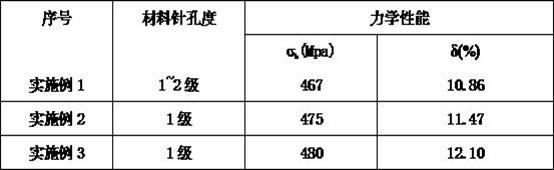

Wear resistant zinc alloy degassing sundries-discharging refining method

The invention discloses a wear resistant zinc alloy degassing sundries-discharging refining method, which comprises the following steps of (1) preheating a crucible and sequentially adding an aluminum ingot and a copper block; (2) rising the temperature to 680-700 DEG C for heat preservation, adding a zinc ingot and stopping heating of the crucible after the copper block is completely melted; (3)stirring metal melt after the zinc ingot is totally melted, keeping the temperature in a pot to be 580-620 DEG C, adding a magnesium block, and discontinuously stirring 3-4 times in 10-15 minutes; (4) adding a rare-earth cerium Ce and enabling the rare-earth cerium Ce to be rapidly and evenly spread in the metal melt; (5) leading in nitrogen after dehydration and purification; and (6) enabling liquid-phase wear resistant zinc alloy to be stewed for 3-5 minutes, discharging from a furnace for molding by casting after drossing, and forming a wear resistant zinc alloy casting. The wear resistantzinc alloy degassing sundries-discharging refining method can effectively conduct degassing and sundries-discharging on melting wear resistant zinc alloy, reduces or removes impurities and air holes in the casting, improves acceptability and mechanical property of the casting, simultaneously solves the problem in the prior art that harmful gas is discharged, greatly reduces environmental contamination, and is simple in process and convenient in operation.

Owner:镇江汇通金属成型有限公司 +1

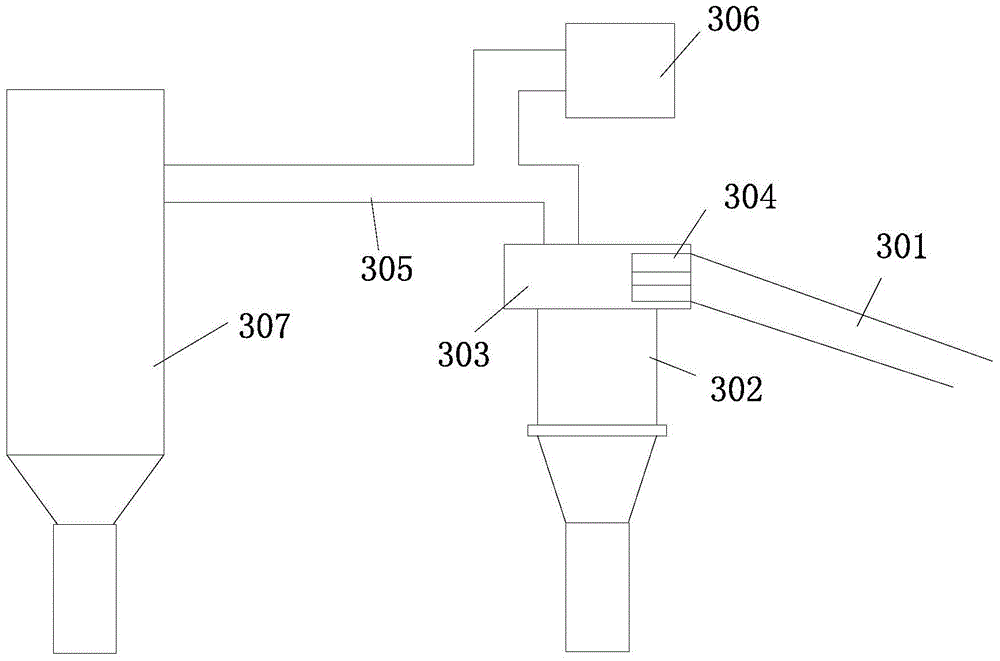

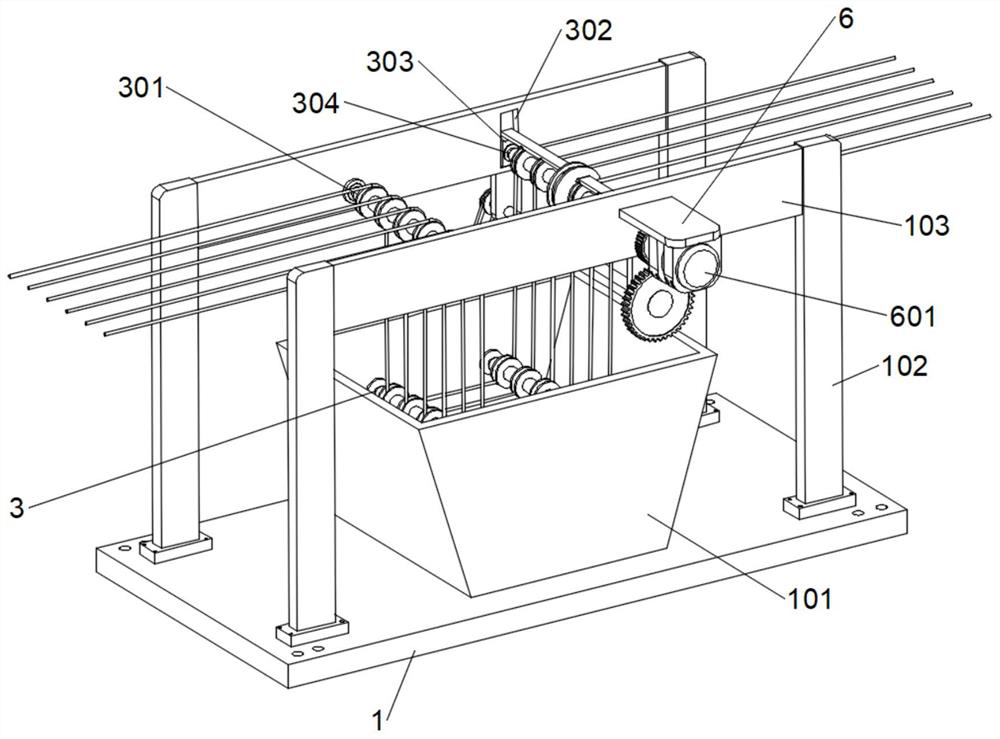

Impurity cleaning device for improving equipment of powder flame retardant

ActiveCN104826796APlay a role in removing impuritiesShaking/oscillating/vibrating mixersGas current separationFire retardantEngineering

The invention discloses an impurity cleaning device for improving equipment of a powder flame retardant. The impurity cleaning device comprises a material falling air duct (301), wherein a material falling barrel (302) is connected to the material falling air duct (301); an exhaust chamber (303) is arranged above the material falling barrel (302); a material falling fan (304) is arranged in the exhaust chamber (303) and is connected with the material falling air duct (301); an impurity cleaning pipe (305) is connected to the upper part of the exhaust chamber (303); an impurity cleaning fan (306) is connected onto the impurity cleaning pipe (305); an impurity barrel (307) is connected to the impurity cleaning pipe (305). According to the impurity cleaning device disclosed by the invention, impurity cleaning equipment is improved, the production efficiency is improved, and the impurity cleaning effect is improved. In addition, mixed materials are improved, and the effect of mixing the materials is improved.

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

Selective filtering precleaner

PendingCN113996522AReduce machine lossIncrease diversitySievingScreeningFeed processingSelective filter

The invention relates to a selective filtering precleaner, and belongs to the field of feed processing.The selective filtering precleaner comprises a machine body, a screen drum is rotationally connected into the machine body, a feeding pipe is arranged on the machine body, a discharging hopper is arranged at the bottom of the machine body, the feeding pipe is communicated with a precleaner pipeline and a receding pipeline, and the receding pipeline is communicated with the interior of the screen drum; the receding pipeline is communicated with the discharging hopper, a reversing mechanism is arranged on the feeding pipe and located between the precleaner pipeline and the receding pipeline, and the reversing mechanism is used for communicating the feeding pipe with the precleaner pipeline or communicating the feeding pipe with the receding pipeline. According to different conditions of the materials, the materials selectively enter the screen drum for preliminary cleaning or directly enter the discharging hopper for subsequent machining procedures, and the effect that the equipment abrasion degree caused by unnecessary use of a preliminary cleaning screen is reduced is achieved.

