Patents

Literature

78results about How to "Strong wrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dust-suppression foaming agent

InactiveCN101824302AImprove adsorption capacityStrong foaming ratioOther chemical processesCelluloseFoaming agent

The invention discloses a dust-suppression foaming agent used for coal mine excavating work surfaces. The dust-suppression foaming agent comprises the following raw material ingredients in percentage by weight: 15 to 20 percent of sodium dodecyl benzene sulfonate, 20 to 25 percent of lauryl sodium sulfate, 2 to 4 percent of wetting agent, 1 to 3 percent of foam improver, 1 to 2 percent of sodium cellulose glycolate and 50 to 60 percent of water. All ingredients are proportionally mixed and uniformly stirred at the room temperature. The generation of dust can be suppressed from a source. The invention can effectively prevent the diffusion of the dust and inhabit the occurrence of pneumoconiosis for easy-dust-generation operation places such as work surfaces of integrated mining and integrated excavating. The foam is fine and has small grain diameter and high viscosity, the dust grains with small grain diameter can be easily humidified, the absorption performance on the dust is strong, the foam coverage surface is wide, foaming times are high, the maximum foaming times can reach 12 times, the dust suppression efficiency on full dust is as high as 96 to 99 percent, and the dust suppression efficiency on respiratory dust is as high as more than 90 percent.

Owner:张仁贵

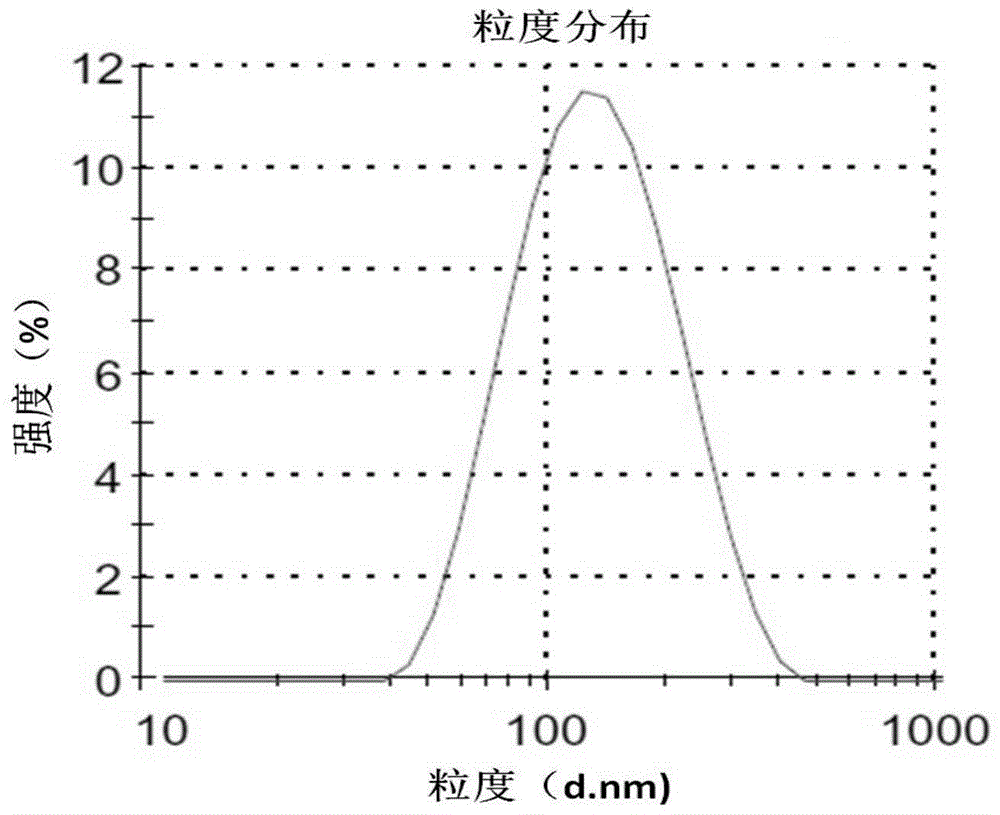

Cationic lipid containing peptide dendrimer, transgenic carrier and preparation method and application of transgenic carrier

ActiveCN102911252ALow cytotoxicityStrong wrappingPeptidesVector-based foreign material introductionDendrimerTransgene

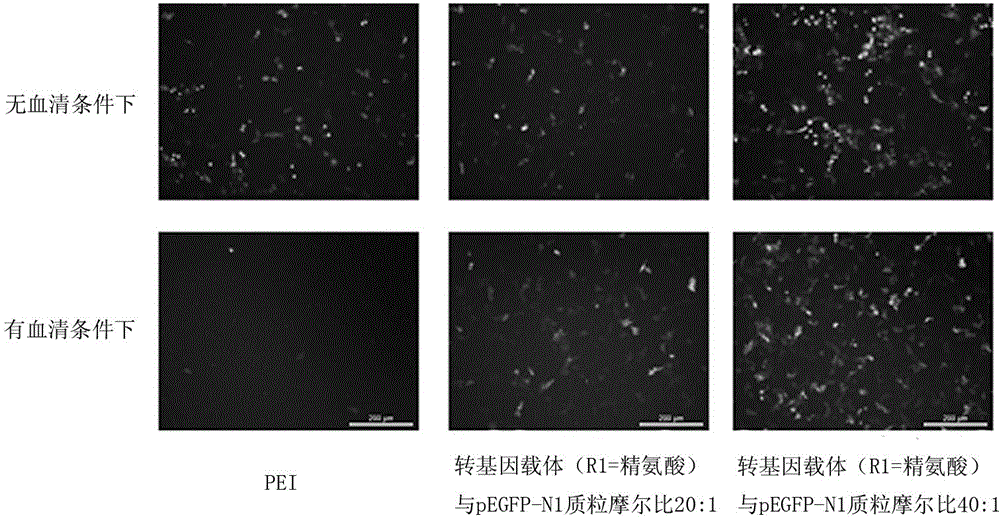

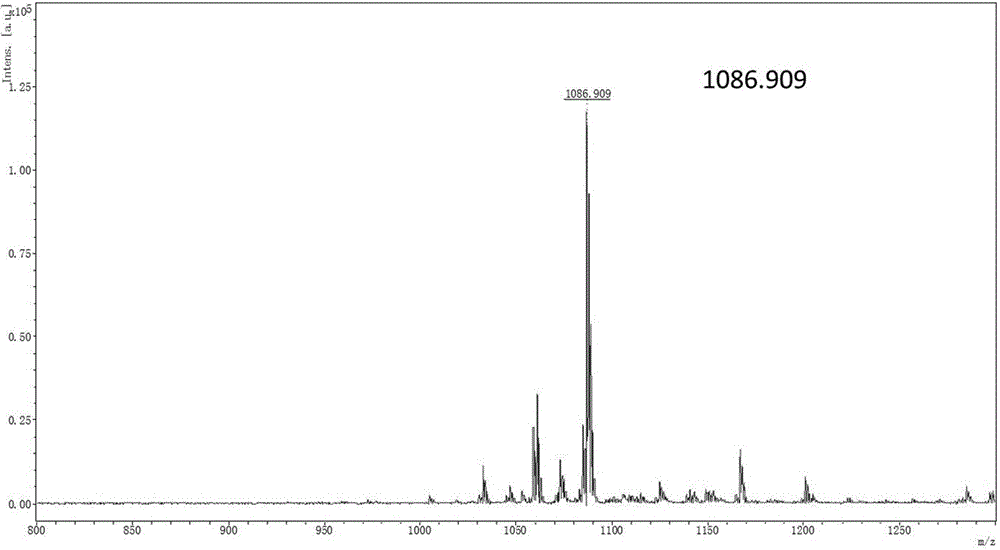

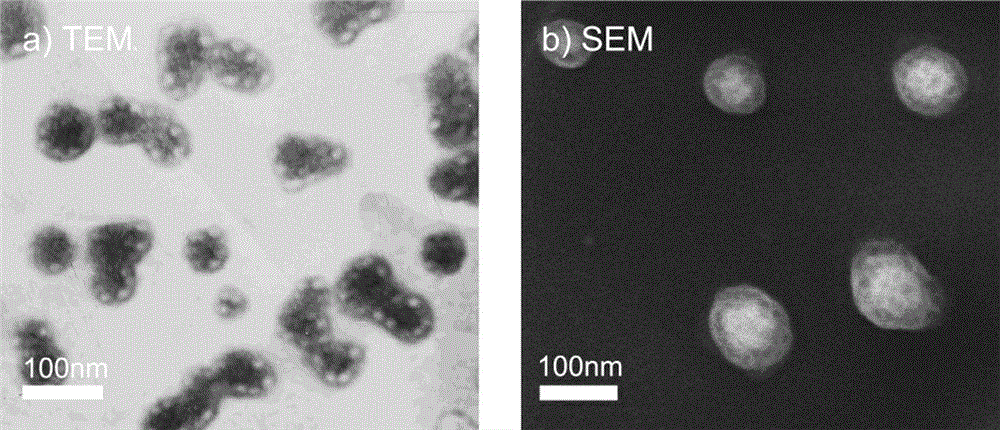

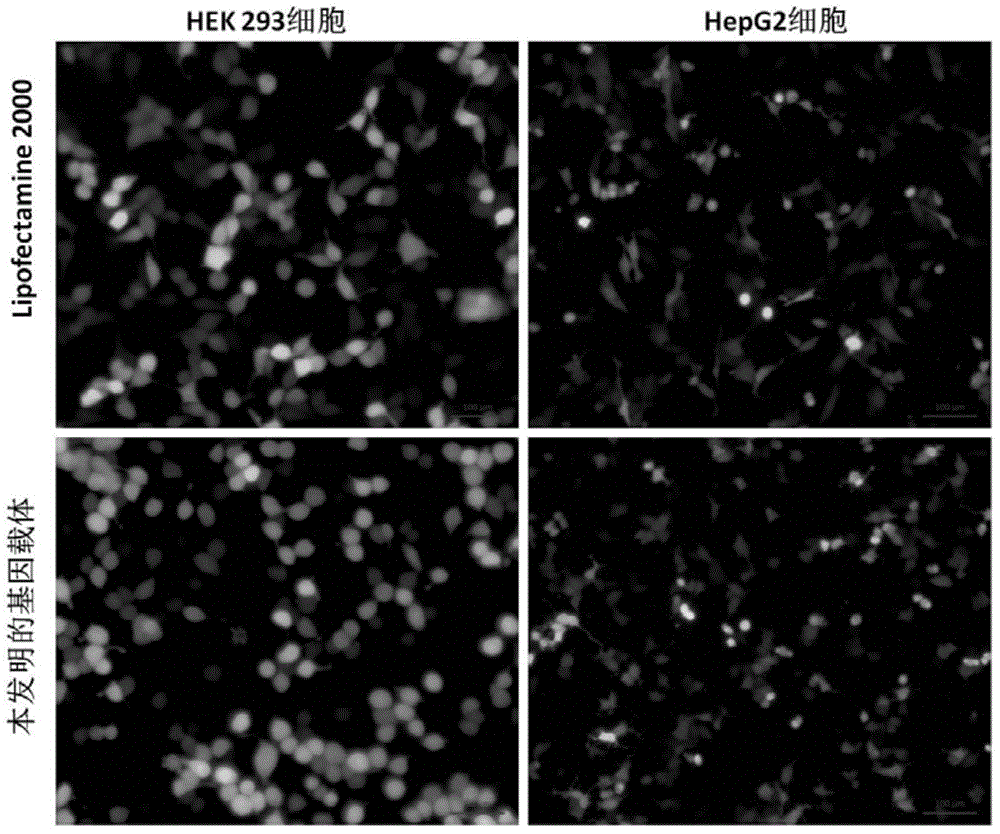

The invention discloses cationic lipid containing peptide dendrimer, a transgenic carrier, and a preparation method and application of the transgenic carrier. The transgenic carrier has low cell toxicity, can effectively retard and coat pEGFP-N1 plasmid or pGL3 plasmid, and is high in coating capacity. As the average particle size of a compound of the transgenic carrier with the pEGFP-N1 plasmid or pGL3 plasmid ranges from 80 nm to 200 nm, and the Zeta potential is within the range of 5-50mV, the transgenic carrier is quite suitable for gene transfection. When the compound formed of the transgenic carrier and the pEGFP-N1 plasmid or pGL3 plasmid is used for gene transfection of cells HepG2, MCF7 and B16F10, good transfection capacity is achieved, the transfection capacity is higher than that of the commercial product PE125K on the condition of transfection optimization, and the transfection advantage is much superior on the condition with serum existence.

Owner:SICHUAN UNIV

Novel cleaning agent additive and synthetic method thereof

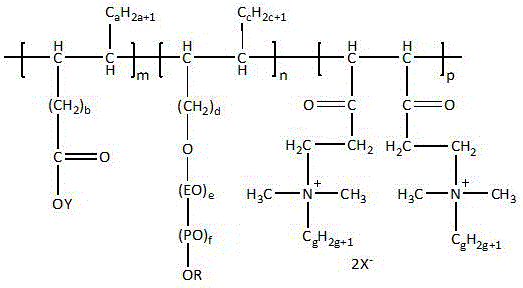

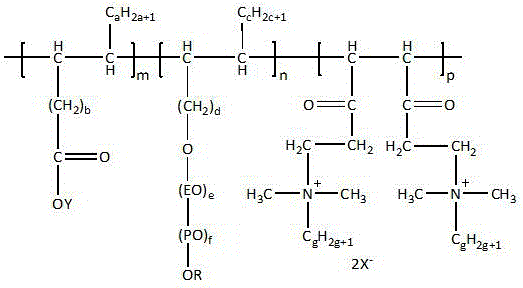

ActiveCN106317341AGood permeabilityLess foamCationic surface-active compoundsOrganic detergent compounding agentsTO-18Propylene oxide

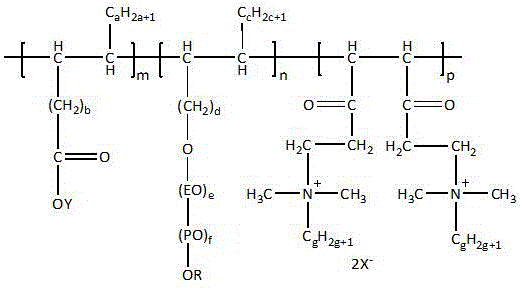

The invention discloses a novel cleaning agent additive. The cleaning agent additive is a liquid gemini polyether cleaning agent additive, the main ingredient of the cleaning agent additive is gemini polyether, and the general structural formula of the gemini polyether is shown in the description, wherein a, b, c and d are integers from 0 to 8 respectively, e is an integer from 8 to 30, f is an integer from 8 to 20, g is an integer from 1 to 18, m, n and p are integers from 2 to 10 respectively, R is a higher fatty acid group or hydrogen, X is Cl or Br, Y is hydrogen or sodium or potassium, EO is ethylene oxide, and PO is propylene oxide. The invention further discloses a synthetic method of the novel cleaning agent additive.

