Patents

Literature

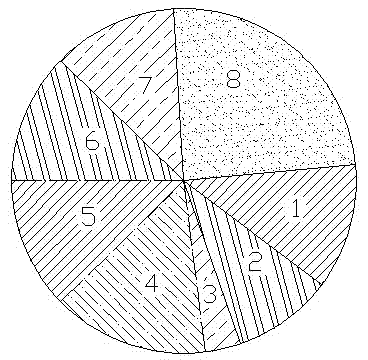

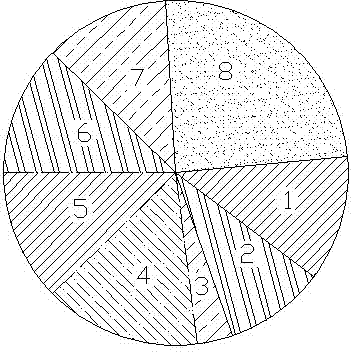

154 results about "Acetic acid ethenyl ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

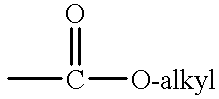

Vinyl Acetate Monomer (also known as acetic acid ethenyl ester, acetic acid ethylene ether, acetoxyethene, 1-acetoxyethylene, ethenyl ethanoate, ethenyl acetate, and acetic acid vinyl ester) is a colourless mobile liquid with a pungent odour.

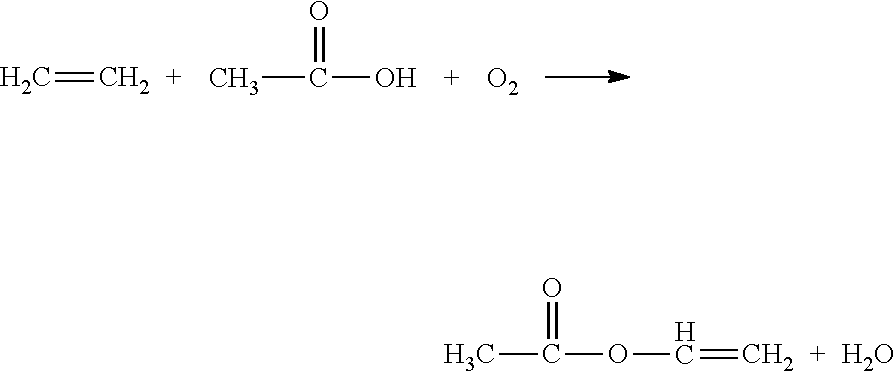

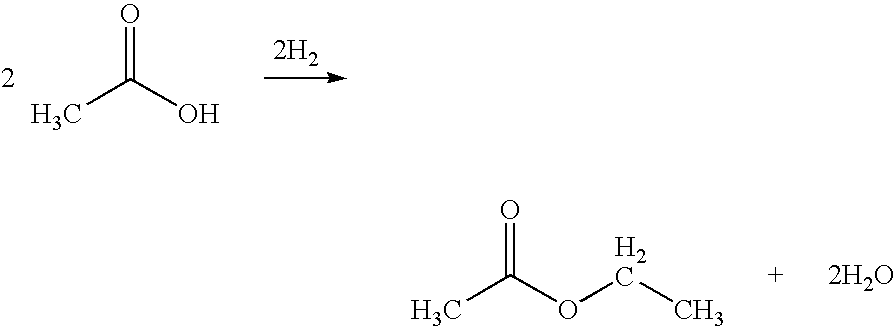

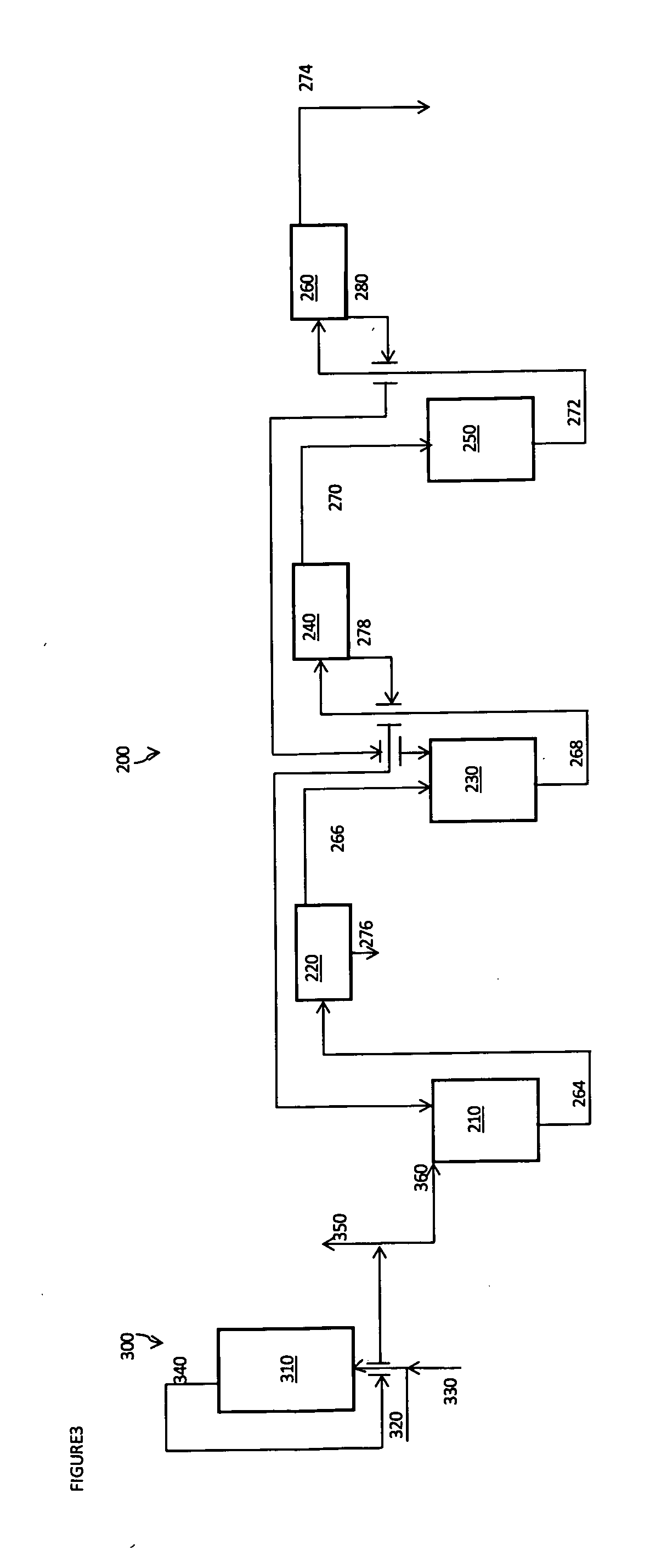

Integrated process for the production of viny acetate from acetic acid via ethy acetate

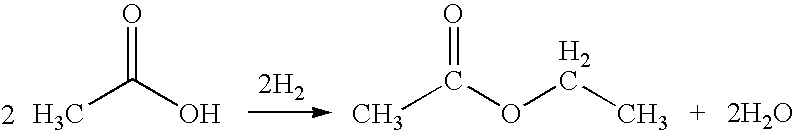

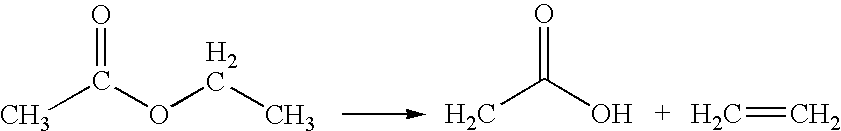

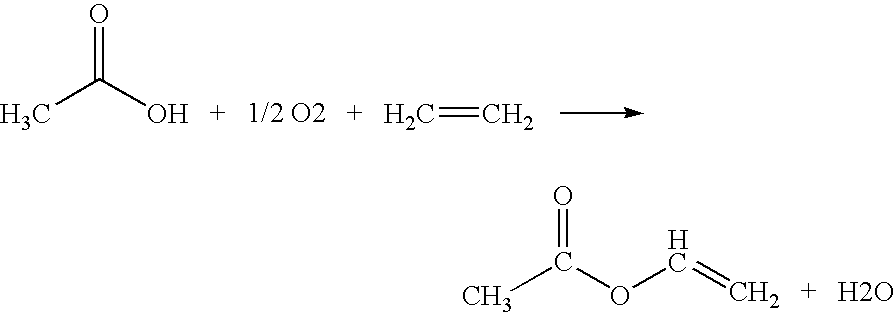

This invention provides an integrated three step economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form ethyl acetate which is cracked to form ethylene and acetic acid in the second step and in a subsequent step so formed ethylene and acetic acid is reacted with molecular oxygen over a suitable catalyst to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and copper supported on silica selectively produces ethyl acetate in a vapor phase at a temperature of about 250° C., which is cracked over a NAFION catalyst to form ethylene and acetic acid at a temperature of about 185° C., which is mixed with molecular oxygen and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

Gel polymer electrolyte of vinyl acetate

InactiveUS6268088B1Enhanced interactionImprove ionic conductivityOrganic electrolyte cellsSolid electrolyte cellsSolventFluid electrolytes

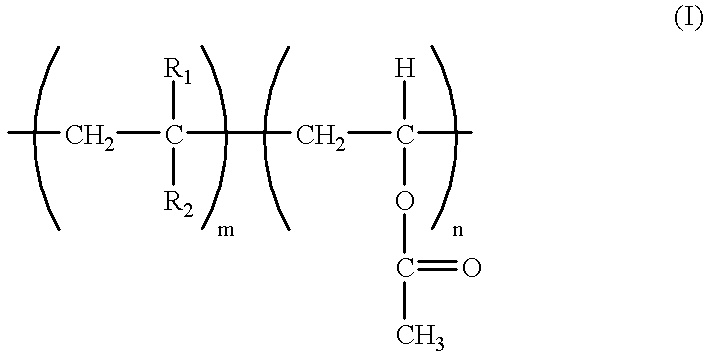

A gel polymer electrolyte according to the present invention comprises a polymer selected from the group consisting of vinyl acetate copolymer, poly(ethylene / vinylacetate / carbon oxide: EVACM), and poly(ethylene / vinylacetate / maleic acid anhydride: EVAMA); an inorganic filler; and a liquid electrolyte that a lithium salt is dissolved in an aprotic solvent. It is preferable that the polymer material in a gel polymer electrolyte according to the present invention is in the range of 20 to 30% by weight, the inorganic material filler is in the range of 5 to 20% by weight, and the liquid electrolyte is in the range of 60 to 80 % by weight. As a specific functional group which has a high compatibility with a liquid electrolyte in the present invention is contained in the polymer material, a lithium ion becomes to move with ease in electrolyte, and the ionic conductivity is over 0.5 mS / cm which is the demand level of a gel polymer electrolyte. Also, it provides the gel polymer electrolyte material with a high film formability, a good property of containing an electrolyte, a good adhesion, and a good mechanical strength.

