Grouting material and preparation method thereof

A technology of grouting materials and cementitious materials, applied in the field of prestressed concrete, which can solve the problems of large fluidity loss, poor fluidity, and low flexural strength, and achieve small fluidity loss, good fluidity, and filling degree Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A grout, comprising the following components in parts by weight: 95.5 parts of cementitious material; 0.4 part of polycarboxylate water reducer; 0.04 part of defoamer; 0.02 part of anti-settling water retention agent; 4 parts of concrete expansion agent; plastic expansion 0.04 parts of agent; the cementitious material includes the following components: 90 parts of Portland cement; 7 parts of silica fume; 2 parts of superfine stone powder; 1 part of fly ash.

[0049] Add the above materials into the mixing equipment and mix evenly, and obtain the pressed slurry after homogenization treatment.

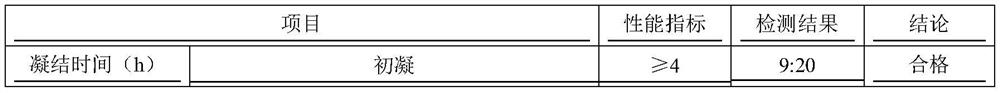

[0050] According to the standard of TB / T 3192-2008 "Technical Conditions for Grouting of Railway Post-tensioned Concrete Beam Pipeline", the water-binder ratio is 0.33, and the test data are as follows:

[0051]

[0052]

Embodiment 2

[0054] A grout comprising the following components in parts by weight: 96.61 parts of cementitious material; 0.3 part of polycarboxylate water reducer; 0.03 part of defoamer; 0.02 part of anti-settling water retention agent; 3 parts of concrete expansion agent; plastic expansion 0.04 parts of agent; the cementitious material includes the following components: 84 parts of Portland cement; 8 parts of silica fume; 5 parts of superfine stone powder; 3 parts of fly ash.

[0055] Add the above materials into the mixing equipment and mix evenly, and obtain the pressed slurry after homogenization treatment.

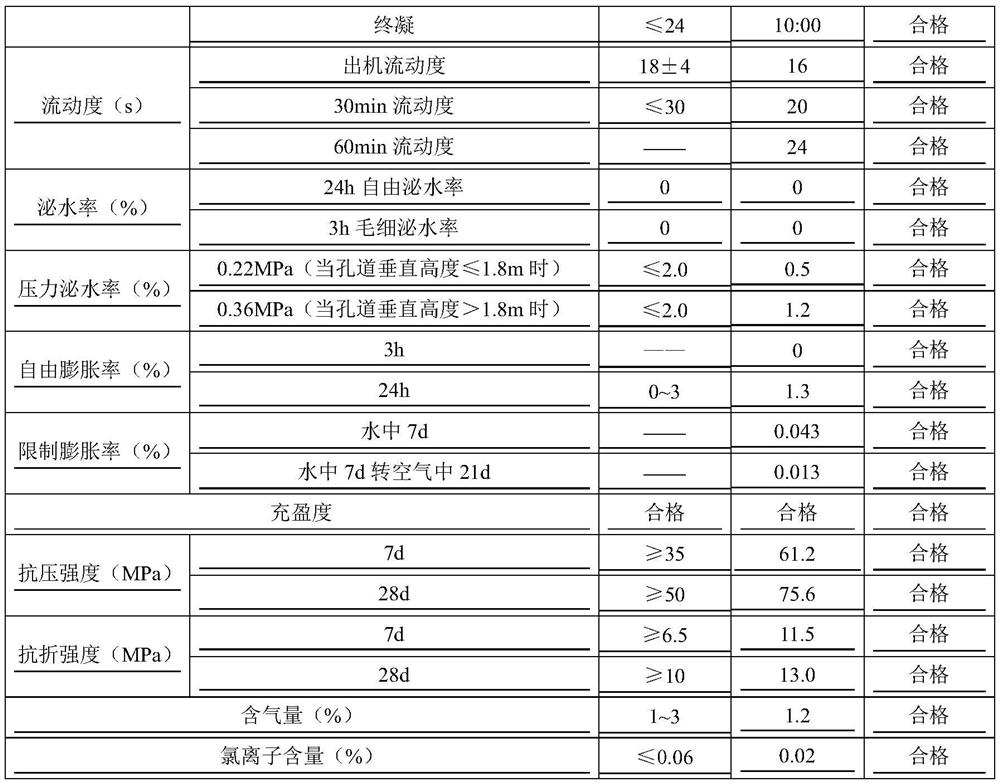

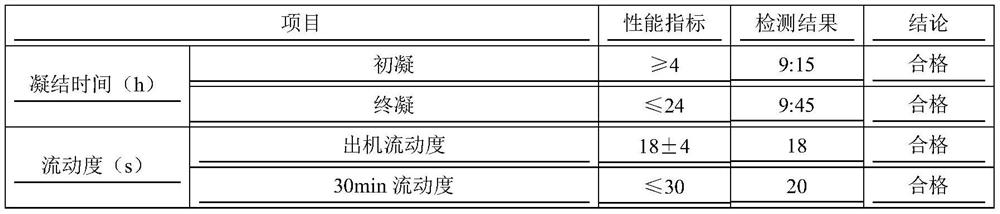

[0056] According to the standard of TB / T 3192-2008 "Technical Conditions for Grouting of Railway Post-tensioned Concrete Beam Pipeline", the water-binder ratio is 0.33, and the test data are as follows:

[0057]

[0058]

[0059] It can be seen that the product of the present invention meets the industry standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com