Patents

Literature

58 results about "Sound reduction index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sound reduction index is used to measure the level of sound insulation provided by a structure such as a wall, window, door, or ventilator. It is defined in the series of international standards ISO 16283 (parts 1-3) and the older ISO 140 (parts 1-14), or the regional or national variants on these standards. In the United States, the sound transmission class rating is generally used instead. The basic method for both the actual measurements and the mathematical calculations behind both standards is similar, however they diverge to a significant degree in the detail, and in the numerical results produced.

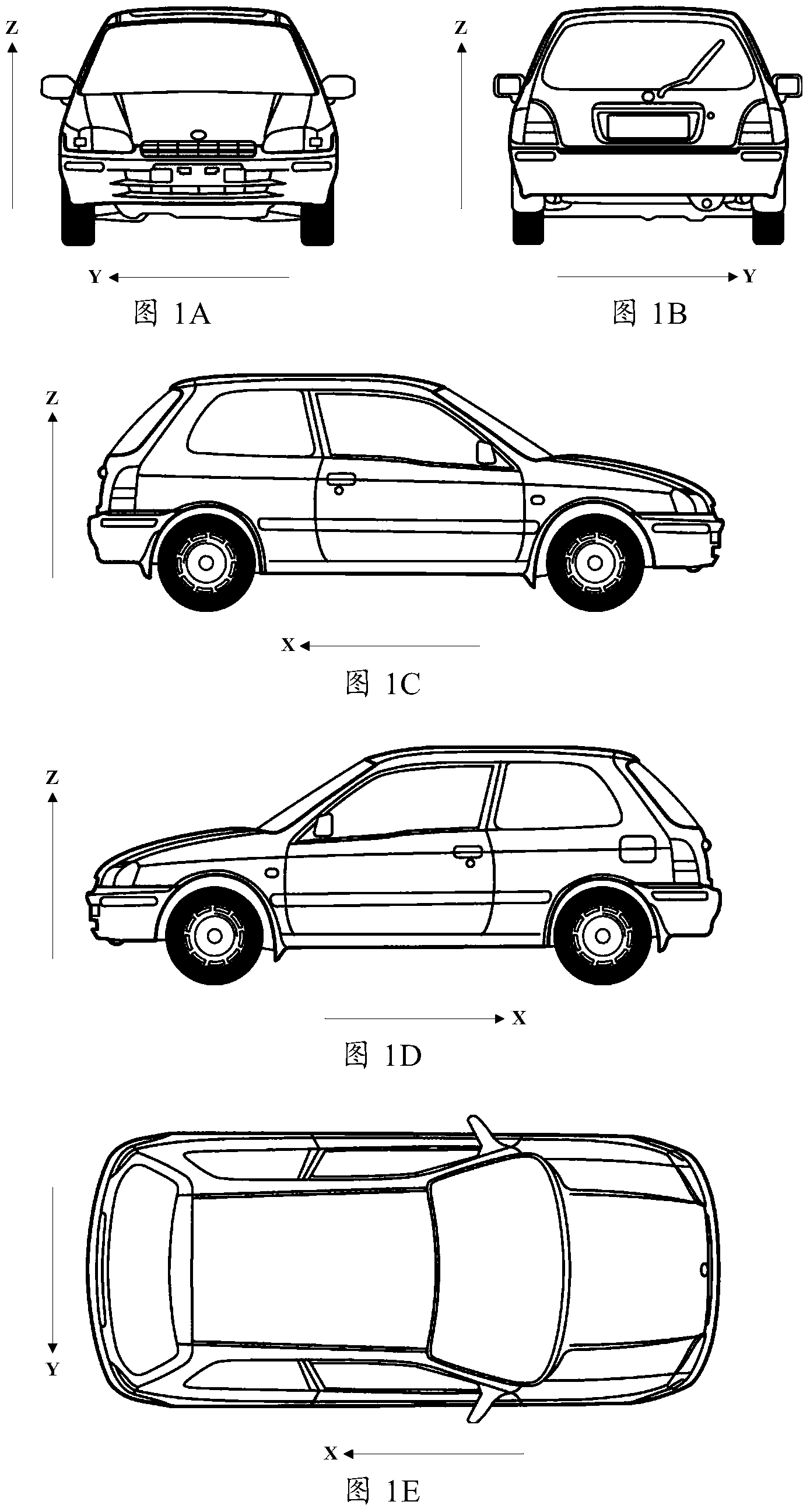

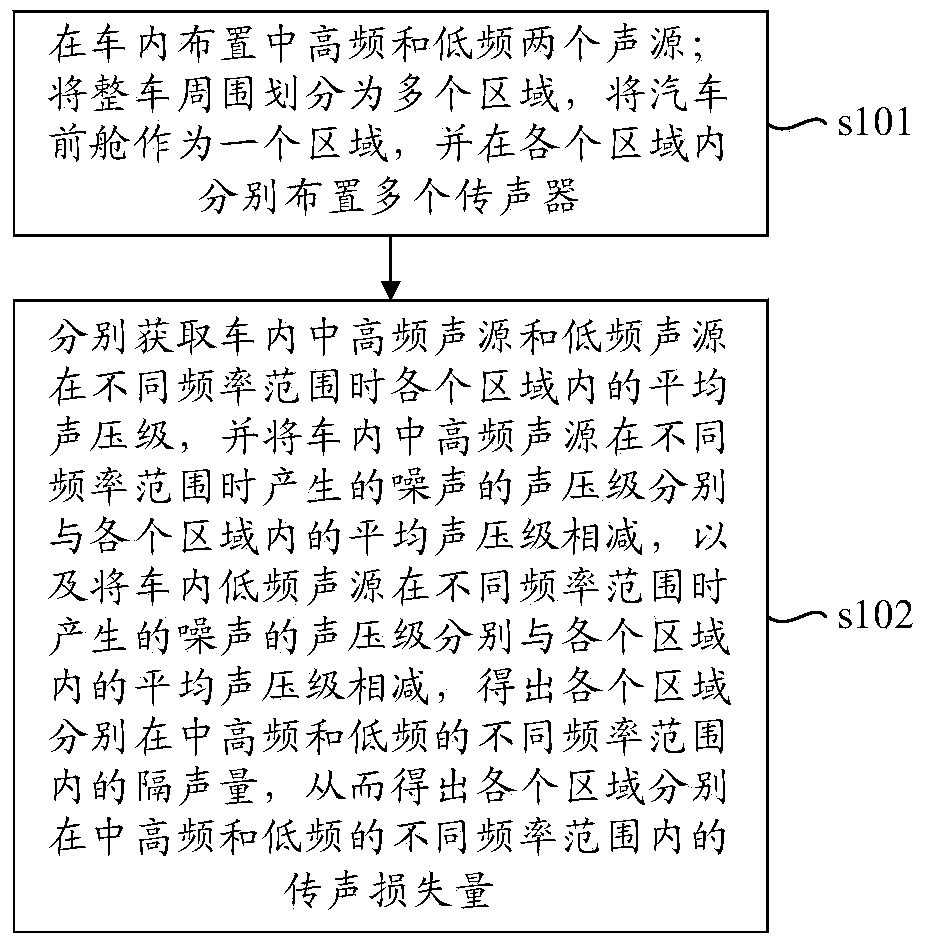

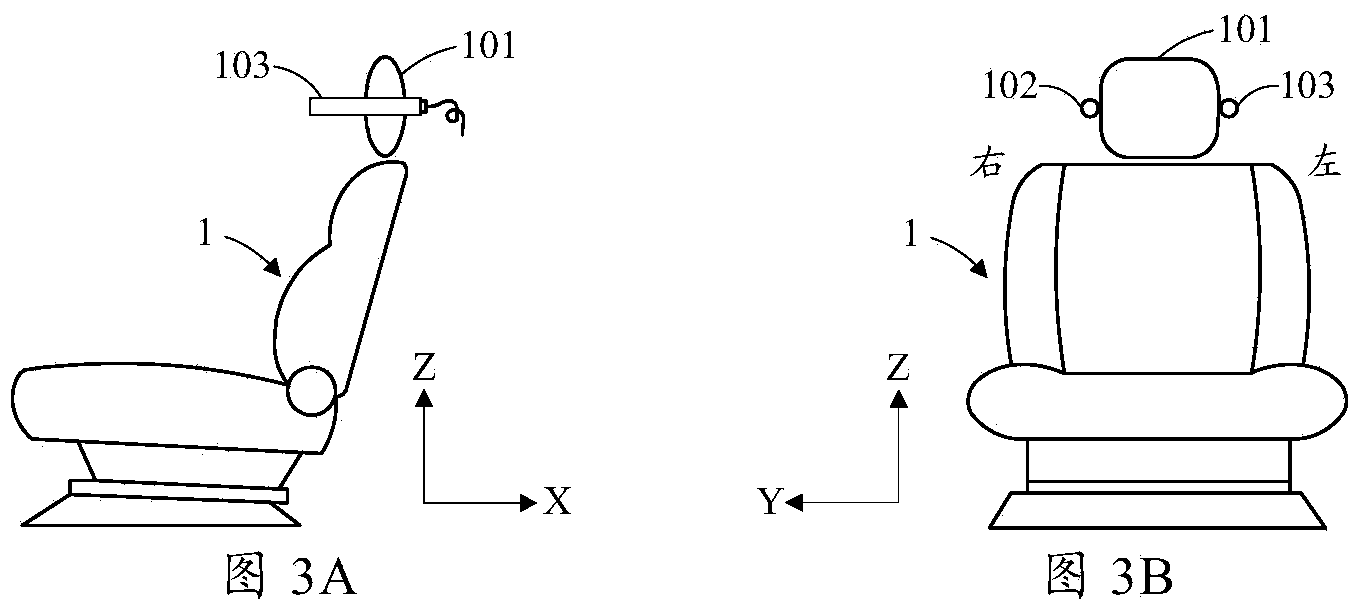

Finished automobile sound transmission loss testing method

ActiveCN104062075ASealing EvaluationImprove noise levelFluid-tightness measurementMicrophoneSound reduction index

The invention provides a finished automobile sound transmission loss testing method based on reciprocity. The finished automobile sound transmission loss testing method comprises the steps that a medium-high-frequency sound source and a low-frequency sound source are arranged in an automobile; the periphery of the finished automobile is divided into a plurality of areas, an automobile forecabin serves as an area, and a plurality of microphones are arranged in the areas respectively; the average sound pressure levels of each area are acquired when the medium-high-frequency sound source and the low-frequency sound source in the automobile are in different frequency ranges, the sound pressure levels of noise produced by the medium-high-frequency sound source in the automobile in the different frequency ranges are subtracted from the average sound pressure levels of the areas, the sound pressure levels of noise produced by the low-frequency sound source in the automobile in the different frequency ranges are subtracted from the average sound pressure levels of the areas, the sound reduction index of the areas in the different frequency ranges of the medium-high frequency and the low frequency are obtained, and accordingly the sound transmission losses of the areas in the different frequency ranges of the medium-high frequency and the low frequency are obtained respectively. The testing method can scientifically and strictly evaluate the sealing performance of the finished automobile.

