Thick fabric composite covering machine

An edge-wrapping machine and fabric technology, applied in the direction of fabric edge trimming, fabric surface trimming, textiles and papermaking, etc., can solve the problems of not meeting production requirements, poor product appearance, low production volume, etc., and achieve uniform gluing and wrapping Strong thickening capacity and enhanced rigidity of the cutter body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

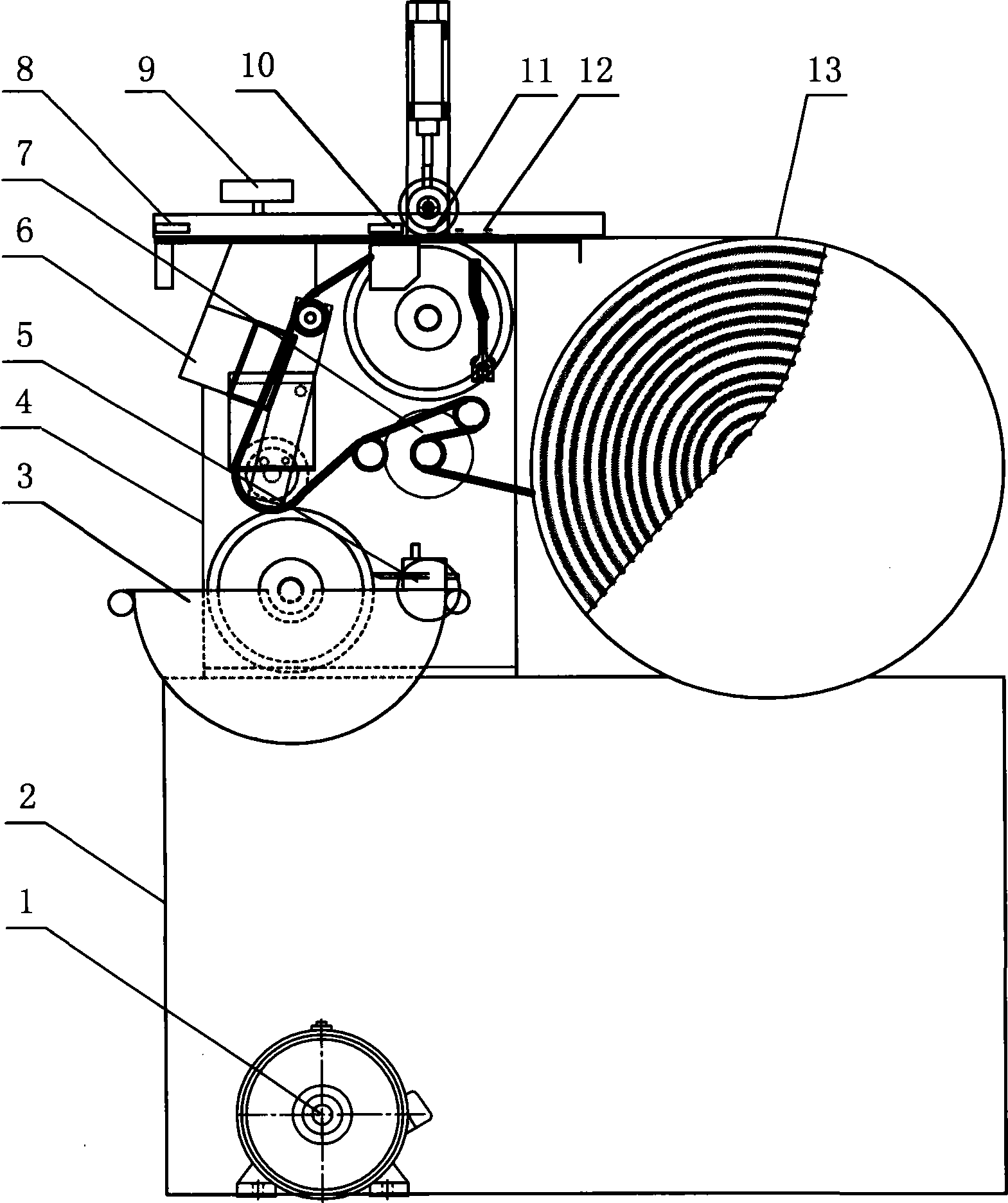

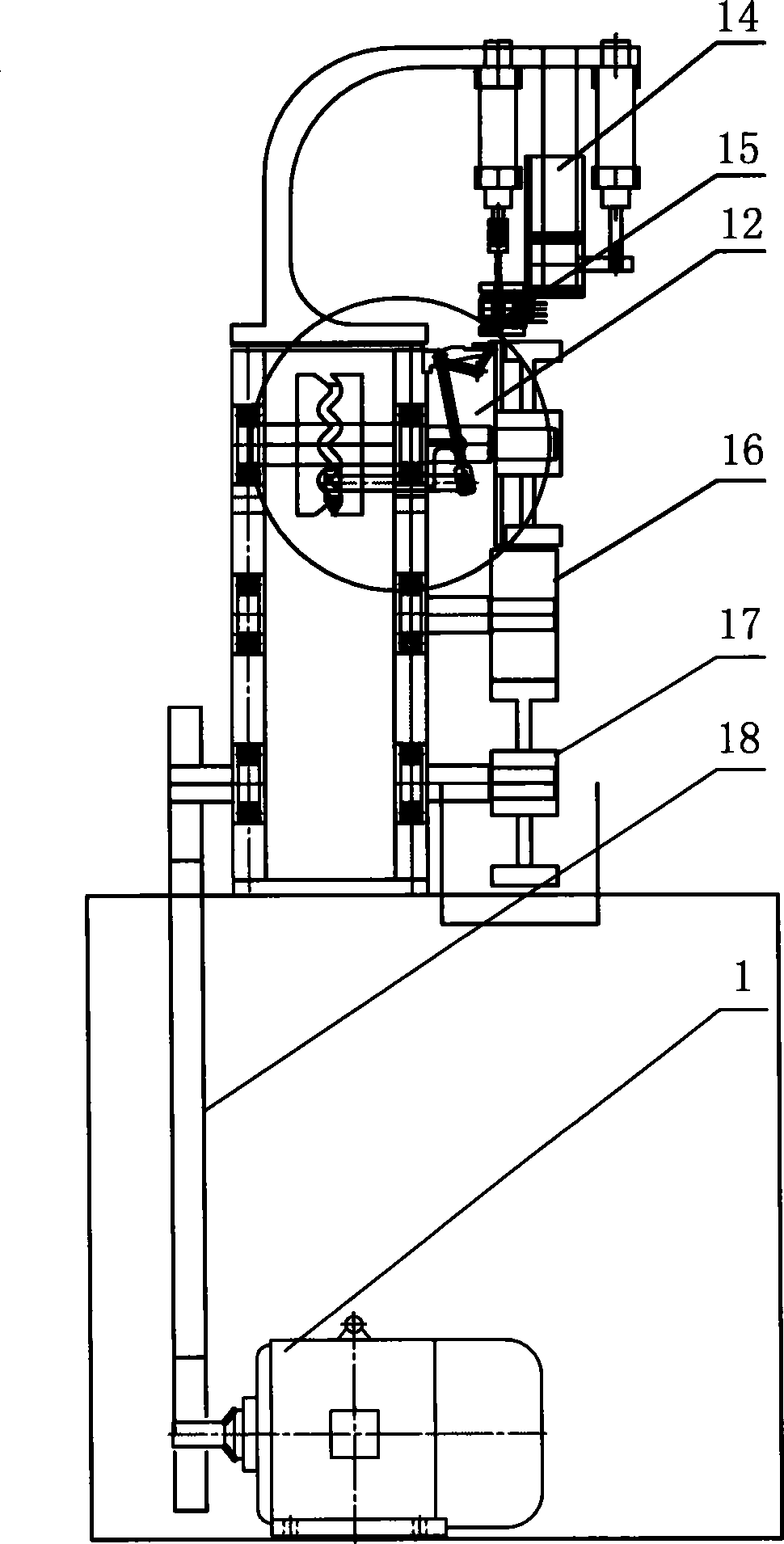

