Incubator and method of incubating mature silkworms by employing same

An incubator and silkworm technology, which is applied in the field of incubators and mature silkworms, can solve the problems affecting the development of downstream deep-processing products, inability to process on-site, short silkworm growth period, etc., and achieve the expansion of large-scale industrial development and utilization, The effect of saving natural resources and reducing the cost of cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

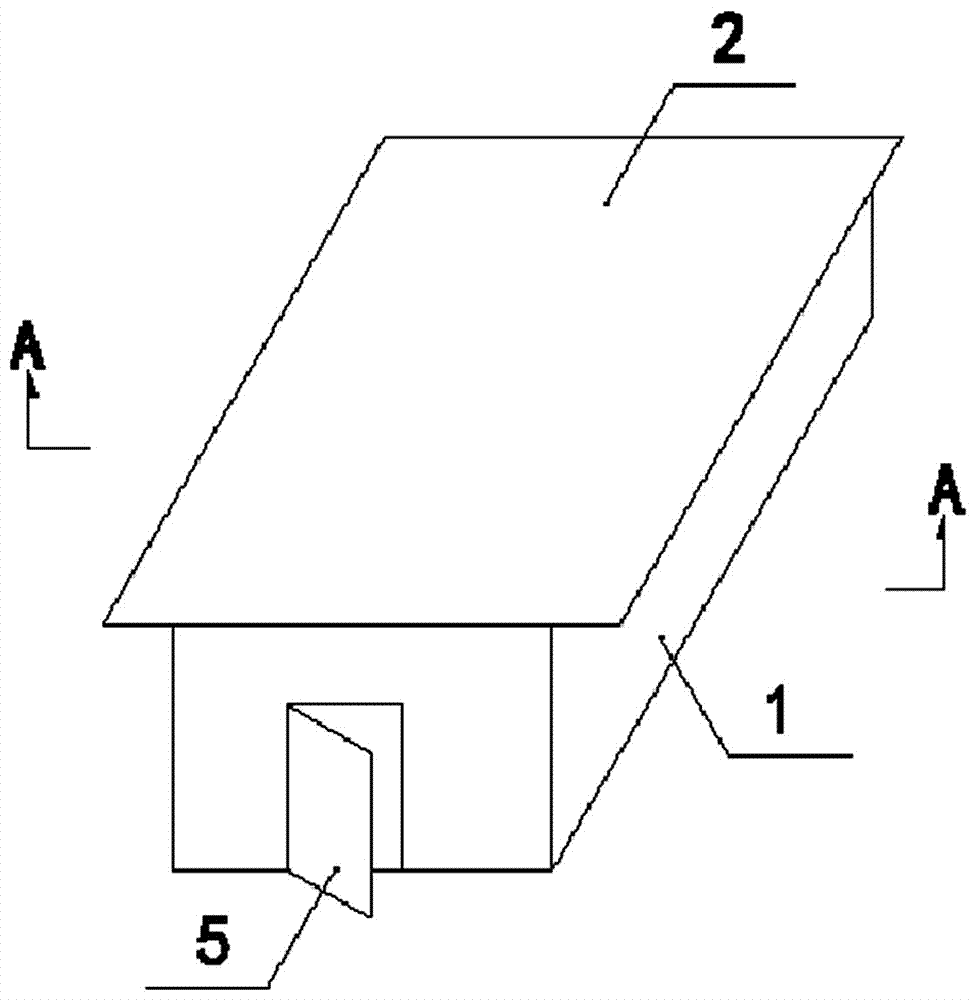

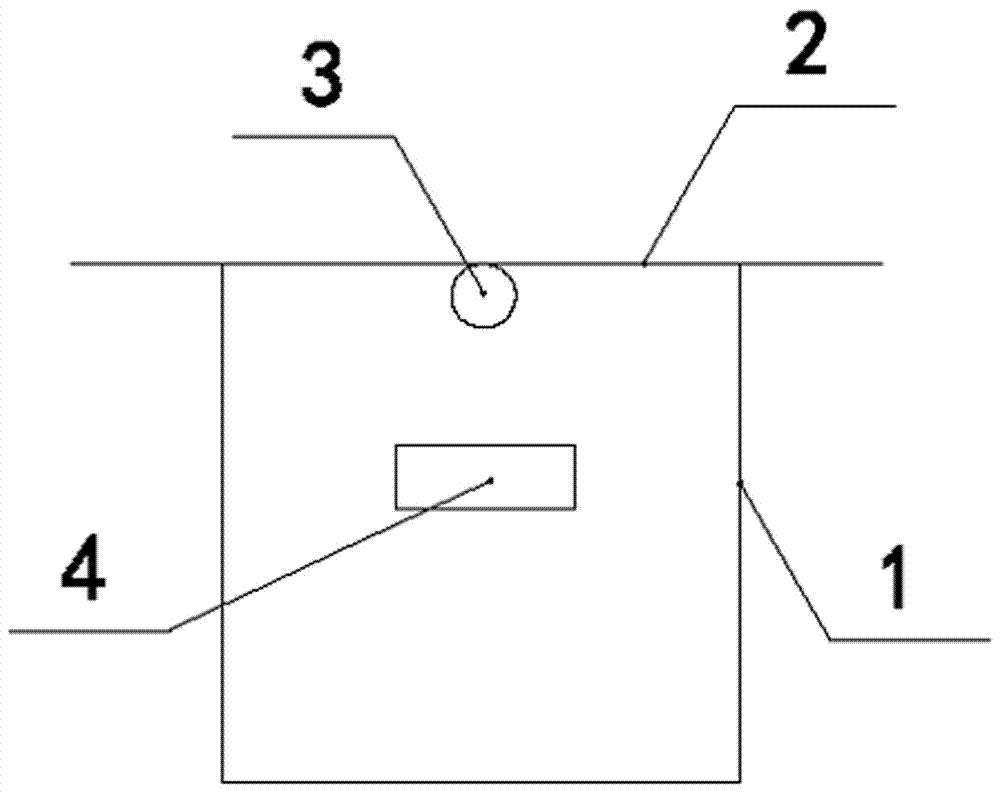

[0037] Embodiment 1: refer to figure 1 , Fig. 2, the top of casing of the present invention covers silicon photocell or selenium photocell, and silicon photocell or selenium photocell are converted into electric energy after receiving light and provide electric energy to temperature-humidity controller and yellow light bulb, as providing to casing to cultivate ripe silkworm carrier and physical conditions. The incubator should be rationally planned and designed, scientifically selected, installed and used according to the specific natural geographical environment, production scale, road traffic and other actual conditions of the mulberry garden, combined with factors such as the development plan and investment budget of the mulberry garden