Owner:溧阳市久隆工程机械有限公司

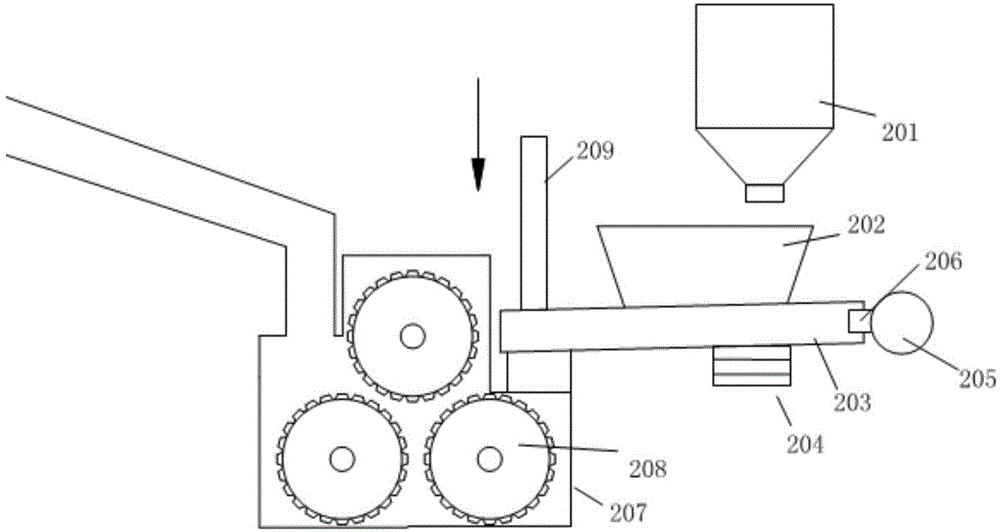

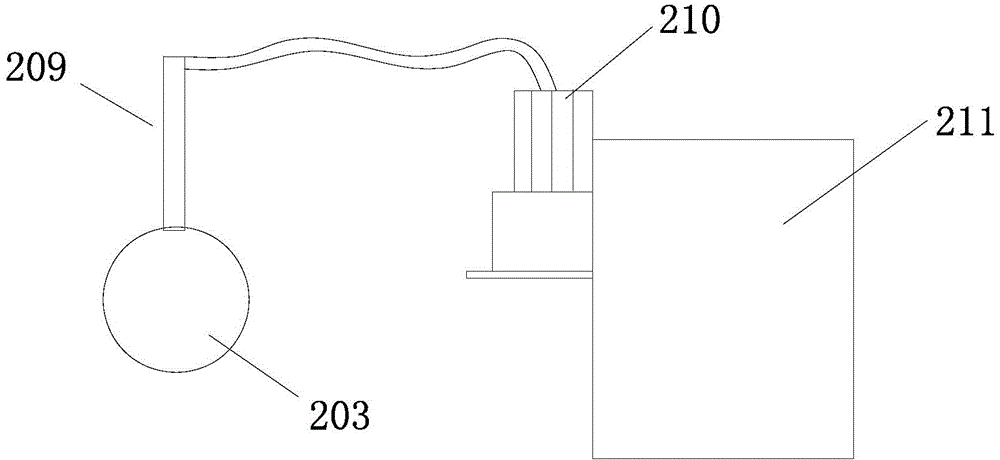

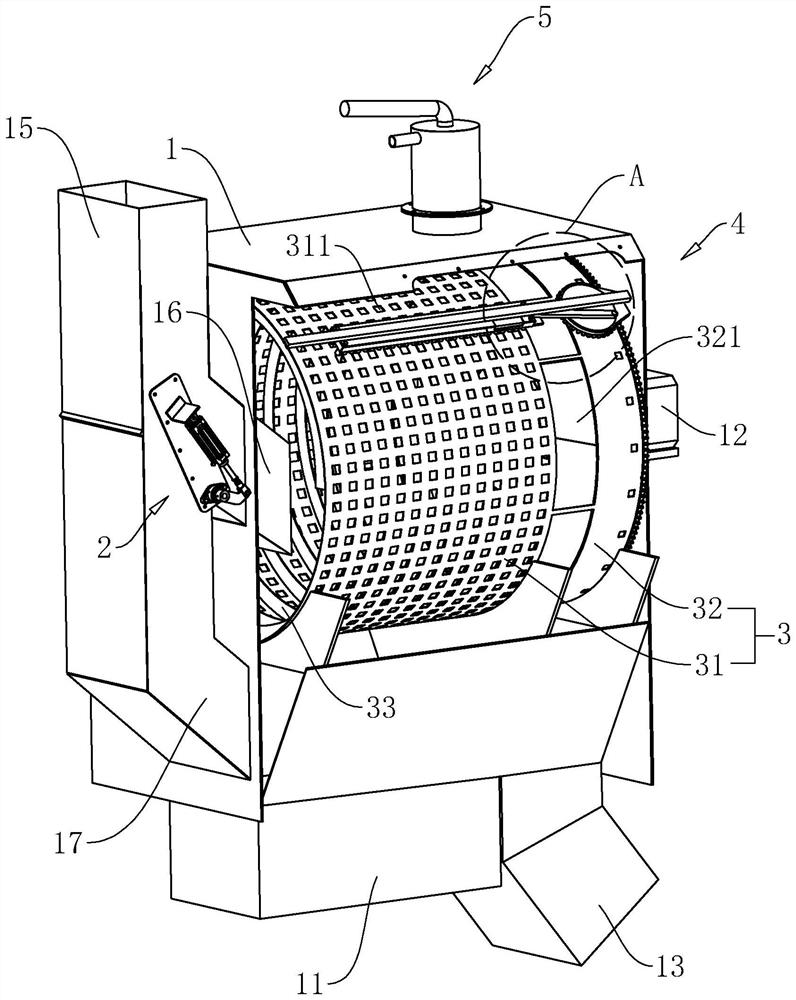

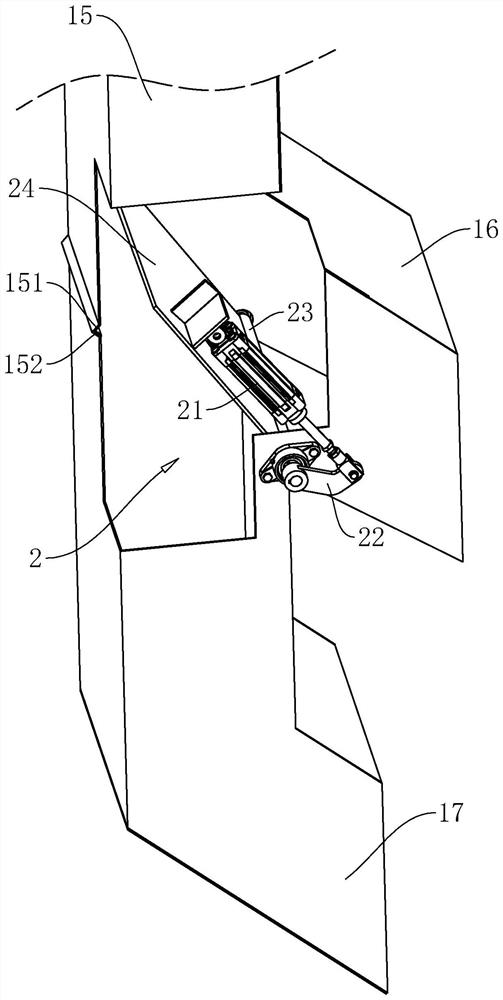

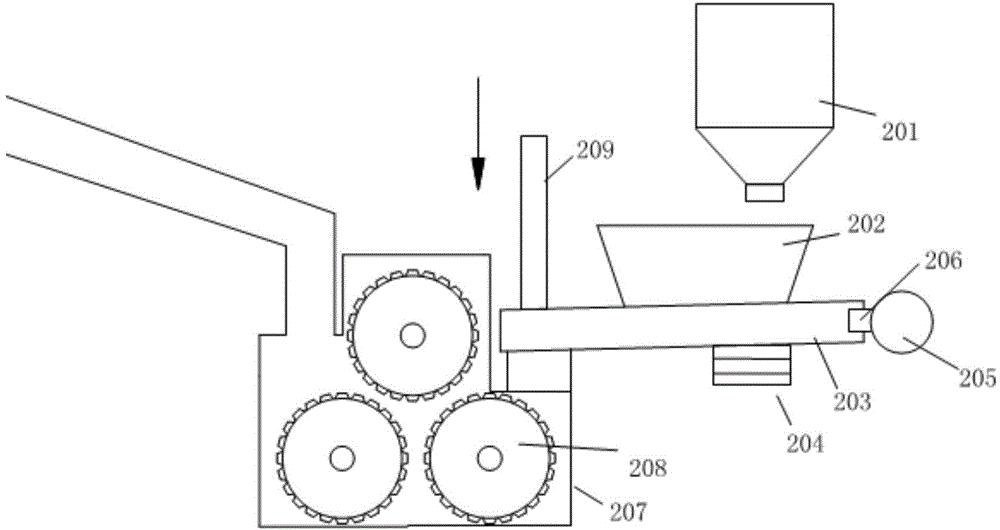

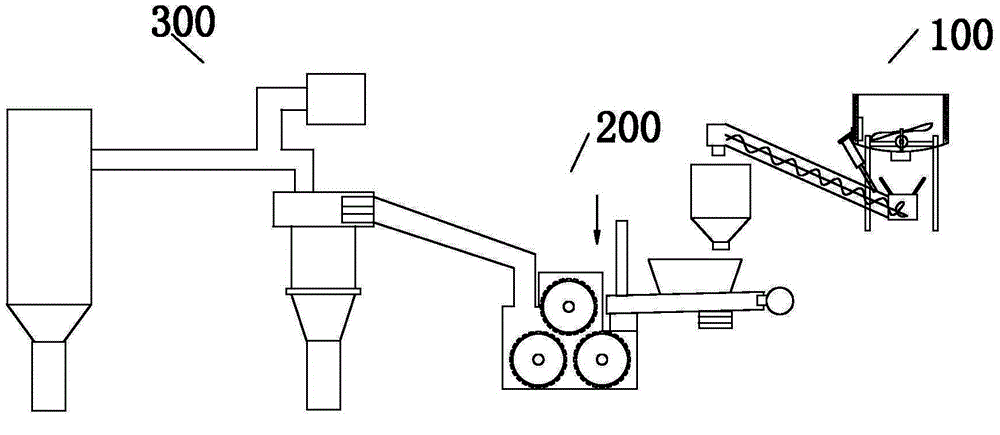

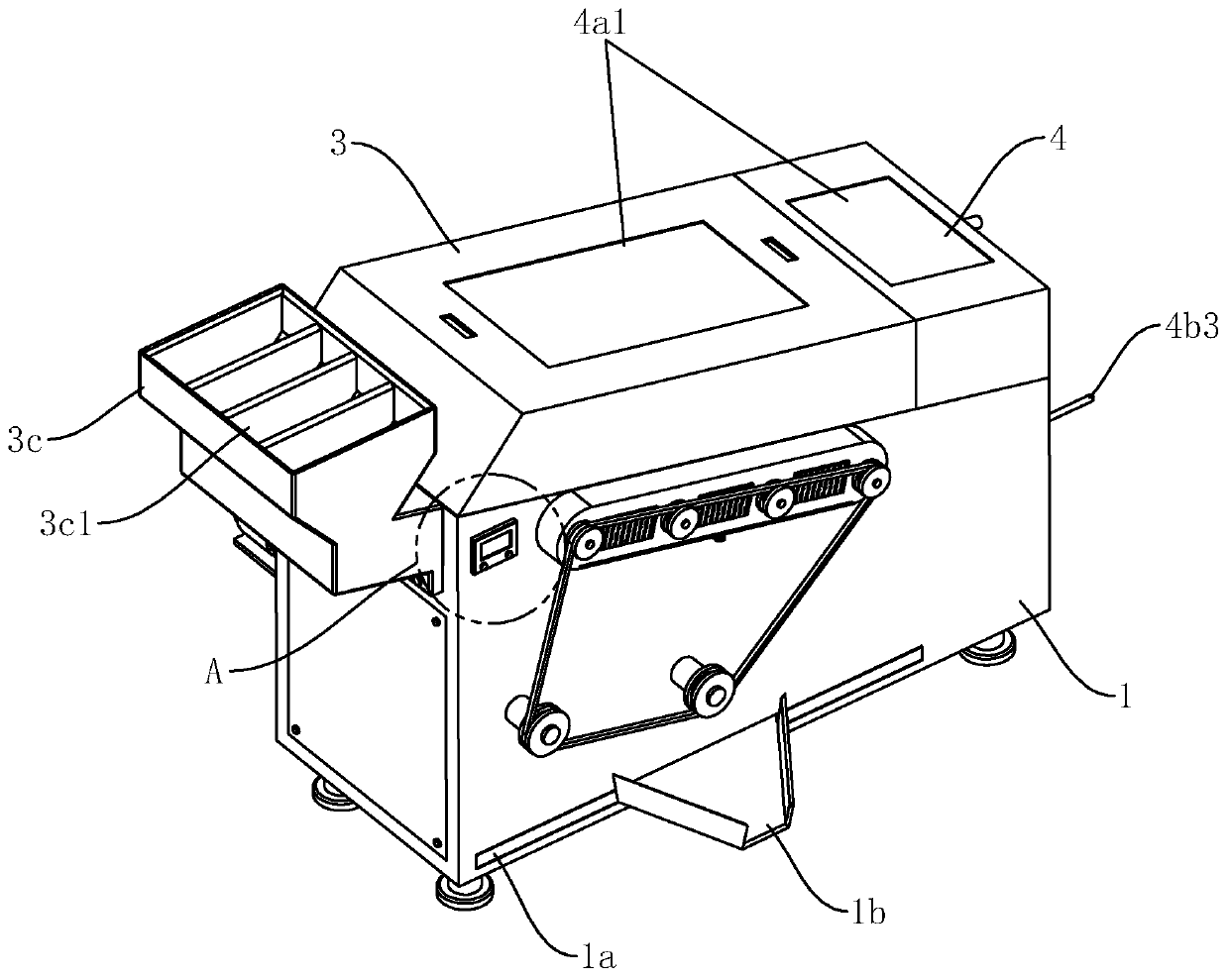

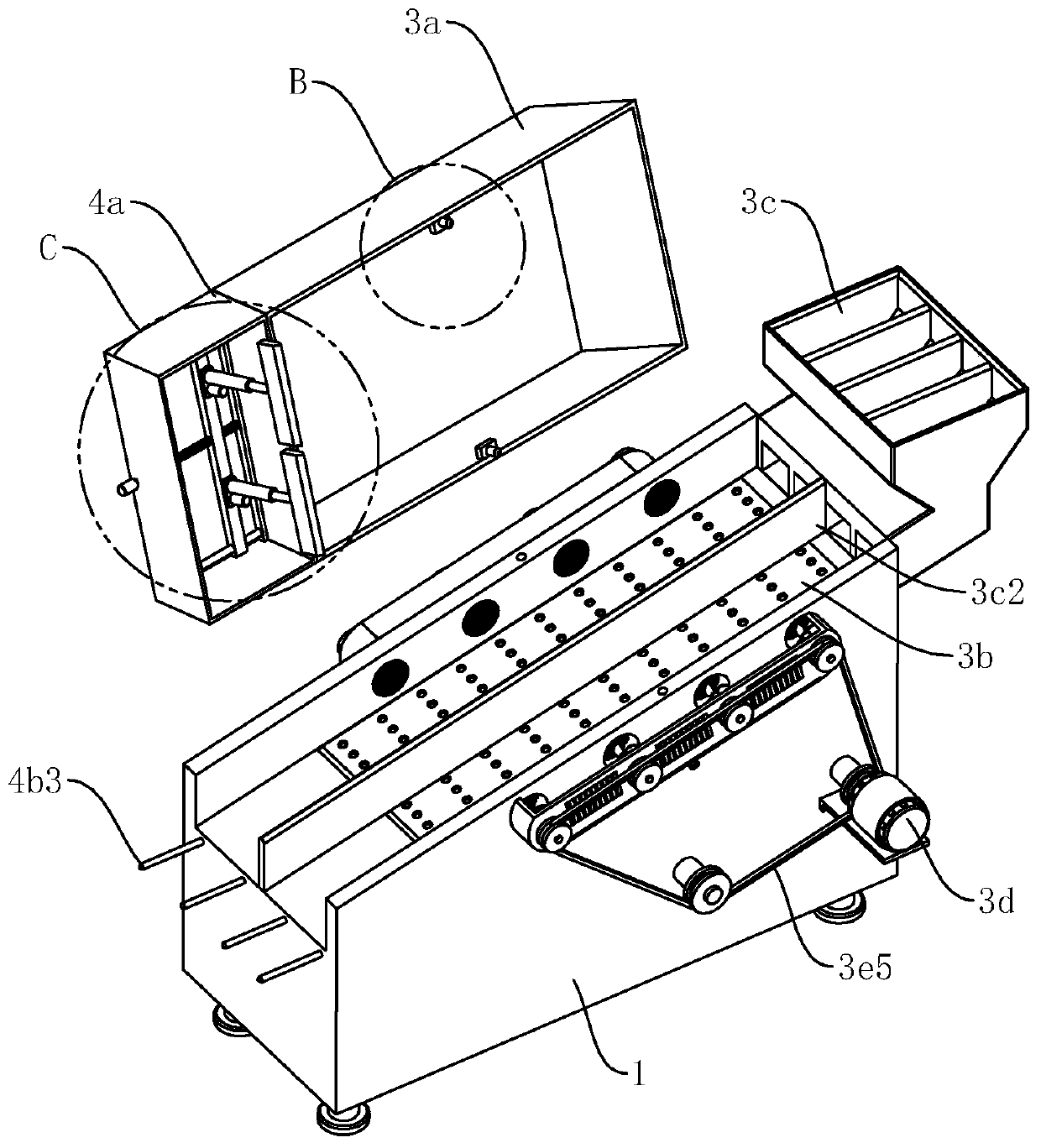

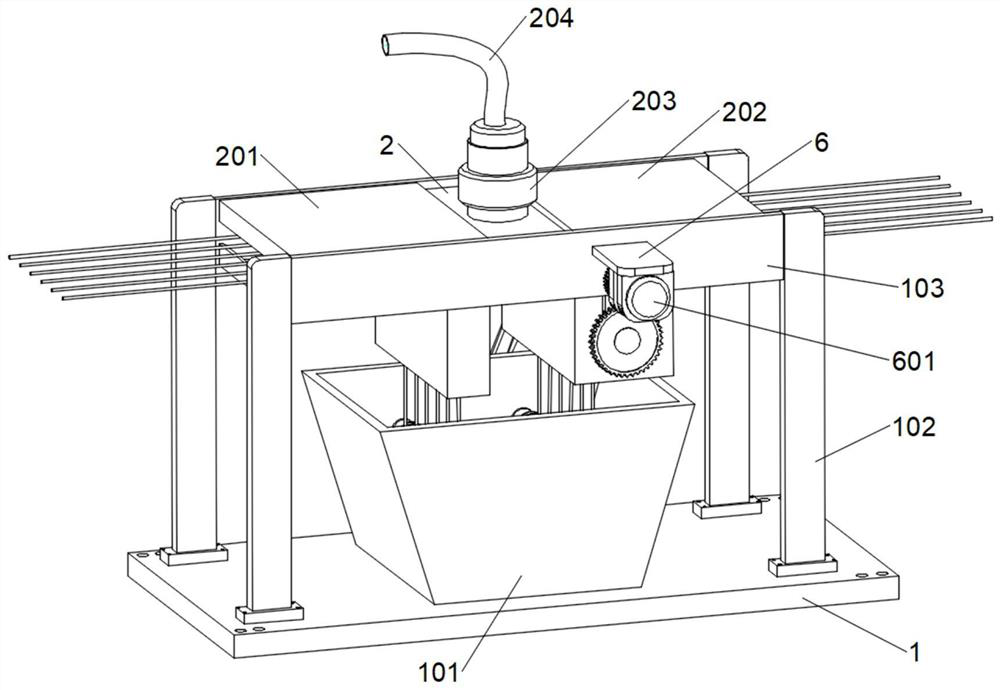

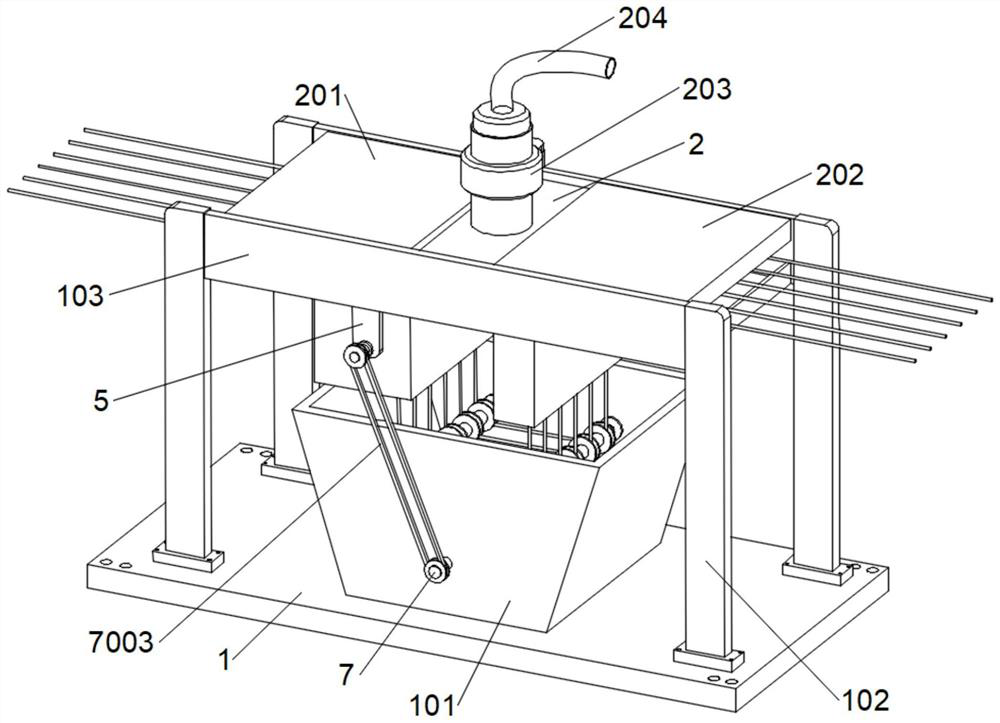

Powder flame retardant improving equipment

ActiveCN104826516AFully automaticIncrease productivityRotary stirring mixersMixer accessoriesGas cylinderEngineering

The invention discloses powder flame retardant improving equipment. The powder flame retardant improving equipment is provided with a heating stirrer (100), a mixer (200) and an impurity removal device (300) which are arranged from front to back in sequence, wherein the heating stirrer (100) comprises a rack (101); a stirring slot (102) is formed above the rack (101); a stirring blade (103) is arranged on the bottom of the stirring slot (102); a wall (104) of the stirring slot (102) is hollow; a heating sheet (105) is arranged in the wall (104); a discharge hole (106) is formed in the bottom of the stirring slot (102), and a material dropping slot (107) is formed below the discharge hole (106) and is connected with a connecting channel (108); a material dropping hole (109) is formed in the other end of the connecting channel (108); a feeding screw rod (110) is arranged in the connecting channel (108); a rotary gas cylinder (111) is fixed outside the wall (104); an output rod of the rotary gas cylinder (111) is fixed on the connecting channel (108).

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

Grain crop light-impurity treatment system

PendingCN110681585AAvoid confusionSave resourcesSievingGas current separationAgricultural engineeringElectric machinery