Owner:CHEIL IND INC

Utilization of acetic acid reaction heat in other process plants

InactiveUS7465823B2Save energy and costOrganic compound preparationChemical industryAcetic acidProcess plant

Owner:CELANESE INT CORP

Fog-resistant packaging film

InactiveUS6706389B1Alter property of filmFilm/foil adhesivesSynthetic resin layered productsAcetic acidPolymer science

A packaging film includes a heat sealable layer coated with one or more antifogging agents disposed in a binder, an antiblocking agent, and no more than about 800 ppm slip agent. The heat sealable layer includes a polymer that includes mer units derived from ethylene while the binder includes a polymer that includes mer units derived from an ester of (meth)acrylic acid and / or vinyl acetate monomers. The antiblocking agent can be in any layer of the film where it provides the desired effect. Such a film, as well as packages made therefrom, can be used to package a variety of products, having particular utility with respect to moist products.

Owner:CRYOVAC ILLC

Taxine kind anti-cancer slow release injection

InactiveCN1923189AOrganic active ingredientsPharmaceutical delivery mechanismCelluloseAcetic acid ethenyl ester

The invention relates to a slow-release injection of taxine anti-cancer drug, which comprises anti-cancer drug, slow-release finding, suspension and / or solvent. Wherein, said anti-cancer drug is taxine, 2'-hydroxy Paclitaxel, etc; the slow-release finding is polymer of hydroxyl, glycollic acid and glycolic acid, one of acetic acid ethyenyl ester polymer and polyphony; the suspension is polyphenyl (sodium), and mannite; the solvent is distilled water, injection water, absolute ethyl alcohol, etc. The invention can be injected to reduce the toxicity effect of drug, and improve the density locally to strengthen the treatment effect of chemotherapy and radiation therapy.

Owner:孔庆忠

Fabric softening laundry detergent

InactiveUS7994112B2Organic detergent compounding agentsNon-ionic surface-active compoundsMethacrylatePolymer science

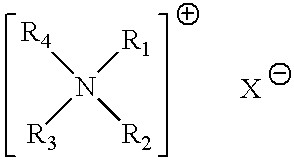

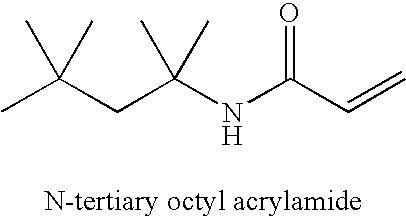

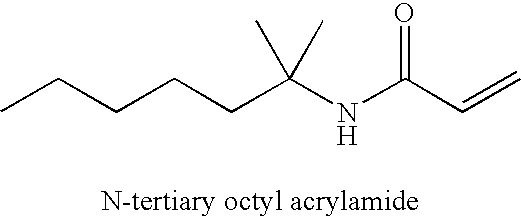

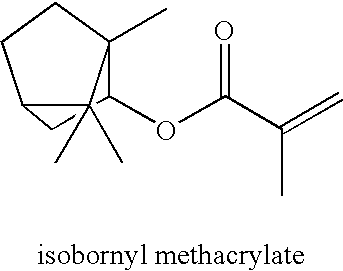

Aqueous laundry detergent compositions containing surfactants and fatty acid, having a pH of from about 6 to about 11 and containing a polymer having a number average molecular weight of from about 700,000 to about 4,000,000 and comprising monomeric units including: nonionic monomers selected from acrylamide, N,N-dialkyl acrylamide, methacrylamide, N,N-dialkylmethacrylamide, hydroxyalkyl acrylate and vinyl pyrrolidone, vinyl acetate, vinyl alcohol, and mixtures thereof; cationic monomers selected from N,N-dialkylaminoalkyl methacrylate, N,N-dialkylaminoalkyl acrylate, N,N-dialkylaminoalkyl acrylamide, N,N-dialkylaminoalkylmethacrylamide, methacylamidoalkyl trialkylammonium chloride, acrylamidoalkylltrialkylammonium chloride, vinylamine, quaternized vinyl imidazole and diallyl dialkyl ammonium chloride, and mixtures thereof; and anionic monomers selected from acrylic acid, methacrylic acid, maleic acid, vinyl sulfonic acid, styrene sulfonic acid, acrylamidopropylmethane sulfonic acid (AMPS), salts thereof, and mixtures thereof; in a specified mole ratio.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation and application methods of thermoplastic adhesive for powder microinjection molding

InactiveCN102775673AExpand the range of product applicationsEasy to shapeParaffin waxPolymer science

The invention discloses preparation and application methods of a thermoplastic adhesive for powder microinjection molding, and belongs to the technical field of powder microinjection. The preparation and application methods are characterized in that the adhesive is composed of a plurality of components, a mixing process with metal and ceramic powder is simple, an injection temperature window is wide, flowability of feedstock is good, green body strength during demoulding and degreasing, no injection and degreasing defects exist, and a residual quantity after degreasing is small. The adhesive contains, by mass, 5-40% of paraffin wax (PW), 5-20% of beewax (BW), 10-32% of high density polyethylene (HDPE), 10-40% of ethylene-vinyl acetate (EVA) and 5-25% of stearic acid (SA). According to the methods, the forming precision of minisize parts produced through the powder microinjection molding technology is improved remarkably, and production and application ranges of metal and ceramic minisize parts are broadened.

Owner:UNIV OF SCI & TECH BEIJING

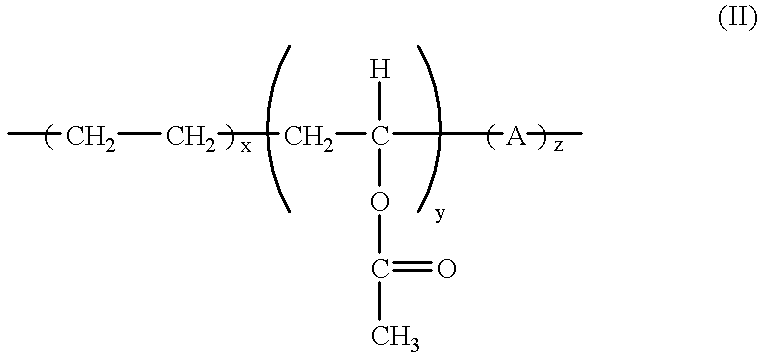

Resin composition and multilayered structure using the same

InactiveUS20120009431A1Good dispersionReduce generationSynthetic resin layered productsAntimony organic compoundsPolymer sciencePolyolefin

A resin composition comprising: a polyolefin (A); a saponified ethylene-vinyl acetate copolymer (B) having an ethylene content of 20 to 65 mol % and having a degree of saponification of vinyl acetate units of 96% or more; a higher fatty acid metal salt (C) having 8 to 22 carbon atoms; and a conjugated polyene compound (D) having a boiling point of 20° C. or higher; wherein the mass ratio (A:B) of the polyolefin (A) and the saponified ethylene-vinyl acetate copolymer (B) is 60:40 to 99.9:0.1, the amount of the higher fatty acid metal salts (C) is in the range of 0.0001 to 10 parts by mass per 100 parts by mass of the total of the polyolefin (A) and the saponified ethylene-vinyl acetate copolymer (B), and the amount of conjugated polyene compound (D) is in the range of 0.000001 to 1 part by mass per 100 parts by mass of the total of the polyolefin (A) and the saponified ethylene-vinyl acetate copolymer (B). This enables suppression of formation of aggregations at a micro-scale level, which serves to improve the dispersibility of EVOH. As a result, the occurrence of poor appearance such as wavy patterns on the molded article surface caused by flow anomalies due to the aggregates is suppressed, and thus, it is possible to obtain molded articles with good appearance.

Owner:KURARAY CO LTD

Method of preparing a synthetic fuel from coal

InactiveUS6964691B1Polymer composition dosage requirementAttendant costSolid fuelsPolymer sciencePolyvinyl alcohol

A method of preparing a synthetic fuel from coal comprising applying to the coal an aqueous emulsion of one or more reactive polymers and thoroughly mixing the coal to yield a complete reaction of the coal with the reactive polymers, wherein the reactive polymers are selected from the group consisting of ethylene / vinyl acetate copolymers, ethylene / vinyl alcohol copolymers, poly(acrylic acid), poly(vinyl alcohol), vinyl alcohol / vinyl acetate copolymers, poly(vinyl acetate), vinyl acetate / acrylic acid copolymers, poly(vinyl acetate / acrylic acid / ethylene), acrylic acid / acrylamide copolymers and poly(acrylamide).

Owner:NALCO CO

Ceramic binding agent and production method

InactiveCN102559132AWide bonding rangeSoft textureMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveAcetic acid ethenyl ester

The invention provides a ceramic binding agent, which belongs to the technical field of adhesives and comprises, by mass, acetic acid ethenyl ester 10%-15%, sodium silicate 5%-7.5%, aluminum powder 2%-3%, sodium aluminate 5%-10%, methyl vinylsiloxane rubber 15%-20%, phenolic resin 10%-15%, ethyl acetate 10%-15% and the balance water. The ceramic binding agent is high in temperature-resisting performance and balanced in texture and strength after being bonded. In addition, the ceramic binding agent can be bonded between ceramics, can be used for bonding various materials including woods, metal, plastics and the like, and is wide in application range and convenient to use.