Owner:CHERY AUTOMOBILE CO LTD

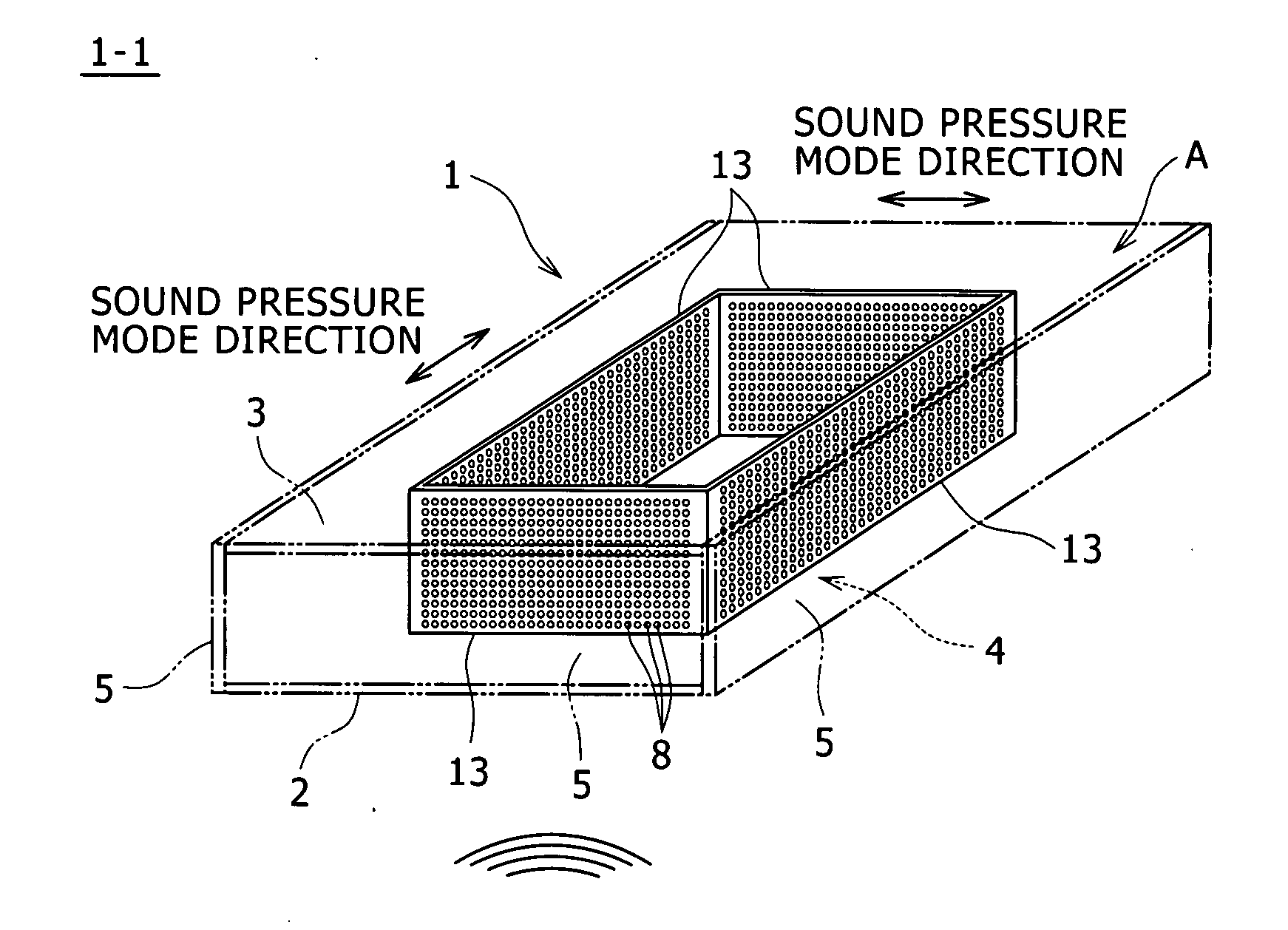

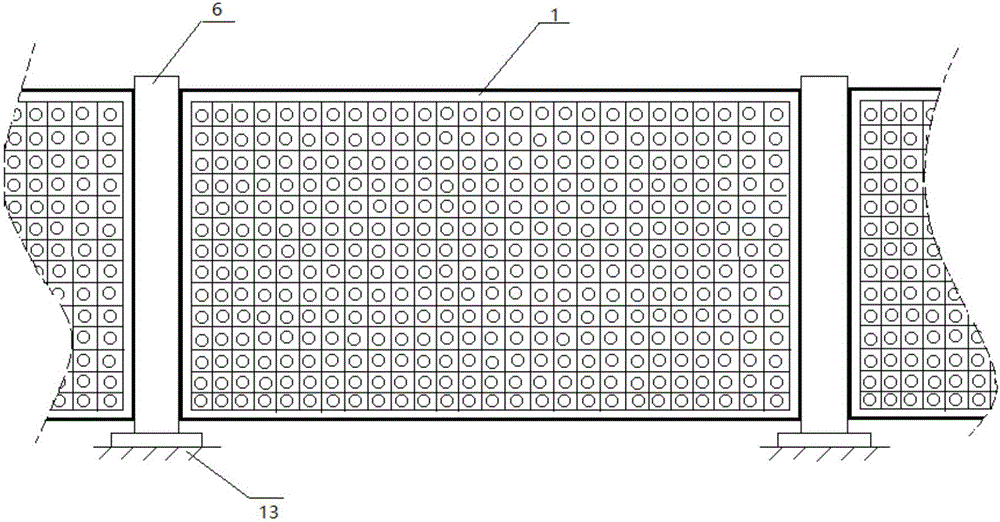

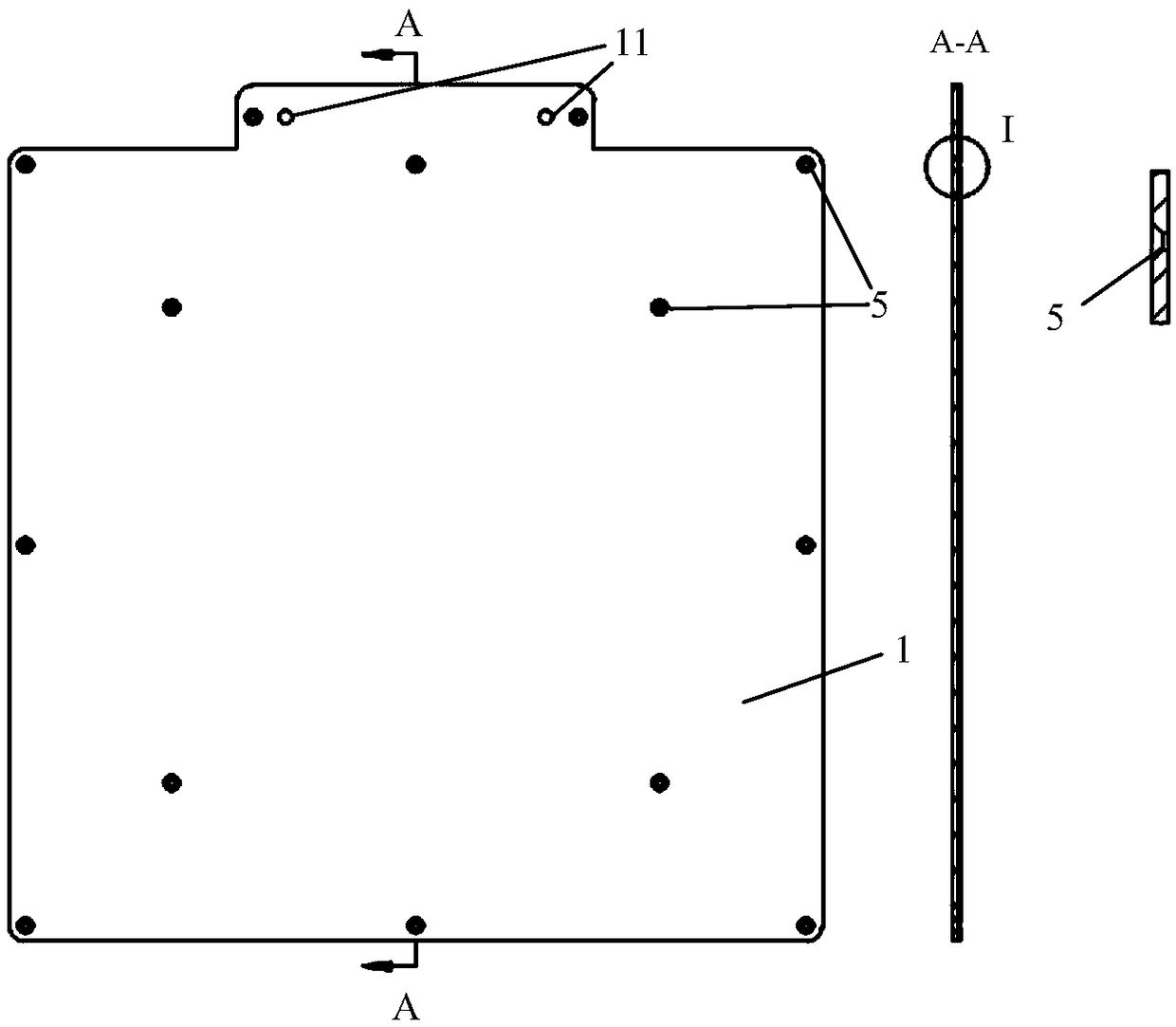

Double-Wall Structure

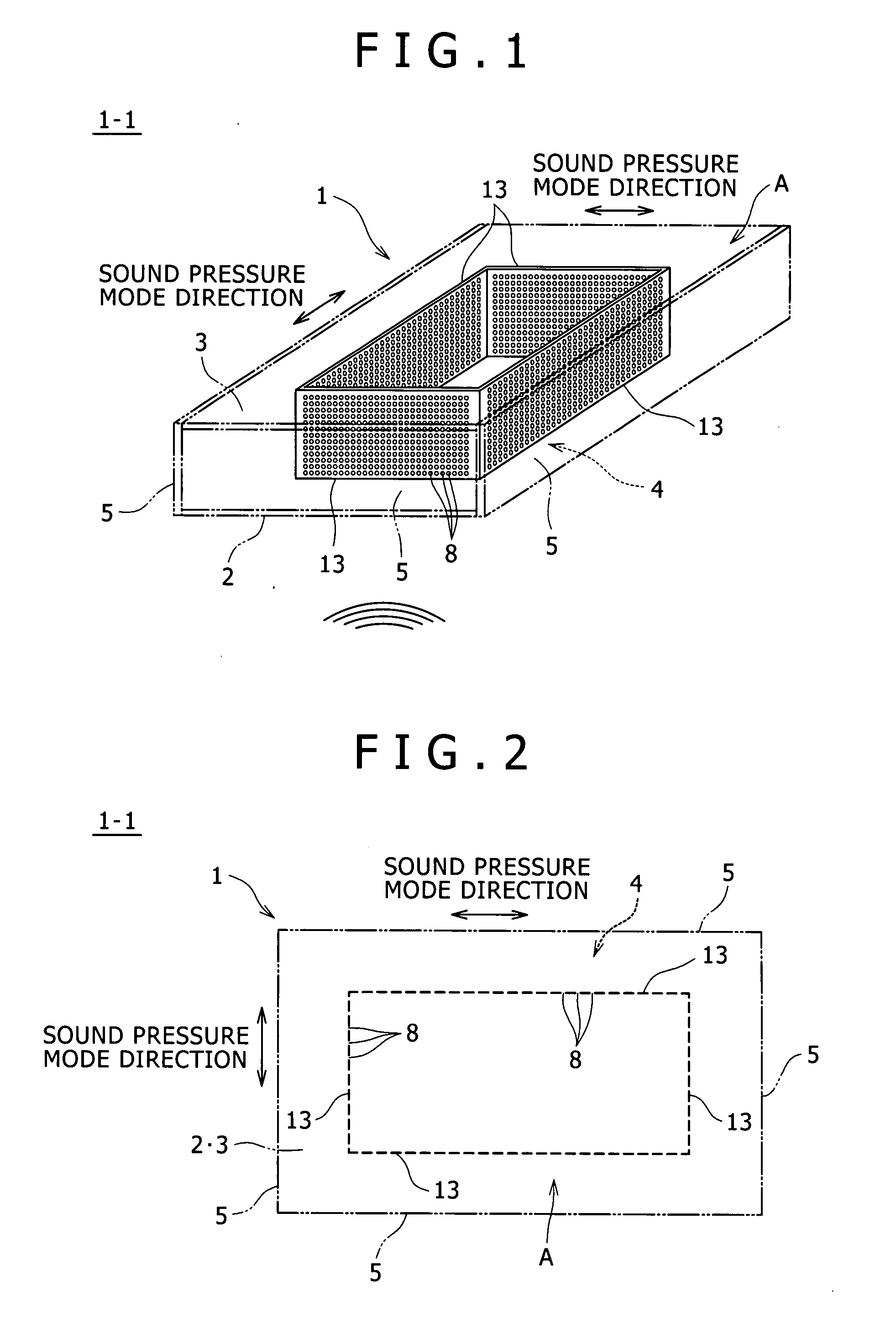

InactiveUS20080128200A1Suppress resonanceImproved sound transmission lossCeilingsSound proofingSound reduction indexEngineering

A double-wall structure (1), comprising plate-like bodies (2) and (3) disposed oppositely to each other to form an inner room (4) therebetween, peripheral members (5) disposed so that the inner room (4) can be completely or approximately closed, and perforated plates (13) with a large number of holes (8) disposed between the plate-like bodies facing each other. The double-wall structure is characterized in that an air layer (A) is interposed between the perforated plates and the peripheral members. Thus, since the double-wall structure can suppress the deterioration of a sound reduction index for sound with specific frequencies, it can stably develop sound insulation performance for sound with the various frequencies.