The invention relates to the technical field of agriculture product processing, in particular to a grain crop light-impurity treatment system which comprises a screening box, a controller, a screeningmechanism and a holding mechanism. The top part of the screening box is of a wedge-shaped structure; the screening mechanism comprises a first cover plate, a filter plate, a clapboard, a drive motor,two groups of adsorption assemblies and two groups of jacking assemblies; the holding mechanism comprises a second cover plate, a pushing assembly and four plug pins; and the drive motor, the pushingassembly and the controller are electrically connected. According to the grain crop light-impurity treatment system provided by the invention, two kinds of grains can be subjected to light-impurity treatment at the same time, and meanwhile, impurities in grain crops are separately screened and collected, so that a secondary utilization effect can be achieved; the whole screening mechanism is driven by one motor, so that the manufacturing cost is saved, and the light-impurity treatment cost is reduced; and in addition, through designing an observation window, the transparency of the treatmentprocess is realized, and the working efficiency is further improved.

Owner:曲广成

Method for preparing silicon dioxide and aluminum oxide from coal ash

ActiveCN101993084BMild desilication reactionWeak corrosiveSilicaSolid waste disposalFoam concreteHigh pressure

The invention relates to a method for preparing silicon dioxide and aluminum oxide, in particular to a method for preparing silicon dioxide and aluminum oxide from coal ash. In the method, the coal ash, sodium carbonate and calcium oxide are used as raw materials, the sodium carbonate is causticized in situ by the calcium oxide, and is dissolved with alkali in a high-temperature high-pressure reaction system to form sodium silicate, calcium carbonate and desiliconized coal ash solid, wherein the sodium silicate solution is carbonated by CO2 to form silicon dioxide; and aluminum oxide and foamconcrete can be prepared from the calcium carbonate and the desiliconized coal ash by a soda lime sintering method. Residues after