Device and method for recovering tin on circuit board

A recovery device and recovery method technology, applied in printed circuit, manufacturing tools, metal processing, etc., can solve the problems of low recycling efficiency of tin pot tin, achieve the effects of ensuring safety, improving economic benefits, and increasing recycling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

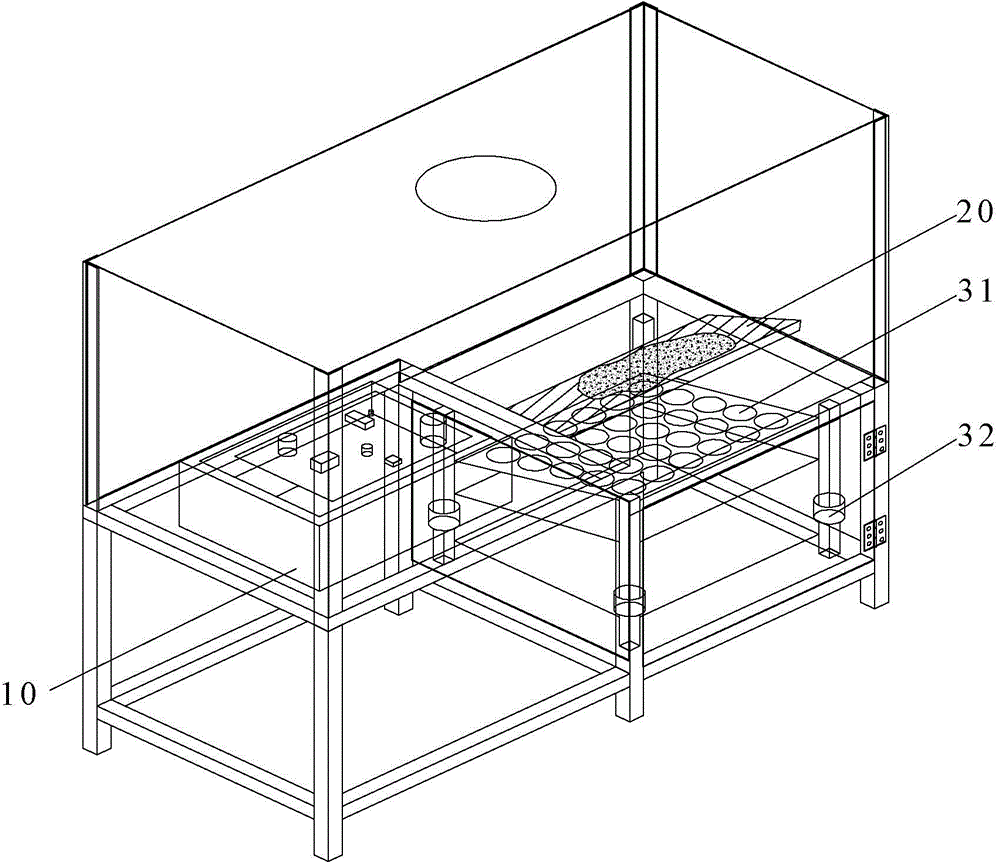

[0028] see figure 1 , according to the circuit board tin recovery device of the present invention, comprising: heating device 10, heating circuit board; Tin recovery plate 20, tin recovery plate 20 is arranged obliquely; The sorting device includes a screen 31 to sort the components on the circuit board according to their size. The use of tin recovery boards and component sorting devices instead of manual operations improves the dismantling efficiency of circuit boards, improves the recovery of tin on circuit boards, and ensures the safety of production employees. Compared with the original tin pot dismantling process The production efficiency can be increased by 70%, and the recovery rate of tin can reach more than 95%, which improves the economic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com