Hopper for sugarcane harvester

A harvester, sugarcane technology, applied in harvesters, applications, agricultural machinery and implements, etc., can solve the problems of high production cost of cane sugar, lack of competitiveness, low degree of mechanization, etc., to reduce its own weight, prevent deformation, and achieve strong strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

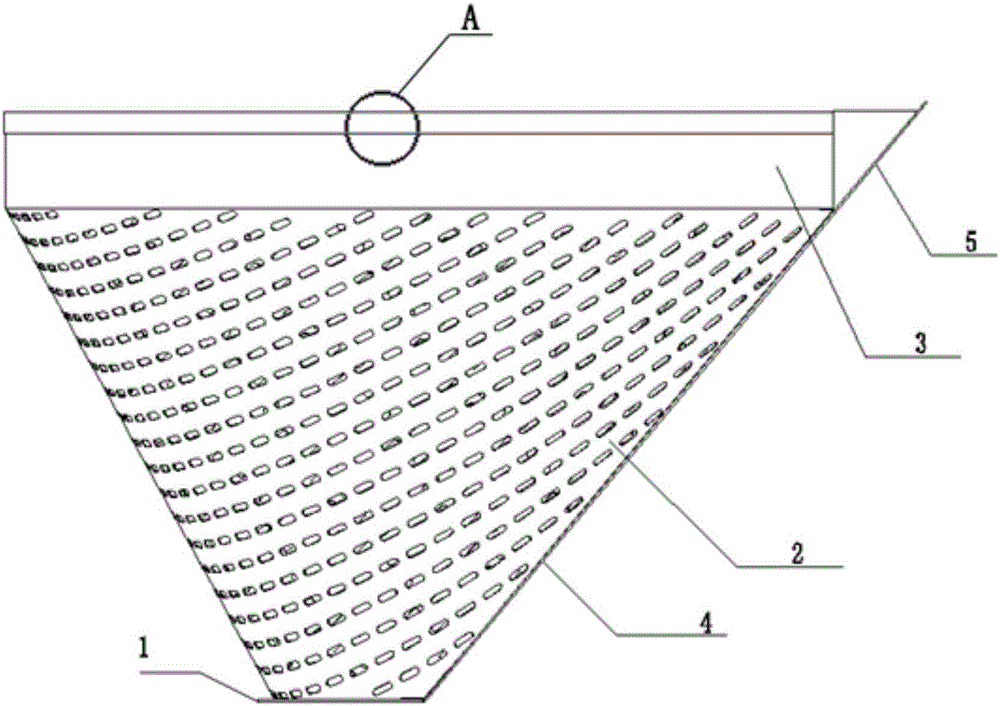

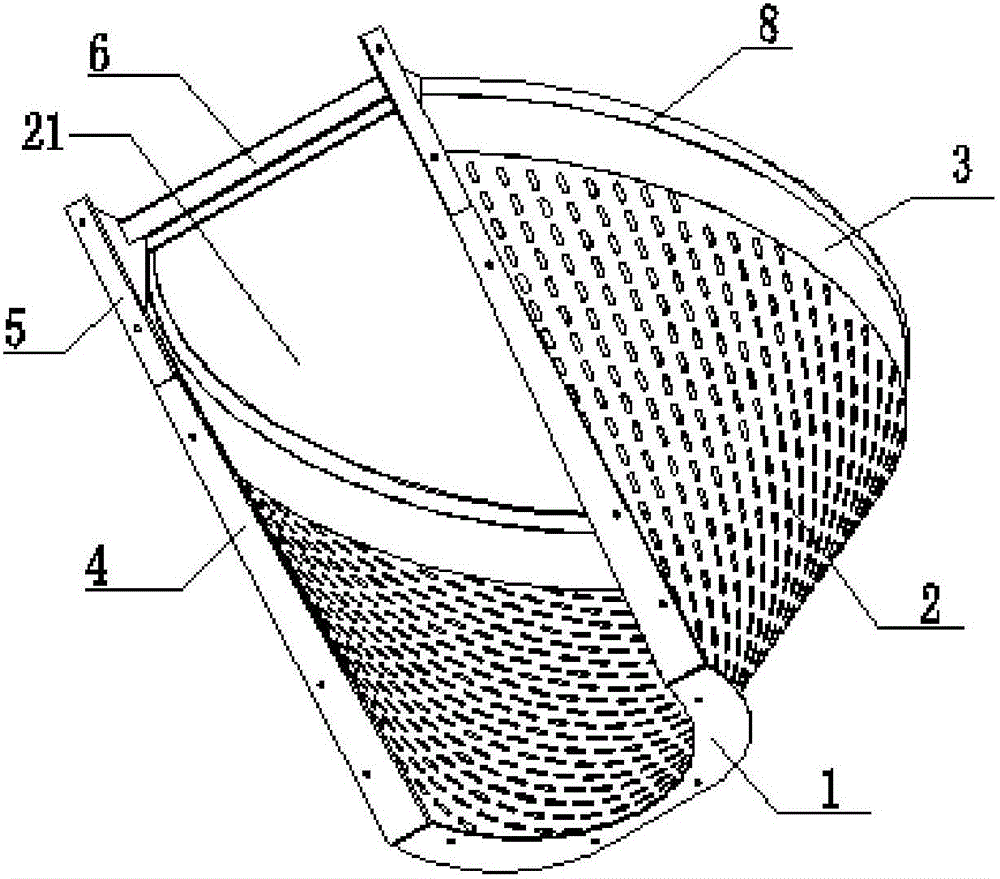

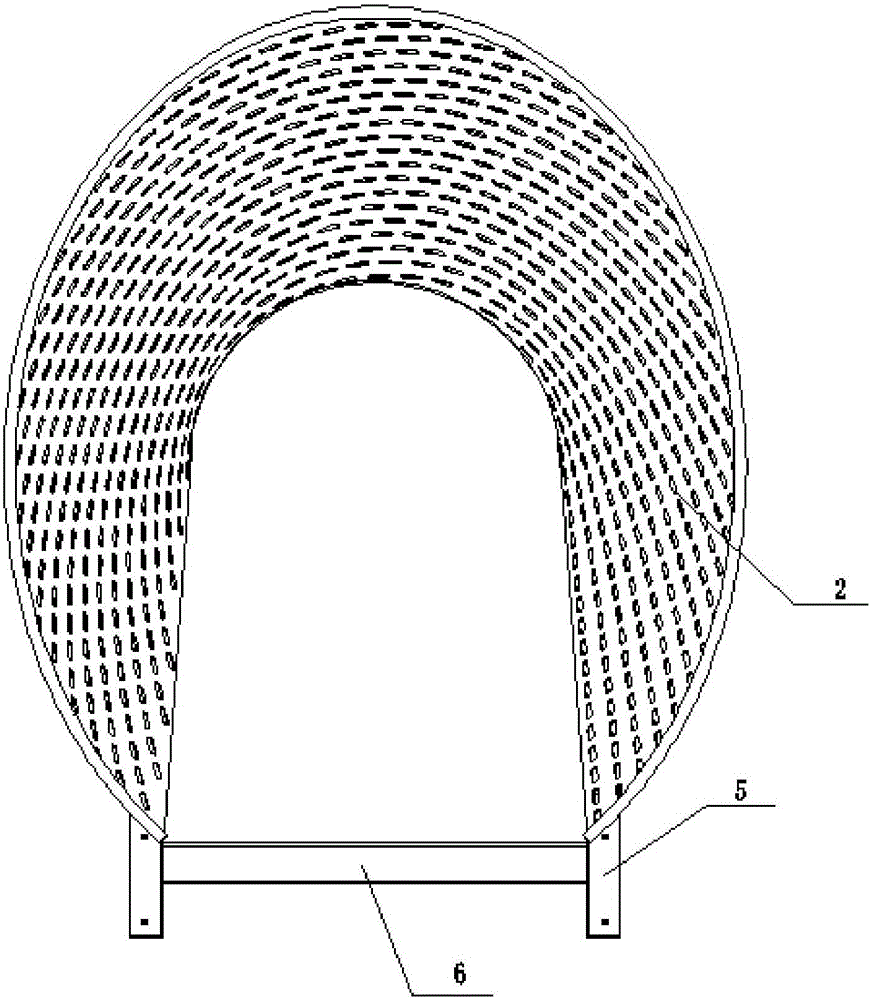

[0017] like Figure 1-4 Shown: a hopper for a sugarcane harvester, including a bottom mounting plate 1, a lower wall plate 2, an upper wall plate 3, a side mounting plate 4, an upper mounting seat 5, a support plate 6, a hoop 7, and a reinforcing wall plate 8, The bottom mounting plate 1 is connected with the lower wall 2, the mounting bottom 1 is a ring-shaped mounting panel with through holes, and the through holes are used for threaded connection and fastening with other components, and the lower wall 2 is a funnel-shaped curved panel. A number of through holes are evenly distributed on the surface of the board, and one side of the peripheral conical surface opening 21, the lower wall 2 is connected to the upper wall 3, the upper wall 3 is a ring-shaped curved panel that matches the shape of the upper end of the lower wall 2 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com