Owner:福建昆冈化学助剂科技有限公司

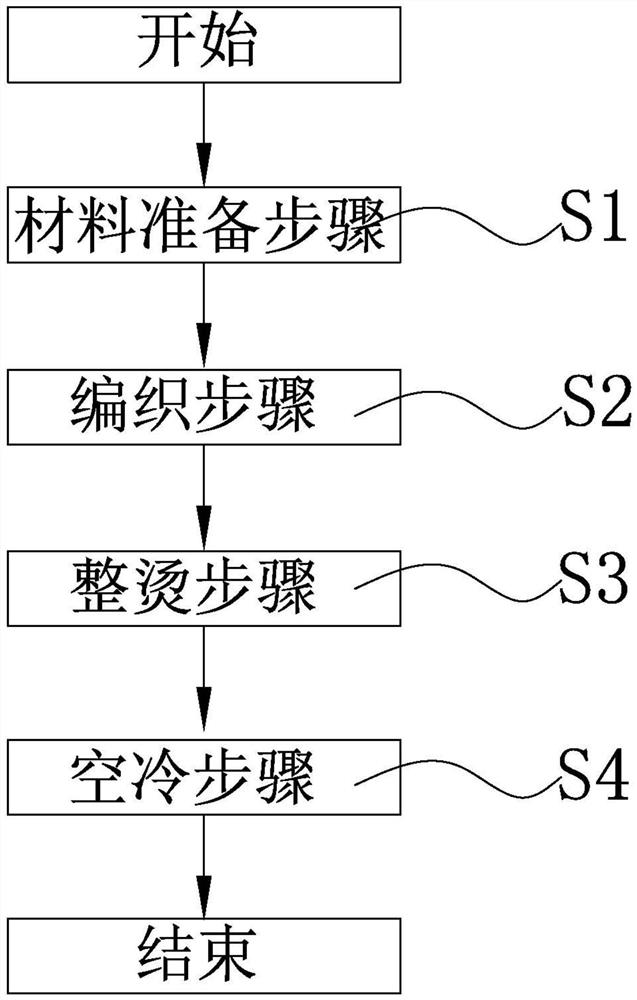

Method for three-dimensional thermoplastic laminating of sock upper

InactiveCN109123913ASafety protectionReduce labor costsUpperBootlegsMaterials preparationThermoplastic

A method for three-dimensional thermoplastic laminating of sock upper includes such step as material preparation, elastic shaping sheet and sock upper positioning, negative pressure adsorption, thermoplastic, cooling and edge cutting, elastic sheet and sock upper gluing. The method has the advantages of one-time molding, good shaping effect, high elasticity, and good wearing feeling for user.

Owner:QUANZHOU HUANQIU SHOES & GARMENTS CO LTD

Water body heavy metal repairing agent and use method thereof

InactiveCN105498685ARepair pollutionImprove adsorption capacityOther chemical processesWater contaminantsMaterials scienceBentonitic clay

The invention discloses a water body heavy metal repairing agent and a use method thereof. The water body heavy metal repairing agent is prepared from a repairing agent A and a repairing agent B, wherein the repairing agent A is prepared from, by mass, 20-35 parts of bentonite, 20-35 parts of cement and 5 parts of vermiculite, and the repairing agent B is prepared from, by mass, 5 parts of bentonite and 20-50 parts of cement. The repairing agent A is put into a water body to be repaired and fully stirred and stands still, then the repairing agent B is put into the water body and stirred and stands still, deposition at the bottom of the water body is removed, and the water body is repaired. By means of extremely strong adsorption performance and cation exchange performance of bentonite in the repairing agent, extremely strong adsorption performance and wrapping performance of cement and the extremely strong adsorption performance and purifying performance of vermiculite, heavy metal ions in the water body are adsorbed quickly through physical and chemical exchange, adsorbed repairing agent particles are wrapped with cement to prevent desorption and deposit at the bottom of the water body, and the aim of repairing water body heavy metal pollution is achieved.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

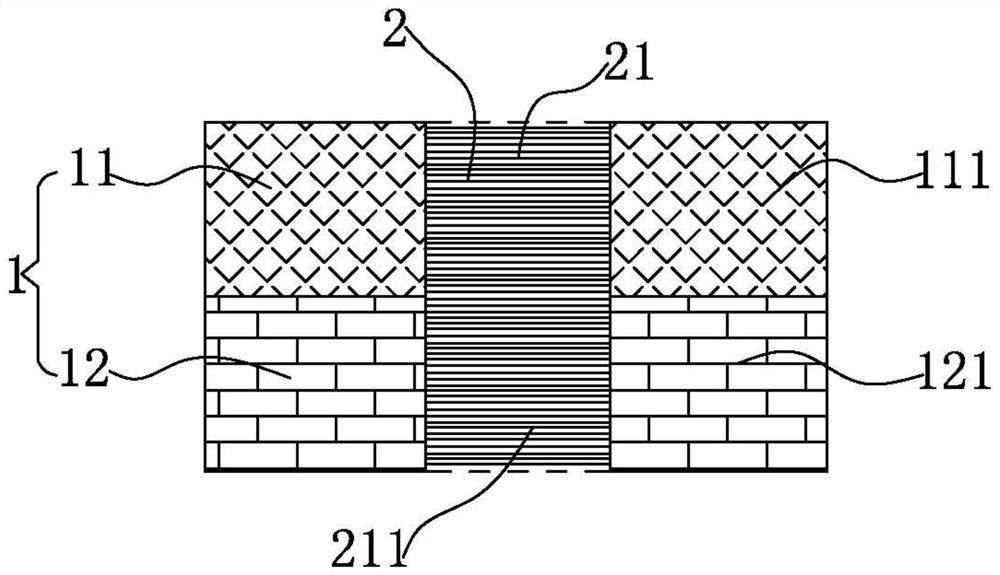

Knitted vamp with suspended floating thread weave and manufacturing method thereof

PendingCN113005610AImprove breathabilityStrong wrappingWeft knittingHeating/cooling textile fabricsYarnMaterials science

The invention relates to the technical field of knitted vamps, in particular to a knitted vamp with suspended floating thread weave. The knitted vamp includes a vamp body that includes first knitted weave and second knitted weave, wherein the first knitted weave includes a first surface layer and a first bottom layer knitted below the first surface layer; the second knitted weave includes a suspended floating thread layer, one end of the suspended floating thread layer is connected with the first surface layer or / and the first bottom layer, and the other end of the suspended floating thread layer is connected with the first surface layer or / and the first bottom layer; and the first knitted weave and the second knitted weave form the vamp body together. Colored yarn is adopted to weave the first surface layer and the first bottom layer, the thermoplastic yarn or the elastic yarn are adopted to weave the suspended floating thread layer in the vamp, the two ends of the suspended floating thread layer are connected with the first surface layer or the first bottom layer, and the middle part of the suspended floating thread layer is completely suspended, so that the decorative effect is achieved; and the vamp is good in air permeability, high in wrapping performance and high in perspective sense.

Owner:SINCETECH FUJIAN TECH CO LTD

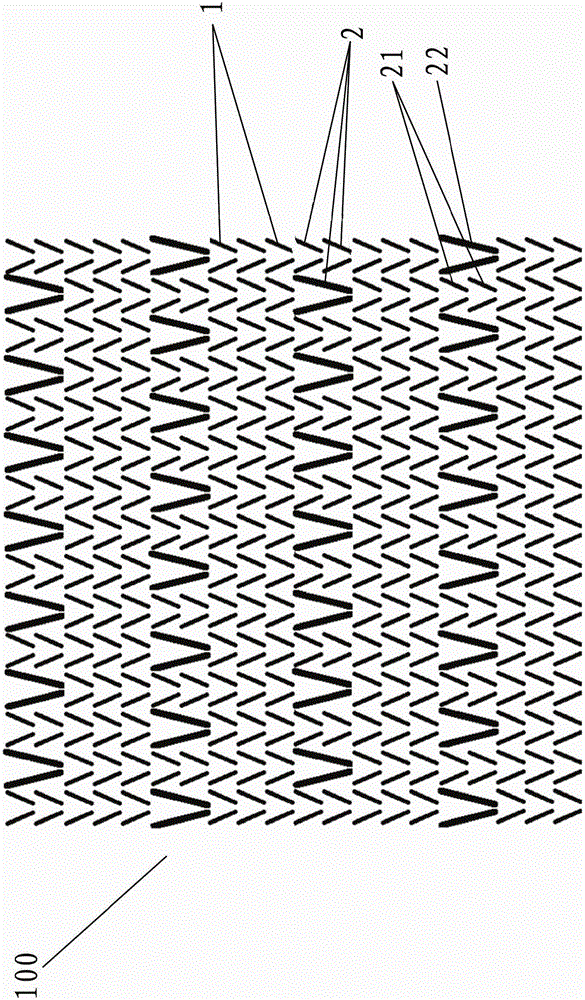

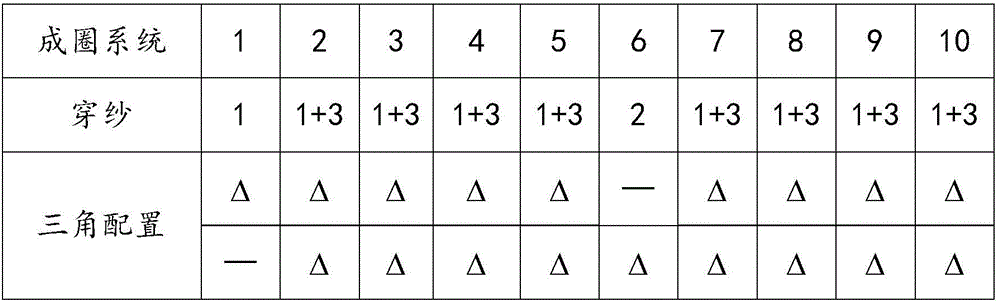

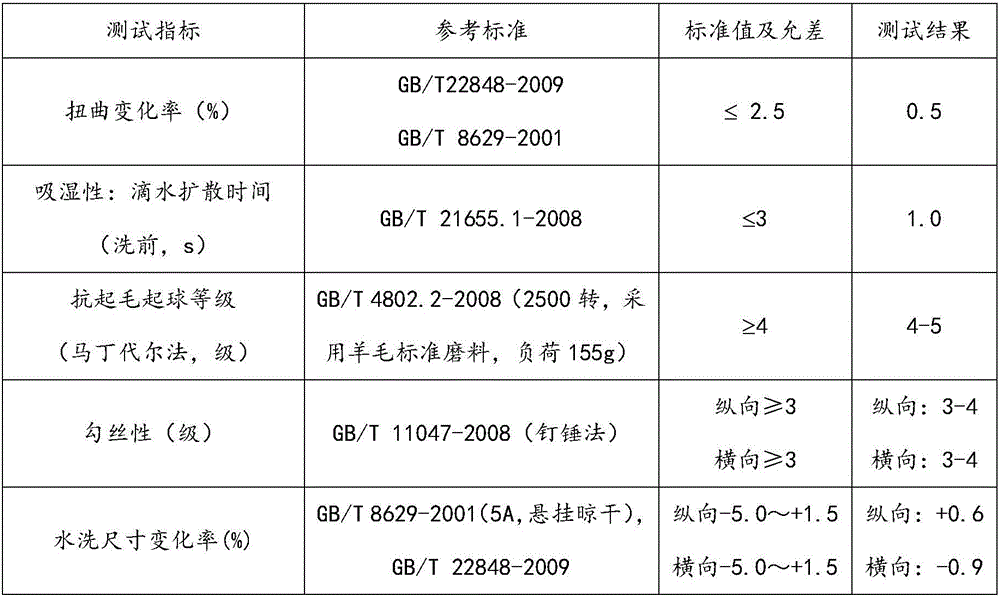

Single-sided weft-knitted fabric with cross-stripe effect and production method of single-sided weft-knitted fabric

ActiveCN106480589AGood bar effectRich fabric surfaceWeft knittingHeating/cooling textile fabricsPolyesterEngineering

The invention provides single-sided weft-knitted fabric with the cross-stripe effect. The single-sided weft-knitted fabric comprises a fabric body with the cross-stripe structure, the cross-stripe structure is formed by first coil rows and second coil rows, the first coil rows and the second coil rows are longitudinally and alternatively arranged, each second coil row behind each first coil row performs 1-stitch displacement, the first coil rows are composed of coils by knitting of three continuous cross-row looped coils protruding the front side of the fabric body, the second coil rows are formed by alternative knitting of looped coils of two cross-row coils protruding the front side of the fabric body and one longitudinal floating-thread stretched coil, the first coil rows are woven by cationic polyester filament and spandex in a doubling manner, and the second coil rows are knitted by half-matting polyester filament. Compared with the prior art, the single-sided weft-knitted fabric has the advantages of remarkable stripe experience, good cross elasticity and extension, good resistance to pilling and the like. The invention further provides a production method of the single-sided weft-knitted fabric with the cross-stripe effect.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