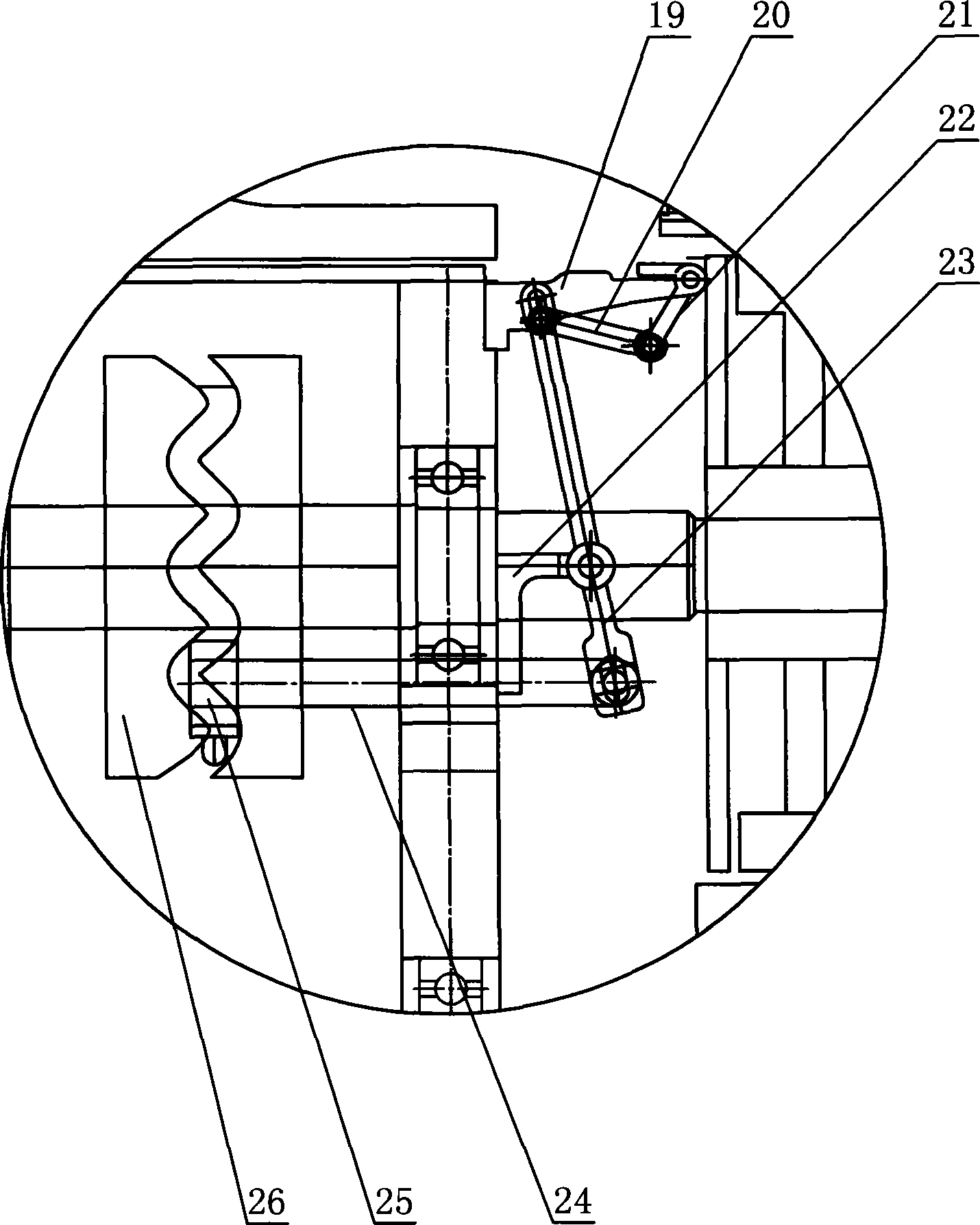

[0013] exist figure 1 , 2 Middle: The lower part of the hemming machine is the box body 2, and the upper part is the bracket body 4. The driving device 1 is arranged inside the box body 2, and the driving device 1 is connected with the glue point roller 17 through the transmission device 18. The box body 2 is equipped with a bracket body 4 and a storage device 13, the storage device 13 is equipped with hemming auxiliary materials, the support body 4 is provided with a glue storage tank 3, a gluing device 5, a die-cutting device 6, and a delivery device 7, and the glue storage tank 3 is located at the bottom end of the support body 4 , which is equipped with composite glue, the upper part of the glue storage tank 3 is provided with a glue point roller 17, the glue storage tank 3 is located at the lower part of the glue point roller 17, and half surrounds the glue point roller 17, and the side of the glue point roller 17 is provided with a gluing device 5. The gluing device 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com