Lithium ion battery electrolyte, preparation method thereof, and lithium ion battery

A technology of electrolyte and lithium battery, which is applied in the field of electrolyte, can solve the problems of liquid analysis failure, etc., and achieve the effect of strong wrapping ability, good low temperature performance, and high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

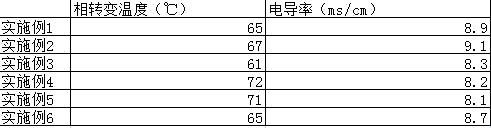

Examples

specific Embodiment 1

[0018] Specific Example 1: First, 1,5-naphthalenediamine and succinic acid are polymerized in bulk with a molar ratio of 1:1 and polymerized under an initiator to form a prepolymer with a molecular weight lower than 50,000, and the lithium salt is dissolved in An electrolyte matrix of 80%-95% is configured in the organic solvent, and the electrolyte matrix is a lithium salt: LiBF4, and the solvent is ethylene carbonate;

[0019] Mix the electrolyte matrix with the prepolymer and the crosslinking agent, stir evenly, wherein the weight of the prepolymer is 5% of the mass of the electrolyte matrix, and at room temperature, use a vacuum liquid injection device to infiltrate the diaphragm and the positive electrode. In the negative electrode material, seal the above mixture, and fully infiltrate the separator for more than 2 hours; polymerize at 30°C to form a colloid.

specific Embodiment 2

[0020] Specific Example 2: Firstly, 2,3-naphthalene diamine and maleic acid are bulk polymerized at a molar ratio of 1:1 and polymerized under an initiator to form a prepolymer with a molecular weight lower than 50,000, and the lithium salt is dissolved In the middle of the organic solvent, it is configured as a 95% electrolyte matrix, and the electrolyte matrix is lithium salt as LiClO 4 , the solvent is propylene carbonate;

[0021] Mix the electrolyte matrix with the prepolymer and crosslinking agent, stir evenly, wherein the weight of the prepolymer is 20% of the mass of the electrolyte matrix, and at room temperature, use a vacuum liquid injection device to infiltrate the diaphragm and the positive electrode. In the negative electrode material, seal the above mixture, and fully infiltrate the separator for more than 2 hours; polymerize at 70°C to form a colloid.

specific Embodiment 3

[0022] Specific embodiment 3: at first 2,7-naphthalenediamine and 2-carbonylsuccinic acid are 1:1 bulk polymerization under the initiator polymerization formation molecular weight is lower than the prepolymer of 50000 with molar ratio, described lithium The salt is dissolved in an organic solvent to form a 90% electrolyte matrix, and the electrolyte matrix is a lithium salt: LiAsF 6 , the solvent is dimethyl carbonate;

[0023] Mix the electrolyte matrix with the prepolymer and crosslinking agent, stir evenly, wherein the weight of the prepolymer is 15% of the mass of the electrolyte matrix, and at room temperature, use a vacuum liquid injection device to infiltrate the separator and the positive and negative electrodes In the material, seal the above mixture, and fully infiltrate the diaphragm for more than 2 hours; polymerize at 50°C to form a colloid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com