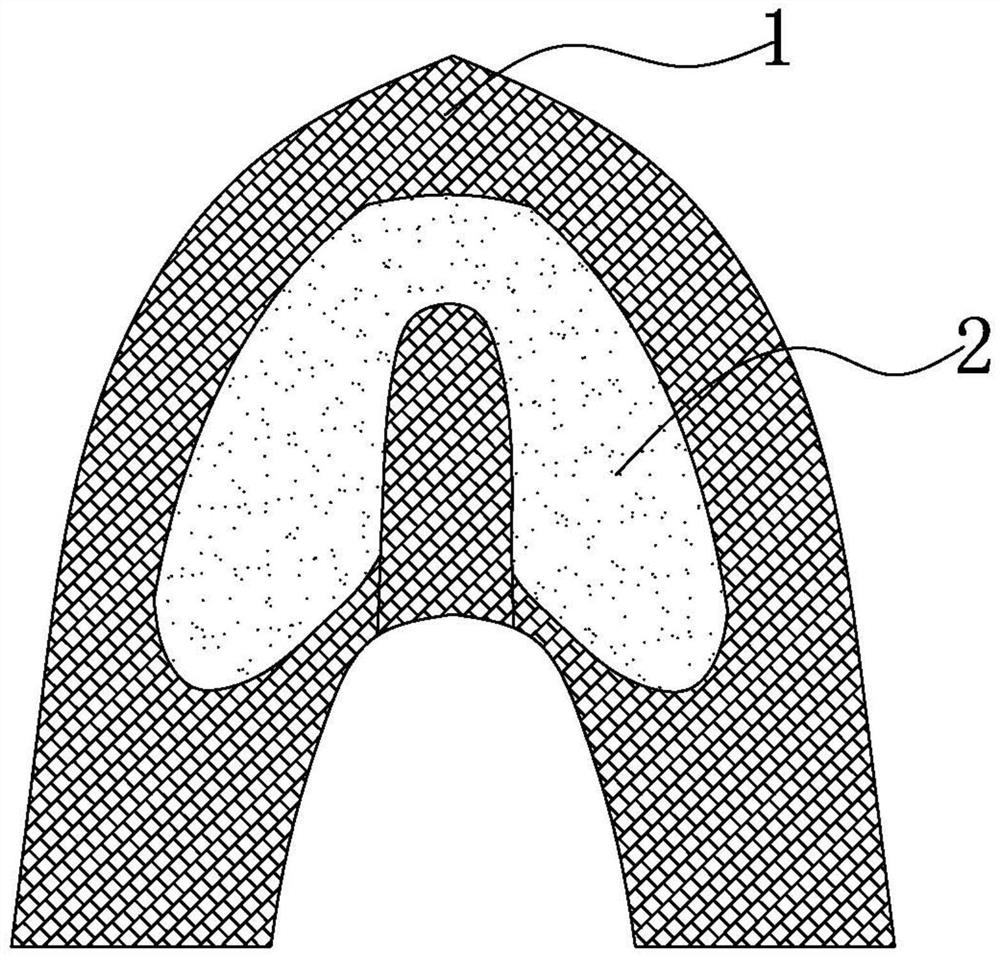

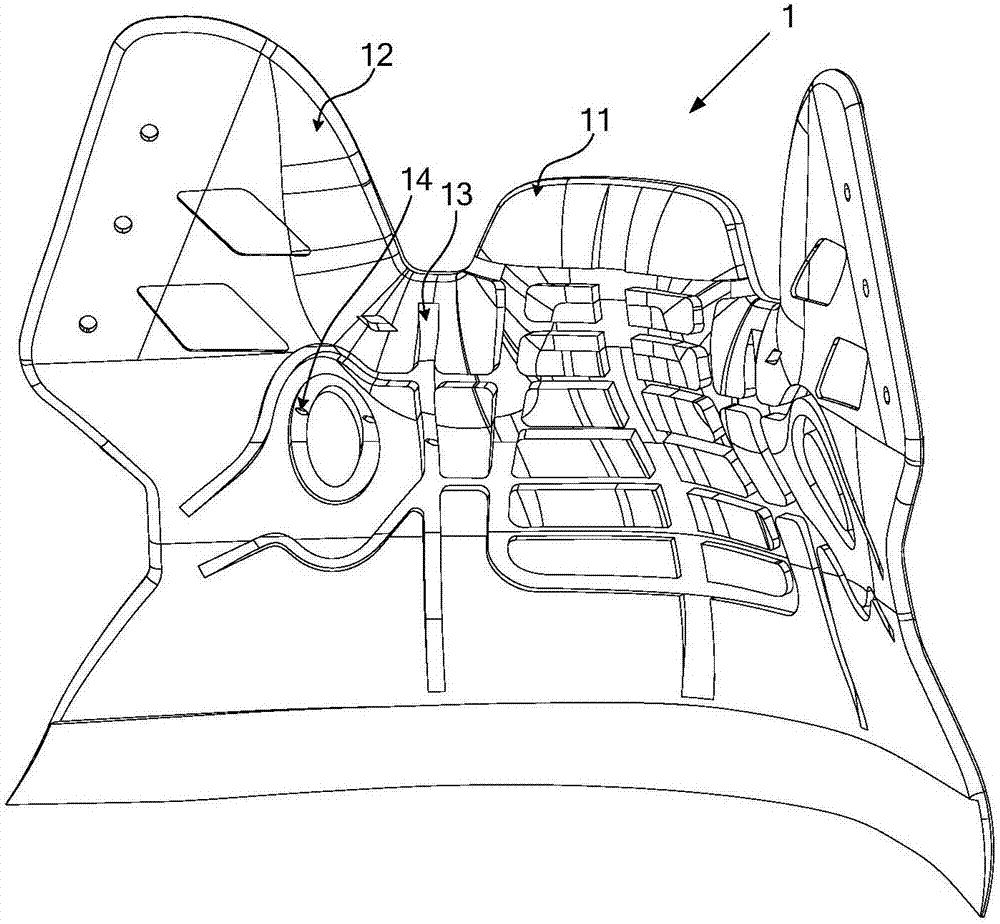

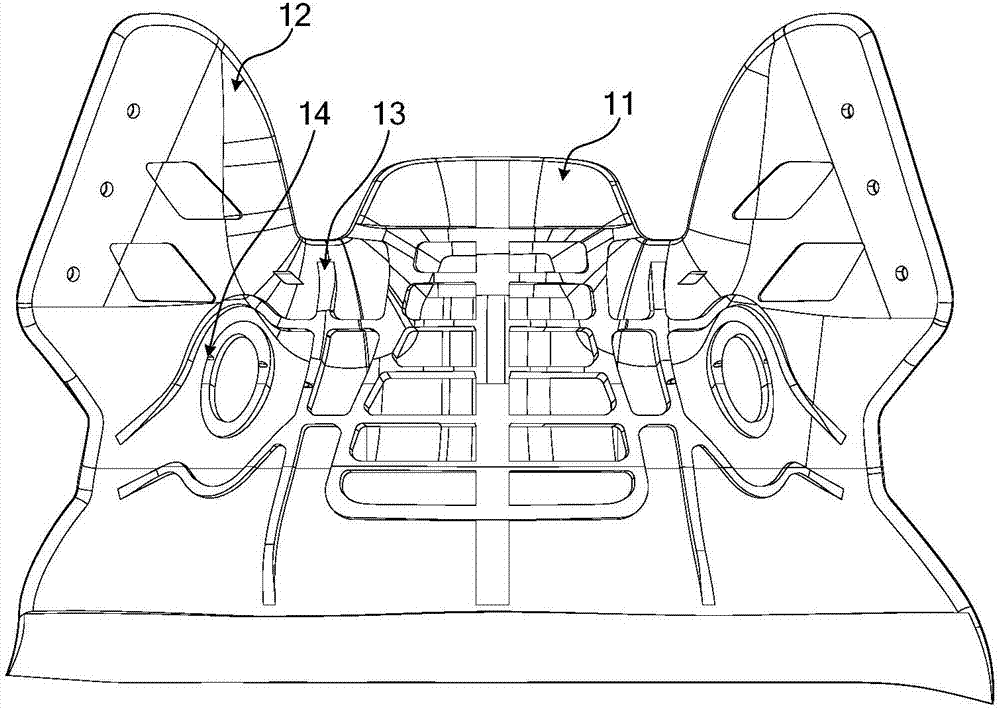

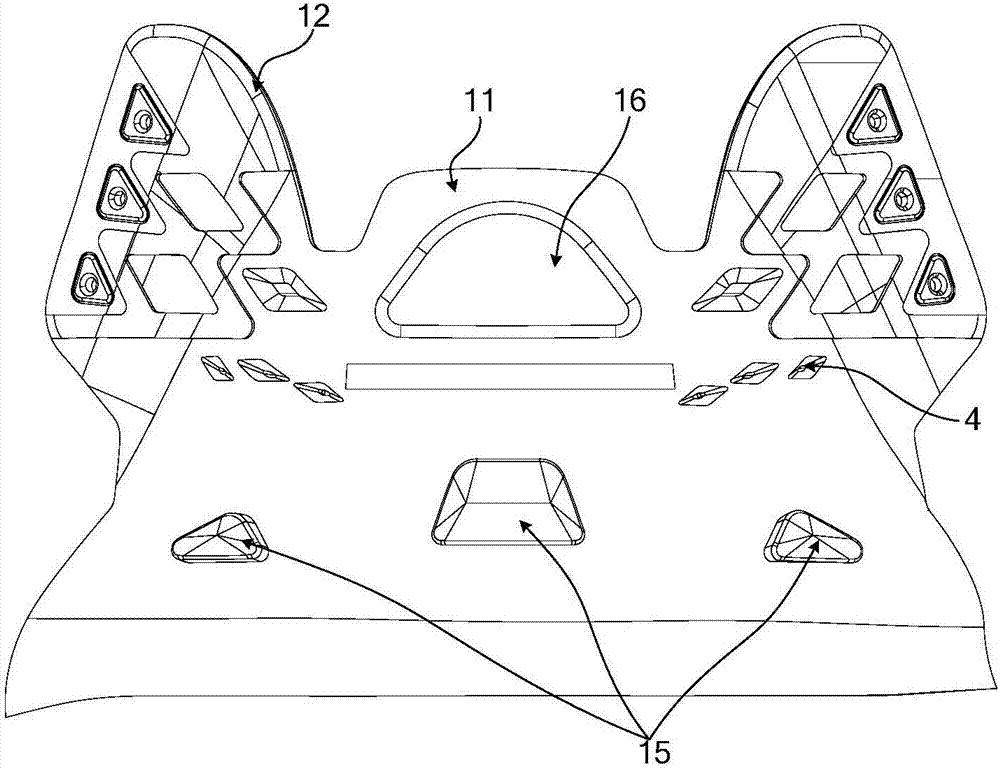

Shoes and rear sleeve components thereof

The invention discloses shoes and rear sleeve components thereof. For each rear sleeve component, a foaming layer and a surface layer are included, the surface layer wraps and is attached to the exterior of the foaming layer which is mainly composed of a main body and fins, and the main body is used for wrapping the heel and is generally in a U shape; the fins extend to the two sides of the main body, that is to say, the fins and the main body are of an integrated structure, and the fins are used for wrapping the ankle; therefore, the rear sleeve components change a design mode of foam filling in the prior art, and according to the principle of human engineering, foaming materials are adopted to be subjected to injection molding to form shapes which fit the heel and the ankle. The shoes are comfortable to wear, the wrapping performance is high, the integrated fins and main body can provide effective protection for the ankle and the heel, and sport injuries are avoided.