Owner:KOBE STEEL LTD

Damping sound-insulating spraying mortar

The invention discloses a damping sound-insulating spraying mortar. The damping sound-insulating spraying mortar is a bagged damping sound-insulating dry-blend spraying mortar prepared through mixing of an inorganic cementitious material, a filling material, an organic cementitious material and an additive under stirring; and the motor is stirred on site and uniformly sprayed on a base layer by using a spray coater. The motor comprises, by weight, 25 to 35 parts of cement, 5 to 15 parts of fly ash, 25 to 50 parts of fine and light aggregate, 10 to 40 parts of rubber powder, 0.6 to 5 parts of redispersible powder, 0.1 to 0.3 part of methylcellulose ether, 0.02 to 0.1 part of short fiber and 0.01 to 0.1 part of a water reducer. The damping sound-insulating spraying mortar can improve the sound reduction index of a wall and a ceiling when sprayed on the wall and the ceiling, and can replace a leveling layer of a floor and improve the impact sound reduction index of the floor when sprayed on the floor; and the damping sound-insulating spraying mortar can totally cover a variety of special-shape structures to form an effective sound-insulating layer and can be constructed in a variety of complex environments with narrow space.

Owner:XIAMEN JIADA GREEN CONSTRUCION ENG CO LTD

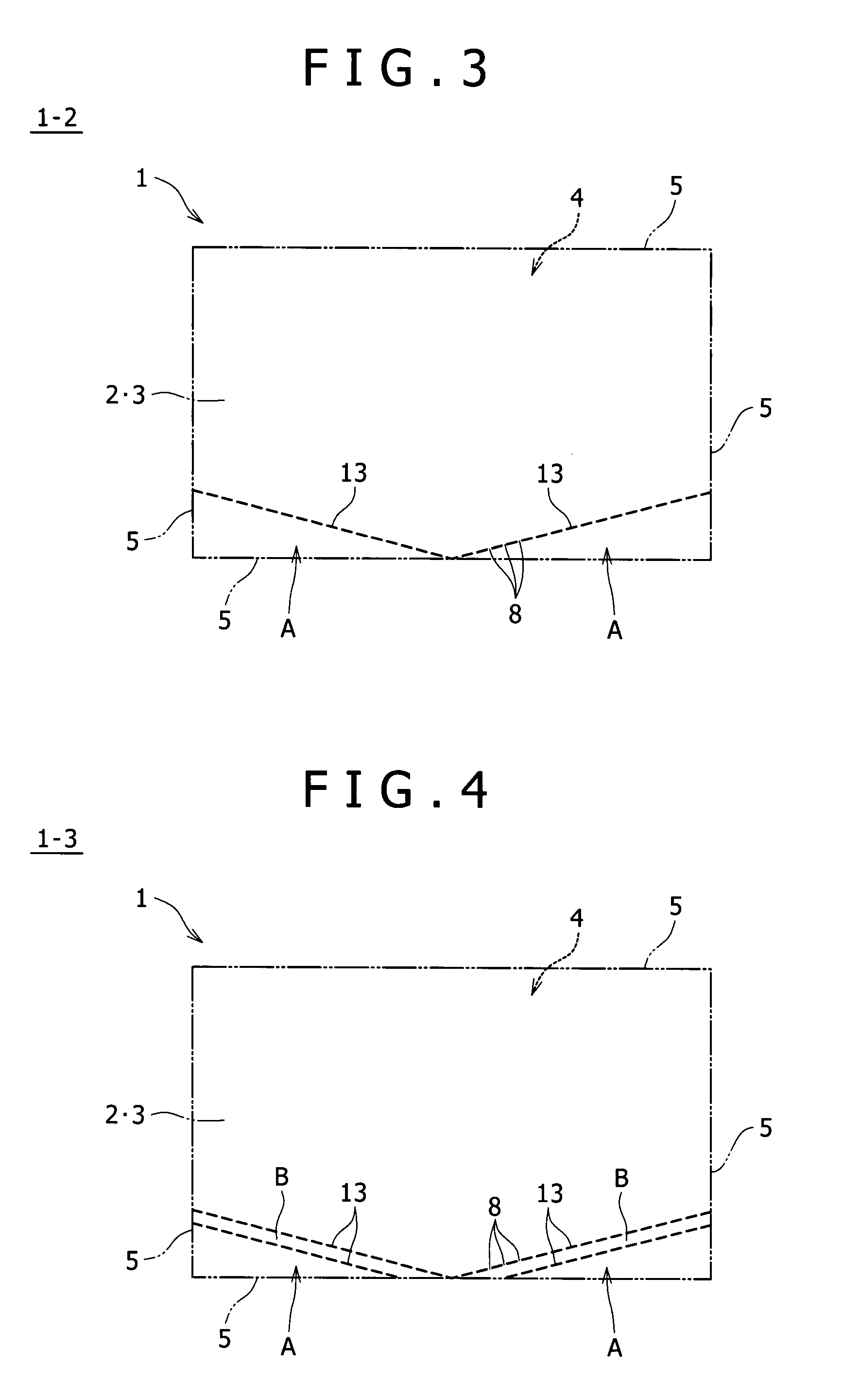

Sound insulation material, composite carpet using the material and preparation method thereof

ActiveCN104629218AHigh affinityEvenly distributedLayered product treatmentSynthetic resin layered productsInsulation layerSulfate

The invention belongs to the technical field of sound insulation polymer composite materials and preparation thereof, and particularly relates to a high sound insulation composite carpet and a preparation method thereof. The composite carpet is provided with a carpet layer, a composite sound insulation layer is arranged below the carpet layer, and the sound insulation layer is prepared from a sound insulation material containing the following components: 100 parts of PVC resin, 10-60 parts of a plasticizer, 1-6 parts of a stabilizer, 30-90 parts of sound insulation function body particles, 0-100 parts of a filler and 1.3-9 parts of additives. The sound insulation function body particles comprise two or more of carbonate, sulfate, hydroxide, oxide and metal powder. The carpet provided by the invention has all the functions of a universal carpet, but also has an outstanding high sound insulation property, and the sound reduction index is as high as 40 dB. The carpet is environment-friendly, non-toxic and pollution-free, and a thermoplastic matrix can be recycled. The production process of the product is simple, and the application is extensive.

Owner:浙江富华新材料科技有限公司

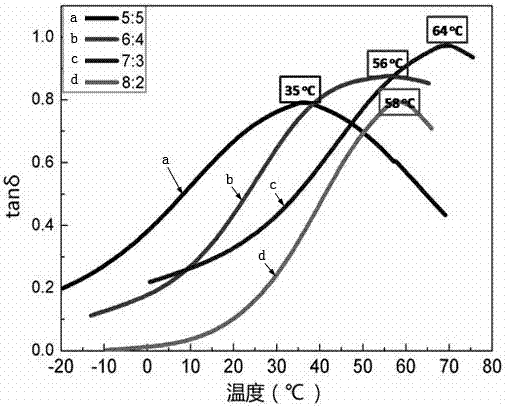

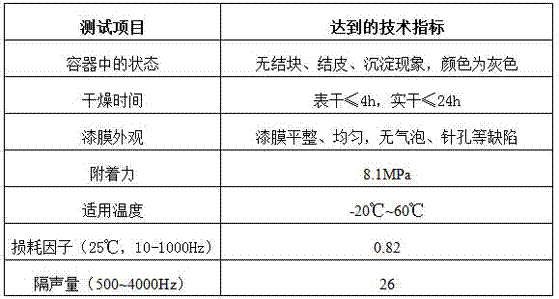

Damping coating with interpenetrating network (IPN) structure, and preparation method of damping coating

ActiveCN107974188AImprove toughnessImprove damping performancePolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyDamping factor

The invention relates to a damping coating with an interpenetrating network (IPN) structure, and a preparation method of the damping coating. The damping coating is prepared from the following raw materials by weight percent: 20-30% of polyurethane resin, 5-30% of epoxy resin, 10-35% of a curing agent, 5-25% of damping filler, 10-40% of sound insulation filler, 0.1-5% of pigment and 1-10% of additives. The IPN type damping coating provided by the invention has a maximum damping factor reaching up to 0.83 within a range of 10-1000Hz (25 DEG C), and has a minimum sound reduction index value of 26dB within a range of 500-4000Hz. The damping coating prepared by the preparation method according to the formula has the interpenetrating polymer network structure and the high damping factor, and can be used for replacing the existing constrained damping structure type damping coating system in China.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

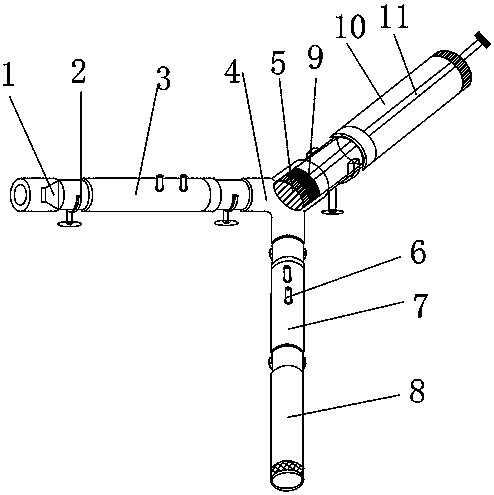

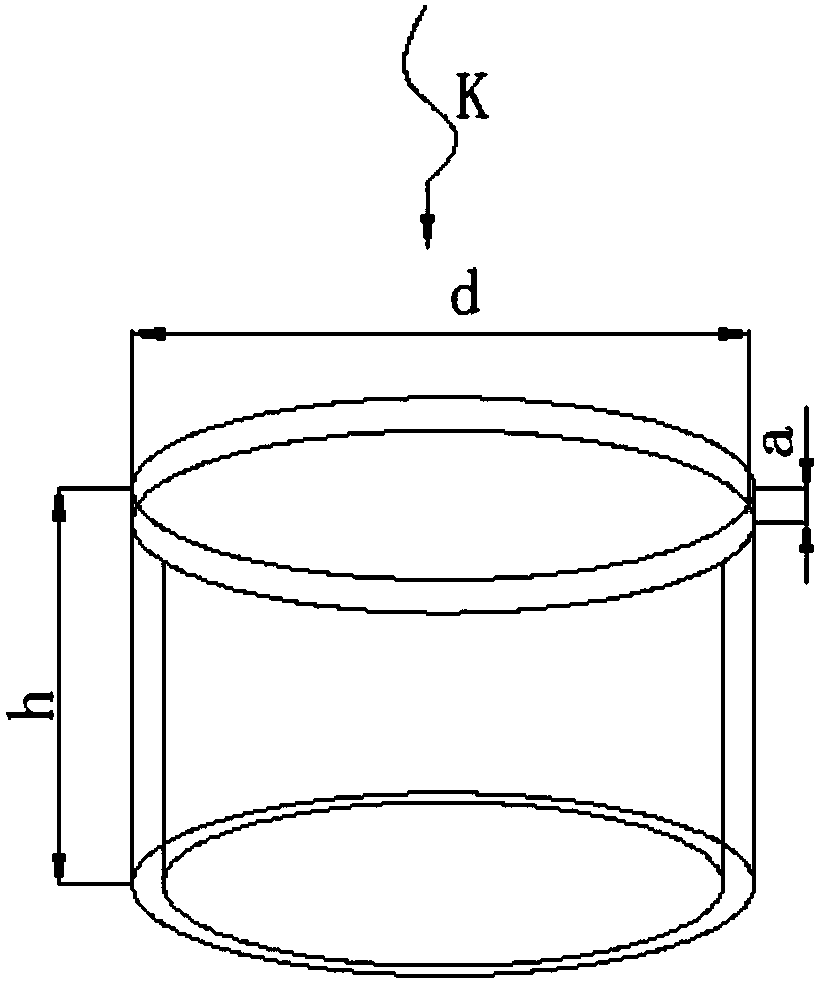

Measuring device and measuring method for acoustic absorption coefficient and sound reduction index of sound wave oblique incidence material

ActiveCN107907595AEasy to measureFew samplesAnalysing solids using sonic/ultrasonic/infrasonic wavesSustainable transportationAcoustic absorptionMeasurement device

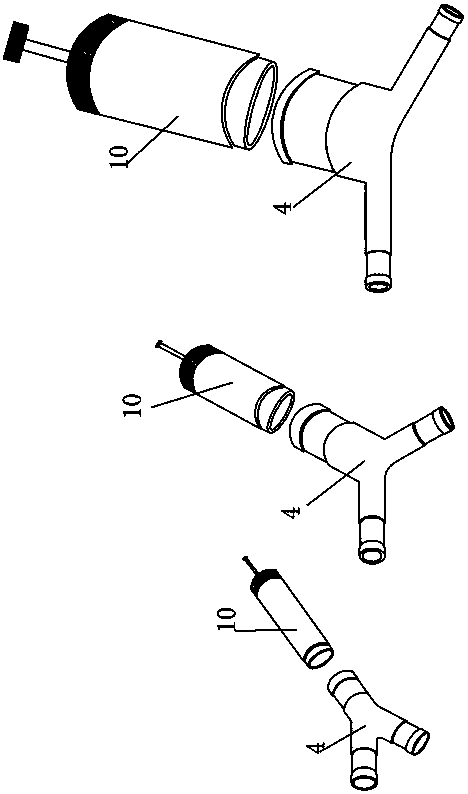

The invention relates to a measuring device and a measuring method for an acoustic absorption coefficient and a sound reduction index of a sound wave oblique incidence material and belongs to the field of acoustical measurement. A loudspeaker is connected with a sound transmission tube; the other end of the sound transmission tube is connected with a first opening of a three-way pipe fitting; a sound absorption tail end pipe A is arranged at one end of a reflection tube; the other end of the reflection tube is connected with a second opening of the three-way pipe fitting; mounting holes are formed in the sound transmission tube and the reflection tube; sound conducting apparatuses are arranged in the mounting tubes; the three-way pipe fitting is a different-diameter three-way pipe fittingor an equal-diameter three-way pipe fitting; a third opening of the different-diameter three-way pipe fitting is connected with a specimen tube; a third opening of the equal-diameter three-way pipe fitting is connected with one end of a refraction tube. The measuring device and the measuring method disclosed by the invention have the advantage that the acoustic absorption coefficient and the soundreduction index of a material with the frequency from 100 to 1600Hz can be realized; in addition, a sample required by the device is small, the equipment is simple and the operation can be realized in an ordinary laboratory.

