Fireproof coating and preparation method thereof

A fire-resistant coating and coating technology, applied in the direction of fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of applicability, single substrate, and poor versatility of fire-resistant coatings, and achieve strong wrapping properties, good flame-retardant performance, Excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Correspondingly, a preparation method of fireproof coating includes the following steps:

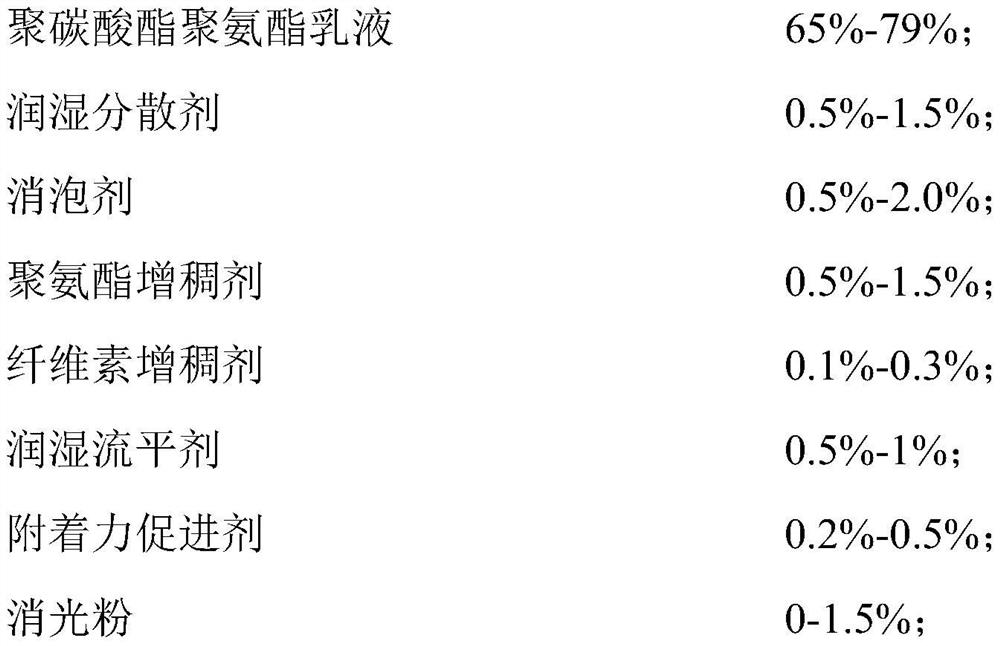

[0038] S01. Based on the total weight of the fire retardant coating as 100%, weigh 65%-79% of the polycarbonate polyurethane emulsion, 0.5%-1.5% of the wetting and dispersing agent, 0.5%-2.0% of the defoamer, and 0.5% of the polyurethane thickener. %-1.5%, cellulose thickener 0.1%-0.3%, wetting and leveling agent 0.5%-1%, adhesion promoter 0.2%-0.5%, matting powder 0-1.5%, anti-settling additives 0.3% -0.8%, film-forming aids 3%-7%, bactericidal and antifungal agent 0.2%-0.5%, flame retardant 11%-20%, water 1%-13%; among them, the adhesion promoter is selected as not containing Polysiloxane nonionic compound;

[0039] S02. Combine polycarbonate polyurethane emulsion, wetting and dispersing agent, defoamer, polyurethane thickener, cellulose thickener, wetting and leveling agent, adhesion promoter, matting powder, anti-settling additives, film forming Additives, bactericidal and antifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com