Owner:WUJIANG DEBANG TECH CHEM

Vinyl Acetate Production Process

ActiveUS20120130119A1Easy to controlOrganic compound preparationCarboxylic acid esters preparationAcetic acidOxygen

Disclosed is a method for controlling a vinyl acetate production process. The method comprises reacting ethylene, acetic acid, and an oxygen-containing gas in the presence of a catalyst in a reactor to produce vinyl acetate, measuring the concentration of a component involved in or associated with the reaction and / or any of the subsequent steps by Raman spectroscopic analysis, and adjusting the conditions in the reactor or in any of the subsequent steps in response to the measured concentration of the component to achieve a proper control of the reaction or any of the subsequent steps.

Owner:LYONDELLBASELL ACETYLS

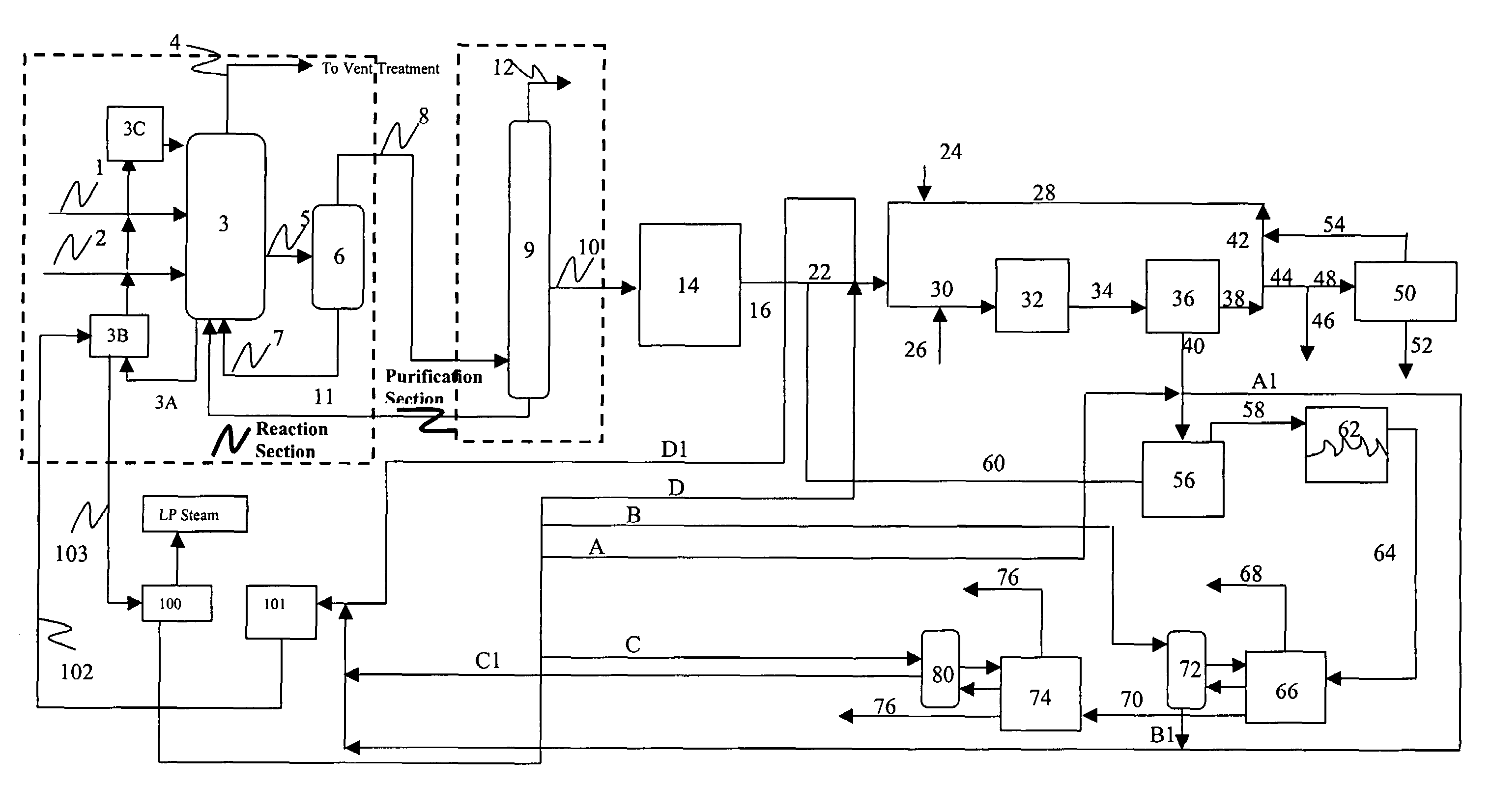

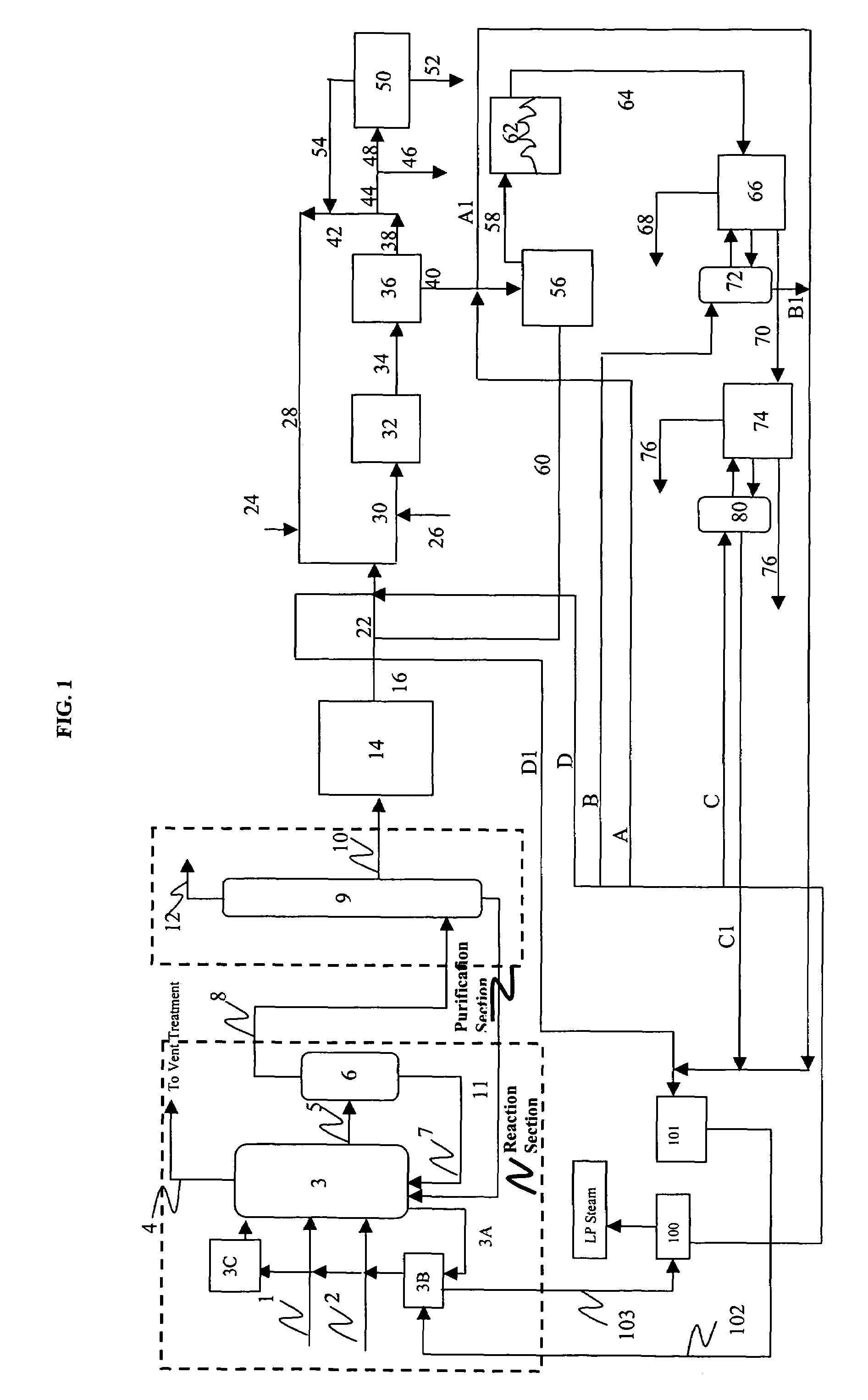

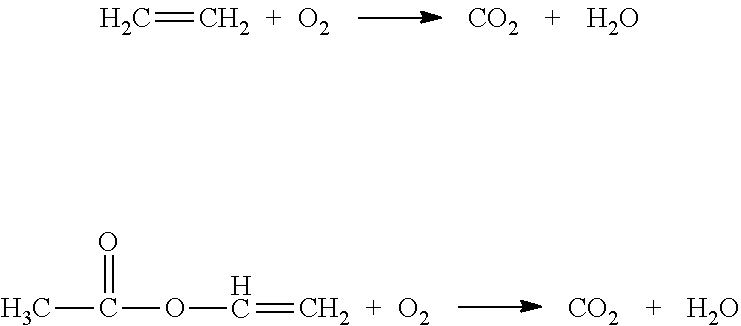

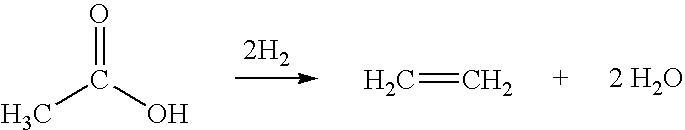

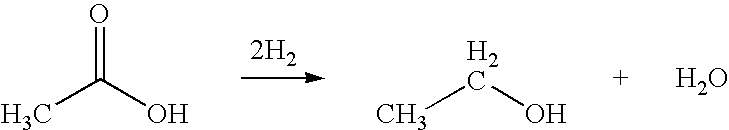

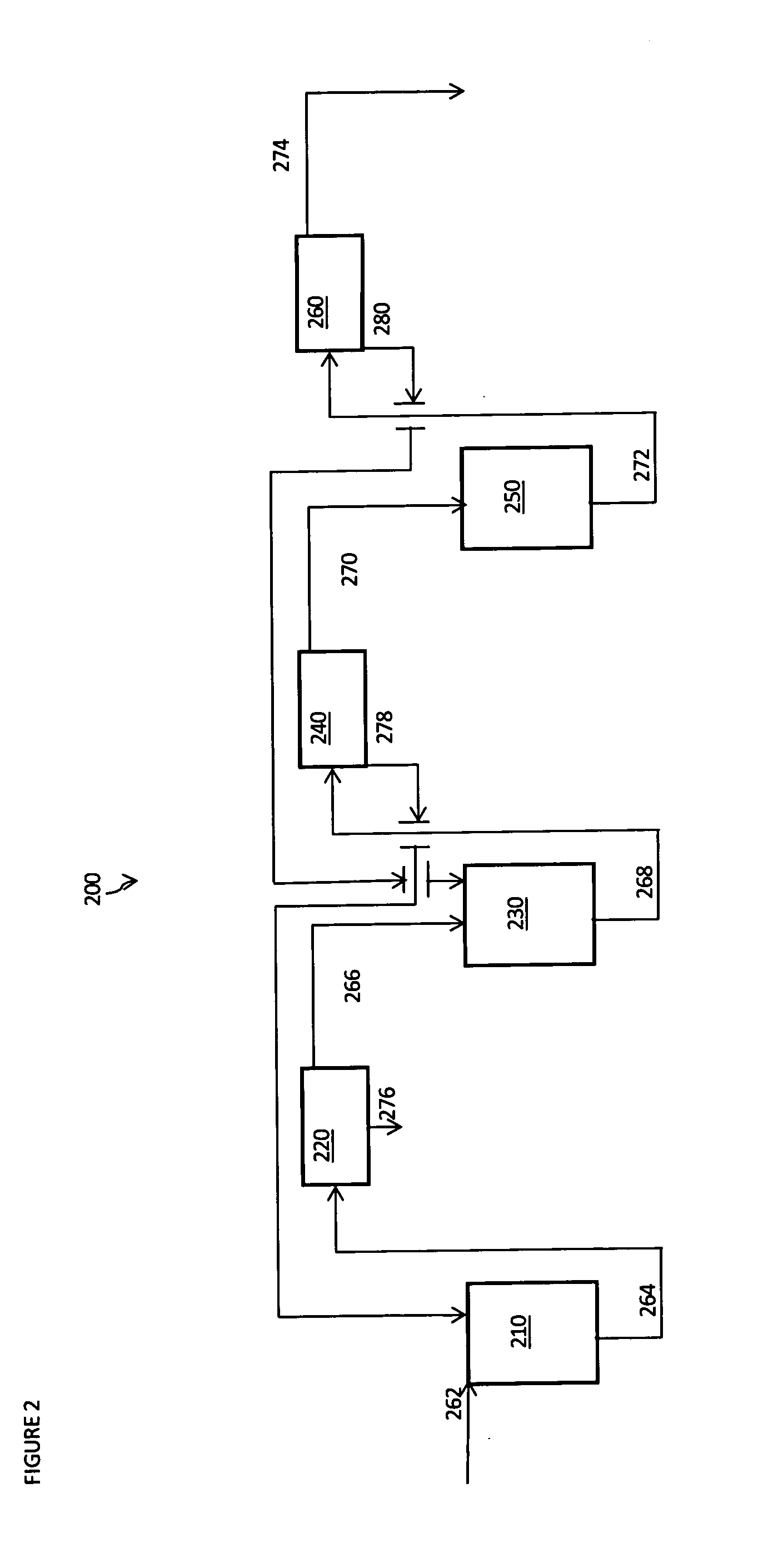

Integrated process for the production of vinyl acetate from acetic acid via ethylene

InactiveUS7855303B2High selectivityHigh yieldMolecular sieve catalystsOrganic compound preparationAcetic acidHydrogen

This invention provides an integrated two stage economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form ethylene either in a single reactor zone or in a dual rector zone wherein the intermediate hydrogenated products are either dehydrated and / or cracked to form ethylene. In a subsequent second stage so formed ethylene is reacted with molecular oxygen and acetic acid over a suitable catalyst to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over a hydrogenation catalyst and subsequent reaction over a dehydration catalyst selectively produces ethylene, which is further mixed with acetic acid and molecular oxygen and reacted over a supported palladium / gold / potassium catalyst.

Owner:CELANESE INT CORP

Semi-crystalline ethylene vinyl-acetic ester emulsion polymer for heat-seal

Owner:WACKER CHEM GMBH

Paper coating compositions

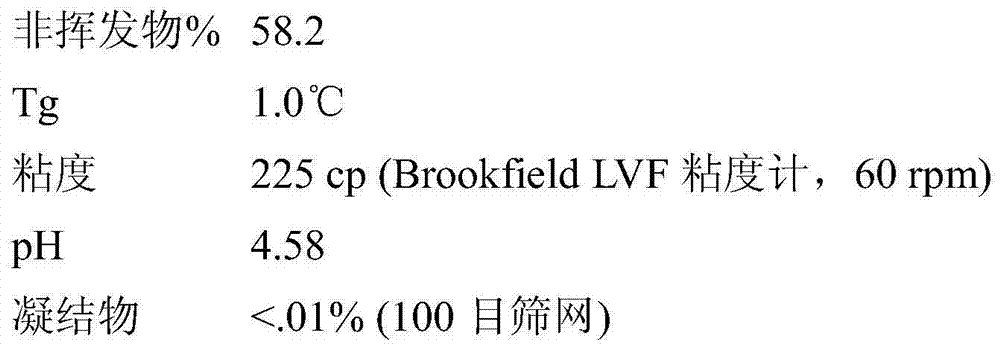

A composition for coating paper includes at least one pigment selected from the group consisting of polymeric pigments, aluminosilicates, calcium carbonate, titanium dioxide, talc, barium sulfate, zinc oxide, aluminum trihydrate, amorphous silica and silicates; wherein the pigment is dispersed in an aqueous dispersion of a polymeric binder that is a copolymer of vinyl acetate, ethylene, at least one ethylenically unsaturated sulfonic acid or salt thereof and optionally one or more other monomers, wherein vinyl acetate units constitute in a range of 70-90 wt % of the polymeric binder and ethylene units constitute in a range of 10-30 wt % of the polymeric binder; and wherein the polymeric binder has a mean particle size in a range from 0.1 μm to 0.3 μm and the optional one or more other monomers do not include any N—(C1-4) alkylol (meth)acrylamide; and wherein the aqueous dispersion of the polymeric binder is free of alkylphenol ethoxylate surfactants and includes a nonionic surfactant component consisting of a polyethylene oxide / polypropylene oxide block copolymer and optionally one or more other nonionic surfactants, and optionally includes an anionic surfactant component consisting of one or more anionic surfactants.