Owner:JILIN UNIV

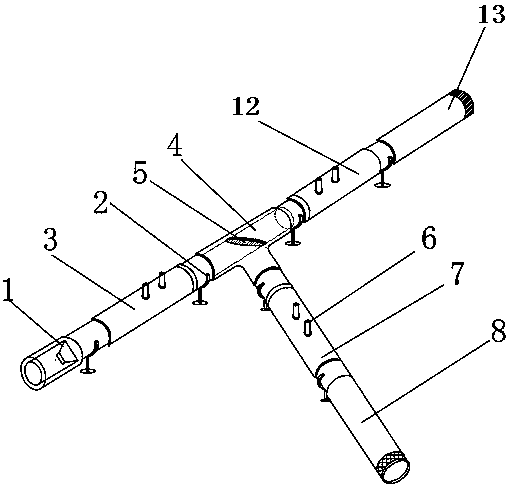

Device and method for measuring sound reduction index of acoustic material by adopting pulse method

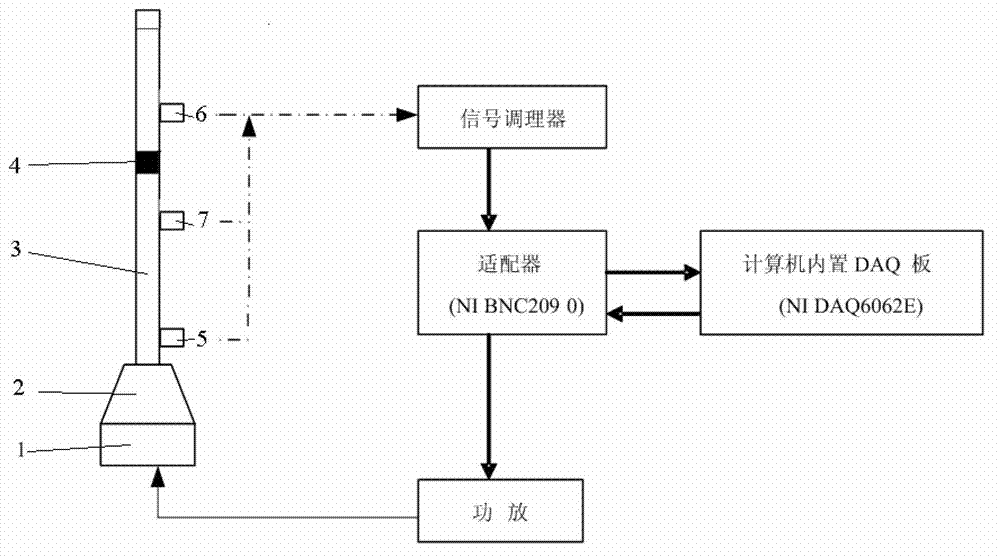

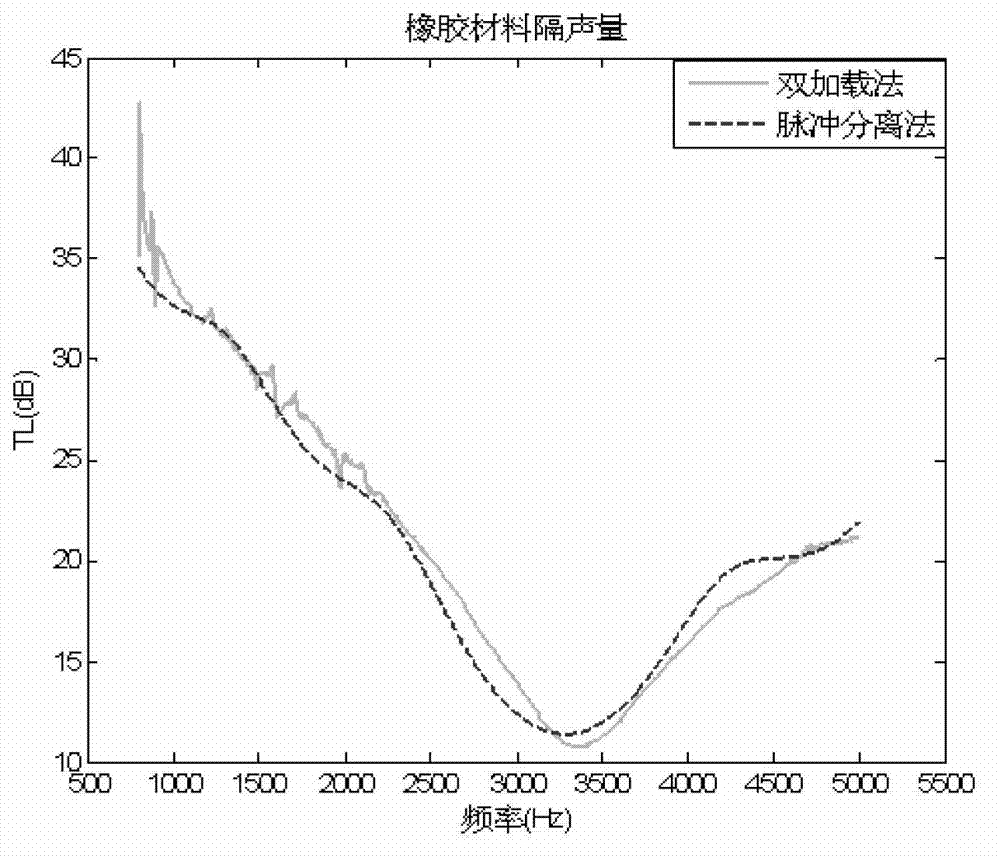

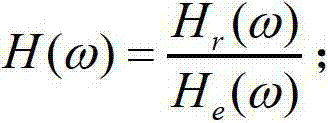

ActiveCN103115966AAvoid influenceEfficient measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesConical tube

The invention provides a device and method for measuring a sound reduction index of an acoustic material by adopting a pulse method. The device comprises a sound tube, a pulse sound source, microphones, a power amplifier, a signal conditioner, an adapter and a data collecting device, wherein the sound tube is formed by sequentially, coaxially and fixedly connecting one section of big-diameter cylinder tube, a conical tube and a small-diameter cylinder tube, three through holes which are vertical to the center axial line of the small-diameter cylinder tube and are used for arranging the microphones are formed in the side wall of the small-diameter cylinder tube, the pulse sound source is arranged in the big-diameter cylinder tube, and a rear cover is connected with the external end of the small-diameter cylinder tube in a threaded manner. The method comprises the steps of: firstly obtaining a frequency response function of the whole measuring system, then obtaining a drive signal frequency spectrum of the required pulse sound source, and finally measuring and driving the pulse sound source by the drive signals of the required pulse sound source to obtain the sound reduction index of a sample to be measured. Compared with a double-loading method and a double-sound source method, the device and method provided by the invention overcome the influence of acoustic impedance of the tail end of the sound tube to a test result.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

