Gel polymer lithium-ion electrolyte and battery containing same

A technology of gel polymer and electrolyte, which is applied in the field of electrolyte, can solve the problems of liquid analysis failure, etc., and achieve the effect of strong wrapping ability, good low temperature performance and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

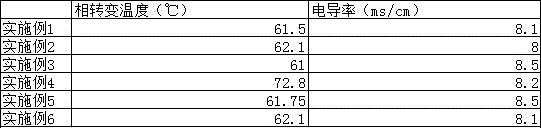

Examples

specific Embodiment 1

[0019] Polymerize terephthalic acid with 1,2-propylenediamine and ethylenediamine at a molar ratio of 1:1 to form two prepolymers, and the molecular weight of the prepolymers can be controlled at less than 3000 .

[0020] Mix ethylene carbonate lithium ion solvent, crosslinking agent divinylbenzene, initiator, terephthalic acid, 1,2-propylenediamine, and ethylenediamine in proportion.

[0021] Stir evenly, at room temperature, use vacuum liquid injection equipment to infiltrate the separator and positive and negative electrode materials; seal the above mixture, and fully infiltrate the separator for more than 1 hour; polymerize at 60°C-70°C to form a colloid.

[0022] Wherein the parts by weight of each component are as follows:

[0023] Lithium ion solvent: 100 parts (1.15mol / L, lithium salt is LiBF4), 10 parts of terephthalic acid monomer; parts; two prepolymers were 10 parts and the normal amount of cross-linking agent and initiator.

specific Embodiment 2

[0025] Isophthalic acid is polymerized with tetramethylpropylenediamine and N,N'-bis(3-aminopropyl)-1,4-butanediamine respectively according to a molar ratio of 1:1 to form two kinds of pre- Polymer, the molecular weight of the prepolymer can be controlled at less than 3000.

[0026] Propylene carbonate lithium ion solvent, crosslinking agent divinylbenzene, initiator, isophthalic acid monomer and tetramethylpropylenediamine, N,N'-bis(3-aminopropyl)-1,4 -Butanediamine mixed in proportion.

[0027] Stir evenly, at room temperature, use vacuum liquid injection equipment to infiltrate the separator and positive and negative materials; seal the above mixture, and fully infiltrate the separator for more than 1 hour; polymerize at 30°C-70°C to form a colloid.

[0028] Wherein the parts by weight of each component are as follows:

[0029] Lithium ion solvent: 100 parts (1.8mol / L, lithium salt is LiClO4), 10 parts of isophthalic acid monomer; tetramethylpropanediamine, N,N'-bis(3-am...

specific Embodiment 3

[0031] Two kinds of prepolymers are formed by polymerizing phthalic acid with 1,3-propylenediamine and distearylethylenediamine respectively at a molar ratio of 1:1, and the molecular weight of the prepolymers is controlled at less than 3000 is enough.

[0032] Mix dimethyl carbonate lithium ion solvent, crosslinking agent divinylbenzene, initiator, phthalic acid, 1,3-propylenediamine, and distearylethylenediamine in proportion.

[0033] Stir evenly, at room temperature, use vacuum liquid injection equipment to infiltrate the separator and positive and negative electrode materials; seal the above mixture, and fully infiltrate the separator for more than 1 hour; polymerize at 35°C to form a colloid.

[0034] Lithium ion solvent: 100 parts (1.7mol / L, LiAsF6), 10 parts of phthalic acid monomer; parts; two prepolymers were 10 parts and the normal amount of cross-linking agent and initiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com