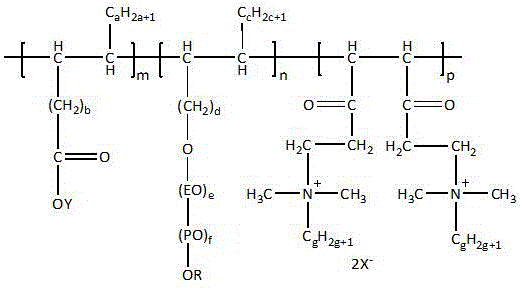

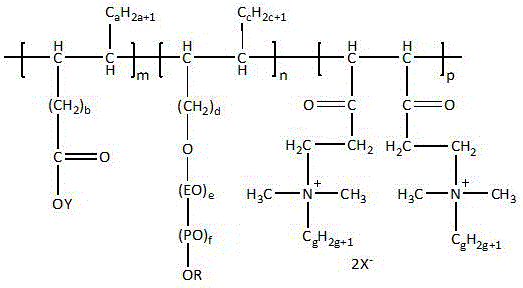

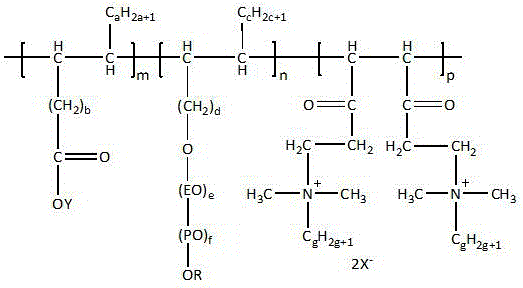

Novel cleaning agent additive and synthetic method thereof

A synthesis method and cleaning agent technology, applied in the direction of detergent composition, detergent compounding agent, surface active detergent composition, etc., can solve the problems of transfer, direct discharge of waste water, impact on ecological environment, etc., achieve strong penetration, The effect of easy washing and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention further provides a synthetic method of a liquid gemini type polyether cleaning agent auxiliary agent, comprising the following steps:

[0029] (1) Synthesis of enol polyether: add the initiator unsaturated fatty alcohol into the reaction kettle, and at the same time add the catalyst potassium hydroxide, start stirring, raise the temperature to 80-120°C, and remove by vacuum or molecular sieve adsorption and dehydration The weight ratio of moisture to moisture is less than 0.3%, and then the temperature is raised to 150-170°C, and ethylene oxide is added. Heat preservation and aging at 165°C for 30-45 minutes to obtain unsaturated enol polyether.

[0030] (2) Synthesis of unsaturated gemini-type quaternary ammonium salt: put dimethylaminoethanol and maleic anhydride into a reaction kettle, add a small amount of catalyst, react at 110-135°C for 2-6 hours, and remove the generated water in a vacuum to obtain cis Dimethylaminoethanol butenedioate. Ad...

Embodiment 1

[0034]1. Add 10mol of the starter 2-propen-1-ol into the reaction kettle, add 50g of potassium hydroxide catalyst at the same time, start stirring, raise the temperature to about 100°C and vacuumize to about 0.1Mpa, remove the water until the weight ratio of the water is less than 0.1%, then raise the temperature to 160°C, slowly add 200mol of ethylene oxide in batches (about 10mol per batch, weight about 440g), add 200mol of ethylene oxide after the addition, keep it warm for 30min, and then add in batches (about 10mol per batch, weight about 440g) 580g) 150mol propylene oxide, after the completion of the reaction, heat preservation and aging at 160±5°C for 35 minutes, after cooling down to below 80°C, adjust the pH to 6-7 with phosphoric acid to obtain prenol polyether.

[0035] 2. Put 20 mol of dimethylaminoethanol and 10 mol of maleic anhydride into the reaction kettle, add 0.01 mol of catalyst, raise the temperature to 125°C, and remove the water generated by the reaction....

Embodiment 2

[0039] 1. Add 10mol of the starter 9-octadecen-1-ol into the reaction kettle, add 55g of potassium hydroxide catalyst at the same time, start stirring, raise the temperature to 120°C and vacuumize to about 0.1Mpa, remove the water until the weight ratio of the water is less than 0.1%, slowly add 300mol ethylene oxide in batches (about 10mol per batch, about 440g), add 300mol of ethylene oxide after the addition is completed, and heat it at 140±5°C for 25min, then add 80mol ring Propylene oxide, after the reaction is completed, heat-preserve at 140±5°C for 30 minutes, cool down to 85°C and adjust the pH to 6-7 with phosphoric acid to obtain allyl alcohol polyether.

[0040] 2. Add allyl alcohol polyether and coconut oil prepared in step 1 into the reaction kettle at a molar ratio of 1:0.8 to 1.0, add 0.3mol of p-toluenesulfonic acid as a catalyst, and add 15mol of toluene solvent at the same time , stirring and raising the temperature to 130-140° C. for reflux reaction for 2-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com