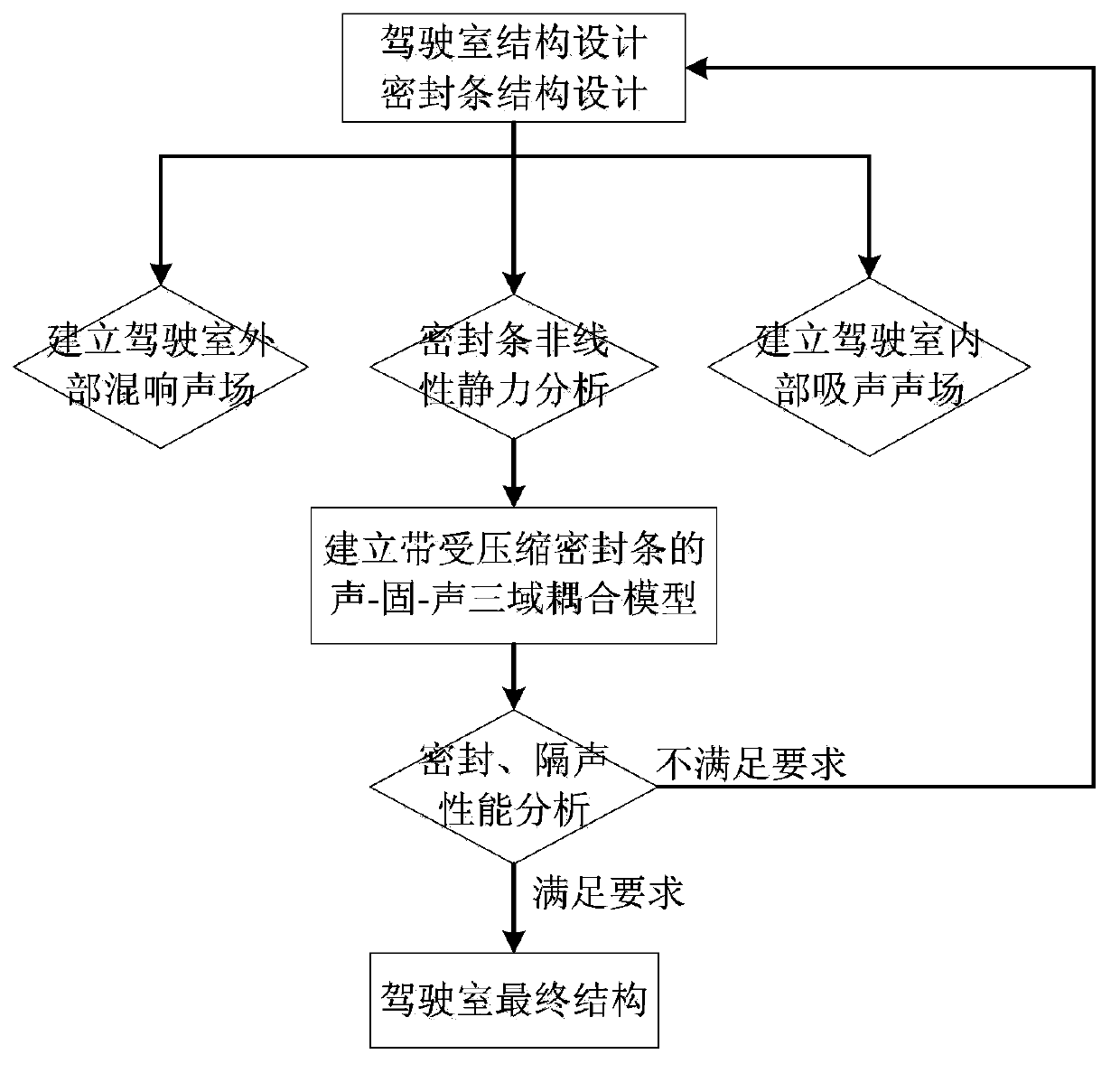

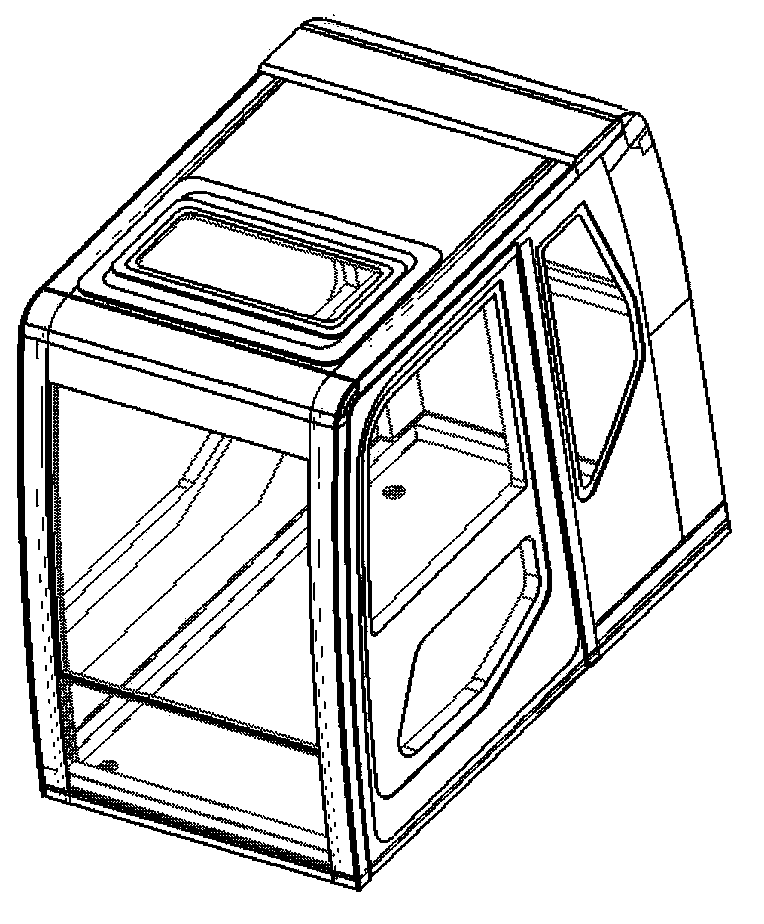

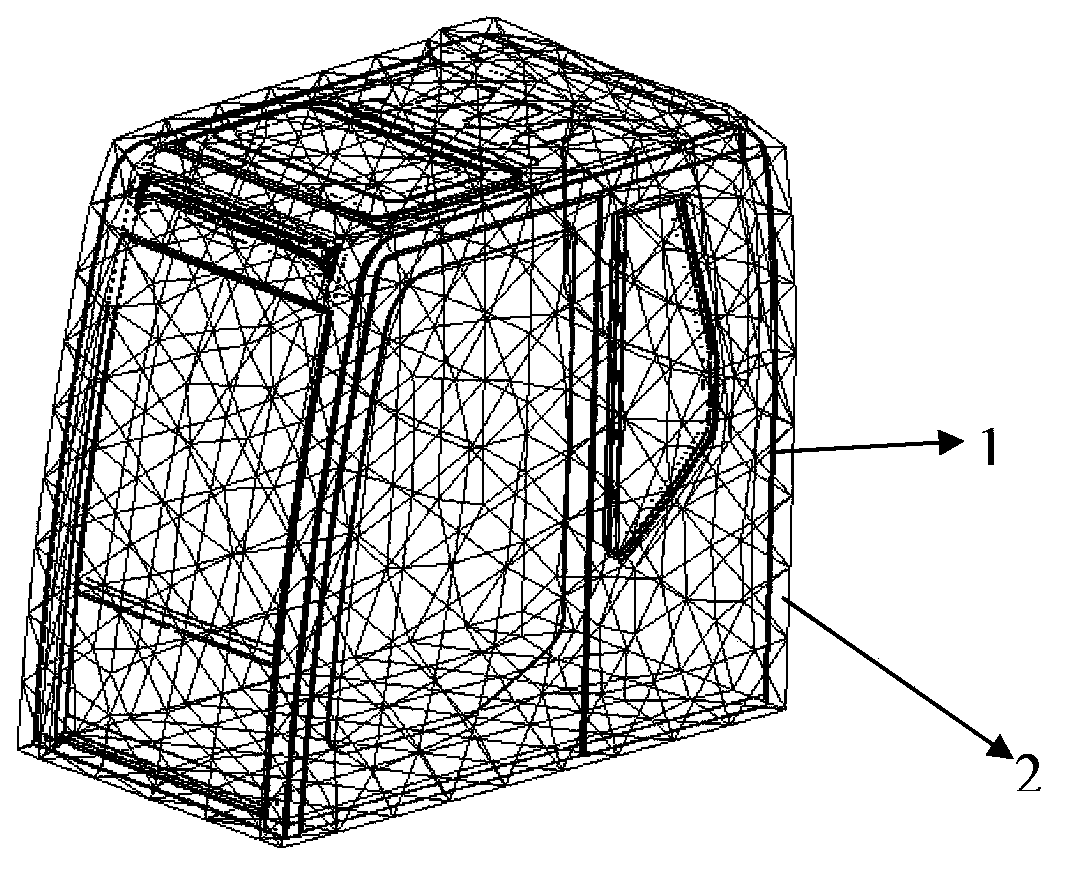

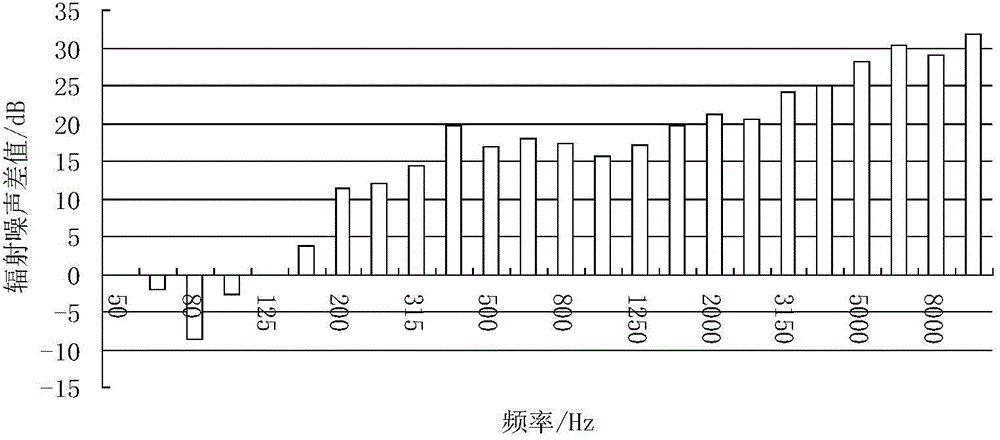

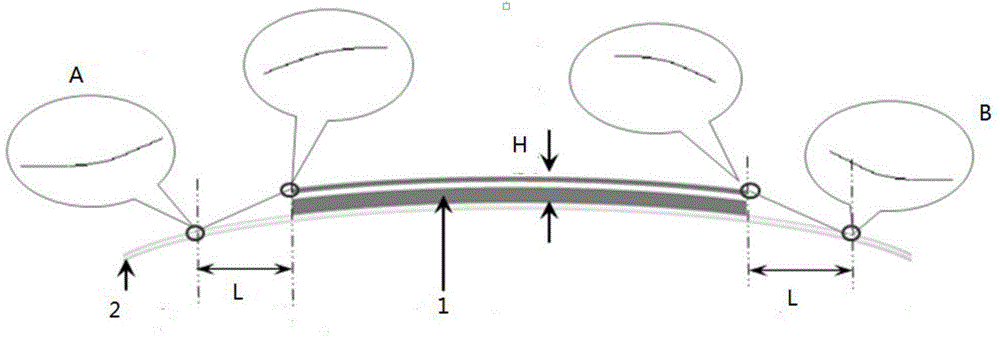

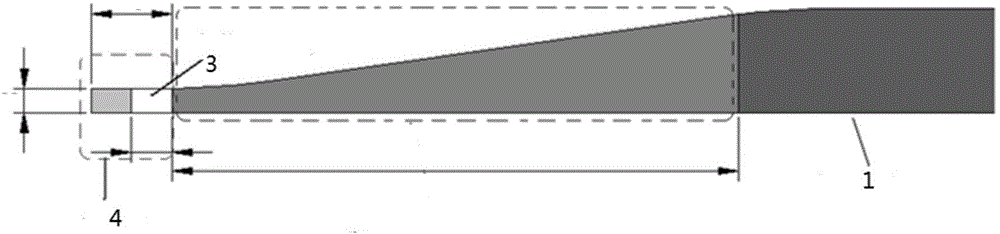

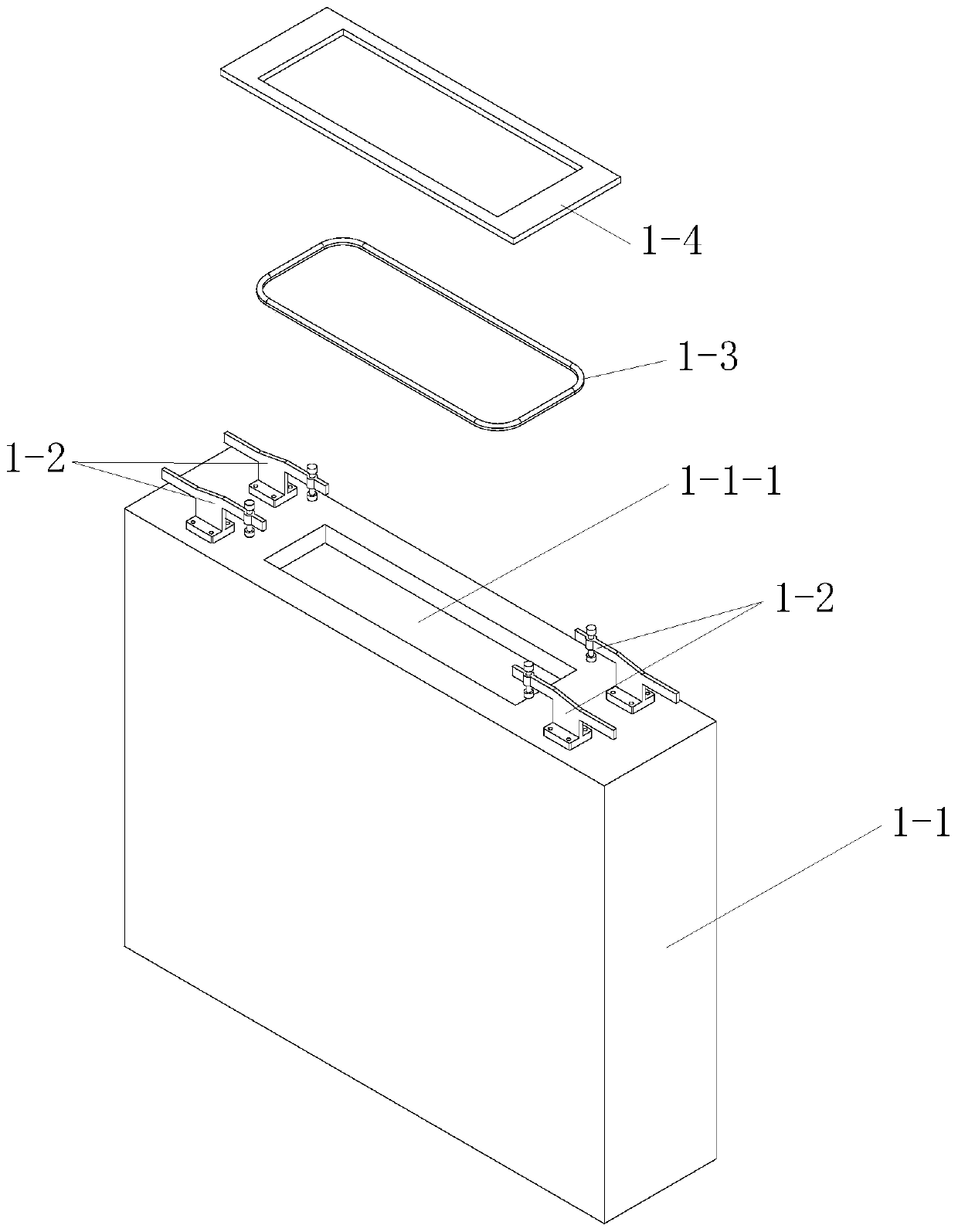

Cab design method based on cab sound reduction index analysis

ActiveCN103970916ACalculation of sound insulationImprove sealingSpecial data processing applicationsComputer Aided DesignElement model

The invention relates to a cab design method based on a cab sound reduction index analysis. The cab design method comprises the following steps: (1) establishing a CAD (Computer-Aided Design) model of a cab assembly, carrying out mesh generation on the CAD model, and establishing a finite element model of the cab assembly; (2) based on the finite element model of the cab assembly, establishing a cab internal sound field and a cab external sound field; (3) according to the shape of a sealing strip in a current design drawing, establishing a finite element model of the sealing strip structure, and carrying out nonlinear static compression on the sealing strip according to a set amount of compression; (4) establishing a sound-solid-sound three-domain coupling model; (5) computing the sound reduction index of the cab; (6) judging whether the sound reduction index of the current cab meets the design requirement, if yes, taking the current design drawing as the final structure output of the cab, and otherwise modifying the shape and the amount of compression of the sealing strip in the design drawing, and returning to the step (3). Compared to the prior art, the cab design method disclosed by the invention has the advantages of reducing the internal noise of the cab, increasing the sound reduction index of the cab, improving the sealing performance, and the like.