Owner:ANTA CHINA

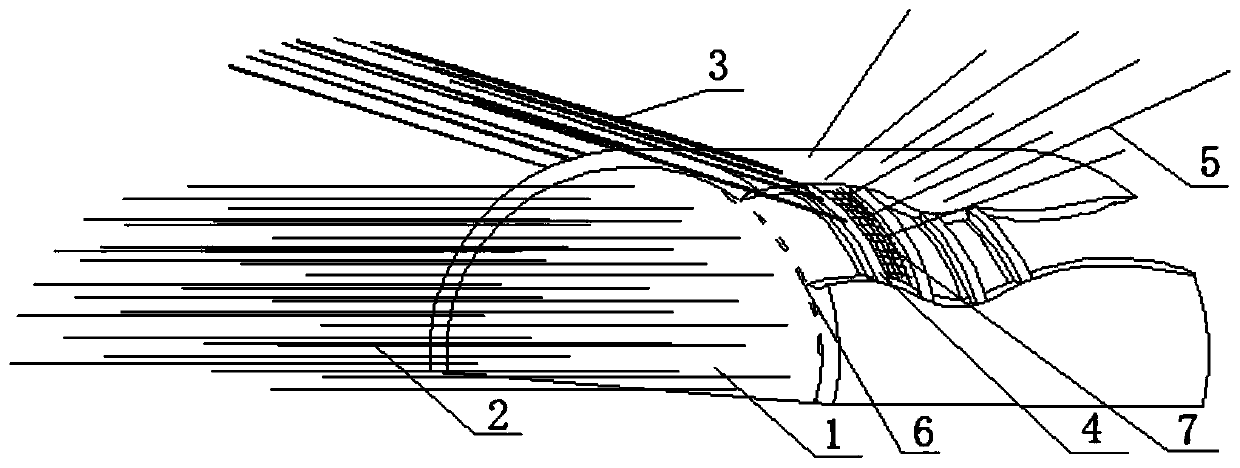

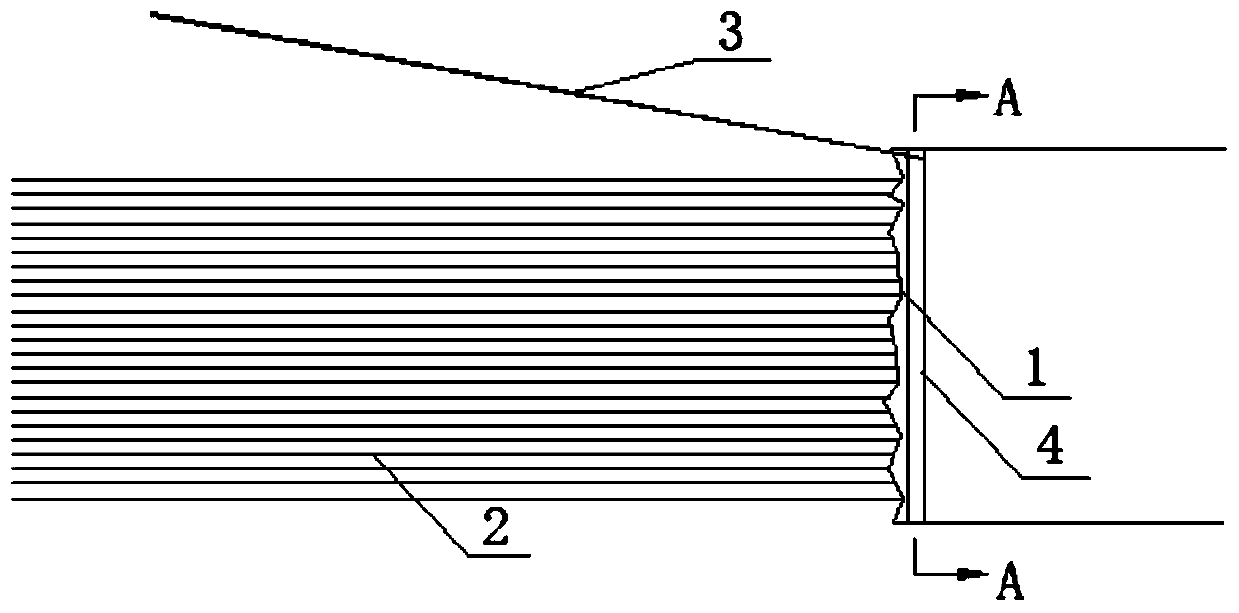

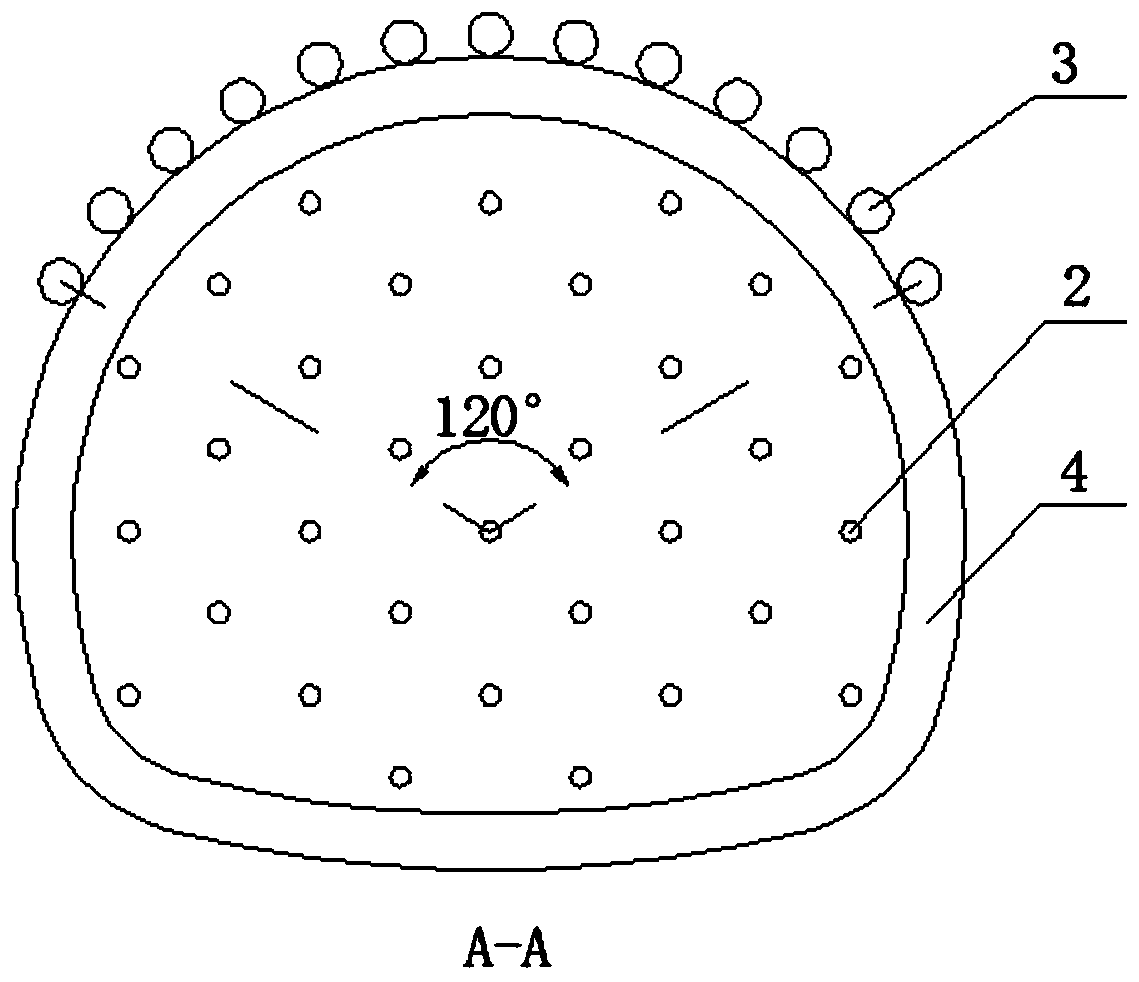

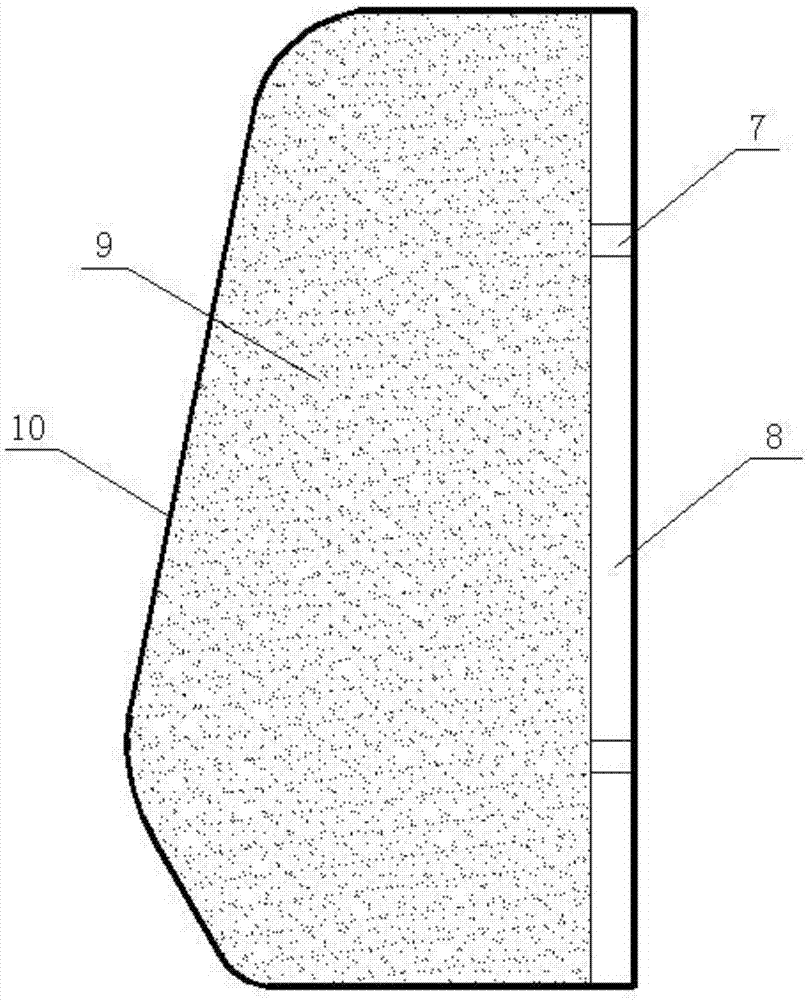

Composite retaining structure suitable for deep tunnel of clastic schist layer and construction method thereof

PendingCN111577321AEnsure excavation efficiencyStable and stableUnderground chambersTunnel liningFiberArchitectural engineering

The invention discloses a composite retaining structure suitable for a deep tunnel of a clastic schist layer and a construction method thereof. The composite retaining structure comprises a forepoling, a tunnel steel arch and a shotcreting mesh combined support, wherein the forepoling comprises a plurality of tunnel face fiber anchor rods which are perpendicularly driven on a tunnel face, multiplesections of advanced small guide pipe supports and a grouting reinforcement area, the plurality of tunnel face fiber anchor rods completely cover the tunnel face, each section of the advanced small guide pipe support is composed of a plurality of advanced small guide pipes, the overlapping length of each section of the advanced small guide pipe support is not less than 1 m or 1 / 4 L of the guide pipes in the tunnel excavation direction, each section of the advanced small guide pipe support, i.e. the plurality of advanced small guide pipes, is driven on the arch of the tunnel face within the range of 120 degrees, and the grouting reinforcement area is formed in a way that the tunnel face fiber anchor rods and tunnel face surrounding rocks in an area in which the advanced small guide pipes are arranged are grouted. According to the composite retaining structure, the stable tunnel face is effectively guaranteed, the collapse of an excavation face is prevented, the deformation of the support is effectively controlled, the safety in construction is guaranteed, and the construction efficiency is improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

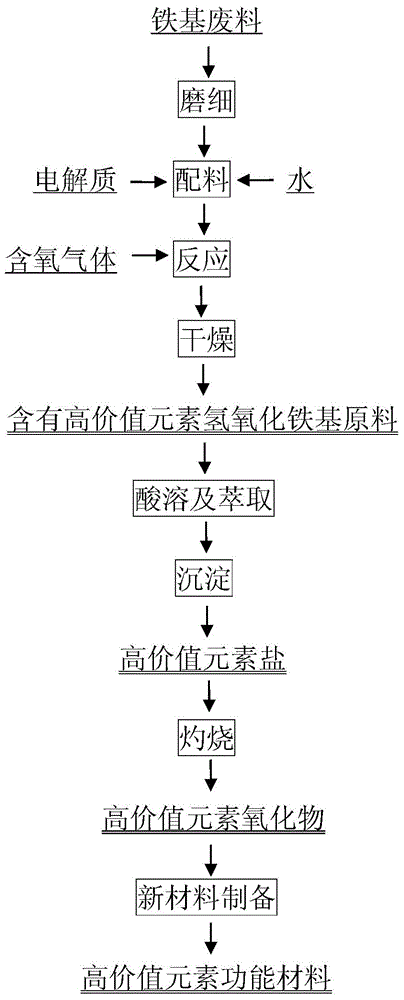

Method for preparing ferric hydroxide-based raw materials containing high value elements

ActiveCN104451151AFacilitate trade flowImprove stabilityIron oxides/hydroxidesSolid waste disposalSpontaneous combustionFerric hydroxide

Owner:GANZHOU RECYCLE NEW TECH

Electrophoretic grinding resin, electrophoretic color paste prepared therefrom and application of color paste

InactiveCN111825823AStrong wrappingGood compatibilityPaints for electrolytic applicationsPigment pastesElectrophoresesAuto industry

The invention discloses an electrophoretic grinding resin, an electrophoretic color paste prepared from the electrophoretic grinding resin and application of the color paste, and belongs to the technical field of surface coating. The electrophoretic color paste is prepared by mixing the following raw materials by mass percentage: 10-30% of electrophoretic grinding resin, 5-70% of toner, 0.2-1.0% of a pH regulator, 2-15% of a dispersing and wetting agent, 5-20% of an auxiliary agent and the balance deionized water. The electrophoretic color paste designed by the invention has relatively high stability and relatively high compatibility, and has relatively good application value in the aspect of surface coating of automobile industry, building materials, hardware, household appliances and thelike.