aluminum oxide preparation can be used as a raw material for preparing a tail gas purification absorbent in cement and chemical plants and coal burning boilers, and the foam concrete. Compared with the prior art, the method has the advantages of weak reacting solutioncorrosion, high desiliconization rate, low metal content of prepared sodium carbonate and high white carbon black quality, high aluminum oxide extraction rate and the like; meanwhile, the raw material source is wide, the process is simple, the production cost is low, and the product additional value is high.

Owner:CHINACOAL PINGSHUO GRP

Grain storage system for grain storage

InactiveCN110946009AImprove work efficiencyReduce the use of manpowerSievingAgriculture tools and machinesDrive motorProcess engineering

The invention discloses a grain storage system for grain storage, and relates to the technical field of grain storage. The system includes a first storage tank, a first conveying cylinder, an impurityremoval box, a drying cylinder, a second storage tank, a second conveying cylinder, a material storage bin and an impurity storage box. The storage system is of a continuous type, continuous impurityremoval, drying and storage of grains can be carried out, not only can the work efficiency be increased, but also use of manpower can be reduced, and the economic benefits can be improved indirectly;through combined use of a first filter net, a fan, a through hole, a fan group, a connection hole, an exhaust hole and a second filter net, lightweight impurities and fallen grain hulls which are contained in the grains can be removed, the effect of impurity removal of the grains can be achieved, and the quality of the grains is improved; and through combined use of a drive motor, a central shaft, an adjustment plate and a material discharge hole, the grains can be introduced evenly into the material storage bin, so that accumulation of the grains in the material storage bin is prevented, andthe service life of the material storage bin is increased.

