Magnesium-neodymium intermediate alloy and preparation method thereof

A magnesium-neodymium master alloy and magnesium powder technology, applied in the field of magnesium-neodymium master alloy and its preparation, can solve the problems of limiting the application of magnesium alloy, affecting the performance of use, pinholes on the surface of the alloy, etc., achieving strong adsorption and wrapping effect, promoting Dry, strong wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

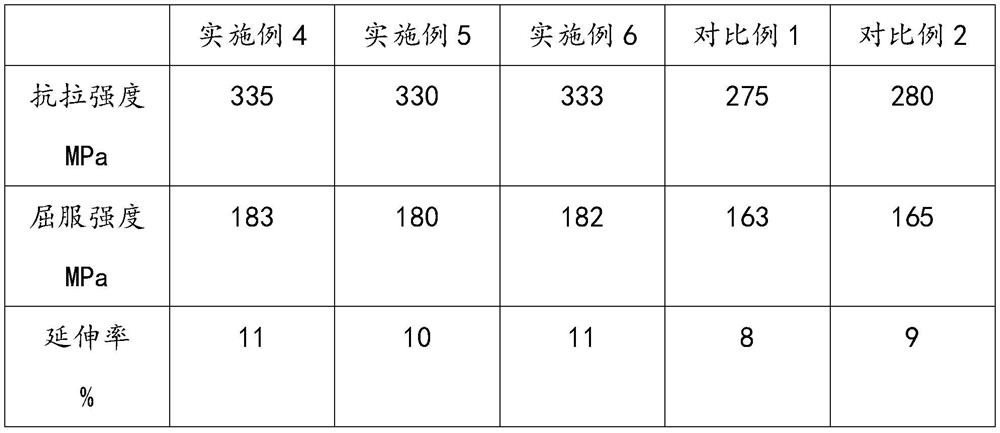

Examples

Embodiment 1

[0024] Multi-element refining agent comprises the following steps:

[0025] Step S1, adding aluminum chloride hexahydrate into a beaker, adding deionized water, stirring at a constant speed until dissolved to obtain liquid a, adding sodium fluoride to deionized water, stirring at a constant speed until dissolved, obtaining liquid b, stirring while Slowly add liquid a to liquid b, stir at a constant speed after complete addition, heat up to 150°C, keep warm and react for 4 hours, centrifuge, wash, and dry after the reaction to obtain crystals, control aluminum chloride hexahydrate and fluoride The weight ratio of sodium is 0.3: 1.05;

[0026] Step S2, add calcium nitrate tetrahydrate, citric acid and diammonium hydrogen phosphate in sequence to deionized water, stir at a constant speed for 15 minutes, then add nitric acid with a mass fraction of 60% to adjust the pH until pH = 2, then heat in a water bath at 75°C for 1 hour, Then raise the temperature to 100°C and keep it warm...

Embodiment 2

[0029] Multi-element refining agent comprises the following steps:

[0030] Step S1, adding aluminum chloride hexahydrate into a beaker, adding deionized water, stirring at a constant speed until dissolved to obtain liquid a, adding sodium fluoride to deionized water, stirring at a constant speed until dissolved, obtaining liquid b, stirring while Slowly add liquid a to liquid b, stir at a constant speed after complete addition, heat up to 150°C, keep warm and react for 4 hours, centrifuge, wash, and dry after the reaction to obtain crystals, control aluminum chloride hexahydrate and fluoride The weight ratio of sodium is 0.4: 1.05;

[0031] Step S2, add calcium nitrate tetrahydrate, citric acid and diammonium hydrogen phosphate in sequence to deionized water, stir at a constant speed for 15 minutes, then add nitric acid with a mass fraction of 60% to adjust the pH until pH = 2, then heat in a water bath at 80°C for 1 hour, Then raise the temperature to 100°C and keep it warm...

Embodiment 3

[0034] Multi-element refining agent comprises the following steps:

[0035] Step S1, adding aluminum chloride hexahydrate into a beaker, adding deionized water, stirring at a constant speed until dissolved to obtain liquid a, adding sodium fluoride to deionized water, stirring at a constant speed until dissolved, obtaining liquid b, stirring while Slowly add liquid a to liquid b, stir at a constant speed after complete addition, heat up to 150°C, keep warm and react for 4 hours, centrifuge, wash, and dry after the reaction to obtain crystals, control aluminum chloride hexahydrate and fluoride The weight ratio of sodium is 0.5: 1.05;

[0036]Step S2, add calcium nitrate tetrahydrate, citric acid and diammonium hydrogen phosphate in sequence to deionized water, stir at a constant speed for 15 minutes, then add nitric acid with a mass fraction of 60% to adjust the pH until pH = 2, then heat in a water bath at 85°C for 1 hour, Then raise the temperature to 100°C and keep it warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com