Special scale inhibitor for MVR system and preparation method thereof

A technology of antiscalant and acrylic acid, which is applied in chemical instruments and methods, descaling and water softening, heating water/sewage treatment, etc. It can solve problems such as lack of pertinence, unsatisfactory treatment effect, and influence on salt production rate. To achieve the effect of promoting energy saving and emission reduction, best application effect and production value, and excellent scale inhibition and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

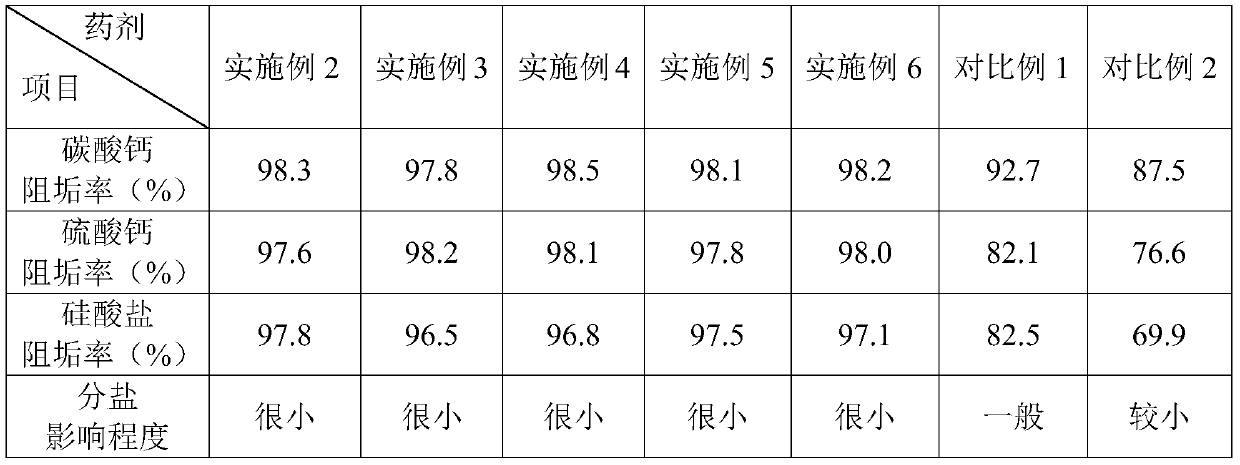

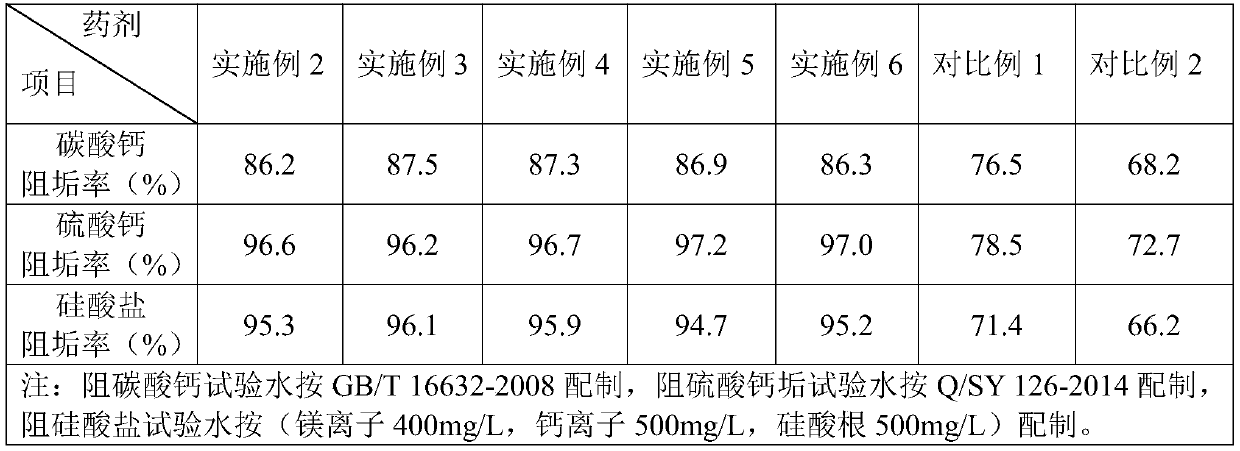

Examples

Embodiment 1

[0020] Preparation of maleic anhydride-acrylic acid-methallyl polyoxyethylene ether scale inhibitor:

[0021] Mix and stir 20 parts by weight of NaOH and 150 parts by weight of distilled water until dissolved, then add 30 parts by weight of maleic anhydride, add 10 parts by weight of methallyl polyoxyethylene ether after dissolving, heat to 85°C, add 4 parts by weight of sodium hypophosphite, and slowly add ammonium persulfate and acrylic acid at the same time, fully stir when adding, and keep warm for 1.5 hours to obtain maleic anhydride-acrylic acid-methallyl polyoxyethylene ether scale inhibitor.

Embodiment 2

[0023] Preparation of a special antiscalant for MVR system:

[0024] Weigh acrylic acid-styrene sulfonic acid copolymer by weight 8 parts, PAPEMP15 parts, HDTMPA10 parts, maleic anhydride-acrylic acid-methallyl polyoxyethylene ether scale inhibitor 20 parts, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-N-tert-butyl Acrylamide Terpolymer 7 parts, adipic acid-amino-terminated polyether-diethylenetriamine copolymer 10 parts, epoxy succinic acid derivative 10 parts, acrylic acid-hydroxypropyl acrylate-sodium hypophosphite copolymer 5 parts, pure water 0 parts.

[0025] Add the above weighed materials into the reaction kettle in turn, and mix well; then slowly add 12 parts by weight of phosphate starch from the manhole into the reaction kettle, raise the temperature to 45°C, stir for 20min, filter, and discharge to obtain the MVR system dedicated Inhibitor.

Embodiment 3

[0027] Preparation of a special antiscalant for MVR system:

[0028] Weigh acrylic acid-styrene sulfonic acid copolymer by weight 5 parts, 10 parts of PAPEMP, 5 parts of HDTMPA, 15 parts of maleic anhydride-acrylic acid-methallyl polyoxyethylene ether scale inhibitor, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-N-tert-butyl Acrylamide Terpolymer 5 parts, adipic acid-amino-terminated polyether-diethylenetriamine copolymer 8 parts, epoxy succinic acid derivative 15 parts, acrylic acid-maleic acid-phosphorus-based copolymer 8 parts, pure water 8 parts.

[0029] Add the above weighed materials into the reaction kettle in turn, and mix well; then slowly add 10 parts by weight of phosphate starch from the manhole into the reaction kettle, raise the temperature to 50°C, stir for 30min, filter, and discharge to obtain the MVR system dedicated Inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com