Treatment process for black and odorous sludge in black and odorous water body

A black and odorous water body and treatment process technology, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Pollution and other issues, to achieve the effect of increasing recovery, facilitating dehydration and drying, and reducing the difficulty of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

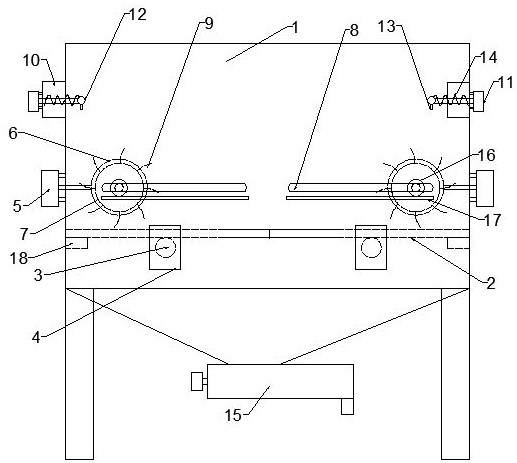

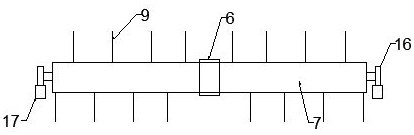

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] Such as Figure 1-2 Shown: the present embodiment is a treatment process for black and smelly sludge in a black and smelly water body, which comprises the following steps in turn:

[0028] Water body desilting: suck out and transport the silt in the water body through the mud pump;

[0029] Garbage cleaning: the sludge is transported to the screening equipment to separate the garbage in the sludge, and then the sand and mud are separated and then the screened sludge flows into the sedimentation tank;

[0030] Concentration and sedimentation: put the flocculant and the sedimentation agent into the sedimentation tank successively, so that the sludge settles at the bottom of the sedimentation tank to form sediment, and the liquid in the upper layer of the sedimentation tank is pumped out for purification and treatment, and then discharged back in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com