Conductive ink for heating of automobile rearview mirror and preparation method of conductive ink

A technology of automobile rearview mirror and conductive ink, applied in the directions of ink, separation method, chemical instrument and method, etc., can solve the problems of poor resistance to cold and thermal shock, great significance for research and development, slow heating speed, etc., to eliminate bubbles and enhance conductivity. Sex and adhesion, the effect of enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0034] A preparation method of conductive ink for automobile rearview mirror heating, each component and composition are shown in Table 1. Among them, the resin carrier is used as the bonding phase, and the graphene powder used is an ultrafine multi-layer flake powder, with an average particle size of 5-10 μm and an average thickness of 5-10 nm; the conductive carbon black used has an average particle size of 5-10 μm; The conductive silver powder has an average particle size of 5-6 μm.

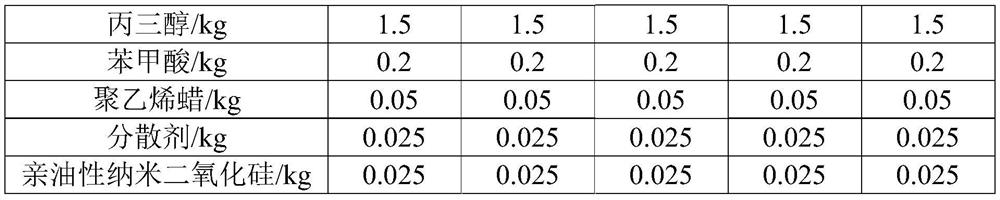

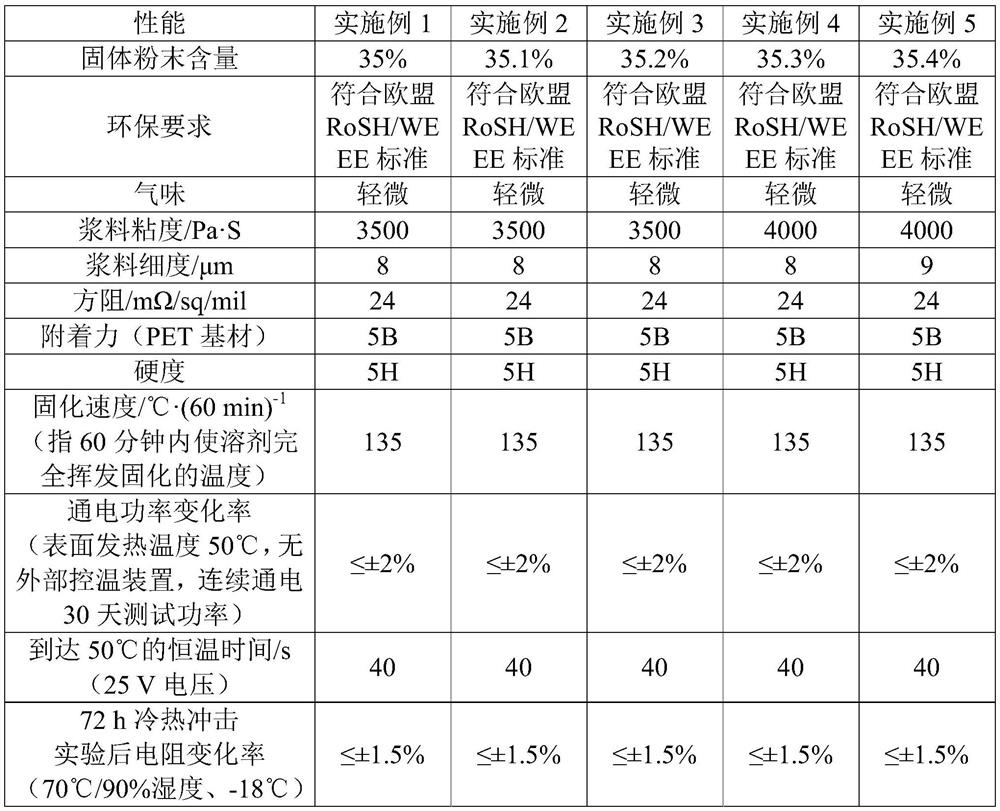

[0035] The consumption of each component in the embodiment is as shown in table 1:

[0036] Table 1

[0037]

[0038]

[0039] The main steps of the actual production process are as follows:

[0040] The preparation of the resin carrier premix is to add the acrylic resin to the reaction kettle according to the formula ratio, and then add the absolute ethanol and glycerin to the reaction kettle in the form of dropwise addition. The dropping time is 1h, and the stirring is continued fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com