Owner:WACKER CHEM GMBH

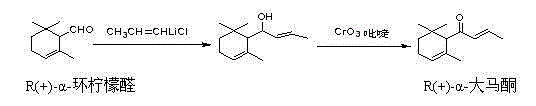

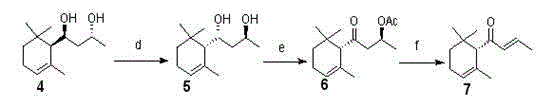

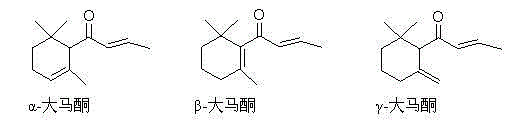

Synthesis method of (S)-(-)-alpha-damascenone

InactiveCN104630289ALoose requirementsHigh optical purityOrganic compound preparationOrganic chemistry methodsDamasconeDouble bond

The invention discloses a synthesis method of (S)-(-)-alpha-damascenone, which comprises the following steps: adding alpha-ionone into an alcohol or ether solvent, adding a hydrogen peroxide water solution and a sodium hydroxide water solution, stirring to perform double bond oxidization reaction to generate alpha,beta-epoxy-alpha-ionone, adding tetrahydrofuran, water and ethanol to generate beta-epoxy-alpha-ionone under the catalytic action of an aluminum-mercury mixture, carrying out ring-opening hydrogenation to generate 4-hydroxy-4-(2,6,6-trimethylcyclohexyl-2-alkenyl)-2-butanone, adding acetonitrile and an acetic acid solution to react with Me4NHB(OAc) to obtain a raw material diol, reacting the diol with vinyl acetate and methyl tert-butyl ether under the catalytic action of lipase while stirring to obtain an optical isomer diol, adding DMP (dimethylpyrazole) and CH2Cl2 to react to obtain propyl 1-methyl-3-oxo-3-(2,6,6-trimethyl-cyclohexyl-2-alkenyl)-acetate, and carrying out elimination reaction under the catalytic action of inorganic alkali to generate the (S)-(-)-alpha-damascenone dominant antipode. The method has the advantages of cheap and accessible raw materials, mild reaction conditions and higher conversion rate, is simple to operate, and can obtain the antipode with higher optical purity.

Owner:ANHUI HYEA AROMAS

Production process for catalyst

InactiveUS20050234262A1High catalytic activityIncreased space-time yieldOrganic compound preparationOrganic chemistry methodsWater solubleVinyl acetate

A production process for a catalyst that supports a noble metal, and an alkali metal compound and / or alkali earth metal compound, useful for synthesis of vinyl acetate is provided. The process includes (a) impregnating a carrier with an aqueous solution of a water soluble noble metal compound, and (b) converting the noble metal compound into a water insoluble noble metal compound, and the noble metal compound is reduced, followed by supporting an alkali metal compound and / or alkali earth metal compound. An element that oxidizes to produce an amphoteric oxide is brought into contact with the carrier at the step (a) and / or the step (b). This process is advantageous in facilities required and the associated running costs for production of an eggshell-type structure catalyst, which offers a high level of catalytic activity, and enables the production of vinyl acetate with a high space-time yield.

