Melt purifying agent for vacuum melting of aluminum-magnesium alloy and preparation method thereof

A technology of vacuum smelting and purifying agent, applied in the field of aluminum-magnesium alloy processing, can solve the problems of long time for hydrogen removal, limited industrial application, limited impurity removal ability, etc., so as to improve the use conditions and application scope, and improve the efficiency of hydrogen removal and impurity removal. and effect, the effect of improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

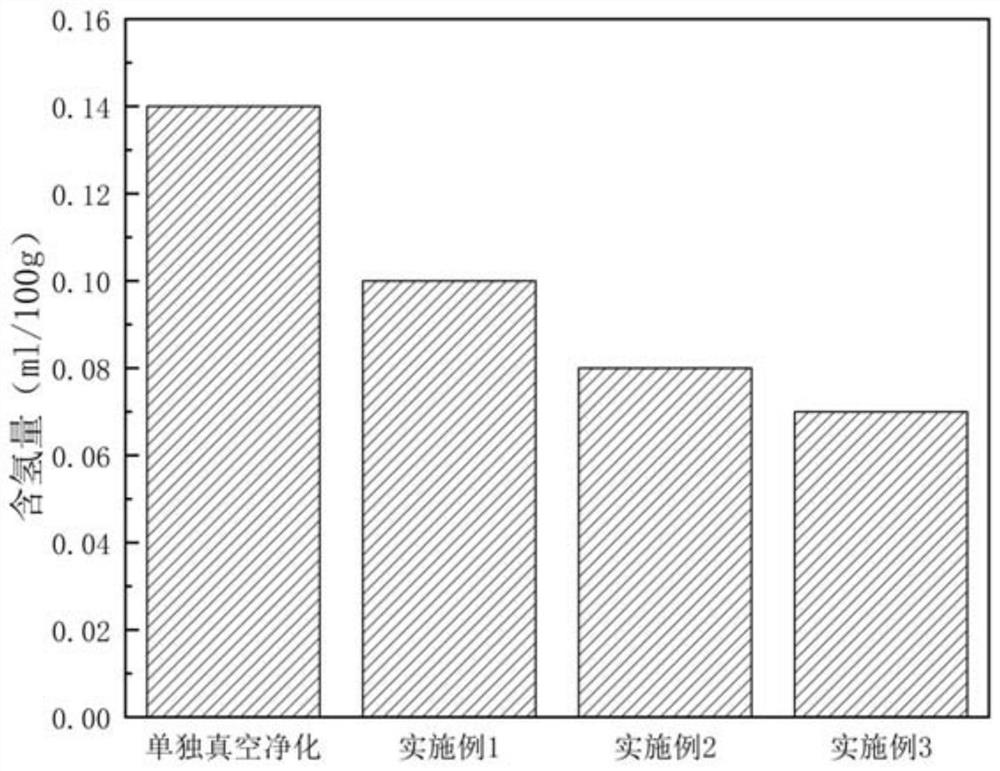

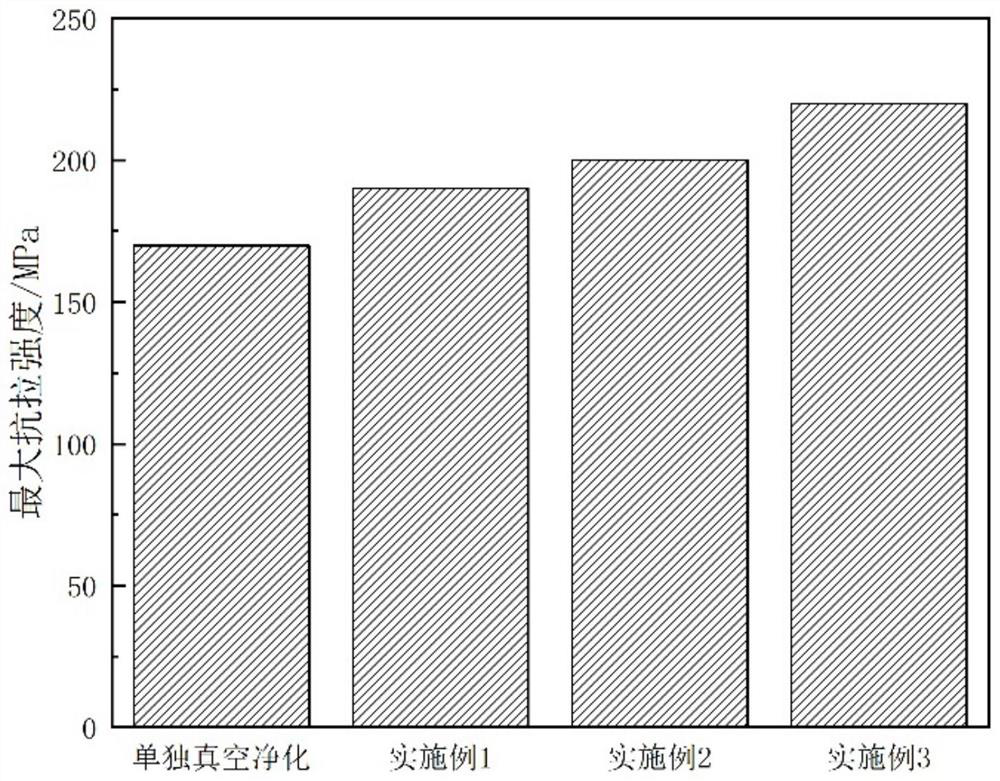

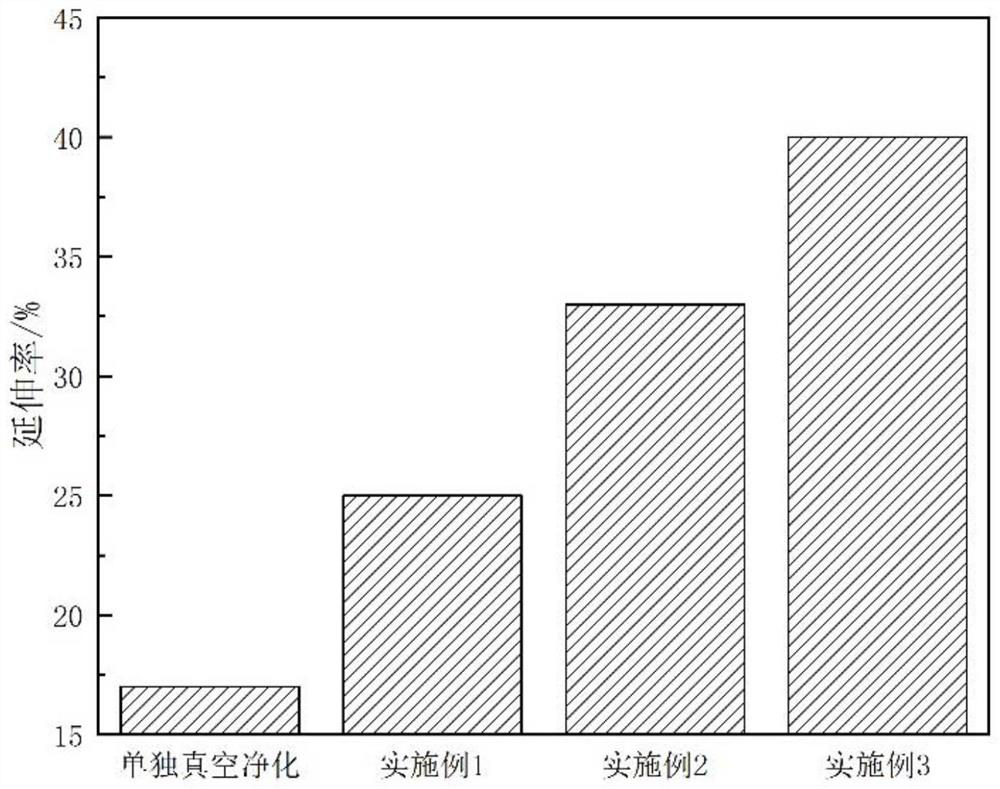

Embodiment 1

[0040] In terms of mass percentage, the composition of the purifying agent for the rubidium bromate-containing aluminum matrix composite material is: 98.8% pure aluminum, 1.1% analytically pure rubidium bromate, and 0.1% 2402 phenolic resin binder.

[0041] Weigh 988g of pure aluminum aluminum powder containing 99.99% aluminum and a particle size of 0.1mm, analyze 11g of pure rubidium bromate, analyze 1g of pure phenolic resin particles, put the above weighed pure rubidium bromate into a mortar and crush and stir. After the rubidium bromate in the mortar is in powder form, add phenolic resin powder and stir until it is evenly mixed. Then put the mixed powder in an oven for drying. The drying temperature is 80°C, and the drying time is 30 minutes. After drying, pour the mixed powder into a ball mill, add pure aluminum and aluminum powder, and carry out ball milling and mixing. The ball-to-material ratio of ball milling is 10:1, the ball milling time is 3 hours, and the rotation ...

Embodiment 2

[0043] In terms of mass percentage, the composition of the purifying agent for the rubidium bromate-containing aluminum matrix composite material is: 97.7% pure aluminum, 2.0% rubidium bromate, and 0.3% 2408 phenolic resin binder.

