Electrophoretic grinding resin, electrophoretic color paste prepared therefrom and application of color paste

A technology of grinding resin and electrophoresis, which is applied in electrophoretic coatings, pigment pastes, coatings, etc., and can solve the problems of limited use range, poor compatibility, and complexity of dispersing resins for grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

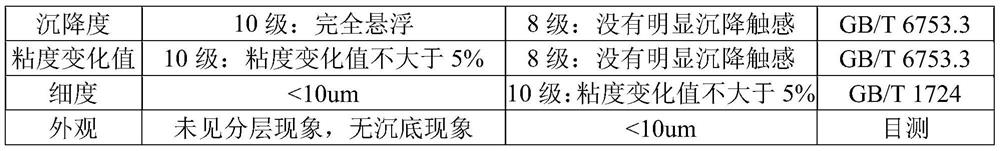

Image

Examples

preparation example Construction

[0032] The preparation process of the electrophoretic grinding resin is that raw materials such as acrylic resin and azobisisobutyronitrile are metered into a mixing and dropping tank, the temperature is maintained below 25° C., and then stirred evenly for use; 1.4-butanediol and ethylene glycol are mixed. The butyl ether raw material is directly put into the reaction kettle. After the feeding is completed, steam is added to heat up under nitrogen protection, and the temperature is raised to 80-95 ° C. The mixture is directly added dropwise, and the dropping time is about 3-5 hours. After dripping the material, continue to be kept at 80~95 ℃ for another 2 hours; after the previous step is finished, cool down to 45~55 ℃, add the isocyanate curing agent of the formula amount, keep the temperature at 45~55 ℃ for 1 hour, and the previous step ends After that, add the formula amount of acetic acid, and keep the temperature at 45-55° C. for 1 hour.

[0033] Meanwhile, the low-molecu...

Embodiment 1

[0057] This embodiment discloses a preparation method of electrophoresis grinding resin, which includes the following preparation process:

[0058] (1) Preparation of isocyanate curing agent: get diblock type isocyanate cross-linking agent: 50%, butanone oxime: 25%, organic catalyst: 10%, ethylene glycol ether: 15% reaction and make isocyanate curing agent; Wherein, The organic catalyst is a commonly used organic catalyst, which is not described in detail in the present invention. At the same time, the process of preparing the isocyanate curing agent is a conventional process, which is not described in detail in the present invention. In addition, the di-blocked isocyanate crosslinking agent consists of toluene diisocyanate: 30%, isophorone diisocyanate: 30%, butanone oxime: 25%, methyl isobutyl ketone: 5%, ethylene glycol Butyl ether: 10% prepared.

[0059] (2) Preparation of electrophoresis grinding resin: it includes taking the following raw materials and mixing them in m...

Embodiment 2

[0062] This embodiment discloses a preparation method of electrophoresis grinding resin, which includes the following preparation process:

[0063] (1) Preparation of isocyanate curing agent: get diblock type isocyanate crosslinking agent: 25%, butanone oxime: 50%, organic catalyst: 10%, ethylene glycol ethyl ether: 15% reaction makes isocyanate curing agent; Wherein, The organic catalyst is a commonly used organic catalyst, which is not described in detail in the present invention. At the same time, the process of preparing the isocyanate curing agent is a conventional process, which is not described in detail in the present invention.

[0064] In addition, the di-blocked isocyanate crosslinking agent consists of toluene diisocyanate: 30%, isophorone diisocyanate: 30%, butanone oxime: 25%, methyl isobutyl ketone: 5%, ethylene glycol Butyl ether: 10% prepared.

[0065] (2) Preparation of electrophoresis grinding resin: it includes taking the following raw materials and mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com