Owner:TONGJI UNIV +1

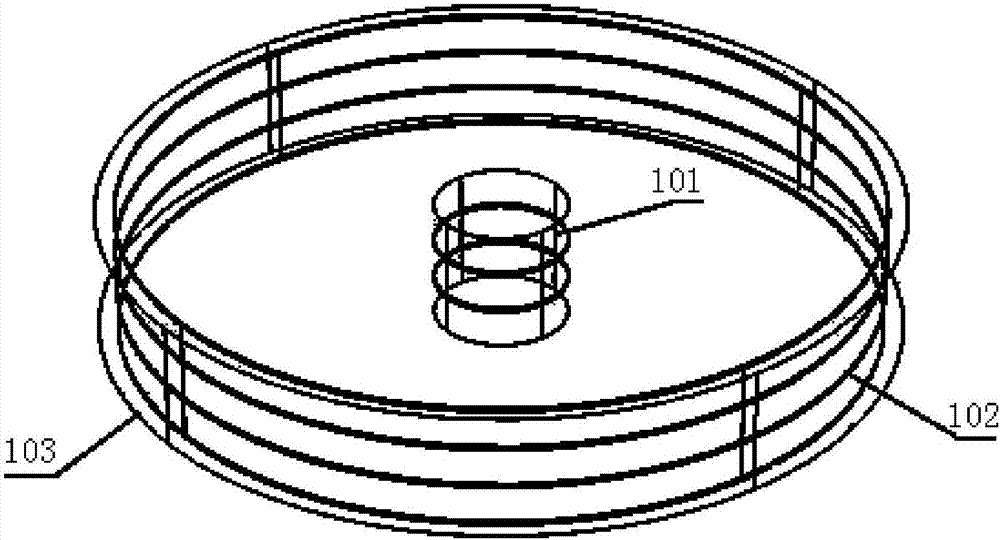

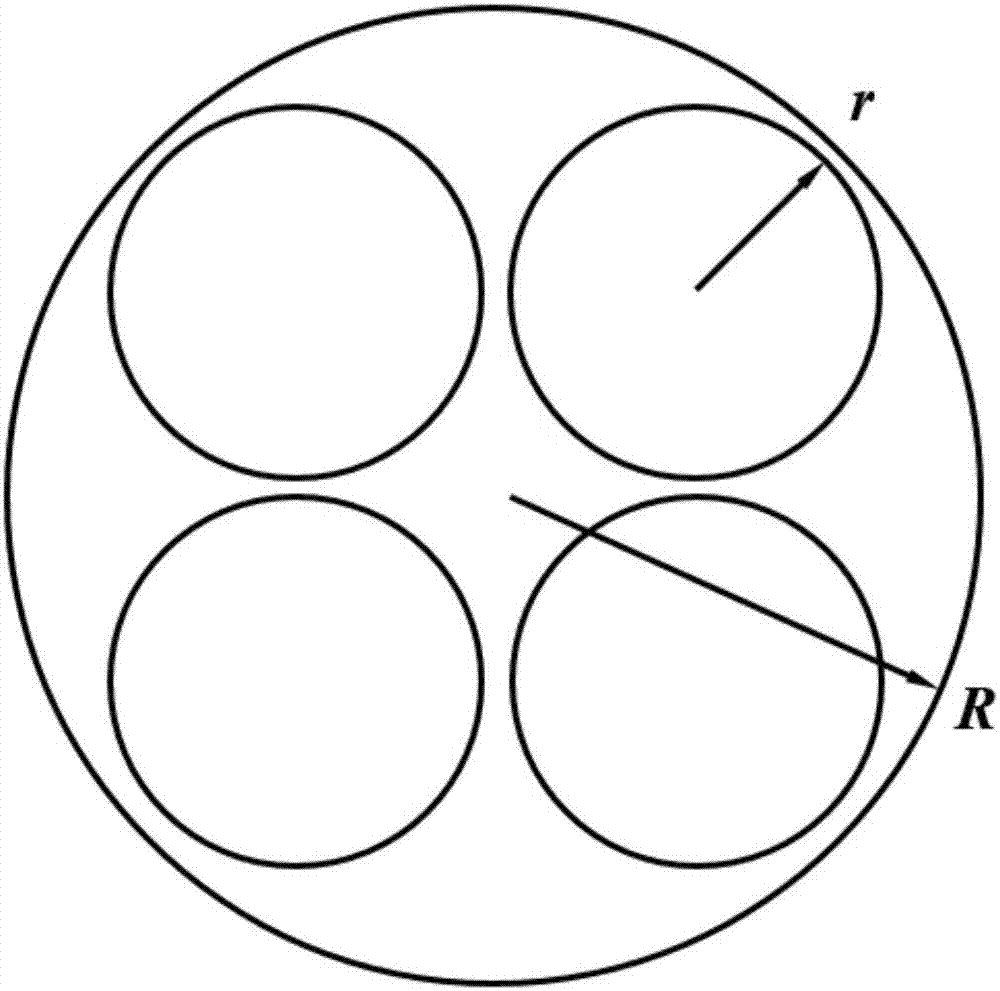

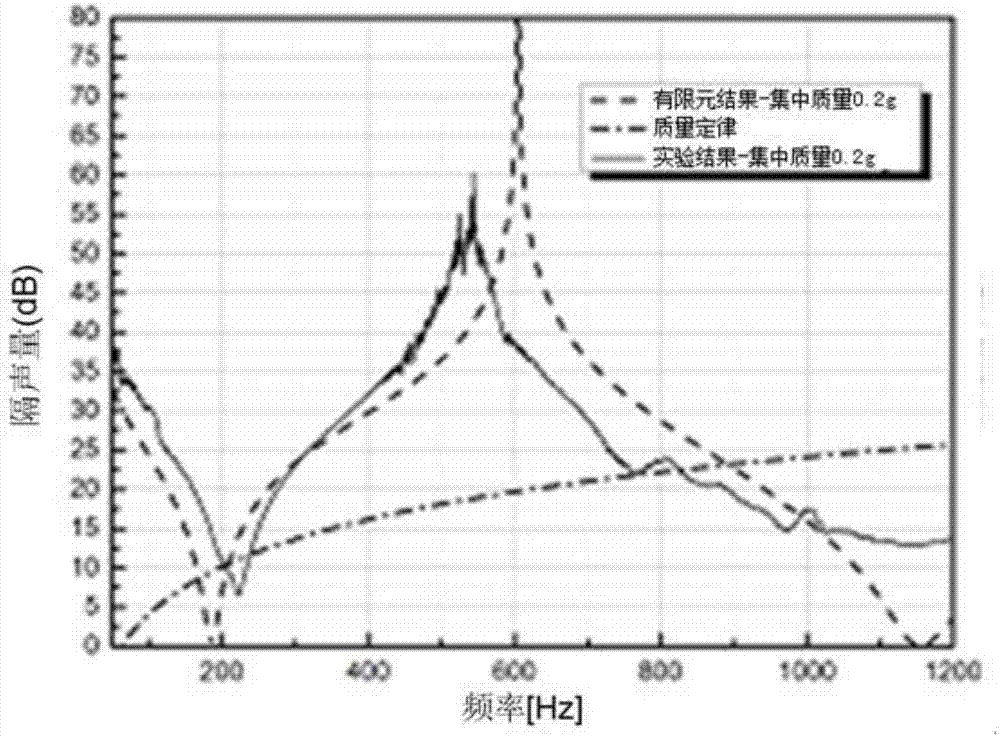

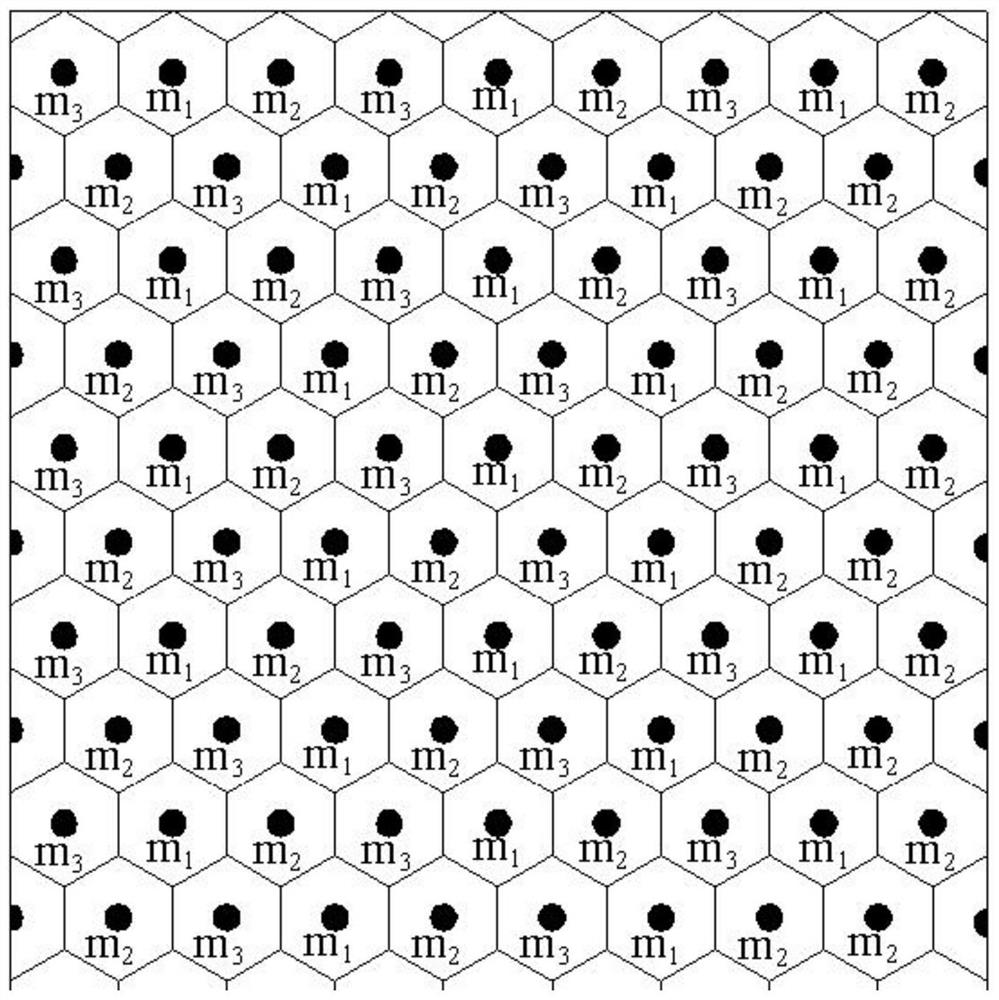

Film and sheet type acoustic metamaterial sound arrester

ActiveCN107170437ABreak controlImprove sound insulationSound producing devicesAcousticsAcoustic metamaterials

The invention discloses a film and sheet type acoustic metamaterial sound arrester. The film and sheet type acoustic metamaterial sound arrester is formed through lamination of cellular structures with different thicknesses and radii. Each cellular structure comprises a concentrated mass block, a film and a framework, wherein the periphery of the film is fixed to the framework, the concentrated mass block tightly adheres to the film, and the film only needs to be flattened and does not need to be tensioned. The cellular structures are closely and periodically distributed to form the slabby sound arrester. The film and sheet type acoustic metamaterial sound arrester is good in sound insulation effect, large in bandwidth and high in sound reduction index, and control of the mass law over the sound reduction index is effectively broken. Furthermore, the structure is highly adjustable, and a sound arrester with the sound reduction index higher than the mass law below 2000 Hz can be obtained through lamination of different structures.

