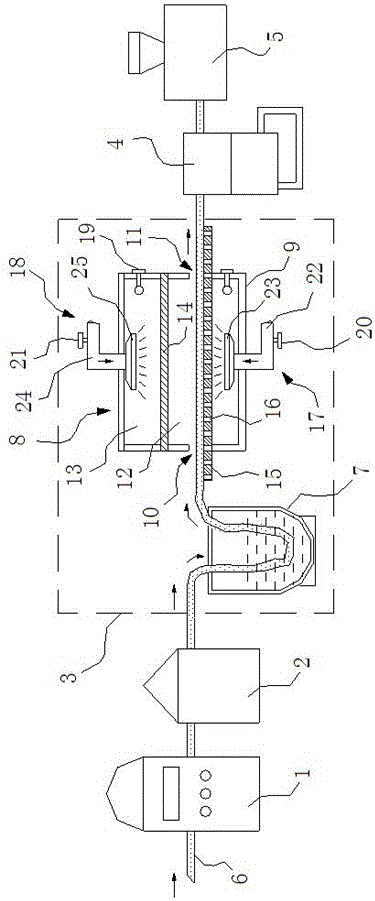

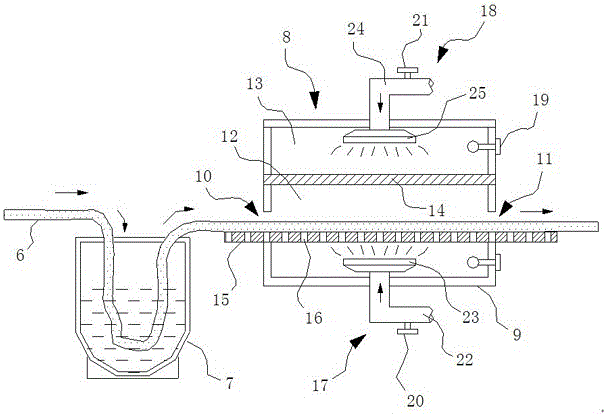

Long vehicle low-temperature steaming technology for fiber textiles and equipment

A technology of low-temperature steam and textiles, which is applied in the processing of textile materials, equipment configuration, textiles and papermaking, dry-cleaning fiber products, etc. It can solve the problems that affect the consumption of coal resources, combustion waste gas emissions, affect the effect of scouring, steam waste, etc., so as to eliminate the human body hazards, environmental protection, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific implementation methods. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0035] A long car low-temperature steam process for fiber textiles, is characterized in that, comprises the steps:

[0036] (1) Raw fabric preparation: According to the production demand, prepare the required fabric according to the quantity, and carry out inspection, turning and seaming;

[0037] (2) Singeing: Place the fabric in the singeing mechanism, make it pass through the flame quickly or rub it over the hot metal surface, and burn off the surface fluff;

[0038] (3), desizing: place the singeed fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com