Owner:安徽都灵精密机械有限公司

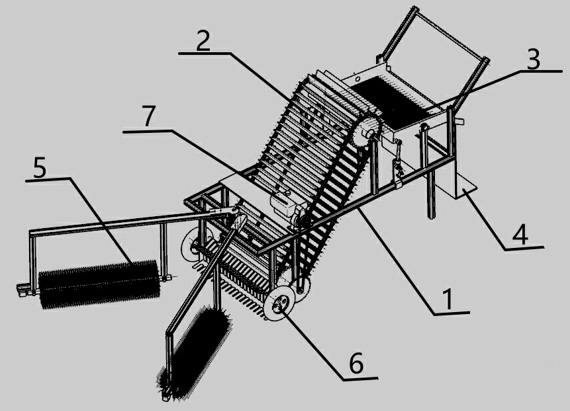

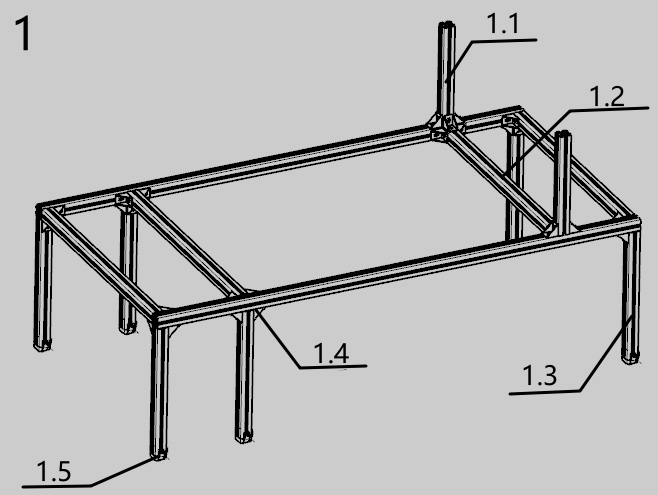

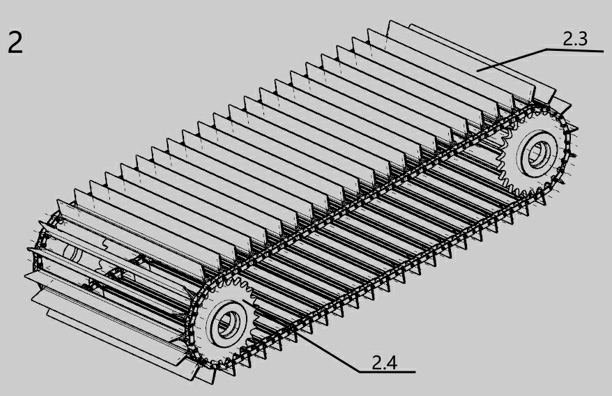

Ground dropped walnut harvesting machine

InactiveCN113207442AExpand the collection areaAchieve jitterSievingScreeningWalnut NutMachine control

The invention provides a ground dropped walnut collecting machine. The machine comprises a support structure, a conveying belt device, an impurity removing device, a collecting device, a v-shaped rolling brush device, a rolling brush device, a power system and a control system. All the devices and systems of the machine are connected through profiles in the support structure. The v-shaped rolling brush device and the rolling brush device are arranged at the head of the machine, rolling brushes with the adjustable angle are adopted for pre-collection, missing of walnuts can be prevented, and the proper angle can be adjusted according to actual conditions; the conveying belt device and the power system are arranged in the middle of the machine, the conveying belt device upwards conveys the walnuts conveyed by the rolling brushes, meanwhile, the hollow-out part of the conveying belt device plays a certain role in impurity removal, and the power system provides power for the conveying belt device; and the impurity removing device and the collecting device are arranged at the tail of the machine, a rocker mechanism converts rotation of motors into telescopic motion of rods, a collecting basket is enabled to shake, then the walnuts obtained after impurity removal enter the collecting device, and collection of the dropped walnuts is completed. The control system of the machine controls rotation of the motors in the v-shaped rolling brush device, the rolling brush device and the impurity removal device, so that movement of all the devices is achieved; and the machine completes collection of the dropped walnuts through the combined action of all the devices and systems, is high in efficiency, saves manpower, and is suitable for being used in small and medium-sized walnut planting areas.

Owner:XINJIANG UNIVERSITY

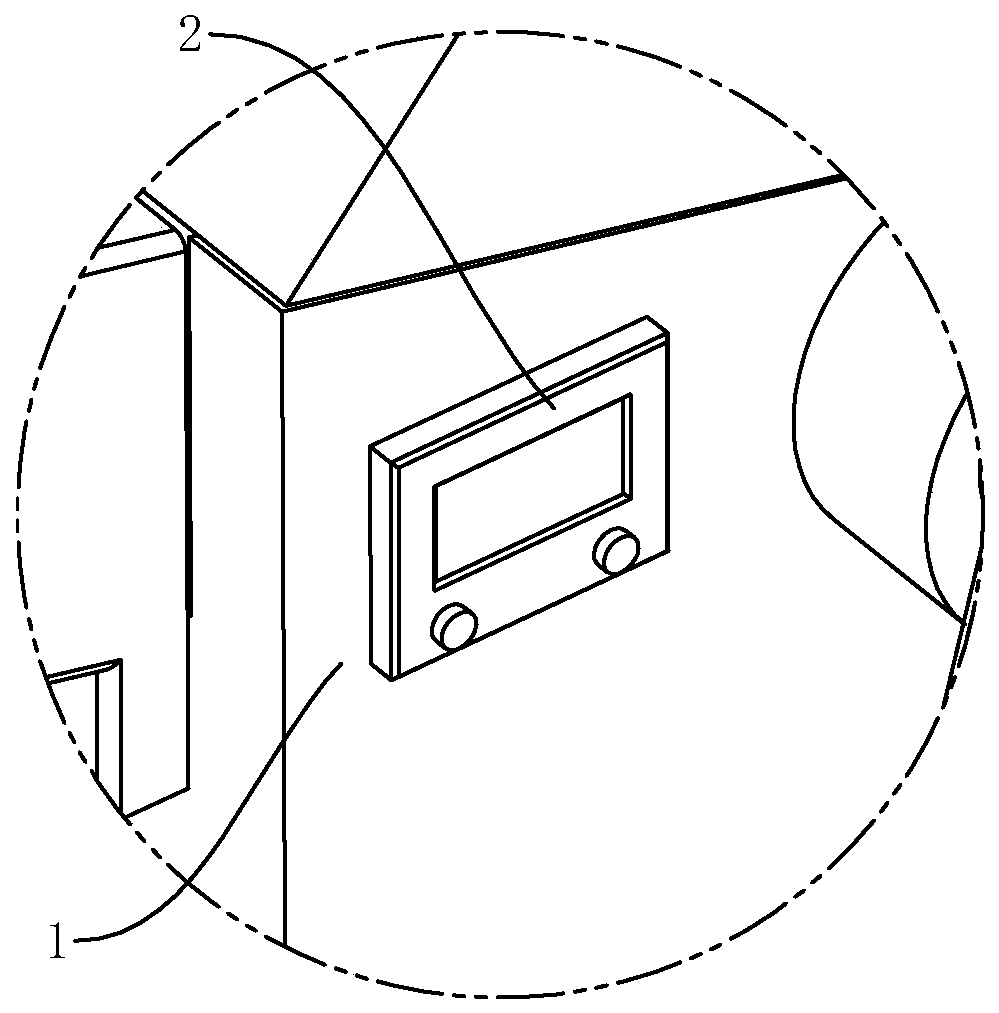

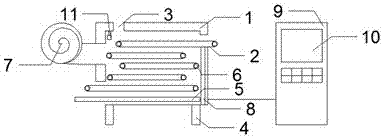

Air speed adjustment dedusting-type conveying belt dryer

InactiveCN107388784AEasy to producePlay a role in removing impuritiesElectrostatic separationDrying machines with progressive movementsEngineeringMechanical engineering

The invention belongs to the field of cereal machines, and relates to an air speed adjustment dedusting-type conveying belt dryer. The air speed adjustment dedusting-type conveying belt dryer comprises a heater, conveying belts, an exhaust hole, a support, a scraper blade, an impurity collecting plate and vibrating motors. The heater is a hollow box-type heater. The conveying belts are arranged inside the heater in staggered and layered modes. One end of the conveying belt at the topmost layer and one end of the conveying belt at the bottommost layer both extend out of the heater. The scraper blade is arranged at an inlet of the conveying belt at the topmost layer, and the height from the scraper blade to the conveying belts can be adjusted. Each conveying belt is of a filter screen structure. The pulling-type impurity collecting plate is arranged at the bottommost side of the heater. The vibrating motors are arranged inside rollers of the conveying belts. One side of the heater is provided with a draught fan and a corresponding air port, and the inner wall of the other side of the heater is provided with an electrostatic dust collector. A console is connected with the heater and is further provided with a display screen. The display screen is connected with a high-temperature resistance camera arranged inside the heater.