Owner:武汉科利尔立胜工业研究院有限公司 +1

Preparation method of abrasive wheel for cutting of blue glass infrared cut-off optical filter

ActiveCN106002650AEasy to controlPromote sheddingAbrasion apparatusGrinding devicesBoron carbideHardness

The invention belongs to a preparation method of an abrasive wheel for cutting of a blue glass infrared cut-off optical filter. Ultrafine-grain-size powder is adopted as raw materials of a metallic bond, better holding force on diamonds is achieved, the service life of the abrasive wheel can be prolonged, and the cutting speed of the abrasive wheel can be increased. By means of the composite mixing process adopting a three-dimensional mixer for premixing and ultrasonic wet mixing, the quality stability of the abrasive wheel and consistency of the cutting performance of the abrasive wheel are guaranteed. A certain amount of boron carbide and a certain amount of titanium diboride are added into the bond, do not participate in sintering and can fall off from the bond in time in the cutting process, and therefore keenness of the abrasive wheel is improved, the stable cutting capacity of the abrasive wheel is improved, and tool repair is avoided in the cutting process; and meanwhile due to the fact that the hardness of the two kinds of matter is high, the cutting assisting effect is achieved, and the cutting capacity of the diamond abrasive wheel is improved. The re-pressing process is adopted, an abrasive wheel blank obtained through hot-pressing sintering is strengthened, and therefore the density, rigidity and strength of the abrasive wheel are improved, and the mechanical performance of the abrasive wheel is further guaranteed.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Fireproof coating and preparation method thereof

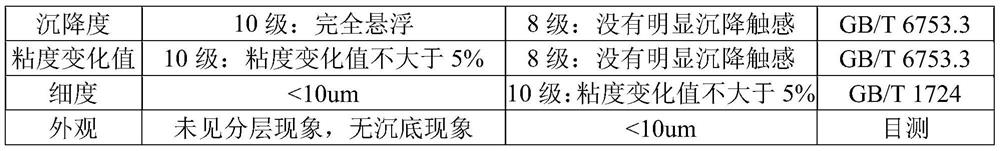

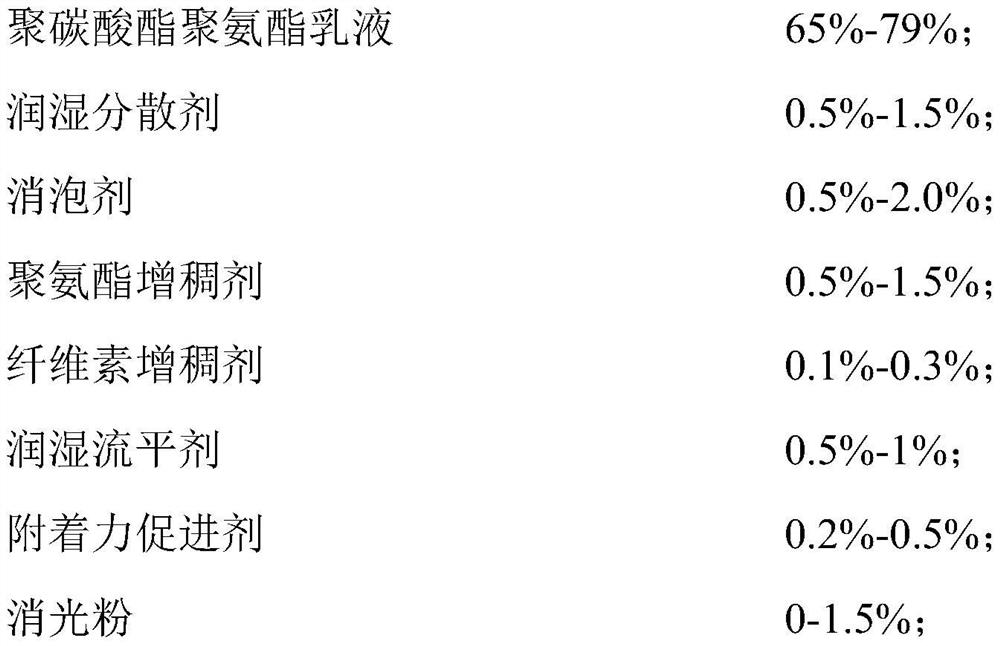

InactiveCN111662624AGood dispersionHigh hardnessFireproof paintsPolyurea/polyurethane coatingsCellulosePolymer science

The invention relates to a coating, and provides a fireproof coating and a preparation method thereof. The total weight of the fireproof coating is 100%, the fireproof coating is prepared from 65 to 79 percent of polycarbonate polyurethane emulsion; 0.5%-1.5% of a wetting dispersant; 0.5%-2.0% of a defoaming agent; 0.5%-1.5% of a polyurethane thickening agent; 0.1%-0.3% of a cellulose thickener, 0.5%-1% of a wetting leveling agent, 0.2%-0.5% of an adhesion promoter, 0-1.5% of matting powder, 0.3%-0.8% of an anti-settling aid, 3%-7% of a coalescing agent, 0.2%-0.5% of a bactericidal mildew preventive, 11%-20% of a flame retardant and 1%-13% of water, wherein the adhesion promoter is selected from a polysiloxane-free non-ionic compound. The fireproof coating has good dispersing performance,storage performance and rheological property, and a paint film formed by the fireproof coating is flat and smooth, excellent in adhesive force, good in flame retardant property, strong in wrapping property, high in hardness and good in chemical resistance.

Owner:中华制漆(新丰)有限公司

Cationic lipid compound as well as preparation method and application thereof

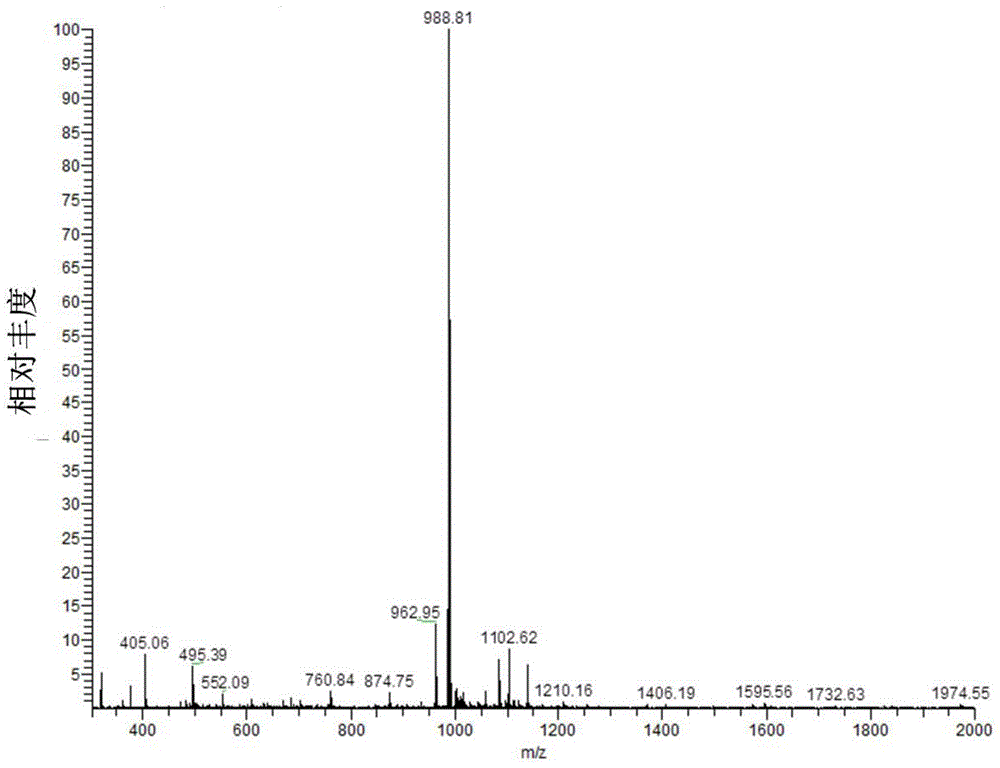

ActiveCN106188230ASimple preparation processHigh yieldMicroencapsulation basedGenetic material ingredientsGene carrierToxicity

The invention provides a cationic lipid compound as well as a preparation method and application thereof, and belongs to the field of preparation of non-virus gene carriers. The chemical structure of the cationic lipid compound is as shown in a general formula (I) (as shown in the description). The compound disclosed by the invention, and DOPE or DOPC or lecithin are mixed according to a mole ratio of the compound to the DOPE or the DOPC or the lecithin being (3-1) to (1-3), a mixture is dissolved in chloroform to be used for preparing a liposome gene carrier, and the carrier is uniform in particle size, good in dispersity, low in preparation cost, low in cytotoxicity and high in transfection foreign gene capacity. The compound disclosed by the invention can be used as a raw material for preparing a gene carrier, the problems of low cell transfection efficiency, large cytotoxicity, high price and the like, generally existing in non viral nucleic acid carriers at present are solved, and the compound has good market application prospects.

Owner:INNER MONGOLIA UNIVERSITY

High value element-containing and iron hydroxide-based raw material and application thereof

ActiveCN104232905AFacilitate trade flowImprove stabilityIron oxides/hydroxidesProcess efficiency improvementSpontaneous combustionHydrometallurgy

The invention relates to a high value element-containing and iron hydroxide-based raw material and application thereof, and belongs to the technical field of resource recycle and hydrometallurgy. The high value element-containing and iron hydroxide-based raw material mainly comprises iron hydroxide, high value element compounds and combustible organic matters, wherein in terms of element, iron accounts for 3.5-45wt%; in terms of oxides, high value elements account for 2-32wt% altogether and Y (Fe3+) / TFe accounts for more than or equal to 54.47wt%; in terms of C, combustible organic matters account for less than or equal to 6.5wt%; the iron hydroxide-based raw material does not combust spontaneously at the temperature of lower than or equal to 200 DEG C. The high value element-containing and iron hydroxide-based raw material is powdery or in form of an easily-crushed briquette and has the advantages of being homogeneous in structure, unlikely in spontaneous combustion, convenient and safe in use and the like; fire hazards during transportation, loading and unloading, storage and production of an iron-based waste material are prevented and safe production is achieved; during using, the dissolution rates of the high value elements are high and the high value elements can be prepared into different products, so that the maximized utilization of resources is achieved and the development of circular economy is benefited.

Owner:QIANDONG RARE EARTH GRP

Efficient organic piston ring carbon removal repairing agent

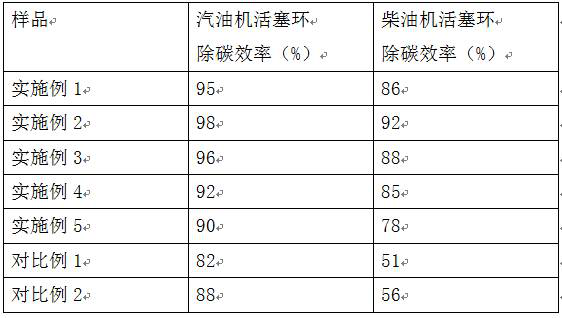

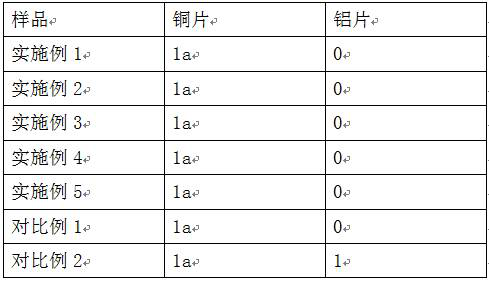

ActiveCN111925844AImprove securityStrong wrappingLiquid carbonaceous fuelsFuel additivesCombustion chamberActive agent

The invention provides an organic piston ring carbon removal repairing agent, which is characterized by comprising the following components in parts by mass: 50-80 parts of a carbon deposition dissolving agent, 5-20 parts of a purification dispersing agent, 1-5 parts of an ester type lubricating tackifier, 1-10 parts of a solvent type surfactant, 1-2 parts of an oil stain disintegration accelerantand 0.1-1 part of an auxiliary agent. The organic piston ring carbon removal repairing agent can effectively remove combustion chamber deposited carbon in a cylinder cover, a piston top and a pistonring groove, clean and release a piston ring, recover the elasticity and cylinder pressure of the piston ring, and recover the stuck piston ring. The problems of knocking, poor heat dissipation, insufficient cylinder pressure, high engine oil consumption and the like are solved.