Owner:N E CHEMCAT

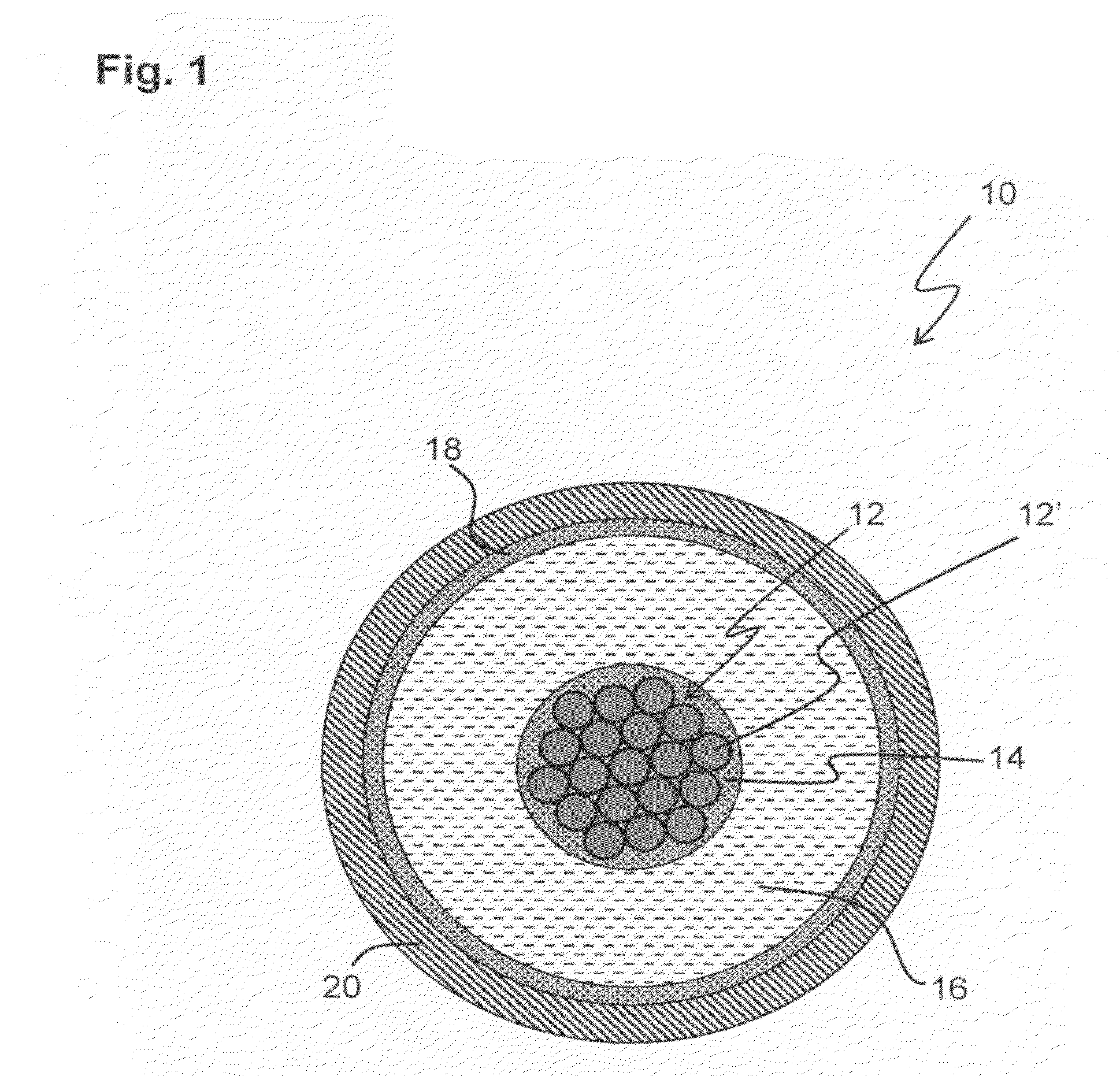

Medium-voltage cable

InactiveUS20120031641A1Provide resistanceIncrease polarityNon-metal conductorsConductive materialInsulation layerAcetic acid ethenyl ester

A cable for transmitting electrical power at a voltage between 5 and 49 kV includes a conductive cable core and an insulation layer for insulating the cable core, the insulation layer including from 50 to 99.9% of cross linked polyethylene, and from 0.1 to 50% of ethylene-alkyl(meth)acrylate and / or ethylene vinyl acetate. In at least one embodiment, the insulation layer is provided with a strippable outer semi conductive screen, which includes from 20 to 80% by weight of a composition of at least one copolymer selected from the group consisting of ethylene-alkyl (meth)acrylate carbon monoxides. The combination of materials in the insulator and the semi conductive screen provides for high water-tree resistance of the insulator and strippability of the semi conductive screen.

Owner:TRELLEBORG FORSHEDA BUILDING

Method for preparing acetylacetone polyvinyl alcohol/graphene nanocomposite

The invention belongs to the technical field of nanocomposites, and in particular relates to a method for preparing an acetylacetone polyvinyl alcohol / graphene nanocomposite. The method adopts an acetic acid vinyl ester monomer emulsion living polymerization reaction method to prepare the acetylacetone polyvinyl alcohol / graphene nanocomposite and an acetylacetone polyvinyl alcohol / reduced graphene oxide nanocomposite. The obtained nanocomposites have excellent mechanical property.

Owner:FUDAN UNIV

Modified low-density polyethylene material, preparation method and application thereof

InactiveCN101215392AImprove mechanical propertiesGood weather resistanceOther chemical processesSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a modified polyethylene material with low density and a process for preparation and the application of the invention. The components and weight part proportion comprise low-density polyethylene 45-60 portions whose density is 0.92-0.93, polyethylene 15-20 portions whose density is 0.94-0.96, acetic acid ethyenyl ester 10-15 portions, toughening master batch 10-15 portions and anti-oxidant 10100.1-0.5 portions. The modified polyethylene material with low density of the invention can be used to prepare water-proofing material. And the water-proofing material at least comprises two-layer polypropylene nonwoven and modified polyethylene material with low density which is arranged between the two-layer polypropylene nonwoven, which can be used to resist water for architecture. The invention adopts a process which is regulated by GB 18173.1-2000 to detect, the result shows that the properties of mechanical mechanics are excellent, the water-proof property of the invention is not only greatly better than the existing products, but also the weathering resistance, in particular to the characteristics of heat resistance are greatly improved. The invention can meet the requirements of the architecture filed.

Owner:上海远盛建筑防水材料厂

Salt-sensitive binders containing vinyl acetate for nonwoven webs and method of making same

InactiveUS20090123773A1Synthetic resin layered productsThin material handlingPolymer scienceAcetic acid ethenyl ester

A solution with a salt-sensitive polymer binder for use in fibrous webs, where the binder contains a copolymer of carboxylic acid monomer units and ethylenically unsaturated monomer units including vinyl acetate. The binder solution is prepared by emulsion-polymerizing a copolymer and then neutralizing the copolymer with base to make it water soluble. The binders provide a higher wet strength in concentrated salt solutions than in deionized water, and are particularly suitable for strengthening nonwoven fibrous webs in disposable articles such as wet-wipes, personal care products, diapers, and the like.

Owner:CELANESE INT CORP

Slow release microsphere containing hormone kind anti cancer medicine and its application

InactiveCN1824313AEnhanced inhibitory effectOrganic active ingredientsSolution deliveryMicrosphereWhole body

A slow-release microball of the anticancer medicine containing hormone component for preparing the slow-release implant or slow-release injection is composed of the active anticancer component chosen from hormone-type anticancer medicine and its synergist and antimetabolic anticancer medicine, and the medicinal additive chosen from polylactic acid, the copolymer of polyoxyacetic acid and hydroxyacetic acid, ethene-vinyl acetate copolymer and polifeprosan.