Owner:朱浩杰

Magnesium-neodymium intermediate alloy and preparation method thereof

The invention relates to a magnesium-neodymium intermediate alloy and a preparation method thereof, and belongs to the technical field of metal materials and metallurgy. The magnesium-neodymium intermediate alloy comprises the following raw materials including, by weight, 10-15 parts of magnesium powder, 10-15 parts of neodymium powder and 0.1-0.15 part of a multi-element refining agent. The magnesium powder is added into a smelting furnace, a protective flux is added, slagging-off is conducted, the neodymium powder is added after slagging-off, the temperature is increased to 1050 DEG C after complete adding, the multi-element refining agent is added, the protective flux is added again after the temperature is increased to 1100 DEG C, secondary slagging-off is conducted, and a smelting material is prepared; brewing and boiling are carried out; ingot casting is carried out; testing is carried out; and carbon powder can serve as a pore-forming agent to decompose and release gas, on one hand, part of hydrogen in molten metal is taken away, on the other hand, nano-calcium-based powder is sintered at the temperature, a large number of porous structures are generated, the specific surface area of the nano-calcium-based powder is increased, the excellent adsorption performance is achieved, residual hydrogen and impurities in melt can be adsorbed, and the effects of refining and impurity removal are achieved.

Owner:LOUDI XINGXIN ALLOY

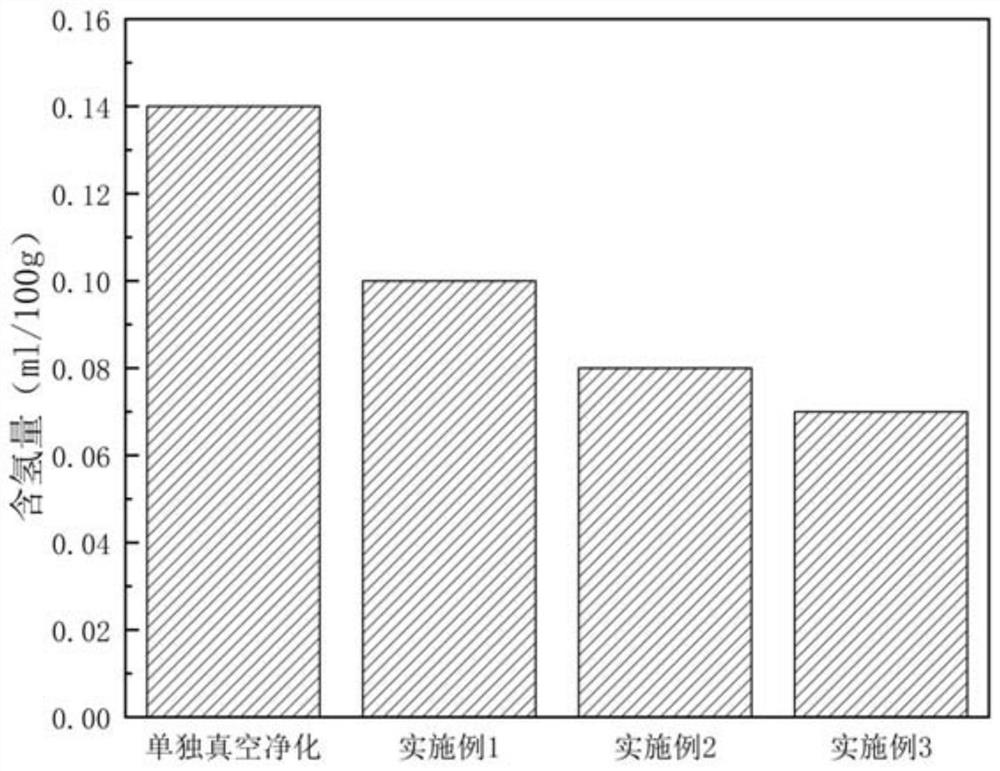

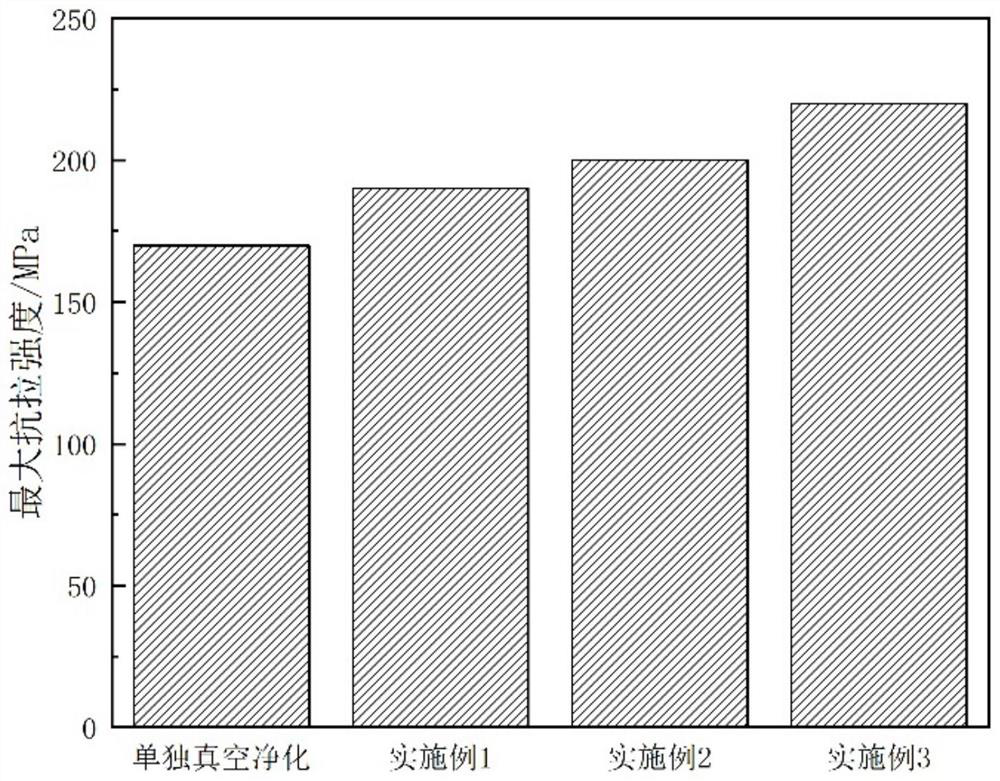

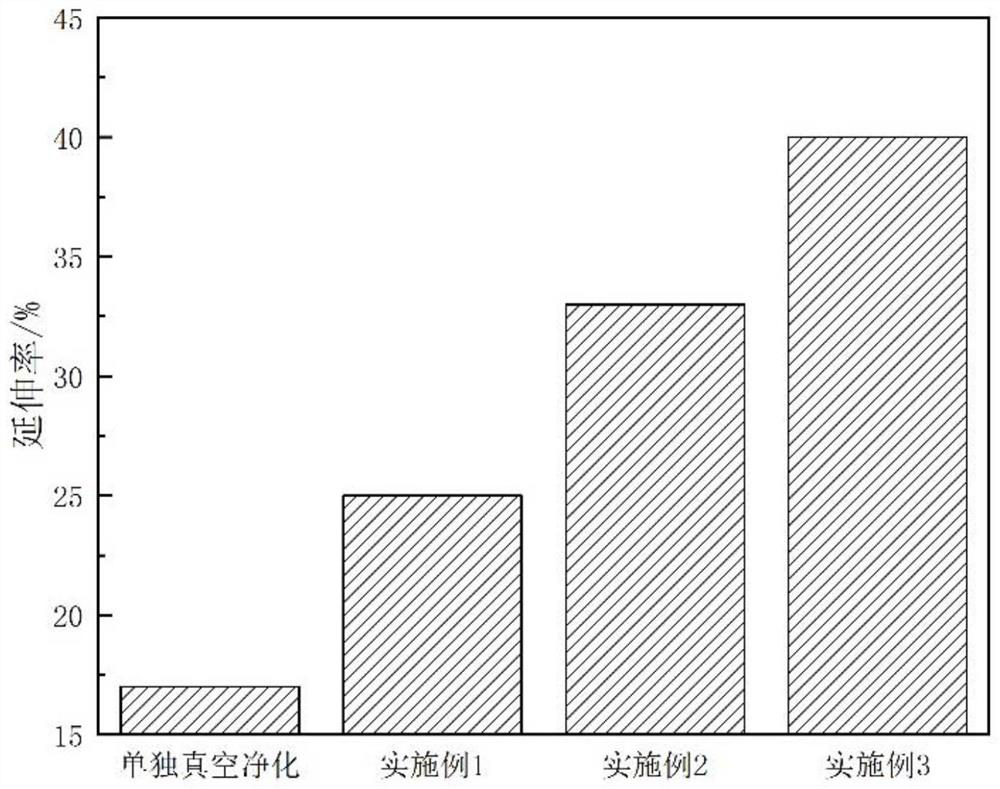

Melt purifying agent for vacuum melting of aluminum-magnesium alloy and preparation method thereof

The invention discloses a melt purifying agent for vacuum melting of a magnesium-aluminum alloy melt and a preparation method thereof. The purifying agent is prepared from the following components in percentage by mass: 1.0-3.0% of rubidium bromide, 0-0.5% of phenolic resin and pure aluminum . The method for preparing the aluminum-based composite material purifying agent comprises the following steps: proportioning, grinding, drying, ball-milling and granulating to prepare particles with the particle size of 1-10mm. The purifying effect of the melt purifying agent combined with a vacuum purifying technology is far better than the effect of singly using the vacuum purifying technology. By using the purifying agent, the melt purifying time can be greatly shortened, the heat loss of the melt is reduced, the sealing requirement of vacuum equipment is lowered, and the application range of the vacuum purifying technology is expanded.