Owner:杭州维客泰美品牌管理有限公司

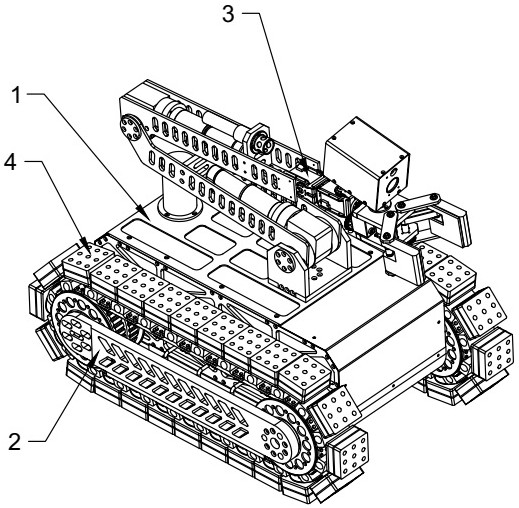

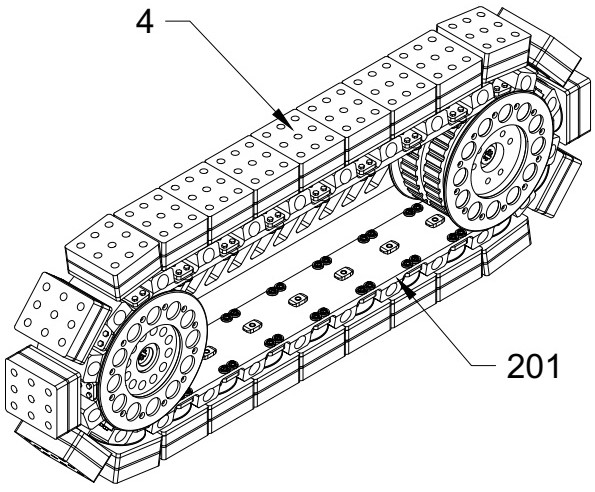

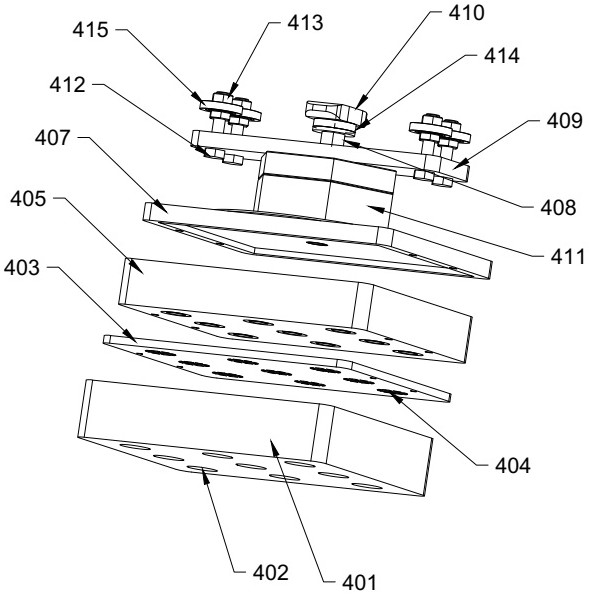

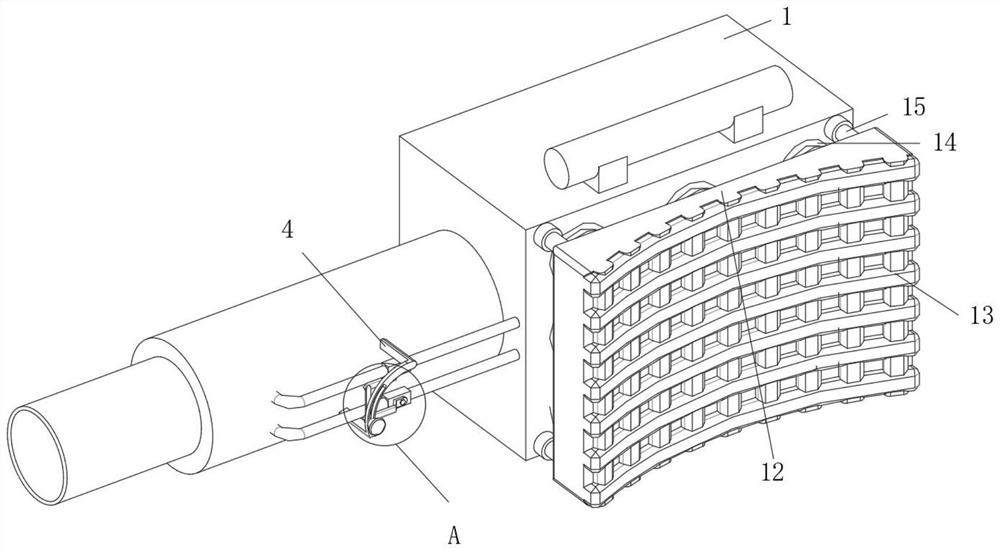

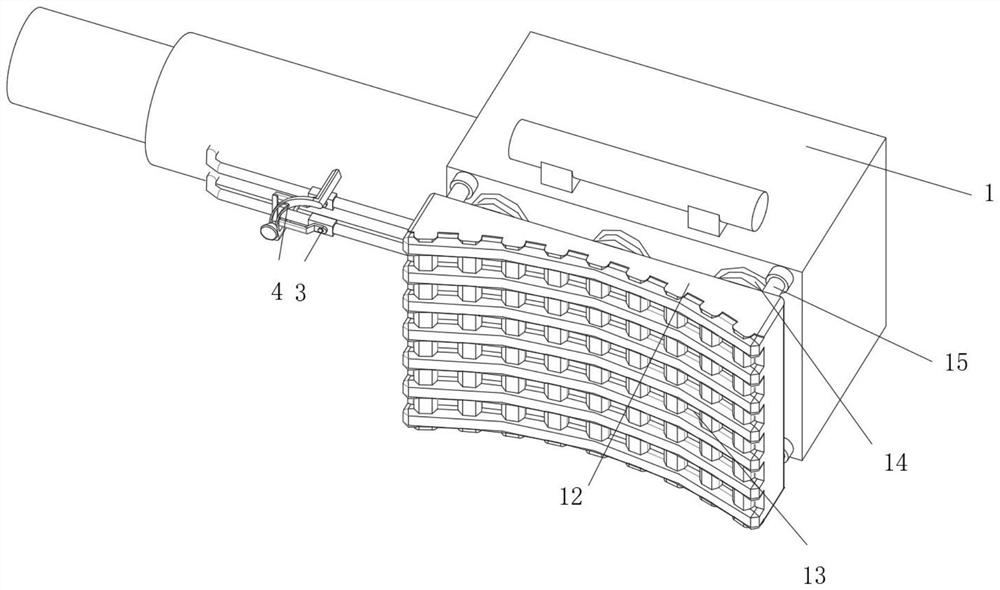

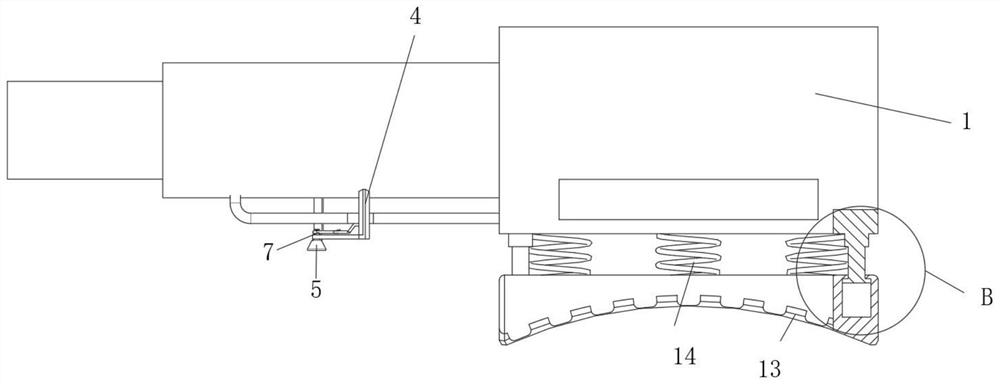

Self-adaptive wall-climbing robot for complex environment

ActiveCN112026949AIncrease elasticityStrong wrappingVehiclesControl engineeringStructural engineering

The invention discloses a self-adaptive wall-climbing robot for a complex environment. The robot comprises a robot body, porous self-adaptive suckers, an air distribution mechanism and a vacuum generation mechanism. The porous self-adaptive suckers are densely distributed on a crawler belt. Each porous self-adaptive sucker comprises a porous flexible adsorption plate, a bottom plate, a differential pressure one-way valve cavity, a rectangular boss, a vacuum adsorption pipe, a fixing plate, a sliding block, a large anti-skid nut, a fixing bolt and a small anti-skid nut. The air distribution mechanism comprises an air distribution groove, and the crawler belt is always fixed by negative pressure in the air distribution groove in the moving process and is tightly attached to the bottom of theair distribution groove. The porous self-adaptive suckers on the crawler belt move along with the crawler belt to dynamically seal the two ends of the air distribution groove, the vacuum generation mechanism is used for vacuumizing to generate negative pressure during adsorption, and an air distribution scheme that the porous self-adaptive suckers on the wall-climbing robot make full contact withan uneven surface and the suckers are distributed to a portion making contact with the ground at a fixed point can be achieved. And a gas loss of the vacuum generator can be effectively reduced.

Owner:CENT SOUTH UNIV

Cationic lipid containing peptide dendrimer, transgenic carrier and preparation method and application of transgenic carrier

ActiveCN102911252BLow cytotoxicityStrong wrappingPeptidesVector-based foreign material introductionDendrimerTransgenesis

The invention discloses a cationic lipid containing peptide dendrimers, a transgene carrier, a preparation method and application thereof. The transgenic carrier of the present invention has very low cytotoxicity, can effectively block and wrap pEGFP-N1 plasmid or pGL3 plasmid, and has strong wrapping ability, and the complex of the transgenic carrier of the present invention and pEGFP-N1 plasmid or pGL3 plasmid averages The particle size is between 80-200nm, and the Zeta potential is between 5-50mV, which is very suitable for gene transfection. Transfection of HepG2, MCF7, and B16F10 cells with the complexes formed by the transgenic vectors of the present invention and pEGFP-N1 plasmids or pGL3 plasmids all showed good transfection ability, and the transfection ability exceeded commercially available under optimized transfection conditions. PEI25K has a more prominent transfection advantage in the presence of serum.

Owner:SICHUAN UNIV

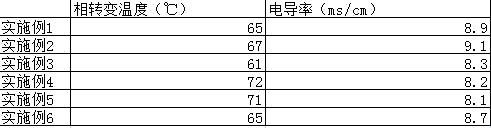

Gel polymer lithium-ion electrolyte and battery containing same

InactiveCN106611874AStrong carrier capacityStrong wrapping abilityFinal product manufactureElectrolyte accumulators manufactureDiamineInorganic salts

The invention discloses a gel polymer lithium-ion electrolyte and a battery containing the electrolyte, and belongs to the field of lithium batteries. The provided electrolyte is good in low-temperature performance and high in conductivity. The electrolyte comprises an inorganic salt, an organic solvent, a polymer, a cross-linking agent and an initiator, and is characterized in that monomer raw materials of the polymer comprise one binary acid monomer containing a benzene ring structure and two diamine monomers.

Owner:DEYANG JIUDING ZHIYUAN INTPROP OPERATION CO LTD

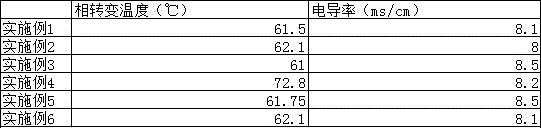

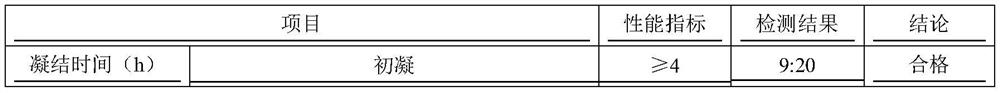

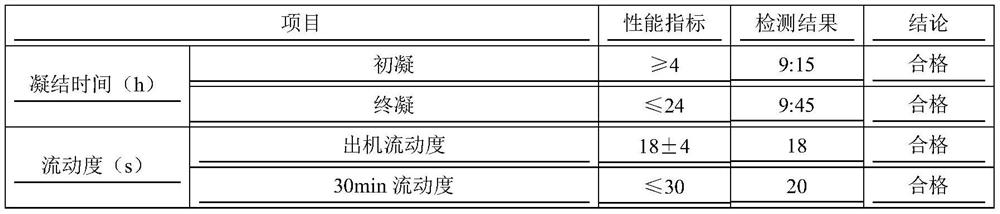

Grouting material and preparation method thereof

The invention discloses a grouting material which comprises the following components in parts by weight: 94.6-96.7 parts of a cementing material; 0.2 to 0.4 part of a polycarboxylic acid type water reducing agent; 0.02 to 0.04 part of a defoaming agent; 0.01 to 0.03 part of an anti-settling water-retaining agent; 3-5 parts of a concrete expansive agent; 0.03 to 0.05 part of a plastic expanding agent; the cementing material comprises the following components: 82-90 parts of Portland cement; 5-10 parts of silica fume; 1-5 parts of superfine stone powder; and 0-3 parts of fly ash. A preparation method comprises the following steps: (1) mixing limestone with gypsum and a grinding aid, and grinding until the specific surface area is 1000-1500m < 2 > / kg to obtain superfine stone powder, wherein the addition amount of the gypsum is 0.3-0.5%, the grinding aid is a mixture of calcium lignosulphonate and silica fume, the mass ratio of the calcium lignosulphonate to the silica fume is 3: 47, and the addition amount of the grinding aid is 0.3-0.5%; and 2) taking the materials in proportion, adding the materials into mixing equipment, uniformly mixing, and homogenizing to obtain the grouting material. The grouting material disclosed by the invention has excellent flowability, water-retaining property and cohesiveness, improves the compactness and filling degree of the slurry, and reduces the shrinkage of the slurry in a plastic stage and the shrinkage of the hardened slurry.

Owner:CHONGQING SANSHENG IND CO LTD

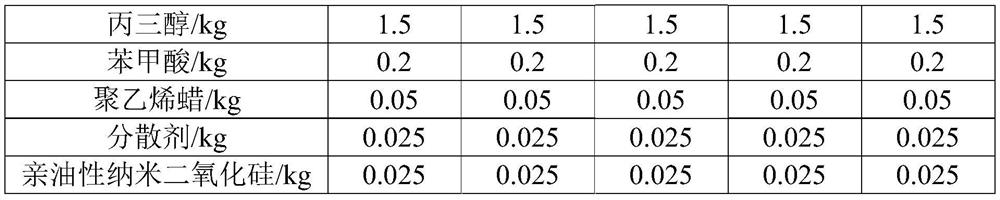

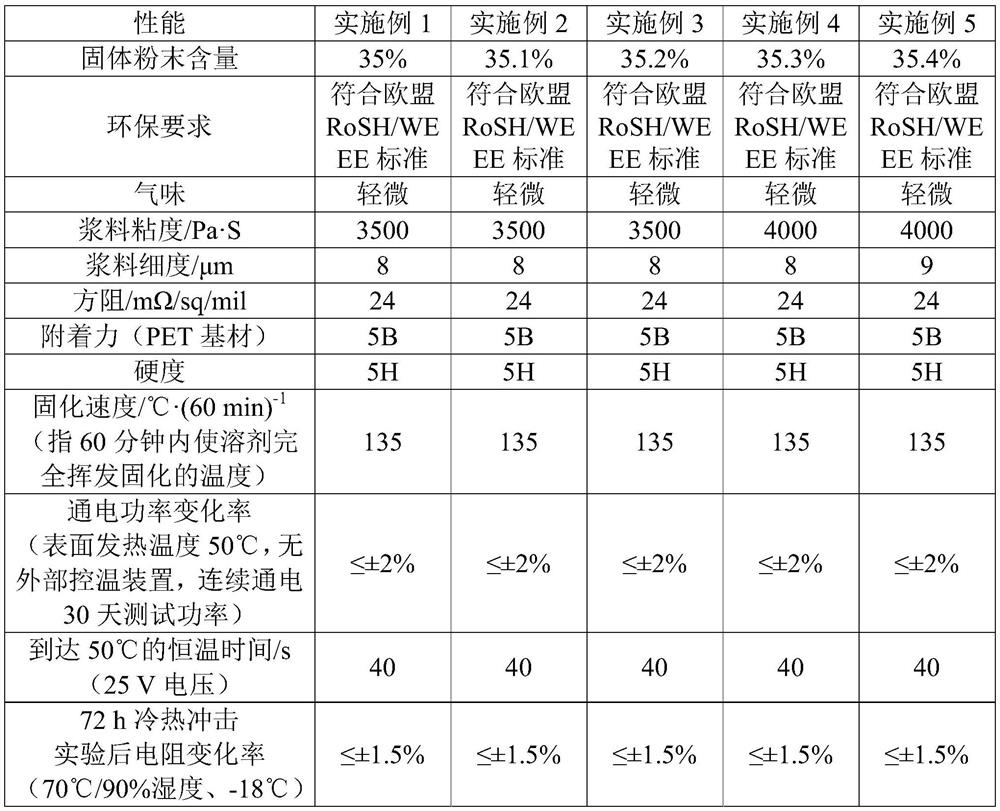

Conductive ink for heating of automobile rearview mirror and preparation method of conductive ink

The invention relates to conductive ink for heating of an automobile rearview mirror and a preparation method of the conductive ink. The conductive ink comprises the following components in parts by mass: 15-20 parts of a conductive and heat-conducting carrier, 20-35 parts of a filling body, 20-85 parts of a resin carrier, 0.5-1 part of an anti-settling agent, 0.2-0.5 parts of a dispersing agent, 0.2-0.5 parts of a thickening agent and 0.2-2 parts of a solvent. The conductive ink is obtained by the steps of: (1) powder drying; (2) sanding and dispersing; (3) vacuum filtration; and (4) homogenizing and stirring. Compared with the prior art, the conductive ink has the advantages of good conductivity, strong adhesive force, good wrapping property, fast curing, long storage time and the like.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Disinfection spraying device for animal husbandry and veterinary medicine

PendingCN114832969AImprove uniformityStrong wrappingClimate change adaptationLiquid spraying apparatusAnimal scienceCrop livestock

The invention belongs to the technical field of livestock breeding, and particularly relates to a livestock veterinary disinfection spraying device which comprises a first valve installed on a disinfectant inlet pipe of a disinfector body, and a second valve is further arranged on the other disinfectant inlet pipe of the disinfector body. The two valves are connected through the connecting rod, the combined pin and the limiting hole, the opening angle of the two valves can be synchronously adjusted according to the actual use condition, quantitative and synchronous output of spraying medicine is achieved, the disinfection spraying uniformity is improved, and the guiding and stability improving effects are achieved by arranging the guiding base and the guiding block for auxiliary adjustment at one end of the connecting rod; by arranging the buffering backup plate, the wrapping performance of the equipment and the human body is higher, the use comfort is improved, the heat dissipation strips are arranged at the end, close to the human body, of the buffering backup plate, the heat dissipation strips have the heat dissipation effect on the basis of the buffering backup plate, the use comfort is better improved, and long-time work is better facilitated.