Owner:JINAN KANGQUAN PHARMA TECH

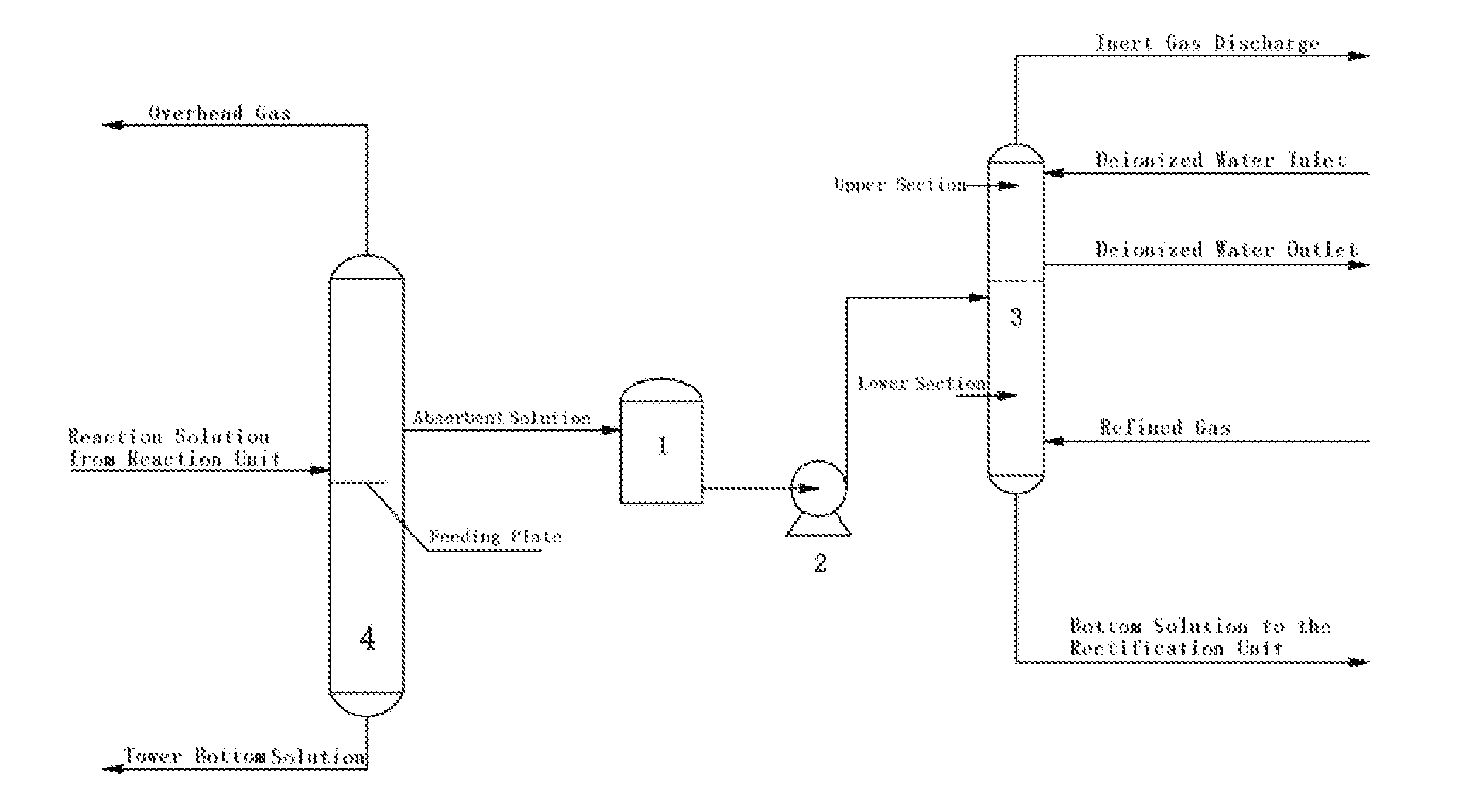

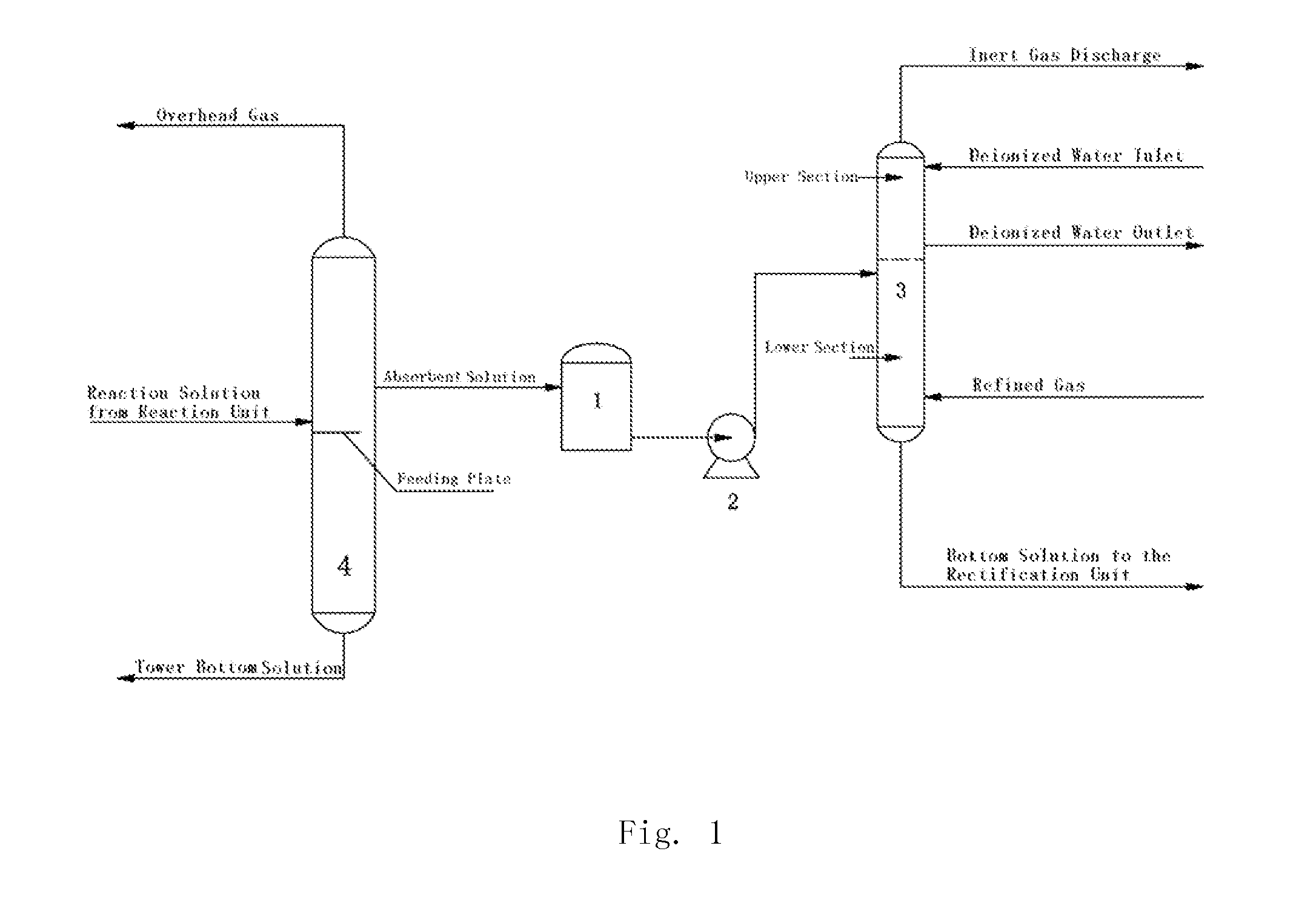

Method for Recovering Ethylene during the Process for Producing VAC and a Device thereof

ActiveUS20140366729A1Emission reductionLow production costGas treatmentUsing liquid separation agentAcetic acidSolvent

The present invention discloses a method and a device for recovering ethylene during the process for producing vinyl acetate, wherein a double solvent absorption method composed of an absorbent solution and deionized water is adopted. The method is as follows: introducing an outlet stream as an absorbent solution from the upper section of the feeding plate in an acetic acid tower during the rectification stage of vinyl acetate production; delivering same to the top of the lower section of the ethylene recovery tower by a delivery pump; charging refined gas from the tower bottom of the ethylene recovery tower for contacting with the absorbent solution in a counter-current; delivering the absorption bottom solution to the rectification stage for treatment; the gas continuing to rise to the upper section of the ethylene recovery tower and contacting with the deionized water introduced from the top of the tower in a counter-current; absorbing and removing the acetic acid therein; and discharging the residual inert gas, such as N2, from the top of the ethylene recovery tower. The absorbent solution is a mixture of acetic acid, vinyl acetate and water, and comprises by weight percentage of 50-85% acetic acid, 5-30% vinyl acetate and 5-20% water.

Owner:TIANJIN UNIV

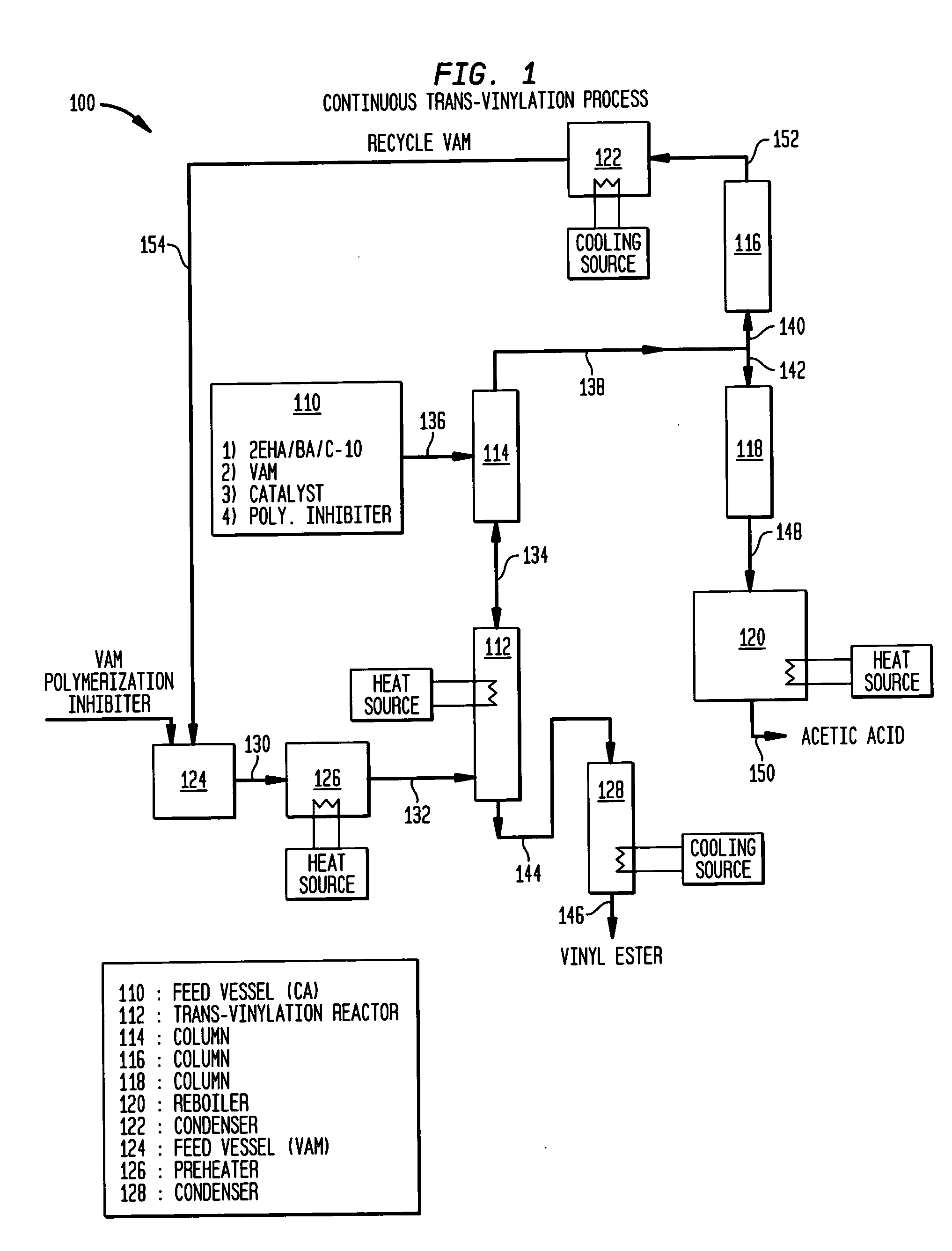

Process for the continuous transvinylation of carboxylic acids with vinyl acetate

InactiveUS20110275853A1More economical route to vinyl ester monomersOrganic compound preparationCarboxylic preparation by ozone oxidationAcetic acidReactive distillation

A continuous process is provided for selective formation of a vinyl ester by reactive distillation from a corresponding carboxylic acid. Carboxylic acid, vinyl acetate, and a palladium acetate—bidentate ligand catalyst complex are provided and reacted in a typical embodiment. Acetic acid and vinyl acetate are continuously removed from the reaction mixture and vinyl acetate is recycled to the reaction mixture. The vinyl ester product is separated from the vinyl acetate, residual carboxylic acid, residual acetic acid, and catalyst.