Owner:DALIAN JIAOTONG UNIVERSITY

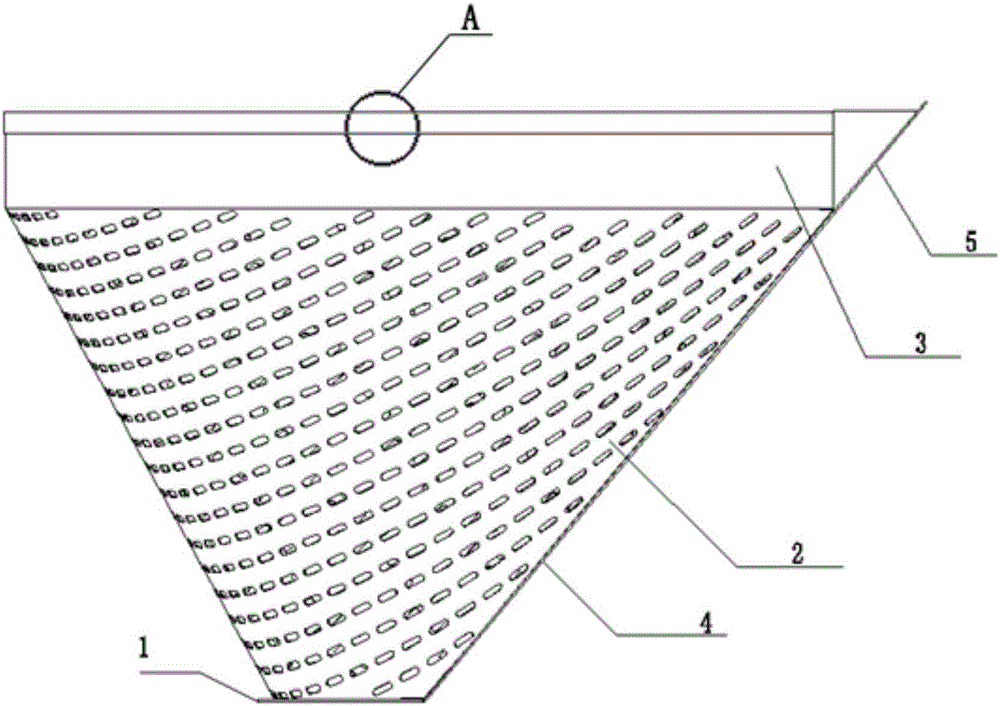

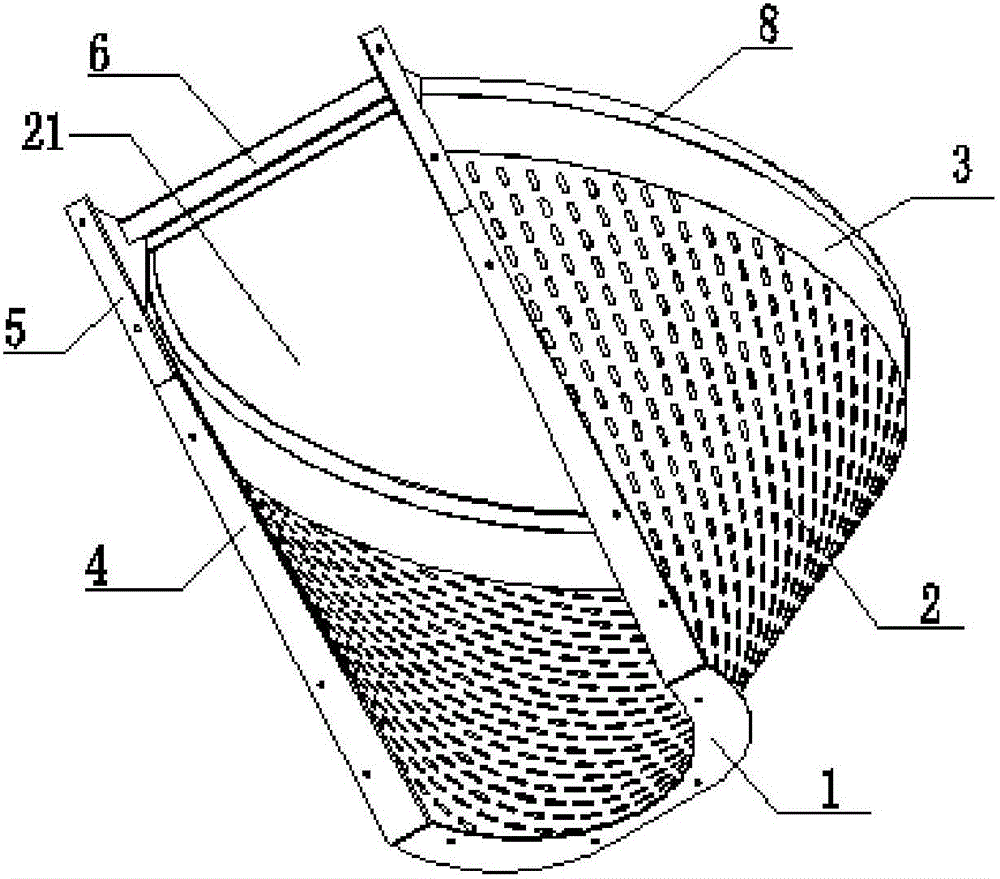

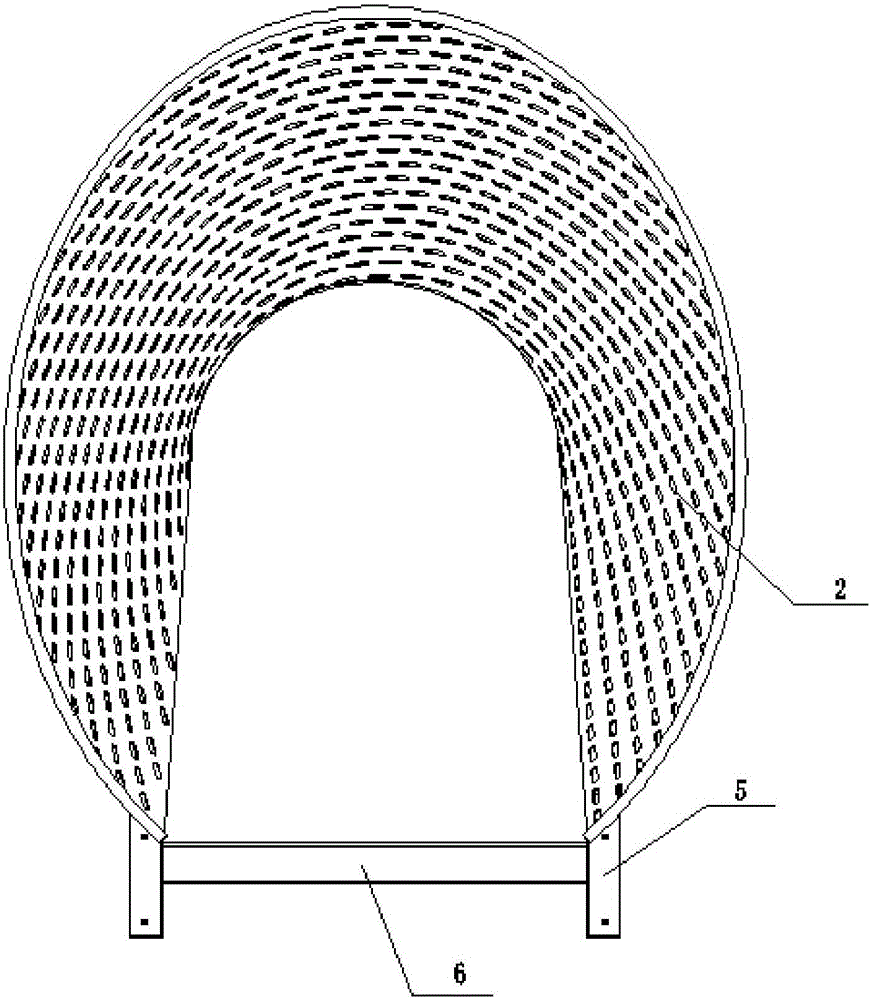

Hopper for sugarcane harvester

The invention discloses a hopper for a sugarcane harvester. The hopper comprises a bottom installation plate, a lower surrounding plate, an upper surrounding plate, a side installation plate, an upper installation base, a supporting plate, a hoop and a reinforcing surrounding plate, wherein the upper portion of the bottom installation plate is connected with the lower surrounding plate, the upper portion of the lower surrounding plate is connected with the upper surrounding plate, the upper surrounding plate is an annular bent face plate, and the shape of the upper surrounding plate is matched with the shape of the upper end face of the lower surrounding plate. For reinforcing the strength of the hopper, the reinforcing surrounding plate is welded to the upper portion of the upper surrounding plate after wrapping the hoop, and the hoop is a reinforcing rib with the shape and size matched with those of the upper end face of the hopper. The opening of the harvester is attached to and fixedly connected with a conveying arm of the sugarcane harvester, and a notch at the opening abuts against a feed port of the conveying arm. Due to the design of through holes evenly distributed in the lower surrounding plate, the weight of the hopper can be effectively reduced, a certain impurity removal effect can be achieved, and mud and slag can be discharged out of the hopper through the through holes of the lower surrounding plate; by adding the hoop, the strength of the hopper is firmer, deformation is prevented, and the service life is prolonged.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

