Terpolymer dispersants and preparation technique and use thereof

A terpolymer and preparation technology, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unsatisfactory dispersion effect, poor dispersion stability, high preparation cost, etc., and achieve good adaptability , Excellent dispersion performance, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of dispersant

[0028] Add 1000 parts of deionized water, 4 parts of chain transfer agent sodium bisulfite, and 100 parts of sodium styrene sulfonate into a four-necked flask, and heat while stirring; when the temperature in the four-necked flask rises to 70°C, add 105 parts of acrylic acid, 95 parts of hydroxypropyl acrylate and 13 parts of initiator ammonium persulfate, heat preservation reaction for 2.5 hours; naturally cool to room temperature, adjust the pH value to 7-8 with aqueous sodium hydroxide solution; put the prepared liquid into a vacuum oven Dry at 70°C to obtain the target dispersant.

[0029] Using aqueous gel permeation chromatography (GPC), using water as mobile phase and sodium polyacrylate as standard, the number average relative molecular weight of the prepared terpolymer dispersant was measured to be 19200.

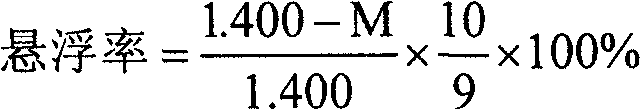

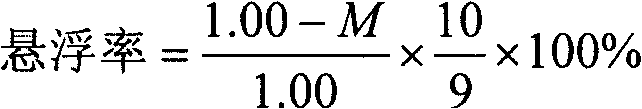

[0030] 2) Determination of the dispersibility of the dispersant to inorganic minerals

[0031] Add 0.4g of this dispersant ...

Embodiment 2

[0041] Add 1000 parts of deionized water, 8 parts of chain transfer agent sodium bisulfite, and 100 parts of sodium styrene sulfonate into a four-necked flask, and heat while stirring; when the temperature in the four-necked flask rises to 90°C, add 105 parts of acrylic acid, 76 parts of hydroxypropyl acrylate and 25 parts of initiator ammonium persulfate, heat preservation reaction for 2.5 hours; naturally cool to room temperature, adjust the pH value to 7-8 with aqueous sodium hydroxide solution; put the prepared liquid into a vacuum oven Dry at 80°C to obtain the target dispersant.

[0042] Using aqueous gel permeation chromatography (GPC), using water as mobile phase and sodium polyacrylate as standard, the number average relative molecular weight of the prepared terpolymer dispersant was measured to be 2400.

[0043] The operation described in Example 1 records: the suspension rate of the titanium dioxide suspension prepared with the prepared dispersant is 98.14%, and the...

Embodiment 3

[0045] Add 1000 parts of deionized water, 6 parts of chain transfer agent sodium bisulfite, and 100 parts of sodium styrene sulfonate into a four-necked flask, and heat while stirring; when the temperature in the four-necked flask rises to 80°C, add 105 parts of acrylic acid, 57 parts of hydroxypropyl acrylate and 37 parts of initiator ammonium persulfate, heat preservation reaction for 2.5 hours; naturally cool to room temperature, adjust the pH value to 7-8 with aqueous sodium hydroxide solution; put the prepared liquid into a vacuum oven Dry at 80°C to obtain the target dispersant.

[0046] Using aqueous gel permeation chromatography (GPC), using water as the mobile phase and sodium polyacrylate as the standard, the number average relative molecular weight of the prepared terpolymer dispersant was measured to be 13,000.

[0047] The operation described in Example 1 records: the suspension rate of the titanium dioxide suspension prepared with the prepared dispersant is 98.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com