Owner:CELANESE INT CORP

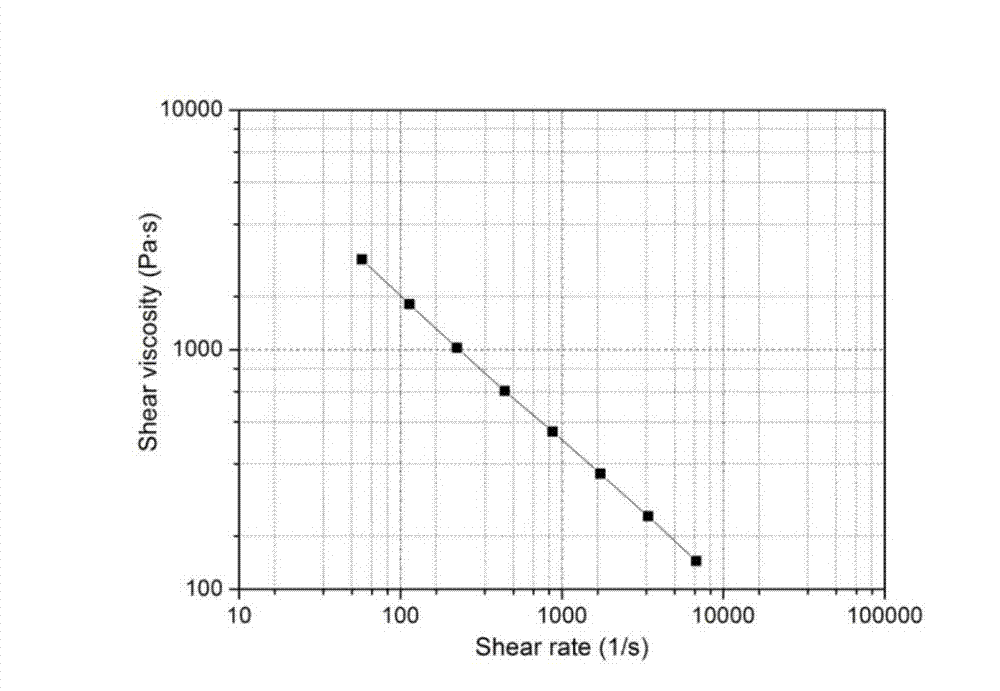

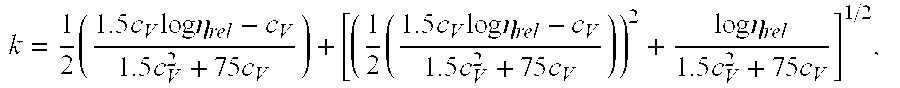

Method for preparing EVA elastomer

The invention discloses a method for preparing EVA elastomer. The method included the step of controlling the pressure of ethylene to make the ethylene completely liquefied in a single reactor with alcohols as a solvent, so that the ethylene and the vinyl acetate are subjected to liquid-liquid single-phase copolymerization and the EVA elastomer is obtained. According to the method based on the existing EVA-elastomer-solution polymerization process, the pressure of ethylene is controlled to make the ethylene completely liquefied so that the liquid-liquid copolymerization can improve the comonomer contact efficiency as well as the solubility of ethylene in the liquid phase, complete the solution single-phase copolymerization, and greatly improve the monomer copolymerization rate and the diffusion as well as the initiator efficiency of the free radicals in the copolymer solution. According to the application requirements of different polymerization products, by adjusting the solvent, the method greatly improves the copolymerization rate and the high solid content of a high-viscosity system. Using the single-reactor process, the method is also capable of avoiding the high-cost and complex-manipulation problem resulting from a raw-material process device of the multi-reactor process. Therefore, the method has high industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sustained-release injection containing methotrexate and synergist thereof

InactiveCN101396338AOrganic active ingredientsPharmaceutical delivery mechanismTreatment effectWhole body

The invention relates to a sustained release injection containing methotrexate, consisting of sustained release microspheres and menstruum, wherein, the sustained release microspheres comprise effective anti-cancer component and sustained release auxiliary material; and the menstruum is ordinary menstruum or special menstruum containing suspending agent. The effective anti-cancer component is the combination of the methotrexate and the methotrexate synergist selected from platinum compound, topoisomerase inhibitor and / or tetrazine compound. The sustained release auxiliary material is selected from one or the combination of the copolymer of polylactic acid, polyglycolic acid and glycolic acid, ethylene vinyl acetate copolymer and the copolymer of polifeprosan, FAD and decanedioic acid. The suspending agent is selected from carboxymethyl cellulose, etc. The suspending agent is used for suspending the effective anti-cancer component or sustained release particle or microsphere containing the effective anti-cancer component, so as to be made into the sustained release injection. The sustained release injection is injected into tumor, which can not only reduce the general toxic reaction of the drug, but also improve the partial drug concentration at the tumour selectively and enhance the treatment effect of non-operative treatments, such as chemotherapeutic drug, radiotherapy, etc.

Owner:JINAN SHUAIHUA PHARMA TECH

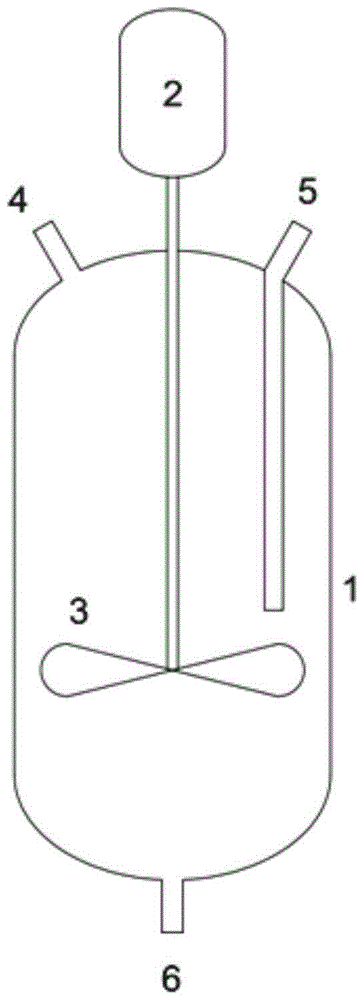

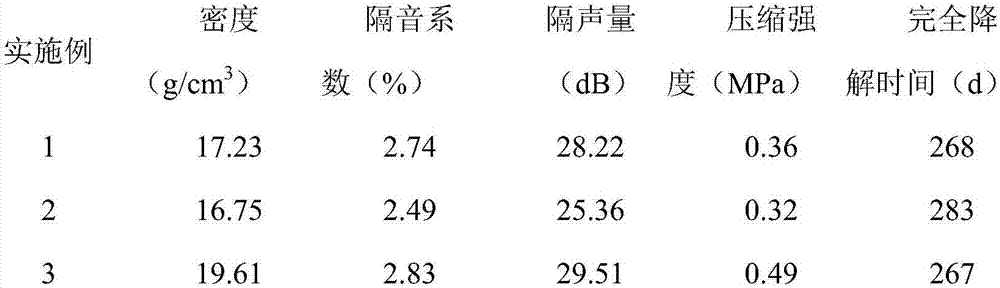

Sound-proof material, preparation method and application of sound-proof material

InactiveCN106893179AImprove sound insulationAdditive manufacturing apparatusCross-linkPolymer science

The invention discloses a sound-proof material, a preparation method and an application of the sound-proof material. The sound-proof material is prepared from the following raw materials: graphene, polyethene, chloroprene rubber, polyoxypropylene triol, caprylic / capric triglyceride, a methacrylate polymer, brominated paraffin, a quartz glass fiber, maleic anhydride, an ethylene-ethyl acrylate copolymer, acetic acid ethenyl ester copolymer emulsion, trisopropanolamine, an adhesive, a dispersing agent, a tackifier, a cross-linking agent, a catalyst, a plasticizer, a flexibilizer, a foaming agent, a foaming regulator, a foam stabilizer, a curing agent, a degradation agent and a stabilizer. The sound-proof material is prepared by the steps of mixing, extruding and the like. The sound-proof material is applied to 3D (three dimensional) printing. The material is degradable, can be degraded completely after 267-283 days, and a sound reduction index is 25.36-29.51 dB which shows that the material has a good sound-proof effect.

