Floating bead based polypyrrole conductive composite with adjustable conductivity and preparation method thereof

A technology of floating bead-based polypyrrole and composites, which is applied in the field of floating bead-based polypyrrole conductive composites and its preparation, can solve the problems of atmospheric and thermal instability, difficult processing and molding, and non-melting, etc. The effect of controlling defects, broadening industrial application value, and meeting the requirements of differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

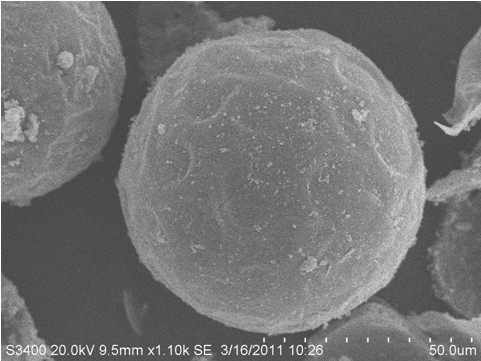

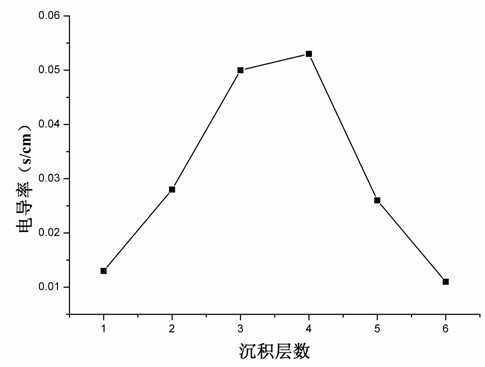

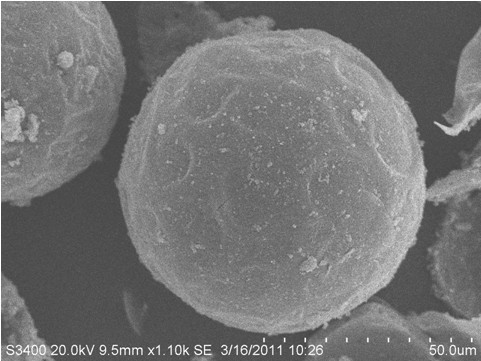

[0028] 1) Pretreatment of floating beads: Soak the floating beads extracted from fly ash with dilute nitric acid for 9 hours, then rinse with distilled water until the effluent water is neutral, and dry them for later use.

[0029] 2) Prepare 0.004 g·mL -1 NaCl solution, add polymethyl diallyl ammonium chloride, namely PDDA, prepare 0.15 wt.% PDDA solution, add the product obtained in the above step 1) and filter after stirring for 60min to obtain floating beads-PDDA; prepare 0.004 g·mL -1 NaCl solution, adding sodium polystyrene sulfonate, that is, PSS, to prepare a 0.05 wt.% PSS solution, adding floating beads-PDDA and stirring for 30min, then filtering to obtain floating beads-(PDDA-PSS) 1 .

[0030] 3) Secondary deposition process: Using the sample obtained in the above step 2) as a carrier, repeat step 2) to obtain floating beads for secondary deposition of polyelectrolyte, which is denoted as floating beads-(PDDA-PSS) 2 .

[0031] 4) Transfer 0.8g of the product pr...

Embodiment 3

[0037] 1) Pretreatment of floating beads: Soak the floating beads extracted from fly ash with dilute nitric acid for 10 hours, then rinse with distilled water until the effluent water is neutral, and dry them for later use.

[0038] 2) Prepare 0.006 g·mL -1 Add polymethyldiallyl ammonium chloride, i.e. PDDA, to prepare a 0.2 wt.% PDDA solution, add the product obtained in the above step 1) and stir for 60min, then filter to obtain floating beads-PDDA; prepare 0.006 g·mL -1 NaCl solution, adding sodium polystyrene sulfonate, that is, PSS, to prepare a 0.1 wt.% PSS solution, adding floating beads-PDDA and stirring for 30min, then filtering to obtain floating beads-(PDDA-PSS) 1 .

[0039] 3) Three deposition processes: using the sample obtained in the above step 2) as a carrier, repeat step 2) twice to obtain polyelectrolyte three-time deposited floating beads, denoted as floating beads-(PDDA-PSS) 3 .

[0040]4) Transfer 1 g of the product prepared in step 3) to 25 ml of di...

Embodiment 4

[0047] 1) Pretreatment of floating beads: Soak the floating beads extracted from fly ash with dilute nitric acid for 11 hours, then rinse with distilled water until the effluent water is neutral, and dry them for later use.

[0048] 2) Prepare 0.006 g·mL -1 Add polymethyldiallyl ammonium chloride, i.e. PDDA, to prepare a 0.2 wt.% PDDA solution, add the product obtained in the above step 1) and stir for 60min, then filter to obtain floating beads-PDDA; prepare 0.006 g·mL -1 NaCl solution, adding sodium polystyrene sulfonate, that is, PSS, to prepare a 0.1 wt.% PSS solution, adding floating beads-PDDA and stirring for 30min, then filtering to obtain floating beads-(PDDA-PSS) 1 .

[0049] 3) Four times of deposition process: with the sample obtained in the above step 2) as a carrier, repeat step 2) three times to obtain floating beads of polyelectrolyte deposited four times, denoted as floating beads-(PDDA-PSS) 4 .

[0050] 4) Transfer 1.2g of the product prepared in step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com