Owner:罗起娟

Shell body nitrogen fixing slow release composite fertilizer

InactiveCN1321948CLow costGood sustained release effectFertilizer mixturesSulfatePotassium chloride 10%

The present invention relates to a shell nitrogen-fixing slowly-released composite fertilizer. It is characterized by that its composition includes the following components: (by wt%) 5-10% of organic diatomite, 6-10% of calcium sulfate, 6-10% of general calcium perphosphate, 23-35% of monoammonium phosphate, 10-20% of potassium chloride and 23-33% of urea.

Owner:天津芦阳肥业股份有限公司

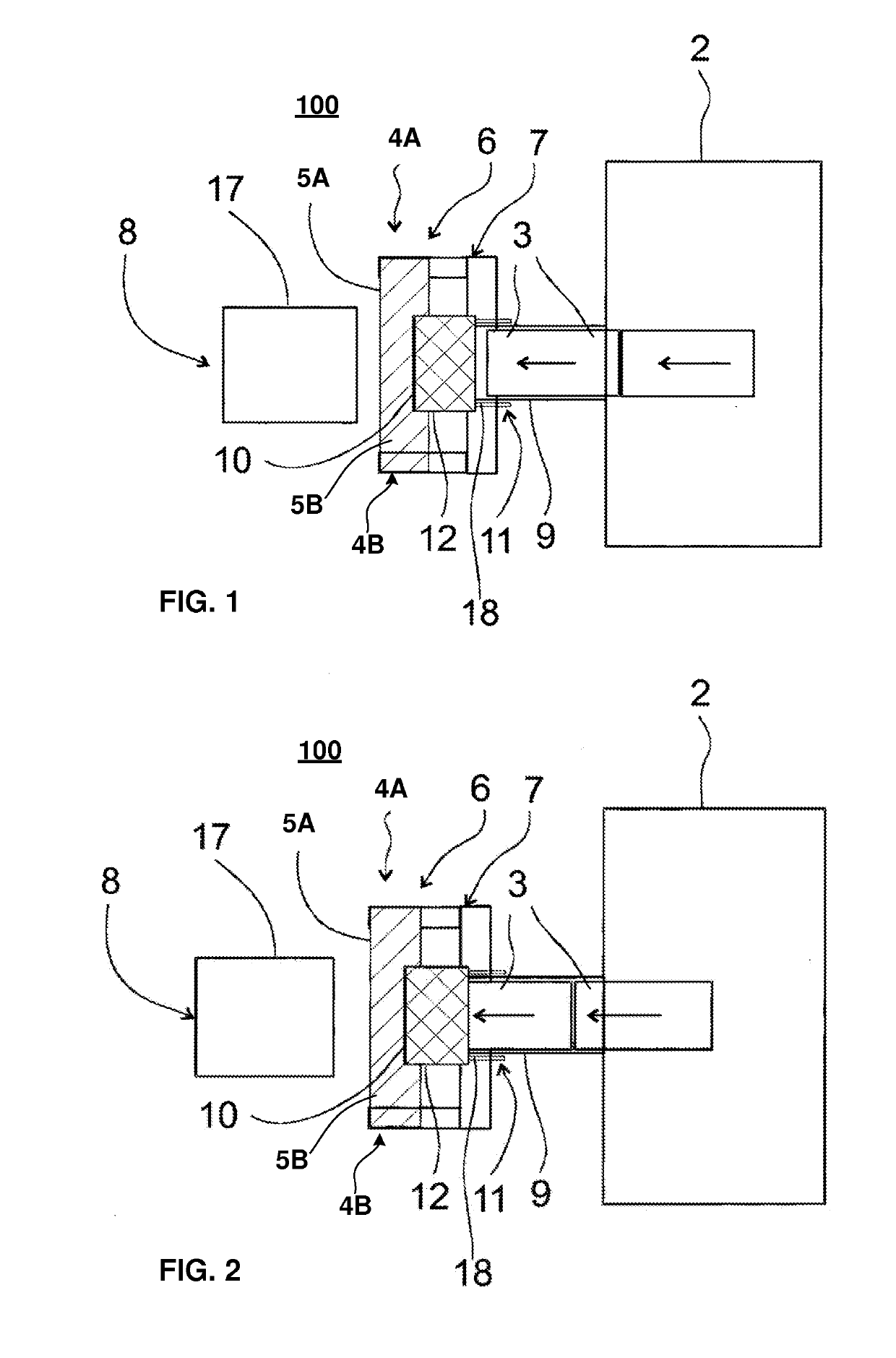

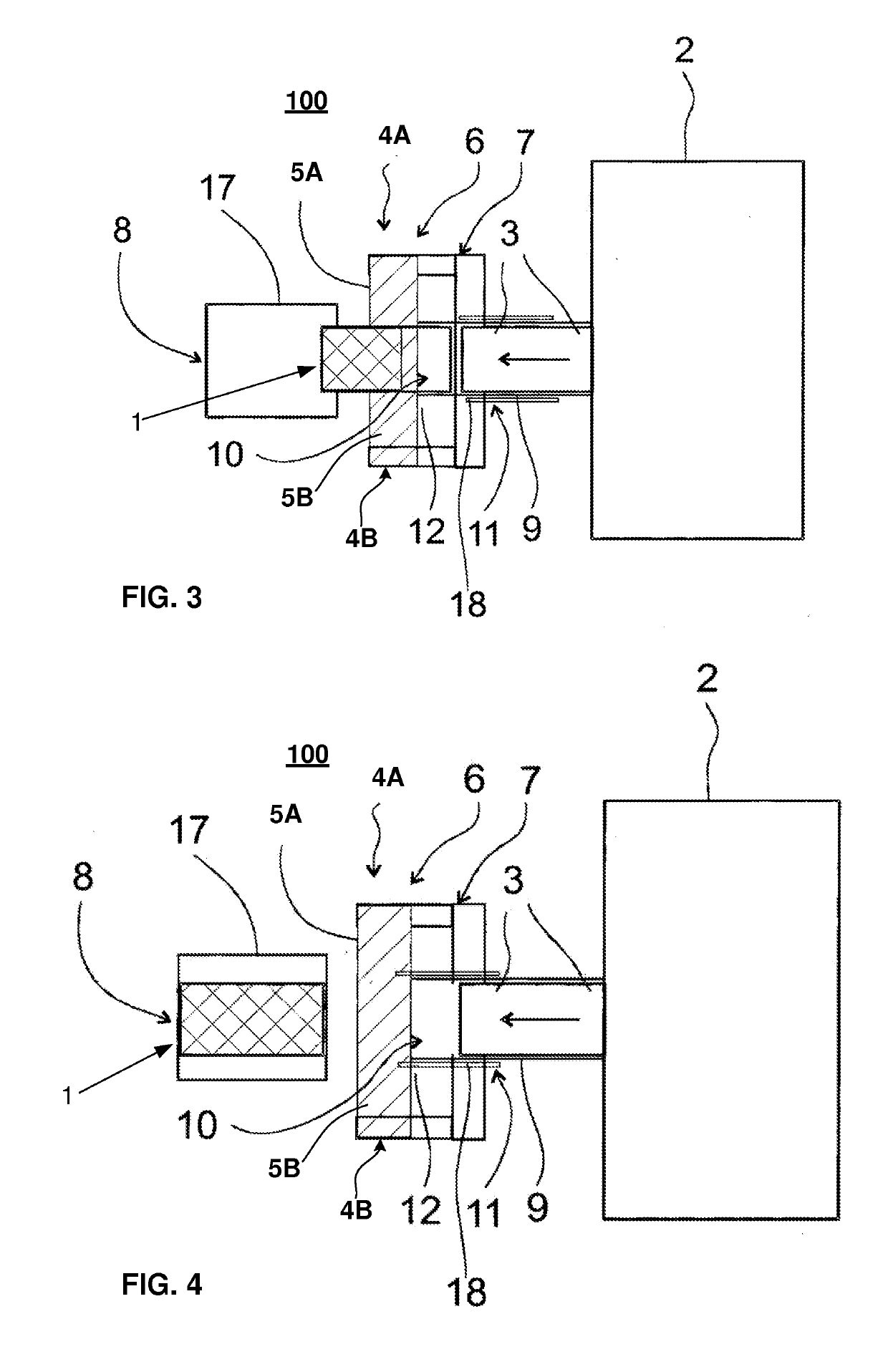

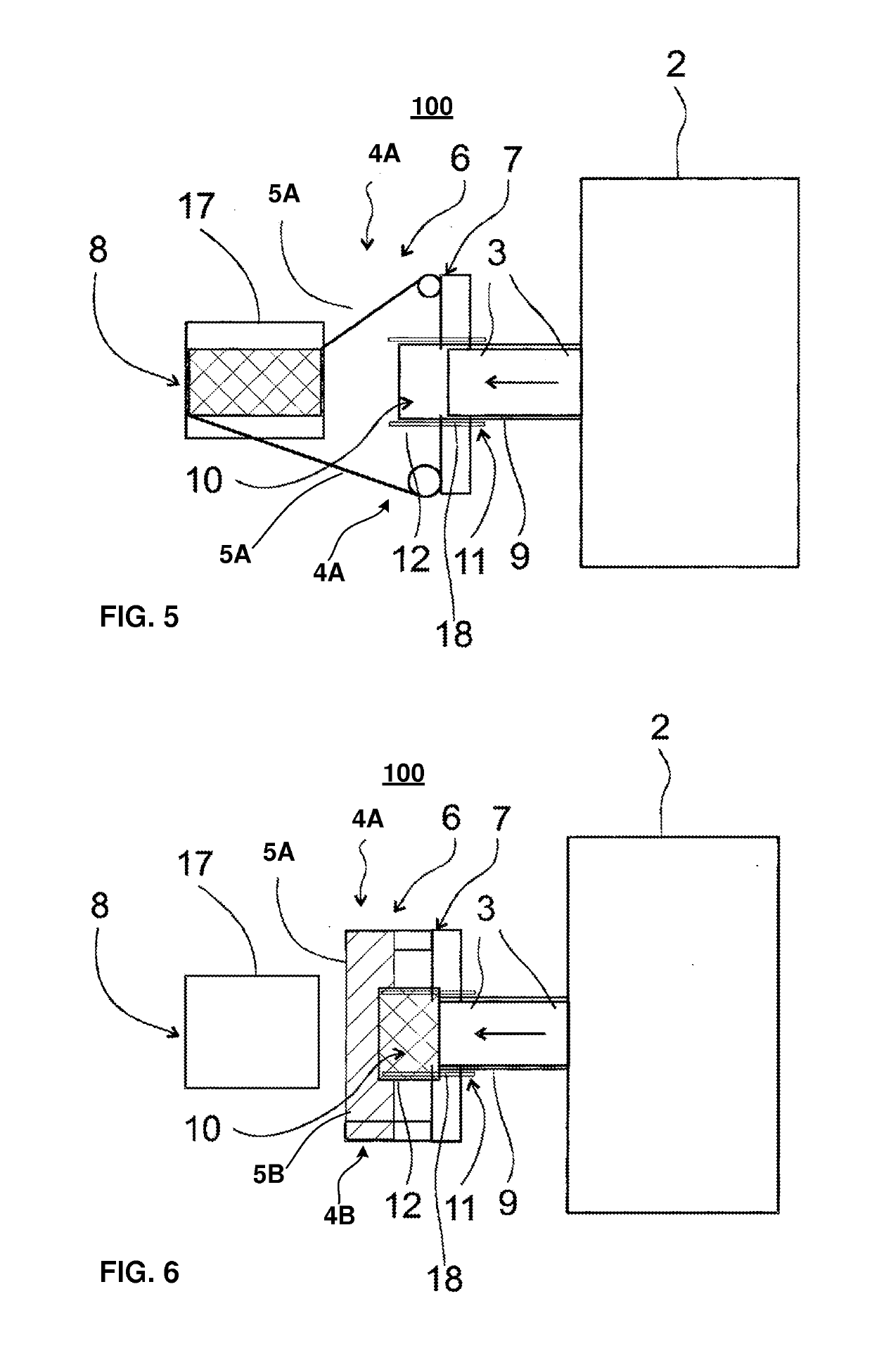

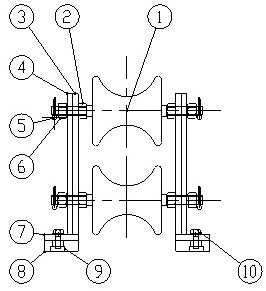

Method and apparatus for producing wrapped bales

InactiveUS20190118986A1Strong supporting areaLess materialWeb rotation wrappingBalingMechanical engineering