enterprise. In this embodiment, the incubator is placed in a mulberry garden with no shelter and sufficient sunlight. The mulberry garden is adjacent to both sides of the road, which is convenient for transportation.

Embodiment 2

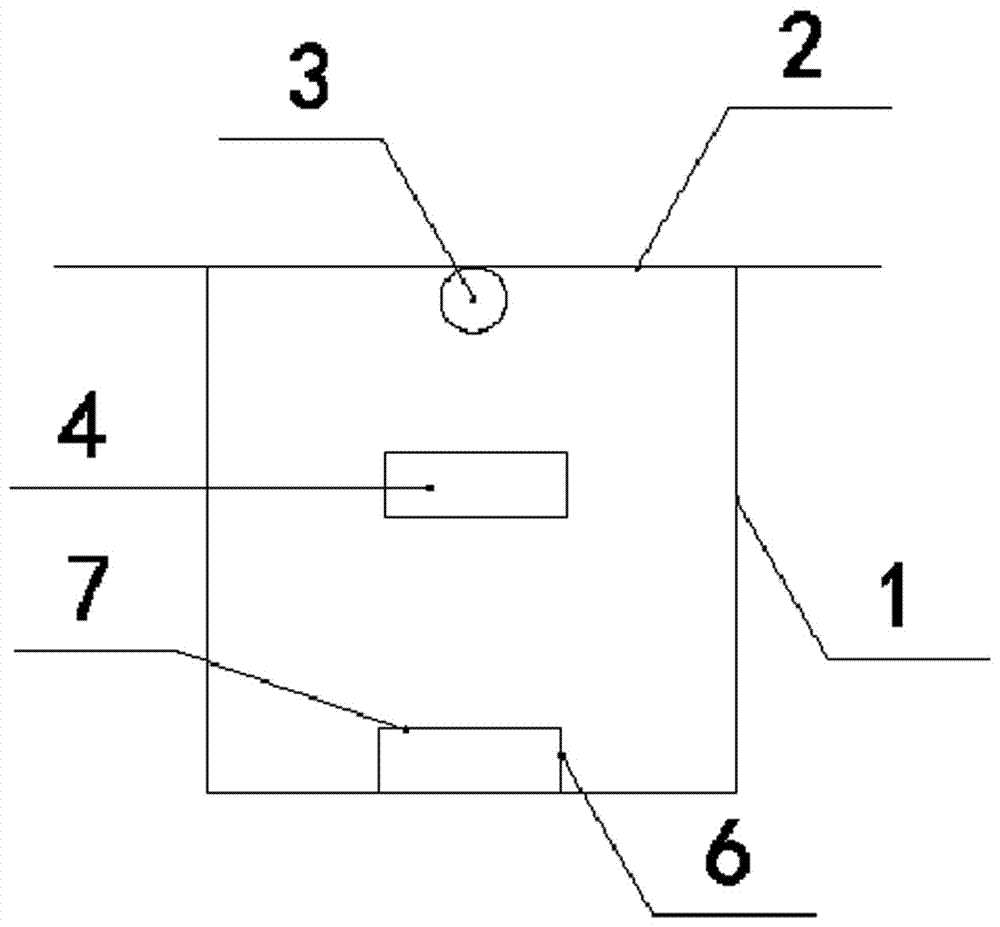

[0038] Embodiment 2: refer to figure 1 ,figure 2, image 3 , silicon photocells or selenium photocells are used as the power supply to provide electric energy to the yellow light bulb and the temperature and humidity controller, so that the temperature in the incubator is 10°C and the relative humidity is 45%. Clusters, the placement angle of the clusters is 0-35°, preferably 25°, placed in the clusters cooked silkworms, the placement density of cooked silkworms is 600-650 heads per square meter, the door is closed, and the cooked silkworms are cultivated for 40 hours. Mature silkworms spit out silk in the process of reciprocating crawling between the baffles on opposite sides of the cluster under the environment of the above-mentioned temperature and relative humidity and the induction of the yellow light emitted by the bulb.

Embodiment 3

[0039] Embodiment 3: refer to figure 1 ,figure 2, image 3 , The selected temperature in the present embodiment incubator is 20 ℃, relative humidity is 68%, cultivates ripe silkworm 70h, other is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com