A kind of solidification process method of spherical surface self-lubricating liner of spherical plain bearing

A joint bearing, spherical surface technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problem that the strength and wear resistance of the joint bearing pad cannot meet the expected requirements, the curing pressure cannot be continuously supplied, and the interference force is weakened, etc. problems, to achieve uniform curing pressure in the circumferential direction, improved strength and wear resistance, and increased heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

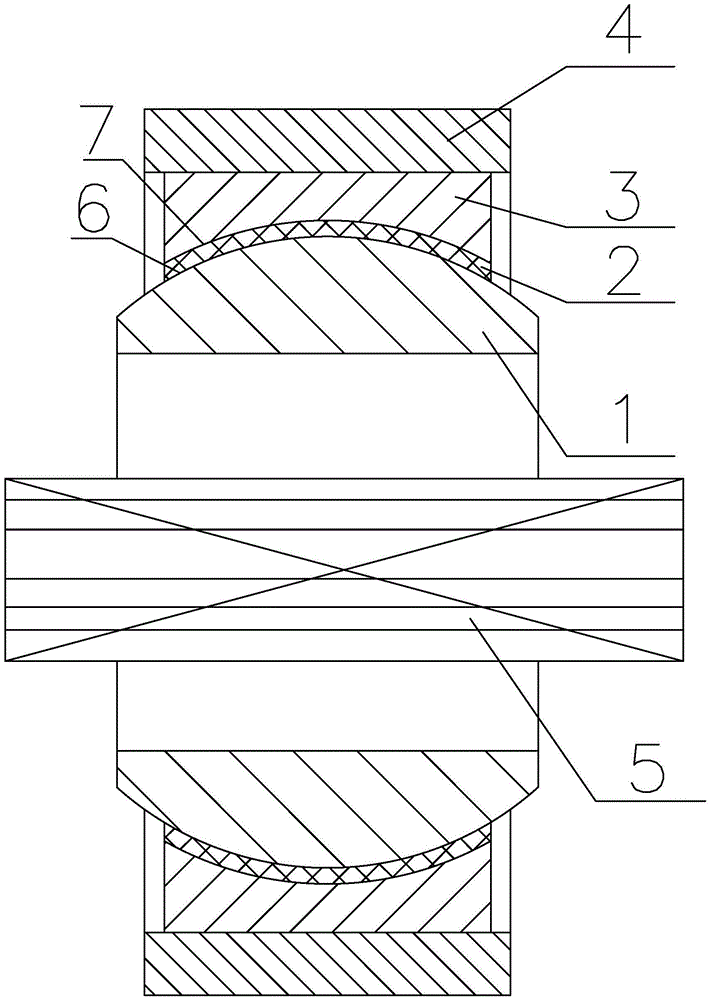

[0016] Please check figure 1 , a preferred embodiment of a solidification process for spherical surface self-lubricating liners of joint bearings.

[0017] Such as figure 1 As shown, the joint bearing includes an outer ring 3 with an inner spherical surface, a self-lubricating liner 2 and an inner ring 1 with an outer spherical surface. The self-lubricating liner 2 has a front face 7 and a back face 6 opposite to the front face 7. The self-lubricating liner Before the pad 2 is cured: the front 7 and the back 6 of the self-lubricating pad have structural adhesives, the front 7 of the self-lubricating pad and the inner spherical surface of the outer ring 3 are pasted together by the structural adhesive, and the outer spherical surface of the inner ring 1 passes through After the isolation layer is processed, it is inserted into the self-lubricating liner 2, the outer spherical surface of the inner ring 1 faces the back of the self-lubricating liner 2, and the outer circumferenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com