Owner:CROSS WRAP OY

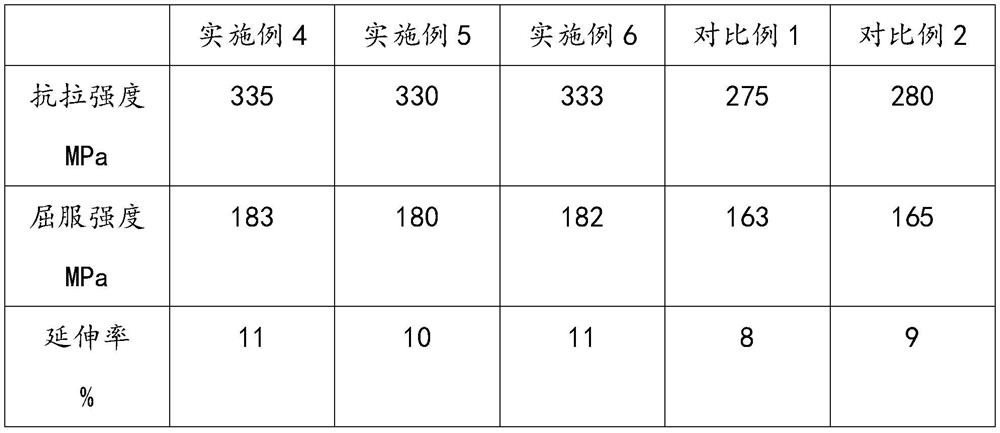

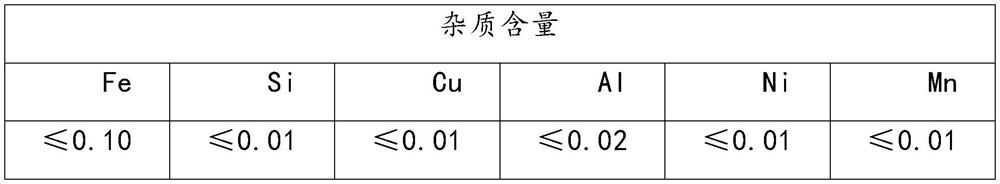

Magnesium-neodymium intermediate alloy and preparation method thereof

The invention relates to a magnesium-neodymium intermediate alloy and a preparation method thereof, and belongs to the technical field of metal materials and metallurgy. The magnesium-neodymium intermediate alloy comprises the following raw materials including, by weight, 10-15 parts of magnesium powder, 10-15 parts of neodymium powder and 0.1-0.15 part of a multi-element refining agent. The magnesium powder is added into a smelting furnace, a protective flux is added, slagging-off is conducted, the neodymium powder is added after slagging-off, the temperature is increased to 1050 DEG C after complete adding, the multi-element refining agent is added, the protective flux is added again after the temperature is increased to 1100 DEG C, secondary slagging-off is conducted, and a smelting material is prepared; brewing and boiling are carried out; ingot casting is carried out; testing is carried out; and carbon powder can serve as a pore-forming agent to decompose and release gas, on one hand, part of hydrogen in molten metal is taken away, on the other hand, nano-calcium-based powder is sintered at the temperature, a large number of porous structures are generated, the specific surface area of the nano-calcium-based powder is increased, the excellent adsorption performance is achieved, residual hydrogen and impurities in melt can be adsorbed, and the effects of refining and impurity removal are achieved.

Owner:LOUDI XINGXIN ALLOY

Lithium ion battery electrolyte, preparation method thereof, and lithium ion battery

InactiveCN106785026AStrong carrier capacityStrong wrappingSolid electrolytesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a lithium battery electrolyte, a preparation method thereof, and a lithium ion battery, and belongs to the field of lithium batteries. The raw material formula of the lithium ion electrolyte providing good low temperature performance and high electricity conductivity comprises an electrolyte matrix and a polymer monomer, and the polymer monomer contains at least one naphthalene ring monomer containing an amino group and at least one monomer containing two carboxyl groups.

Owner:DEYANG JIUDING ZHIYUAN INTPROP OPERATION CO LTD

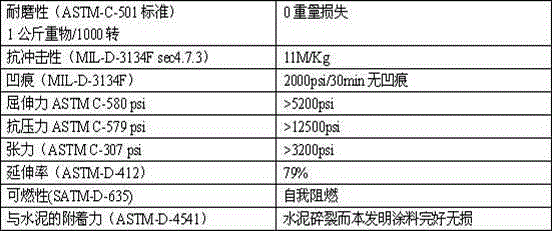

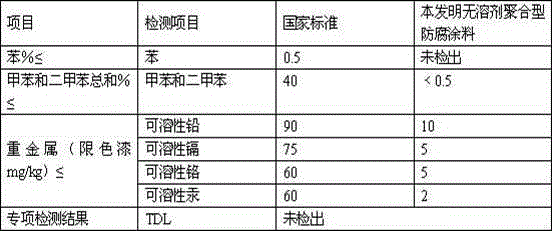

Solvent-free polymerized anticorrosive coating and preparation method thereof

InactiveCN103952070AStrong adhesionImprove permeabilityAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePolyol

The invention belongs to the field of coatings and in particular relates to a solvent-free polymerized anticorrosive coating and a preparation method thereof. The coating is characterized by comprising the following components by weight percent: 30%-50% of polyether polyol, 8%-12% of isocyanate, 8%-20% of a modifier, 0.5%-2% of a catalyst, 18%-30% of fillers, 8%-12% of light calcium carbonate and 3%-8% of aids. The preparation method comprises the following steps: fully neutralizing dewatered polyether polyol, catalyst and isocyanate, performing high-speed shearing for dispersing, adding dispersed materials into a reaction kettle installed with a temperature meter, a stirring device and a reflux condenser, measuring the NCO value by using a di-n-butylamine titration method, dropwise adding, and preserving heat; adding the modifier, the fillers, light calcium carbonate and the aids after the NCO value is a theoretical value. The method is simple and safe in process, environmental friendly and energy-saving; the coating is large in adhesive power and long in service life.

Owner:HULUDAO YITUO IND

Shield pipeline guide device

ActiveCN112707247AAvoid cuts and wearImprove the extension guide effectFilament handlingTunnelsEngineeringStructural engineering

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

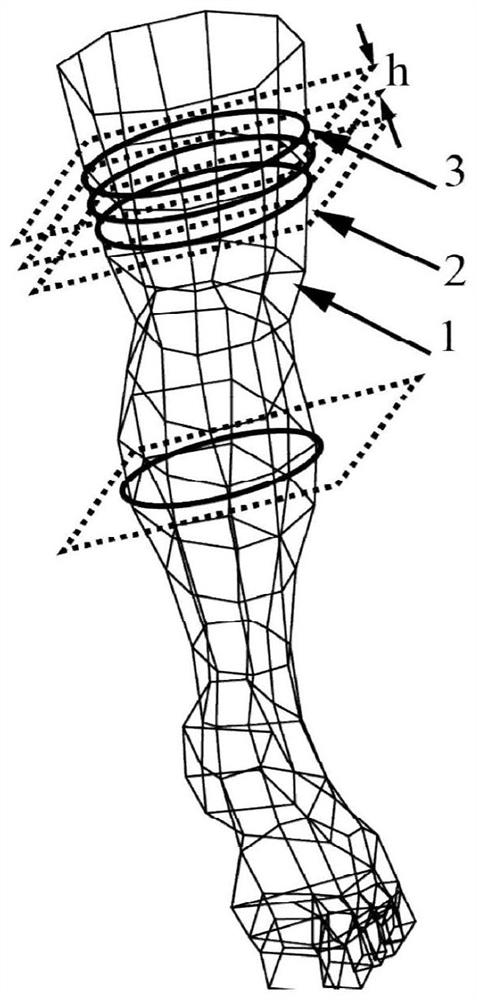

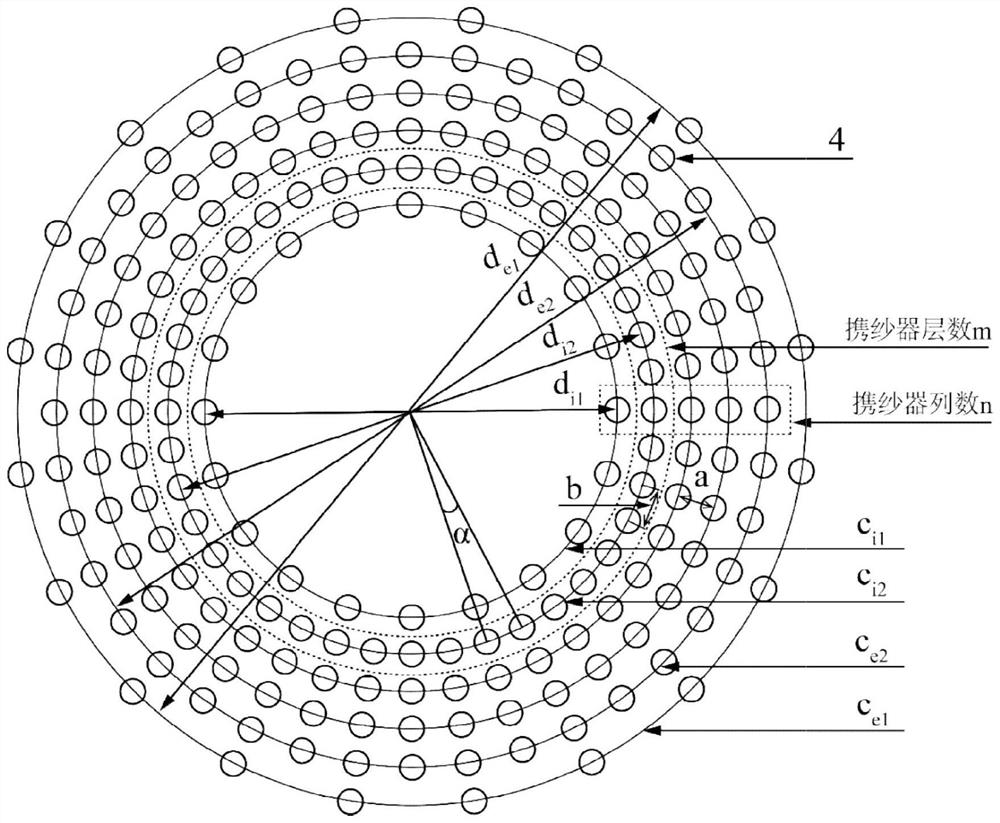

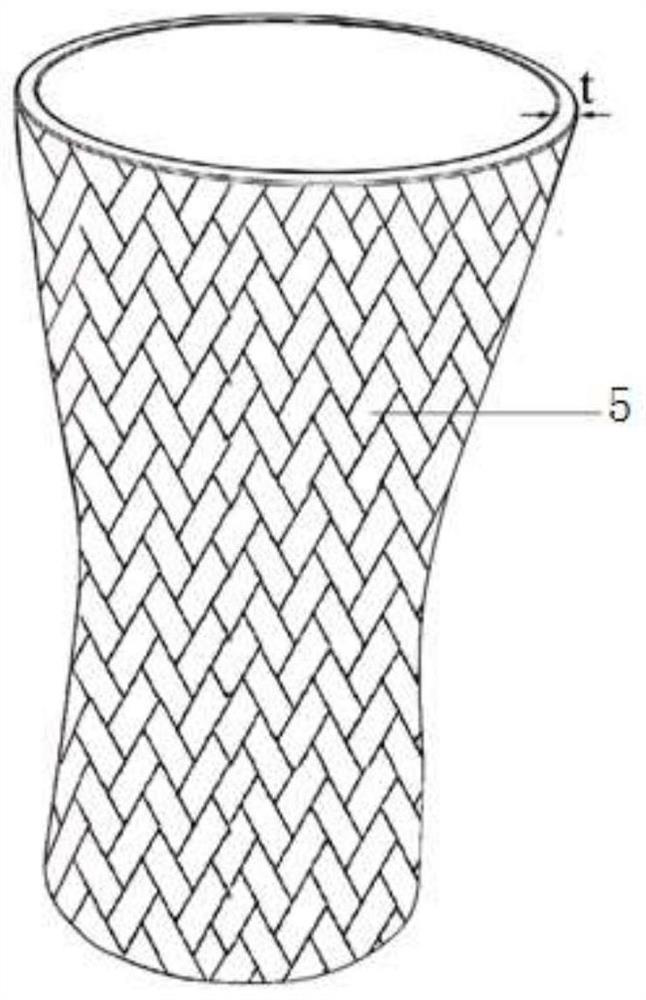

Method for personalized customization of protector product

The invention discloses a method for personalized customization of a protector product. The method comprises obtaining a corresponding three-dimensional model through three-dimensional scanning of a protected part of a user and a circular three-dimensional weaving method for continuous spun yarn of a novel mechanical intelligent material. A three-dimensional model is obtained through three-dimensional scanning of the protected part of the user and serves as a basis for designing arrangement of yarn carriers of all weaving planes in three-dimensional weaving, and then circular three-dimensional weaving of continuous spun yarn of the novel mechanical intelligent material is conducted according to the designed arrangement of the yarn carriers of all the weaving planes, so that the protector product prepared from the novel mechanical intelligent material is obtained. According to the method for personalized customization of the protector product, the novel mechanical intelligent material, the three-dimensional scanning technology and the circular three-dimensional weaving technology are combined, and a foundation is laid for the good effect in functional performance of the protector product from the aspects of material, forming method and the matching degree to the user.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com