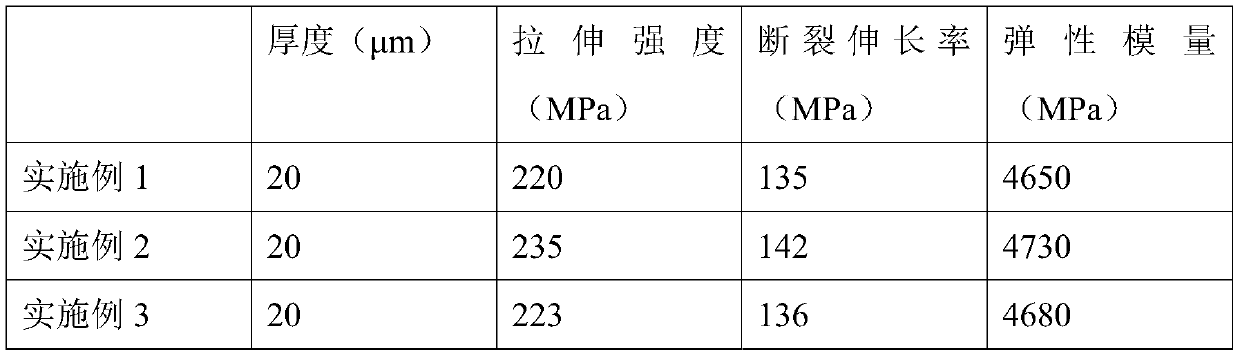

Method for preparing PET film from waste PET material

InactiveCN111138697APlay a role in removing impuritiesSmall molecular weightPlastic recyclingPtru catalystMaterials science

The invention belongs to the technical field of waste recycling, and particularly relates to a method for preparing a PET film from a waste PET material. According to the invention, waste PET is usedas a basic material; by mixing a solvent, on one hand, the material can be dissolved; on the other hand, impurities can be removed. Then, a primary reaction is carried out through the mixture; trace new PET is formed, and waste is combined; under the high-temperature and high-pressure action, degradation is performed and the molecular weight is reduced to form micromolecular PET; meanwhile, gas making is conducted by using an auxiliary agent to make new PET enter the waste; then, silane polymerization is performed to form a polymer, and the polymer is modifed to improve the performance; and finally through the use of a catalyst, macromolecular PET is formed to improve the performance.

Owner:陈志威

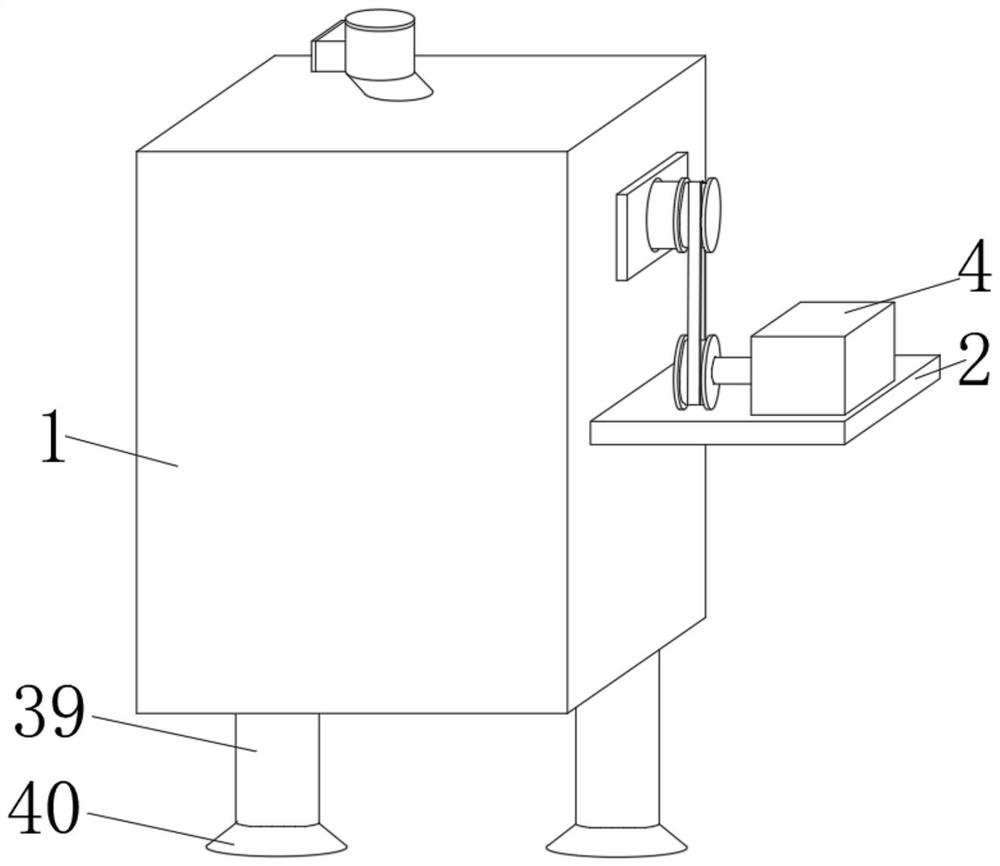

Yarn impurity removing and cleaning device based on spinning processing

PendingCN114108206AEffective cleaning and removalAvoid adsorptionLiquid/gas/vapor treatment machines driving mechanismsFibre cleaning/openingYarnWater storage tank

The invention relates to the technical field of spinning production equipment, in particular to a yarn impurity removing and cleaning device based on spinning processing, which comprises a base, a water storage tank is fixed at the center of the upper surface of the base, a stirring assembly is arranged at the bottom in the water storage tank, and supports are fixed at four top corners of the upper surface of the base. Transverse plates are fixedly installed between the ends of the two adjacent supports on the long side, and a driving assembly is arranged between the two transverse plates. Yarns can be effectively cleaned and subjected to impurity removal through the arrangement of the water storage tank and the stirring assembly, the yarns can be further subjected to impurity removal through the cooperation of the driving assembly and the extrusion assembly, water in the yarns or adsorbed small floccules which are not easy to remove can be sucked through the draught fan, and the impurities in the yarns can be effectively removed. And suction objects are guided into the dust collection bag through the guide pipe to be collected, so that later centralized treatment is facilitated, the drying and impurity removing functions are further achieved, the environment of a workshop is further guaranteed, and secondary pollution of impurities to the yarn is also avoided.

Owner:ANHUI HANLIAN TEXTILE CO LTD

Rice impurity removal device for agricultural machinery processing and impurity removal method thereof

InactiveCN113231312ACost reductionReduce workloadSievingGas current separationElectric machineryAgricultural engineering

The invention discloses a rice impurity removal device for agricultural machinery processing and an impurity removal method thereof. The rice impurity removal device comprises an impurity removal box, a second motor is fixedly connected to the interior of a groove, a second transmission shaft is in transmission connection to the upper end of the surface of the second motor, a rotating plate is fixedly connected to the upper end of the surface of the second transmission shaft, a spring is fixedly connected to the surface of one side of the interior of each buffer groove, and a sieve plate is fixedly connected to the end, away from the corresponding spring, of each connecting block. According to the rice impurity removal device, the groove is arranged, the second motor arranged inside the groove controls the second transmission shaft to rotate, so as to drive the rotating plate, a connecting pipe and a collecting hopper to rotate, the connecting blocks are slidably connected with the buffer grooves under the action of the springs, the connecting blocks drive the sieve plates to move left and right, then rice on the sieve plates is automatically sieved under the action of grids, impurities and particle dust are blocked on the sieve plates under screening of the sieve plates, the cost of manual screening can be reduced, the workload of workers is greatly reduced, and time and labor are saved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com