Preparation method of highly sulfonated polystyrene resin

A technology of polystyrene resin and sulfonated polystyrene, which is applied in the field of functional modification of polymers, can solve the problems of low content of sulfonic acid groups on the surface, high cost, and low strength of resin microspheres, and achieve the goal of not being prone to sulfonic acid The effect of base content and large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

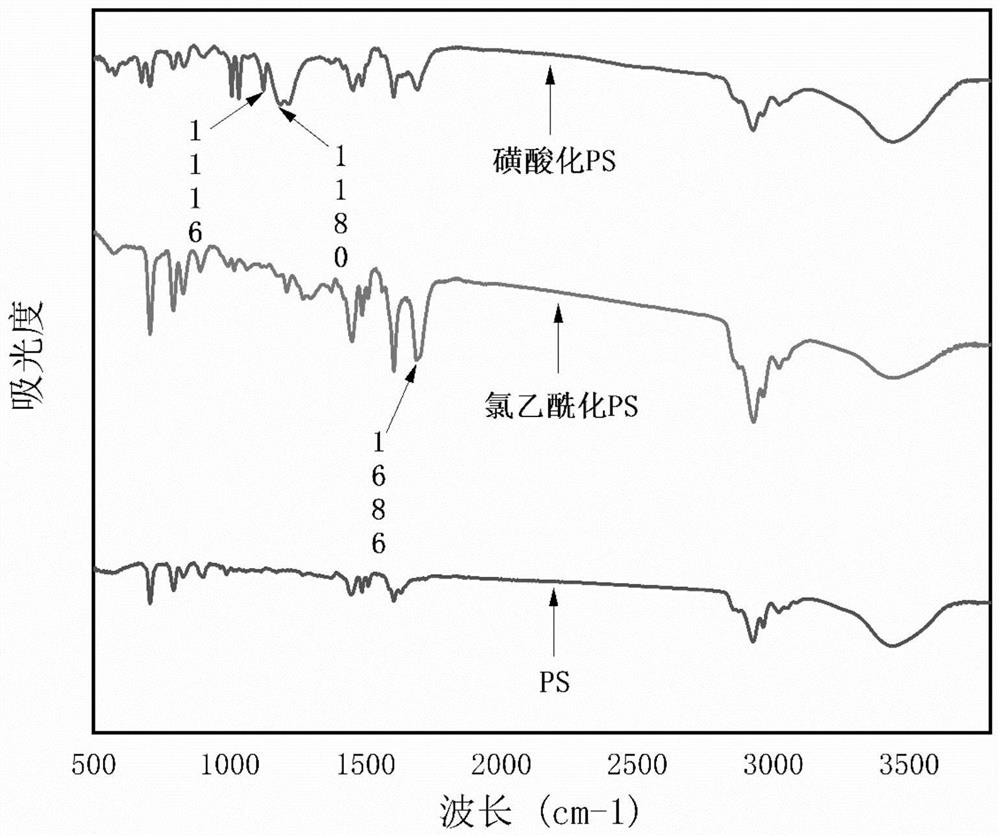

[0020] The invention discloses a preparation method of highly sulfonated polystyrene resin, the method comprising the following steps:

[0021] Step 1. Pretreatment of unmodified polystyrene resin: Weigh a certain amount of polystyrene resin microspheres, add dichloromethane to swell for 5-15 hours, and then use tetrahydrofuran, ultrapure water, absolute ethanol, and anhydrous methanol Wash and filter each for 2-3 times, and finally vacuum-dry at 20-30°C to constant weight;

[0022] Step 2. Chloroacetylation of polystyrene resin microspheres: Weigh the polystyrene resin microspheres treated in step 1, add dichloromethane to the high-pressure reaction bottle to swell for 5-10 hours, and then add aluminum chloride to the reaction system React with chloroacetyl chloride at 25-50°C under high pressure for 1-5h, and finally filter off the reaction reagent, wash and filter with tetrahydrofuran, water, 3% mass fraction of dilute hydrochloric acid, absolute ethanol, and methanol for 2...

Embodiment 1

[0028] Example 1: Weigh 0.5g of polystyrene resin microspheres, add dichloromethane to swell for 5 hours, wash and filter with tetrahydrofuran, ultrapure water, absolute ethanol, and anhydrous methanol three times in a sand core funnel, and finally 20°C Dry in vacuo to constant weight.

[0029] Acylation of polystyrene resin microspheres: Weigh 0.3 g of pretreated polystyrene resin white balls, put them into a high-pressure reaction bottle and swell with 20 ml of dichloromethane for 5 h, add catalyst aluminum chloride 0.28 g, acetylation reagent ethyl chloride 100 μl of acid chloride was reacted in a water-bath shaker in a high-pressure reaction flask at 50°C for 5 hours. After cooling to room temperature, wash and filter twice with tetrahydrofuran, 3% dilute hydrochloric acid, ultrapure water, absolute ethanol, and methanol successively, and finally vacuum-dry at 30°C to constant weight to obtain chloroacetylated polystyrene resin microspheres.

[0030] Sulfonation modificatio...

Embodiment 2

[0031] Example 2: Weigh 0.5g of polystyrene resin microspheres, add dichloromethane to swell for 10 hours, wash and filter with tetrahydrofuran, ultrapure water, absolute ethanol, and anhydrous methanol three times in a sand core funnel, and finally 30°C Dry in vacuo to constant weight.

[0032] Acylation of polystyrene resin microspheres: Weigh 0.3 g of pretreated polystyrene resin white balls, put them into a high-pressure reaction bottle and swell with 20 ml of dichloromethane for 10 h, add catalyst aluminum chloride 0.59 g, acetylation reagent ethyl chloride 300 μl of acid chloride was reacted in a water-bath shaker in a high-pressure reaction bottle at 50°C for 5 hours. After cooling to room temperature, wash and filter twice with tetrahydrofuran, 3% dilute hydrochloric acid, ultrapure water, absolute ethanol, and methanol successively, and finally vacuum-dry at 30°C to constant weight to obtain chloroacetylated polystyrene resin microspheres.

[0033] Anionic modificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com