Selective filtering precleaner

A selective and initial cleaning technology, which is applied in the fields of filtering, dust removal, cleaning methods and appliances, etc., can solve the problems of increasing the internal wear degree of the initial cleaning sieve, so as to increase diversity, improve cleaning effect, and reduce the size of the machine. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-5 The application is described in further detail.

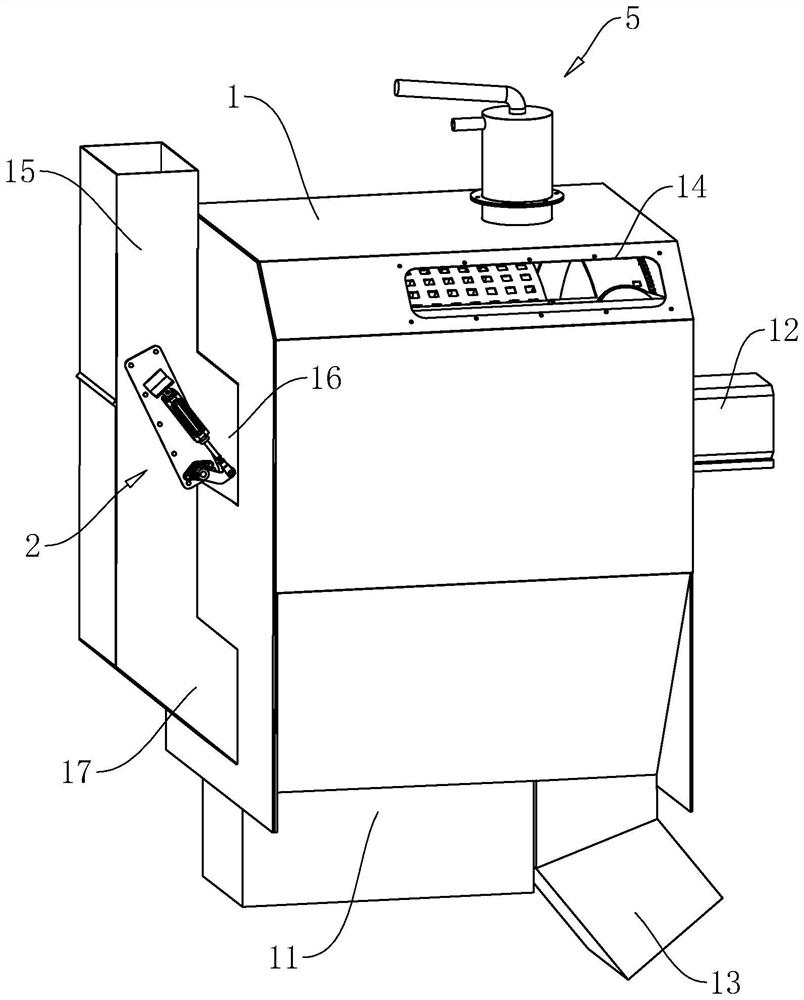

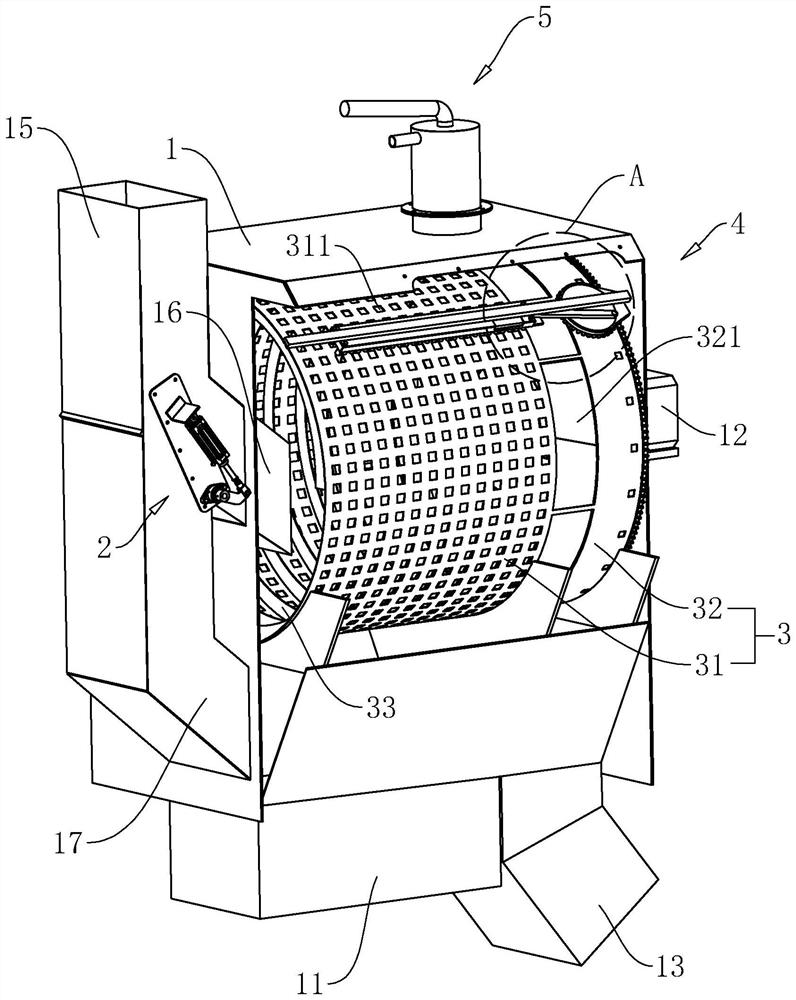

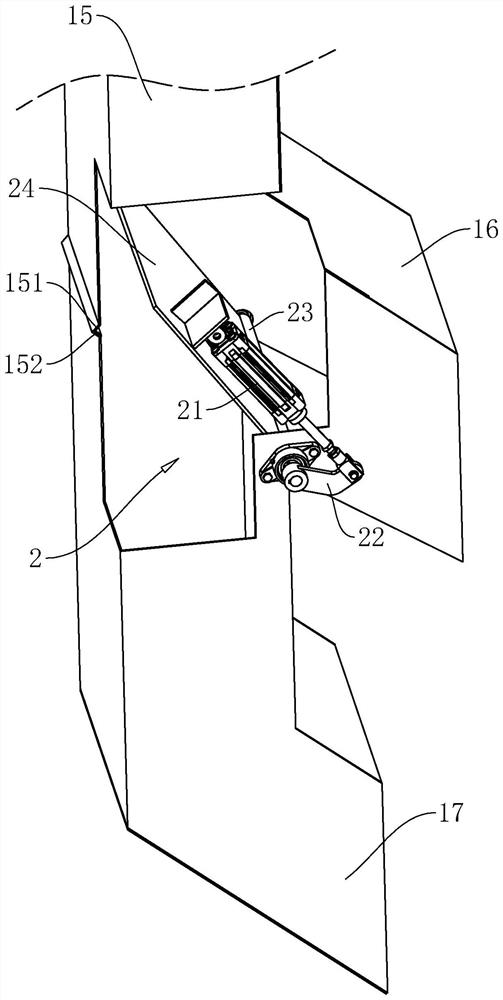

[0038] The embodiment of the present application discloses a kind of primary cleaning screen of selective filtration, such as figure 1 and 2 As shown, the machine body 1 is included, and the machine body 1 is provided with a sieve cylinder 3 for preliminary filtering and impurity removal processing of the material. The body 1 is provided with a feed pipe 15 for adding materials to the sieve cylinder 3. In the discharge hopper 11 for discharging the filtered raw material, a drive motor 12 for driving the screen cylinder 3 to rotate is arranged on the machine body 1 . The cylinder primary cleaning screen is used as the equipment in the first process of the material entering the processing line, which can be used for the selection of whether the material in the feeding pipe 15 enters the sieve drum 3 .

[0039] Such as figure 2 and 3As shown, the axis of the screen cylinder 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com