Owner:广西丰达三维科技有限公司

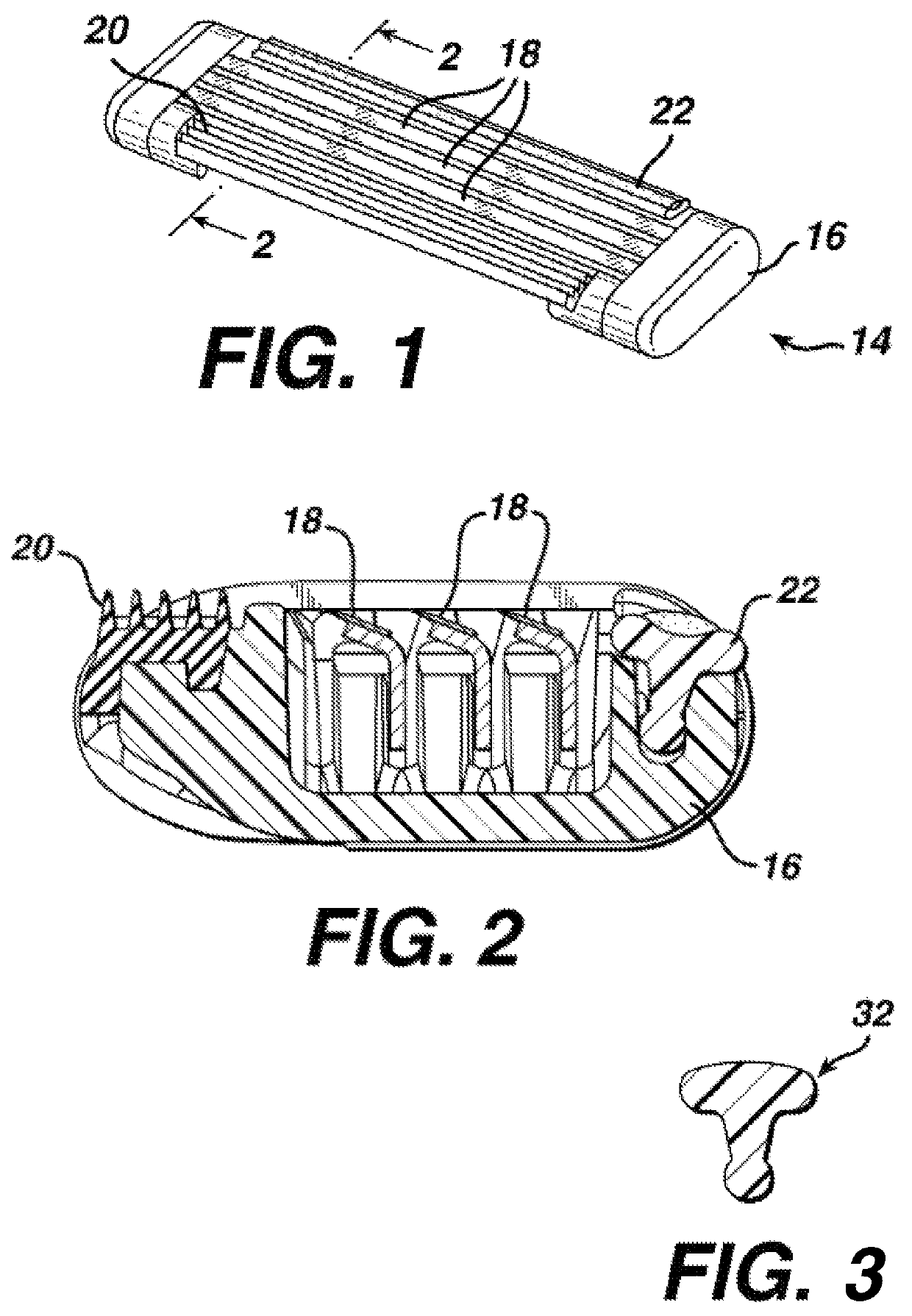

Skin engaging member comprising ethylene vinyl acetate

Owner:THE GILLETTE CO

Process for preparing vinyl acetate-ethylene copolymers by means of emulsion polymerization

ActiveUS8586686B2Monocarboxylic acid ester polymer adhesivesSynthetic resin layered productsPolymer scienceAcetic acid ethenyl ester

Owner:WACKER CHEM GMBH

Floor covering adhesive composition comprising a vinyl acetate-ethylene copolymer

ActiveUS20160289512A1Monocarboxylic acid ester polymer adhesivesLaminationPolymer scienceAcetic acid ethenyl ester

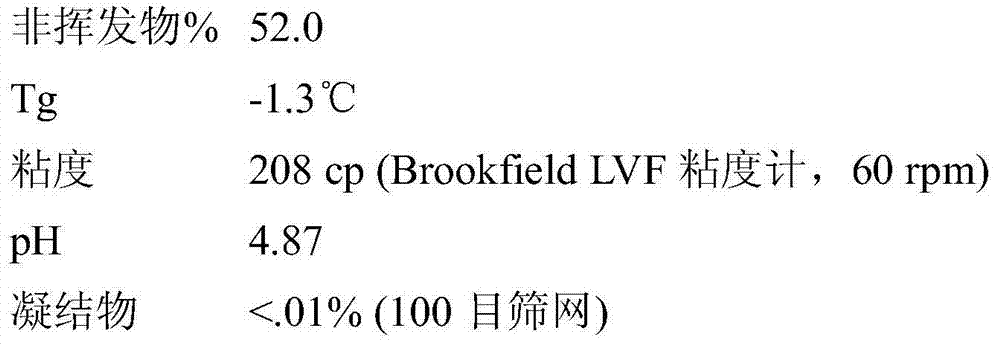

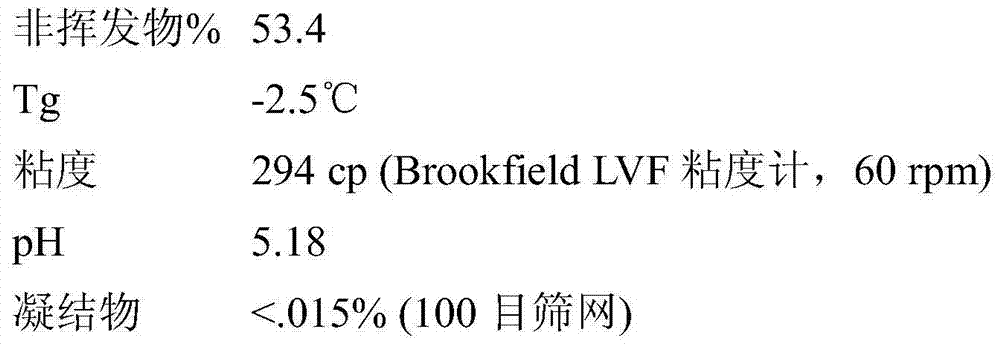

The invention relates to a floor covering adhesive composition, based on an aqueous, emulsifier-stabilized polymer dispersion of vinyl acetate-ethylene copolymer, containing A) tackifying resin, B) one or more fillers, and C) a vinyl acetate-ethylene copolymer in the form of an emulsifier-stabilized aqueous dispersion, characterized in that the vinyl acetate-ethylene copolymer is obtained by radical-initiated emulsion polymerization in an aqueous medium, of a) 60 to 89.9% by weight of vinyl acetate, b) 10 to 36% by weight of ethylene, c) 0 to 2% by weight of one or more monomers selected from the group of vinyl esters of carboxylic acids having 8 to 12 C atoms and acrylic acid alkyl esters having a C to C8 alkyl radical, d) 0.1 to 5% by weight of one or more ethylenically unsaturated auxiliary monomers having a carboxylic acid group, amide group, nitrile group or sulfonic acid (salt) group, wherein the percentages stated in % by weight are each in relation to the total weight of the comonomers and add up to 100% by weight, and the polymerization is carried out in the presence of one or more emulsifiers.

Owner:WACKER CHEM GMBH

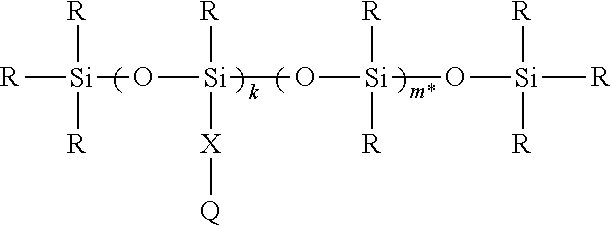

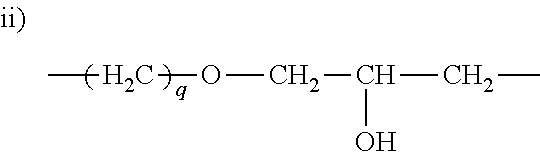

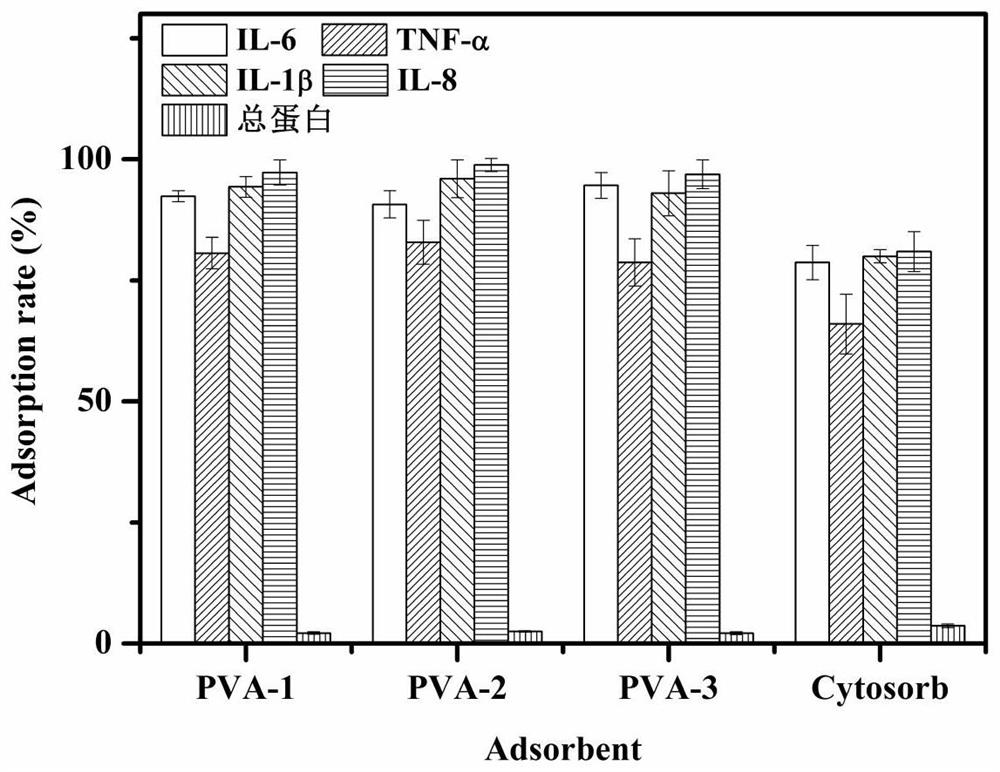

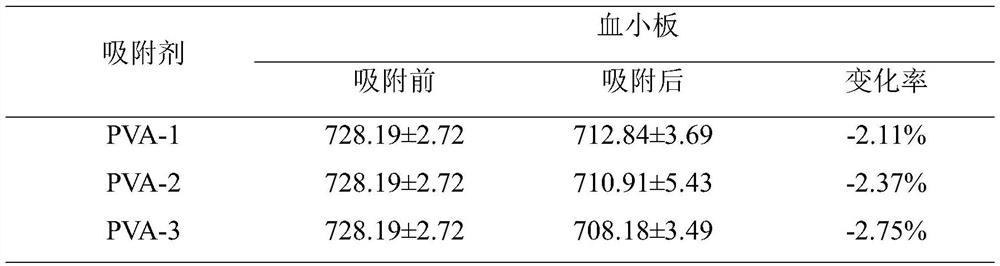

Immunosorbent for removing inflammatory factors in blood and preparation method thereof

ActiveCN108855003BGood blood compatibilityGood biocompatibilityOther blood circulation devicesOther chemical processesAlkaneInflammatory factors

Owner:NANKAI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com