[0044] Weigh 20g of analytically pure rubidium bromate, put it into a mortar, mash it and stir it. After the rubidium bromate in the mortar is powdery, weigh 3g of phenolic resin powder and add it, stir it until it is evenly mixed, and then put the mixed powder Put it in an oven for drying, the drying temperature is 80°C, and the drying time is 30 minutes. After drying, pour the mixed powder into a ball mill, weigh 977g of pure aluminum powder with a particle size of 0.1mm and add it, and perform ball milling and Mixing, the ball-to-material ratio of ball milling is 20:1, the ball milling time is 10h, and the rotation speed is 400r / min. After the mixing is completed, put the mixture into the granulator, set the granulation temperature to 160°C, the...

Embodiment 3

[0046] In terms of mass percentage, the composition of the purifying agent containing rubidium bromate-aluminum matrix composite material is: 96.55% pure aluminum, 2.95% rubidium bromate, 0.5% 2127 phenolic resin binder.

[0047] First, weigh 29.5g analytically pure rubidium bromate and 5g phenolic resin powder, add them into a mortar for grinding and mixing, after the rubidium bromate in the mortar is powdered and mixed evenly with phenolic resin, put the mixed powder into an oven Drying, the drying temperature is 80°C, and the drying time is 30 minutes. After drying, pour the mixed powder into a ball mill, add 965.5g of pure aluminum aluminum powder with a particle size of 0.1mm, and perform ball milling and mixing. The ball material for ball milling Ratio 30:1, ball milling time 20h, rotation speed 500r / min. After the mixing is completed, put the mixture into the granulator, set the granulation temperature to 170°C, the extrusion speed to 1m / min, and the particle size to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com