Method for preparing ferric hydroxide-based raw materials containing high value elements

An iron hydroxide-based, high-value technology, applied in the directions of iron oxide/iron hydroxide, process efficiency improvement, solid waste removal, etc., can solve the difficult, time-consuming and unfavorable large-scale production of iron-based waste high-value elements metering and other issues, to achieve the effect of facilitating further utilization, reducing security risks, and facilitating trade circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

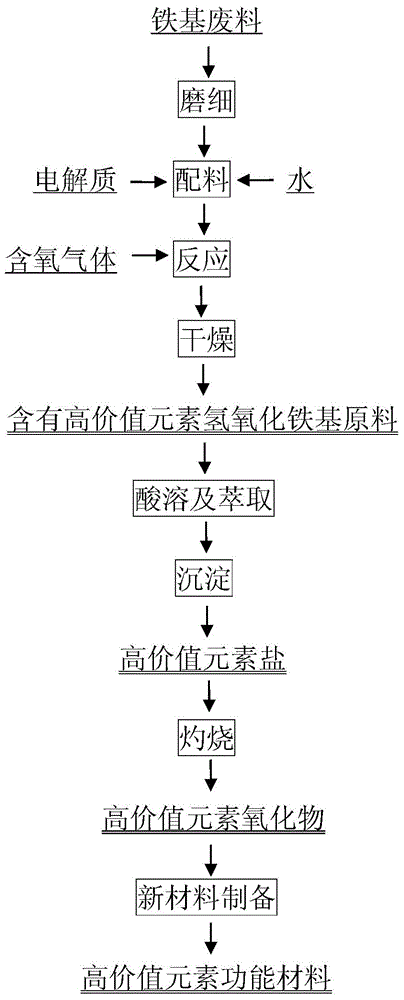

[0088] see figure 1 .

[0089] The NdFeB waste slag in the form of hard clay lumps can be ignited with matches, and it will spontaneously ignite when heated to about 75°C, and the ignition point is 104.4°C according to the measurement. Grinding into NdFeB alloy waste with a particle size of ≤5mm. After testing, REO23.11wt%, CoO1.22wt%, Fe42.53wt%, combustible organic matter calculated as C element 3.85wt%, moisture 15.02wt%, and the balance for other substances. Take 2000Kg of NdFeB alloy waste, 1100L of water and 400L of 7N hydrochloric acid and mix them evenly in a reaction pot. The temperature of the materials rises to 48°C and keeps stirring so that the Reynolds number Re=ρND 2 / μ≥2240000 (where ρ is the fluid density, N is the rotational speed, D is the diameter of the stirring paddle, μ is the viscosity, the same below), with 5-20M 3 / min flow into the reaction pot with compressed air at about 50°C. During the process, the reaction temperature is controlled at 50-90°C...

Embodiment 2

[0102] see figure 1 .

[0103] NdFeB waste slag can be ignited with a match, and it will catch fire when heated to 55°C, and the ignition point is 105°C according to the measurement. After wet ball milling, it becomes NdFeB alloy waste with a particle size of ≤0.15mm. After testing, REO18wt%, CoO0.99wt%, Fe33.53wt%, combustible organic matter in terms of C elements are 4.85wt%, moisture 30.74wt%, and residual Quantities are other substances. Take 2000Kg of the NdFeB alloy waste, put it into a reaction pot with 300L of water and 25L of 98% industrial sulfuric acid and mix evenly, keep stirring until the Reynolds number Re=10460, and use 0.2-1M 3 Oxygen is fed into the reaction pot at a flow rate of / min, and the temperature increases by 5-10M after the temperature reaches 50°C 3 / min air, during the process, the reaction temperature is controlled to be 70-100°C by replenishing water and other means. After reacting for 1.5h, the prepared material is sent to a rotary dryer tha...

Embodiment 3

[0109] see figure 1 .

[0110] NdFeB waste slag can be ignited with matches, and it will catch fire when heated to 45°C. It has been detected that REO27.67wt%, CoO0.95wt%, Fe47.46wt%, combustible organic matter calculated as C element is 10.4wt%, moisture is 6.7wt%, and the balance is other substances. Take 100g of the aforementioned NdFeB alloy waste with a particle size of ≤0.1mm, put them into a three-necked flask placed in an ultrasonic water bath at 70°C, and mix them evenly with 500ml of water and 2.7gAR ammonium chloride, and keep the Reynolds number Re=ρND 2 / μ≥29000, feed oxygen into the three-necked flask at a flow rate of 1L / min, and after 4 hours of reaction, 287g of ferric hydroxide-based raw materials containing high-value elements are obtained. Wherein Y(Fe) is 0.01wt%, Y(Fe 3+ ) is 16.26wt%. The ferric hydroxide-based raw material containing high-value elements is in the form of agglomerates, which cannot be ignited with a match. Keep the ignition source he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com