Additive used for increasing flexural and compressive strength of cement mortar, and preparation and application method thereof

A technology of compressive strength and cement mortar, applied in the field of cement admixture and its preparation, can solve the problems of poor reinforcement effect of polymer cement admixture and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

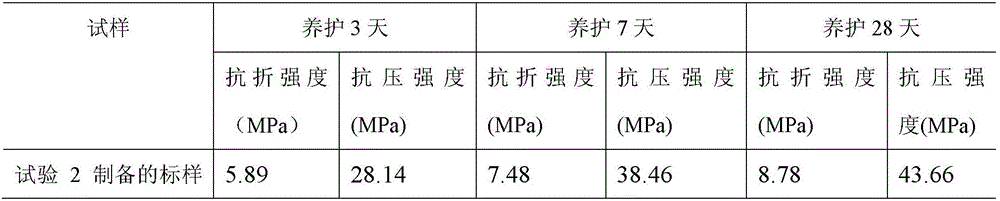

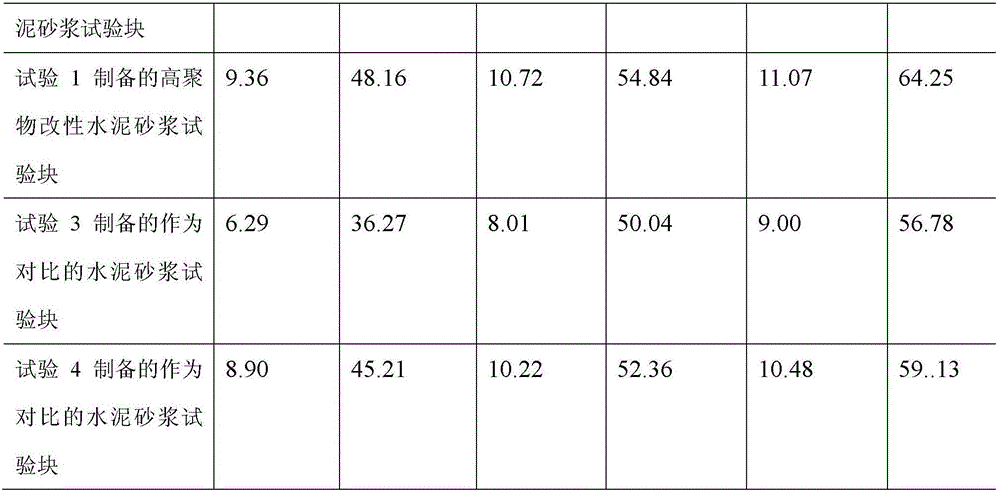

Examples

specific Embodiment approach 1

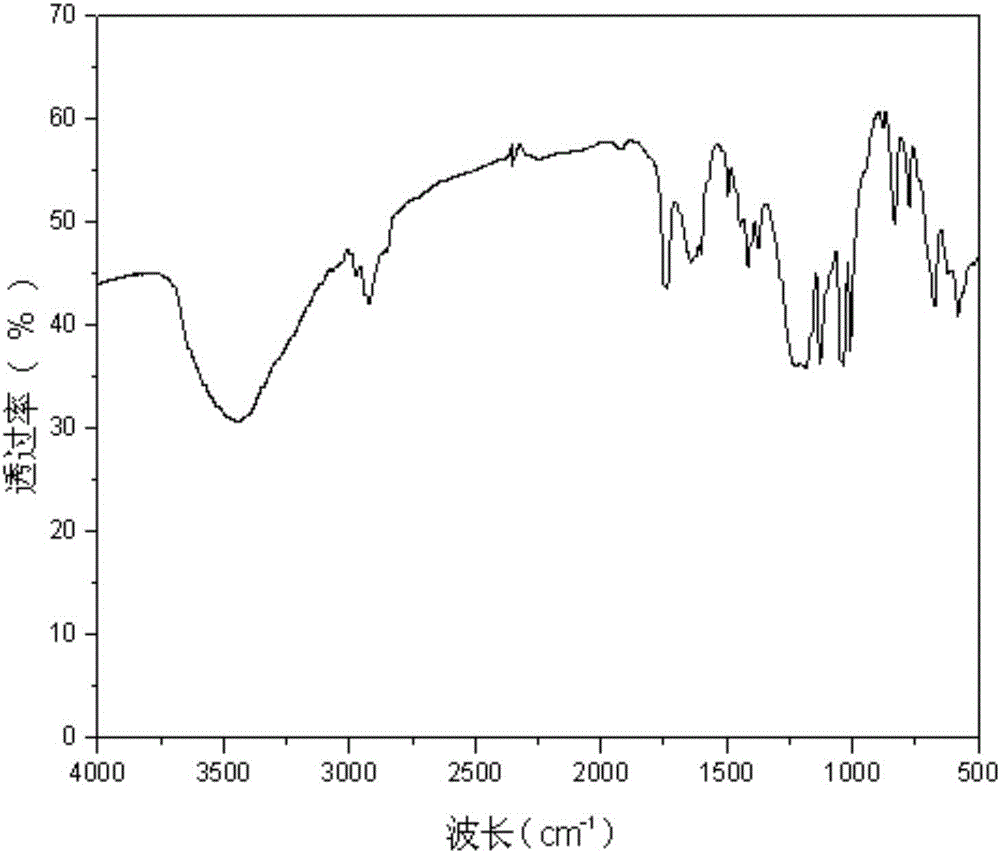

[0024] Specific embodiment one: the admixture that improves the flexural and compressive strength of cement mortar material of the present embodiment is CMC-XYX type polymer emulsion, wherein CMC is carboxymethyl cellulose in the polymer, X is styrene sulfonic acid group , Y is a vinyl acetate group.

specific Embodiment approach 2

[0025] Specific embodiment two: the preparation method of the admixture that improves cement mortar material bending resistance and compressive strength described in specific embodiment one, carries out according to the following steps:

[0026] 1. Take sodium carboxymethyl cellulose, sodium styrene sulfonate, vinyl acetate, potassium persulfate and water; wherein the mass ratio of sodium carboxymethyl cellulose to potassium persulfate is 1: (0.18~0.833); The mass ratio of sodium carboxymethyl cellulose to sodium styrene sulfonate is 1: (1-10.5); the ratio of the mass of sodium carboxymethyl cellulose to the volume of vinyl acetate is 1 g: (2.15-11.25) mL; The ratio of the mass of sodium carboxymethyl cellulose to the volume of water is 1g: (22-28) mL; then divide the sodium styrene sulfonate into two equal parts, and divide the potassium persulfate into three equal parts;

[0027] 2. Add water into the reaction vessel with a reflux condenser and a stirrer, heat it in a water ...

specific Embodiment approach 3

[0035] Specific embodiment 3: The difference between this embodiment and specific embodiment 2 is that the dropping rate in step 6 is (0.004-0.007) mL / s, which is equivalent to adding 1 drop every 3-5 s. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com