Method for separating and recycling positive plates of waste lithium iron phosphate batteries

A lithium iron phosphate battery, separation and recycling technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as poor performance of lithium-ion batteries, failure to reach lithium iron phosphate products, complex process routes, etc. , to achieve the effect of maintaining toughness, low processing cost and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

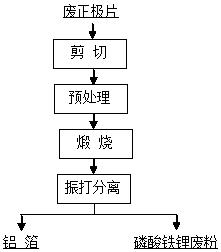

[0036]Step A, cutting: Cut the positive electrode sheet of the waste lithium iron phosphate battery into 20 cm long pieces or fragments, and at the same time separate the cut positive electrode sheet into loose shapes.

[0037] Step B, pretreatment: Put the waste pole pieces into the sintering furnace, and feed 99.95% argon gas into the sintering furnace, so that the oxygen concentration in the sintering furnace is 50 ppm, and the furnace pressure is 20 Pa.

[0038] Step C, calcining: heat up the sintering furnace at a rate of 1°C per minute for 6 hours, and keep it warm for 6 hours when the temperature reaches 360°C to obtain calcined spent pole pieces.

[0039] Step D, vibration separation: put the calcined waste pole pieces into a vibrating screen with a screen mesh of 5 meshes in batches, and add 1 kg of steel balls with different particle diameters between 5-15 mm in diameter at the same time to vibrate Sieve and vibrate at a frequency of 60 beats per minute to obtain alu...

Embodiment 2

[0042] Step A, cutting: Cut the positive electrode sheet of the waste lithium iron phosphate battery into 25 cm long pieces or fragments, and form them loosely.

[0043] Step B, pretreatment: Put the waste pole pieces into the sintering furnace, and feed 99.99% nitrogen gas into the sintering furnace, so that the oxygen concentration in the sintering furnace is 500ppm, and the furnace pressure is 120 Pa.

[0044] Step C, calcining: heat up the sintering furnace at a rate of 3°C per minute, the heating time is 2.72 hours, and keep the temperature for 1 hour when the temperature reaches 490°C to obtain the calcined spent pole piece.

[0045] Step D, vibration separation: put the calcined waste pole pieces into a vibrating screen with a mesh of 50 meshes in batches, and add 2 kg of steel balls with different diameters between 5-15 mm in diameter at the same time to vibrate Sieve and vibrate at a frequency of 90 beats per minute to obtain aluminum foil and lithium iron phosphate w...

Embodiment 3

[0048] Step A, cutting: Cut the positive electrode sheet of the waste lithium iron phosphate battery into 35 cm long pieces or fragments, and form them into loose shapes.

[0049] Step B, pretreatment: put the waste pole pieces into the sintering furnace, and inject 99.995% neon gas into the sintering furnace, so that the oxygen concentration in the sintering furnace is 1000ppm, and the furnace pressure is 300 Pa.

[0050] Step C, calcining: heat up the sintering furnace at a rate of 6°C per minute for 1 hour, and keep it warm for 3 hours when the temperature reaches 360°C to obtain calcined spent pole pieces.

[0051] Step D, rapping and separating: put the calcined waste pole pieces into a vibrating sieve with a screen mesh of 5 meshes in batches, and add 3 kilograms of steel balls with different diameters between 5-15 mm in diameter at the same time to vibrate. Sieve and vibrate at a frequency of 120 beats per minute to obtain aluminum foil and lithium iron phosphate waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com