Cerium oxide polishing solution, preparation method and applications thereof

A technology of polishing liquid and cerium oxide, which is applied in the field of polishing liquid, can solve problems such as hindering the uniform and effective contact between cerium oxide and glass substrates, reducing polishing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

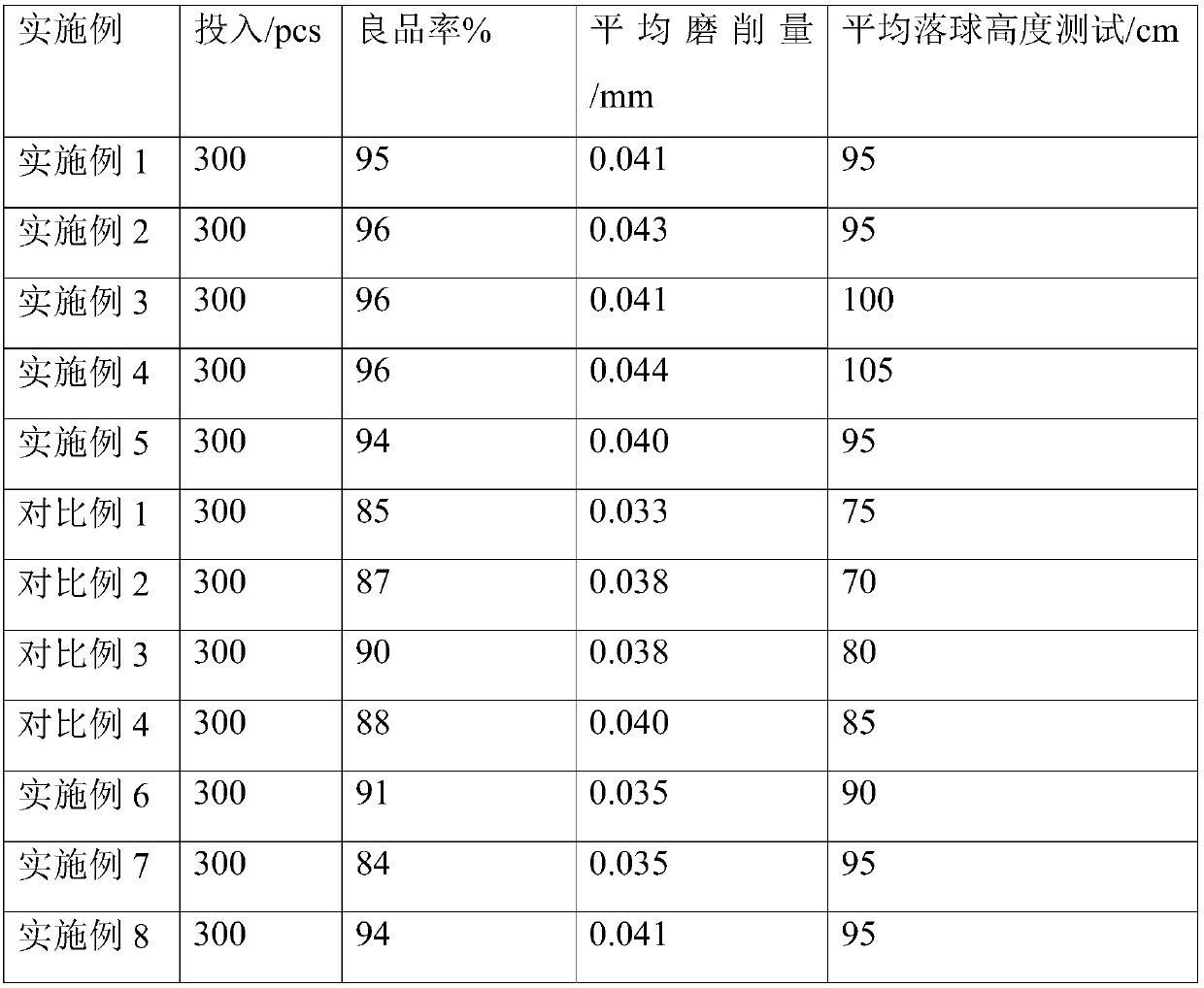

Examples

Embodiment 1

[0061] This example is to illustrate the cerium oxide polishing solution prepared by the preparation method of the present invention.

[0062] (1) Each component and weight percentage

[0063] Abrasive: particle size D 50 = 1.0 μm, D 100 = 8.6 μm;

[0064] 360 parts by weight of cerium oxide; 150 parts by weight of lanthanum oxide; 30 parts by weight of lanthanum fluoride; 28 parts by weight of lanthanum oxyfluoride; 32 parts by weight of titanium oxide;

[0065] Dispersant:

[0066] 38 parts by weight of allyl polyoxyethylene ether; 18 parts by weight of triethylhexyl phosphoric acid; 8 parts by weight of vinylbisstearamide; 6 parts by weight of sodium styrene sulfonate;

[0067] Defoamer:

[0068] 8 parts by weight of polyoxyethylene polyoxypropylene alcohol amine ether; 6 parts by weight of polyether dimethyl siloxane copolymer;

[0069] Water: 2400 parts by weight.

[0070] (2) Preparation method

[0071] ①Prepare 2400 parts of water, stir with a 1500r / min high-spe...

Embodiment 2

[0075] This example is to illustrate the cerium oxide polishing solution prepared by the preparation method of the present invention.

[0076] (1) Each component and weight percentage

[0077] Abrasive: particle size D 50 = 1.6 μm, D 100 = 9.4 μm;

[0078] 320 parts by weight of cerium oxide; 170 parts by weight of lanthanum oxide; 40 parts by weight of lanthanum fluoride; 32 parts by weight of lanthanum oxyfluoride; 38 parts by weight of titanium oxide;

[0079] Dispersant:

[0080] 38 parts by weight of polyoxyethylene octylphenol ether; 18 parts by weight of triethylhexyl phosphoric acid; 8 parts by weight of vinylbisstearamide; 6 parts by weight of sodium styrene sulfonate.

[0081] Defoamer:

[0082] 10 parts by weight of polyoxyethylene polyoxypropylene alcohol amine ether; 8 parts by weight of polyether dimethyl siloxane copolymer;

[0083] Water: 2400 parts by weight.

[0084] (2) Preparation method

[0085] ①Prepare 2400 parts of water, stir with a 1500r / min hig...

Embodiment 3

[0089] This example is to illustrate the cerium oxide polishing solution prepared by the preparation method of the present invention.

[0090] (1) Each component and weight percentage

[0091] Abrasive: particle size D 50 = 1.0 μm, D 100 = 5.4 μm;

[0092] 310 parts by weight of cerium oxide; 182 parts by weight of lanthanum oxide; 22 parts by weight of lanthanum fluoride; 42 parts by weight of lanthanum oxyfluoride; 44 parts by weight of titanium oxide;

[0093] Dispersant:

[0094] 20 parts by weight of allyl polyoxyethylene ether; 20 parts by weight of polyoxyethylene octylphenol ether; 16 parts by weight of triethylhexyl phosphoric acid; 10 parts by weight of vinylbisstearamide; 8 parts by weight of sodium styrene sulfonate;

[0095] Defoamer:

[0096] 6 parts by weight of polyoxyethylene polyoxypropylene alcohol amine ether; 12 parts by weight of polyether dimethyl siloxane copolymer;

[0097] Water: 2400 parts by weight.

[0098] (2) Preparation method

[0099] ①...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com