Owner:XI AN JIAOTONG UNIV

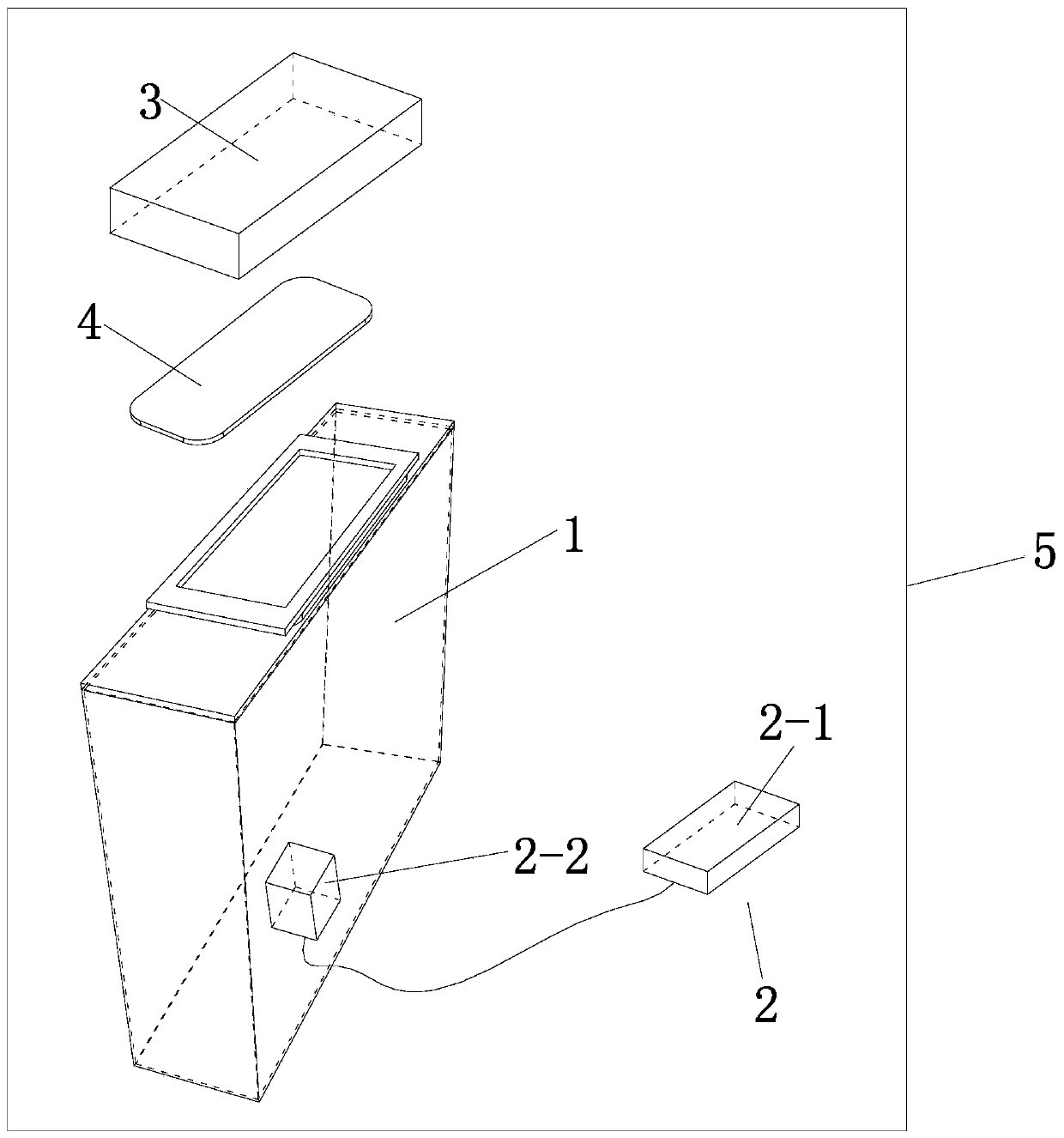

Full-band noise-reducing shield and shielding device for substation

InactiveCN106192785AControlling Noise Propagation PathsReduces noise across the entire frequency bandNoise reduction constructionNoise controlTransformer

The invention relates to the field of noise control, in particular to a full-band noise-reducing shield and a shielding device for a substation. The full-band noise-reducing shield comprises a low-frequency noise-reducing metamaterial layer and a high-frequency noise-reducing layer, wherein the low-frequency noise-reducing metamaterial layer is arranged at the front end of a full-band noise-reducing shield body; the high-frequency noise-reducing layer is arranged at the back end of the low-frequency noise-reducing metamaterial layer; the low-frequency noise-reducing metamaterial layer comprises a plurality of periodically-arranged lattices; a silicone rubber elastic film is arranged in each lattice; a mass block is stuck to the sound incidence side of each silicone rubber elastic film. The full-band noise-reducing shield can be arranged near a transformer to effectively reduce full-band noises from the noise transmission path of the transformer; compared with the conventional sound shield, the full-band noise-reducing shield has the advantages of large sound reduction index, small thickness, light weight and the like, and can effectively make up the deficiency that the conventional sound shield is unlikely to block low-frequency noises below 500Hz.

Owner:STATE GRID CORP OF CHINA +2

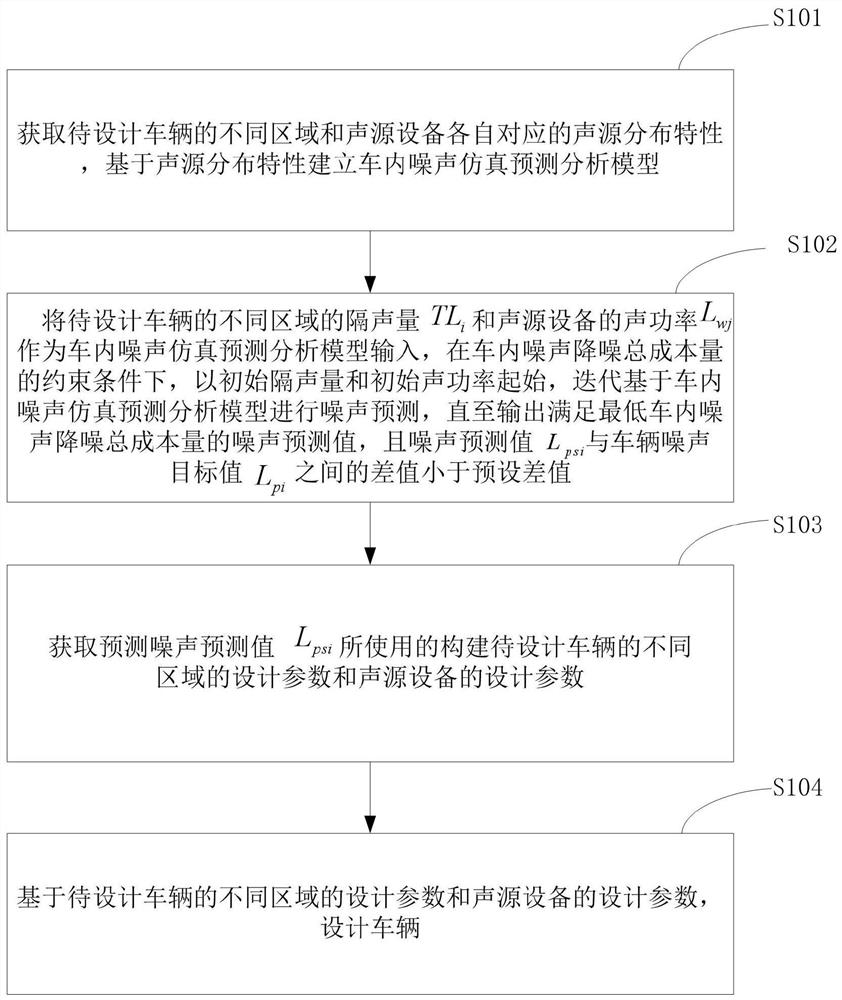

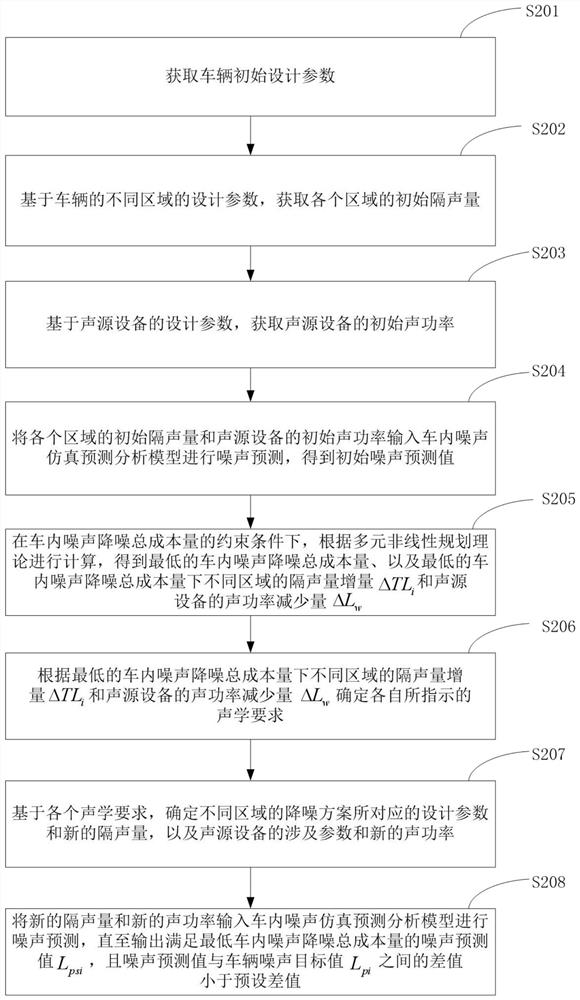

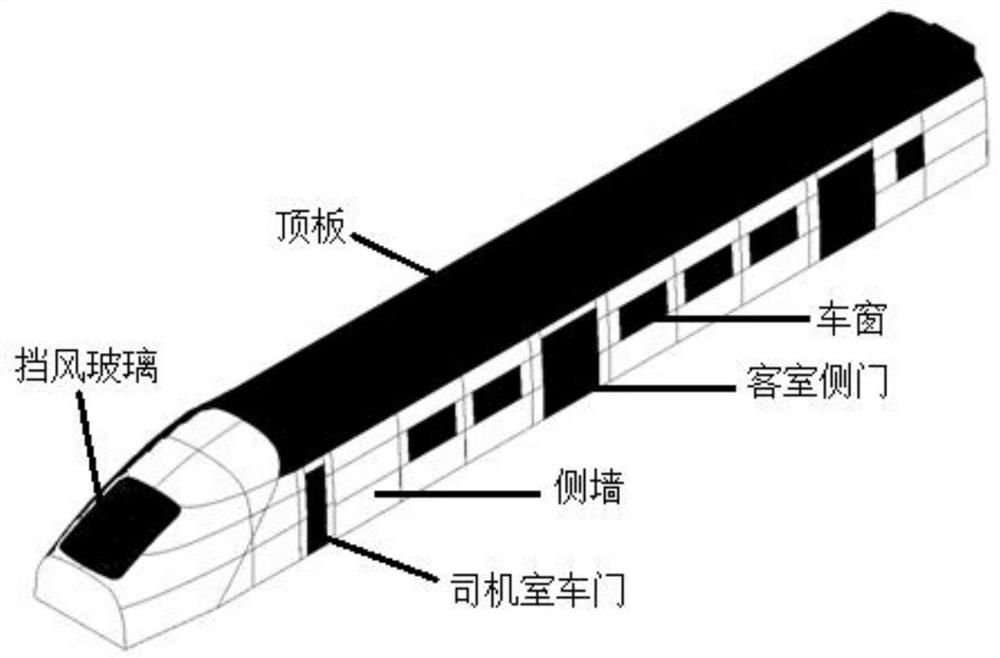

In-vehicle low-noise optimization design method and system

The invention discloses an in-vehicle low-noise optimization design method and system, and the method comprises the steps of inputting the sound reduction indexes TLi of different regions of a to-be-designed vehicle and the sound power Lwj of sound source equipment into an in-vehicle noise simulation prediction analysis model, and carrying out the in-vehicle noise simulation prediction analysis ofthe to-be-designed vehicle through employing an initial sound reduction index and initial sound power under a preset constraint condition; and iteratively carrying out noise prediction based on the in-vehicle noise simulation prediction analysis model until a noise prediction value Lpsi meeting the minimum in-vehicle noise reduction total cost amount is output, and obtaining design parameters used for constructing different areas of the to-be-designed vehicle and sound source equipment used for predicting the noise prediction value Lpsi to design the vehicle; performing noise prediction through iteration based on an in-vehicle noise simulation prediction analysis model. It is ensured that an unbiased noise prediction value Lpsi is obtained at the lowest in-vehicle noise reduction total cost, and the in-vehicle noise optimization design method is short in period, low in cost and free of deviation. In addition, based on the method, vehicle design does not need to be conducted through subjective experience of personnel, and therefore subjectivity does not exist.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

