Method for preparing PET film from waste PET material

A film and waste technology, which is applied in the field of using waste PET materials to prepare PET films, can solve the problems of difficult operation and difficult recycling of waste PET plastics, and achieve the effect of improving performance and increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

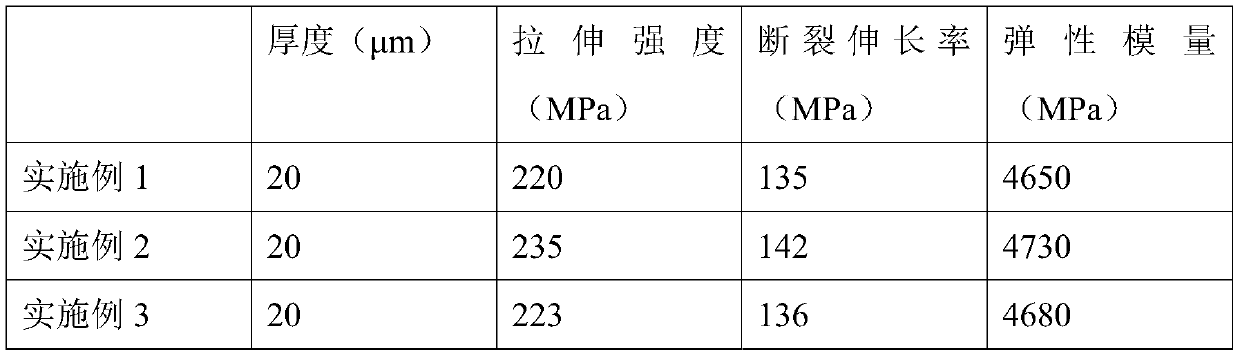

Examples

preparation example Construction

[0029] A kind of method utilizing waste and old PET material to prepare PET film, this preparation method comprises the steps:

[0030] (1) Take the waste PET material for washing, drying, crushing, passing through a 200-mesh sieve, collecting the sieved particles, mixing the sieved particles with the mixed solvent at a mass ratio of 3 to 9:18, heating and dissolving, and adding 10 sieved particles ~15% mixture, stirring at 600r / min for 20min;

[0031] (2) After the stirring is finished, raise the temperature to 110-120°C, increase the pressure to 0.4-0.6MPa, keep it warm for 5 hours, cool down to 60-70°C, add 6-12% auxiliary agent of sieved particles, discharge, and collect the mixture. The mixture was rotary evaporated to remove the solvent, and the residue was collected;

[0032] (3) Filter the residue, collect the filter cake, dry it, grind it at 1200r / min for 30 minutes, collect the ground material, mix the ground material, mixed silane raw material and water at a mass r...

Embodiment 1

[0036] The mixed solvent is a mixture of phenol and tetrachloroethane in a volume ratio of 6:5.

[0037] The mixture of terephthalic acid and ethylene glycol is mixed in a mass ratio of 6:7.

[0038] The auxiliary agent is ammonium bicarbonate and urea mixed in a mass ratio of 7:5.

[0039] The mixed silane raw material is made by mixing vinyltriethoxysilane and dimethyldiethoxysilane in a mass ratio of 6:5.

[0040] The monomer is bishydroxyethyl terephthalate.

[0041] The catalyst is a mixture of titanium dioxide and antimony acetate in a mass ratio of 6:3.

[0042] A kind of method utilizing waste and old PET material to prepare PET film, this preparation method comprises the steps:

[0043] (1) Wash the waste PET material, dry, pulverize, pass through a 200-mesh sieve, collect the sieved particles, mix the sieved particles with the mixed solvent at a mass ratio of 9:18, heat to dissolve, and add 15% of the sieved particles For the mixture, stir at 600r / min for 20min; ...

Embodiment 2

[0049] The mixed solvent is a mixture of phenol and tetrachloroethane in a volume ratio of 6:5.

[0050] The mixture is made of terephthalic acid and ethylene glycol in a mass ratio of 6:5.

[0051]The auxiliary agent is mixed with ammonium bicarbonate and urea in a mass ratio of 7:4.

[0052] The mixed silane raw material is made by mixing vinyltriethoxysilane and dimethyldiethoxysilane at a mass ratio of 6:4.

[0053] The monomer is bishydroxyethyl terephthalate.

[0054] The catalyst is a mixture of titanium dioxide and antimony acetate in a mass ratio of 6:3.

[0055] A kind of method utilizing waste and old PET material to prepare PET film, this preparation method comprises the steps:

[0056] (1) Wash the waste PET material, dry, pulverize, pass through a 200-mesh sieve, collect the sieved particles, mix the sieved particles with the mixed solvent at a mass ratio of 3 to 9:18, heat to dissolve, and add 13 sieved particles % of the mixture, stirred at 600r / min for 20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com