Powder flame retardant improving equipment

A flame retardant and equipment technology, which is applied in the field of powder flame retardant improvement equipment, can solve problems such as low production efficiency, high cost, and unsatisfactory performance of powder flame retardants, and achieve the effect of improving the mixing effect and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

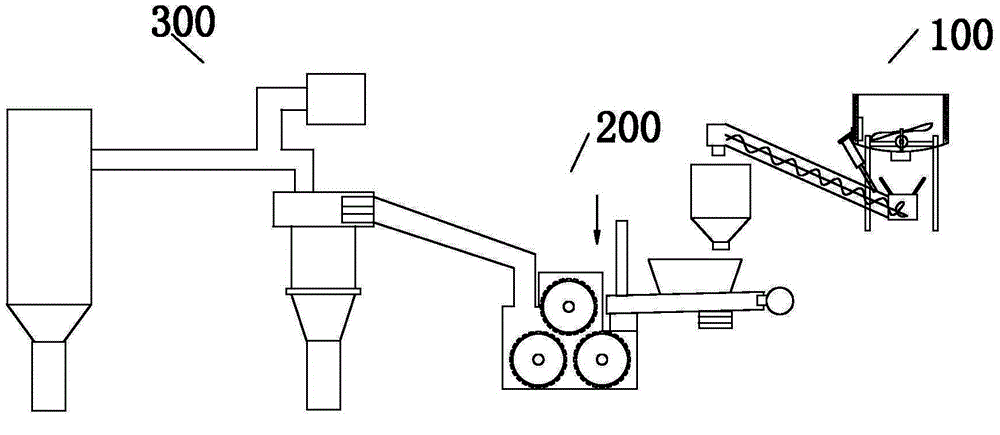

[0020] Embodiment: a kind of powder flame retardant improvement equipment, as attached figure 1 As shown, a heating agitator 100, a mixer 200 and an impurity removal device 300 are arranged in sequence from front to back;

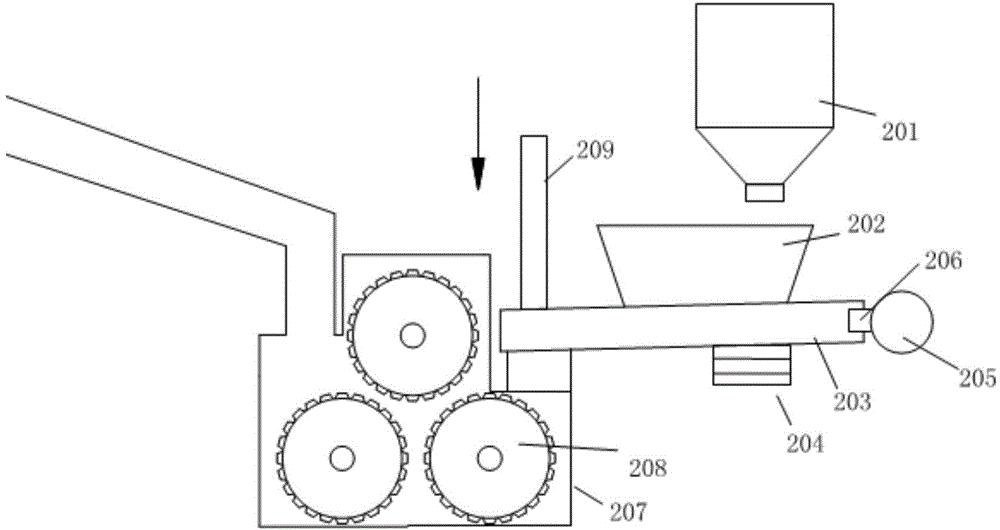

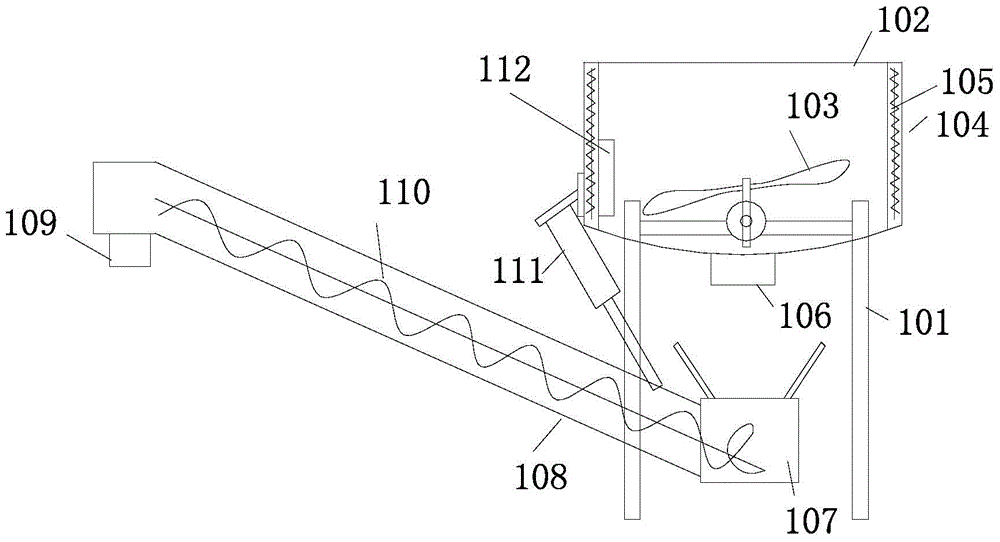

[0021] as attached figure 2 As shown, described heating stirrer 100 comprises frame 101, is provided with stirring tank 102 above frame 101, and the tank bottom of stirring tank 102 is provided with stirring blade 103, and the tank wall 104 of stirring tank 102 is hollow, and tank wall A heating plate 105 is arranged inside the tank wall 104; a mixing block 112 is arranged inside the tank wall 104, and the mixing block 112 is in the shape of a triangular pyramid. The tank bottom of the stirring tank 102 is provided with a discharge port 106, a blanking tank 107 is provided below the discharge port 106, the blanking tank 107 is connected with a connection channel 108, and the other end of the connection channel 108 is provided with a discharge port 109 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com