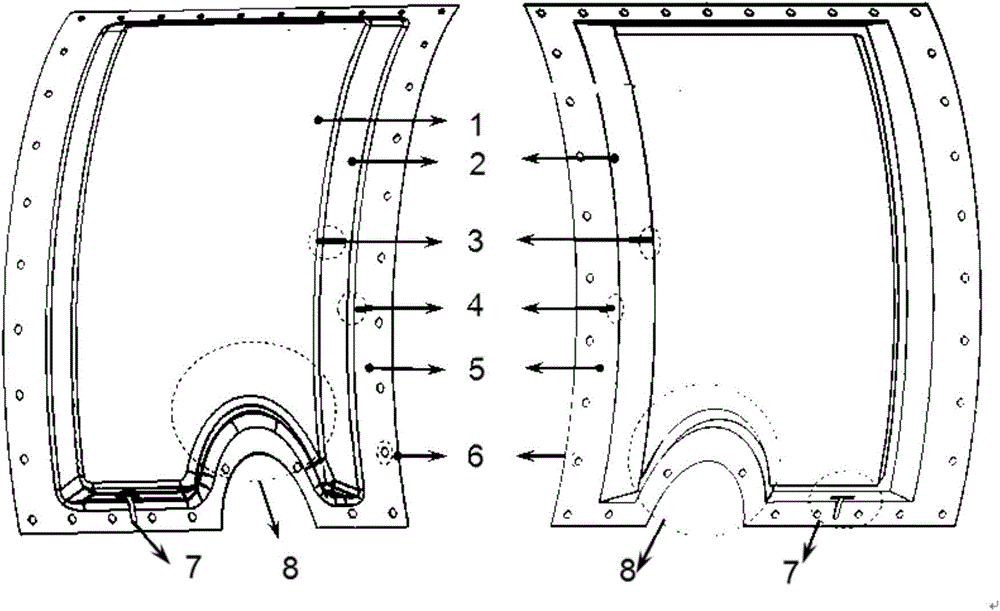

Acoustic anti-icing panel structure for controlling noise in cabin of turbo-propeller plane

ActiveCN104443349AAvoid damagePromote absorptionFuselage bulkheadsFuselage insulationNoise controlEngineering

The invention provides an acoustic anti-icing panel structure for controlling noise in a cabin of a turbo-propeller plane. The acoustic anti-icing panel structure comprises an anti-icing panel and an acoustic material inner core attached onto the anti-icing panel, wherein the periphery of the anti-icing panel is in arc connection with a pneumatic sealing edge; the other side of the pneumatic sealing edge is in the arc connection with a body installation edge; and an arc-shaped opening matched with a raised plane body structure is also formed in the bottom of the anti-icing panel. The acoustic anti-icing panel structure has the characteristics of low pneumatic sound and high sound reduction index, and the sound insulation performance of the wall panel structure can be effectively improved, so that the influence of the propeller noise on a sound field in the cabin of the plane is reduced, and the cabin comfort level of the turbo-propeller plane is improved.

Owner:CHINA AIRPLANT STRENGTH RES INST

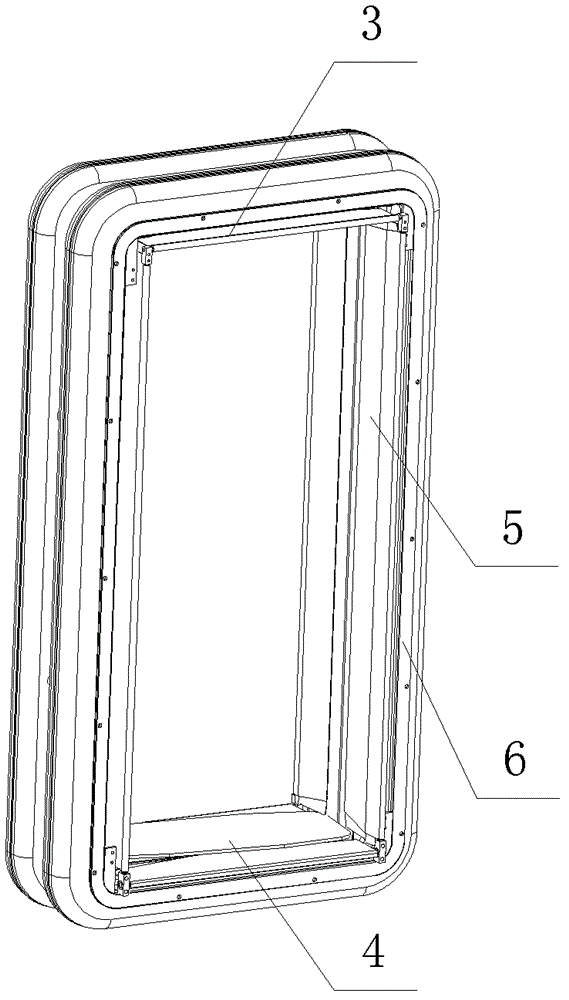

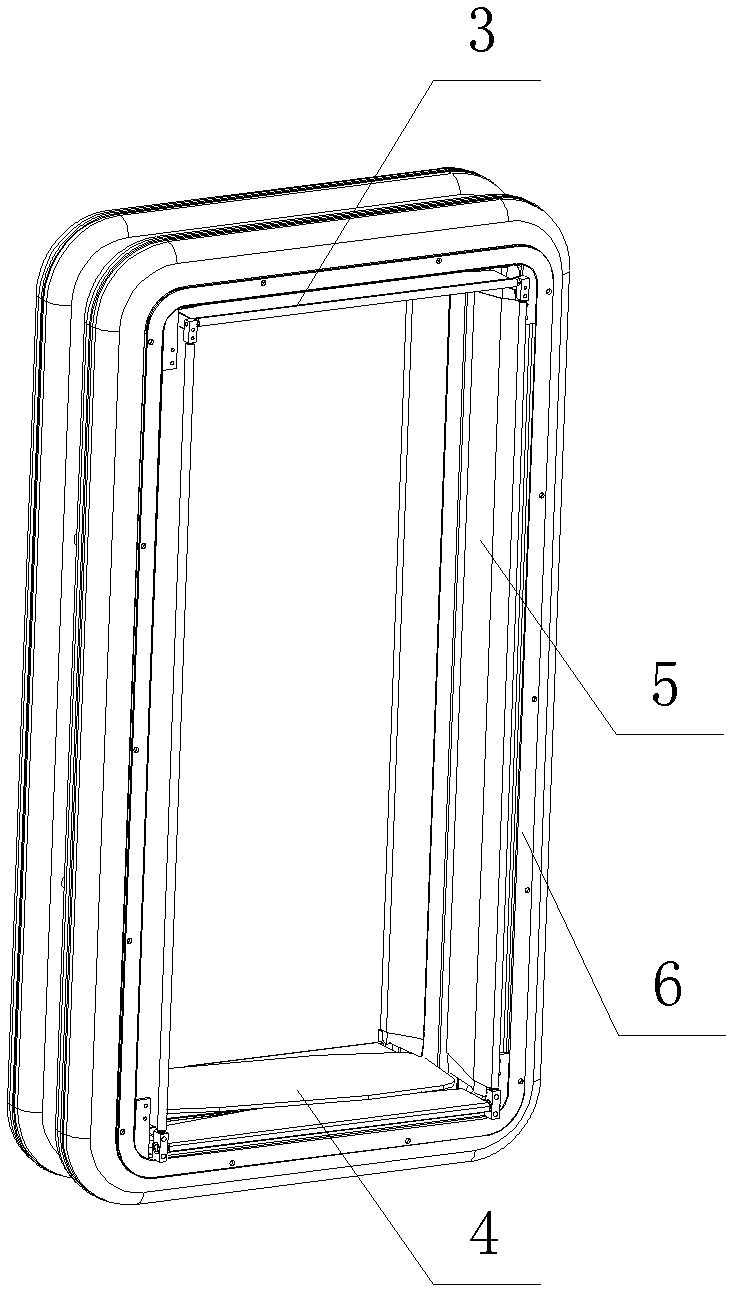

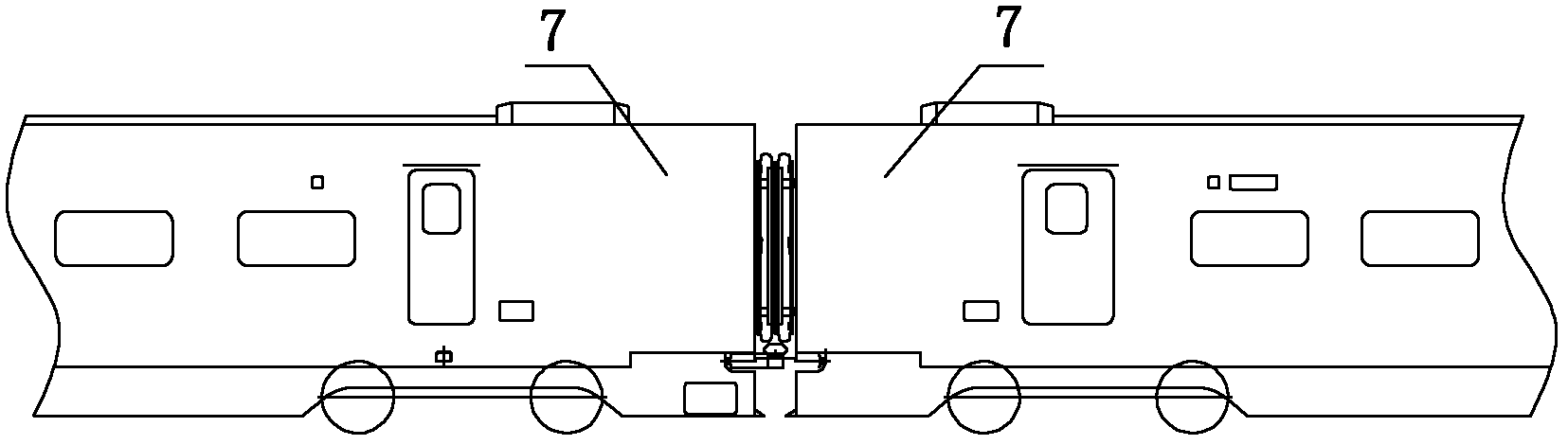

Windshield at car end of rail vehicle and its installation and use method

ActiveCN103129571BImprove sound insulationSimple preparation processAxle-box lubricationRailway bodiesNoise controlEngineering

Owner:CRRC QINGDAO SIFANG CO LTD

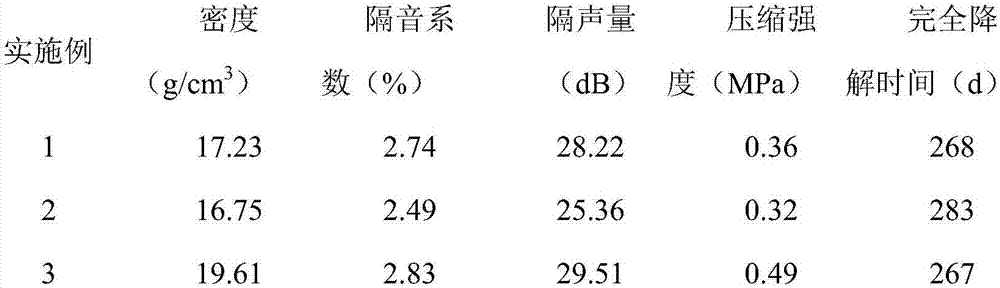

Sound-proof material, preparation method and application of sound-proof material

InactiveCN106893179AImprove sound insulationAdditive manufacturing apparatusCross-linkPolymer science

The invention discloses a sound-proof material, a preparation method and an application of the sound-proof material. The sound-proof material is prepared from the following raw materials: graphene, polyethene, chloroprene rubber, polyoxypropylene triol, caprylic / capric triglyceride, a methacrylate polymer, brominated paraffin, a quartz glass fiber, maleic anhydride, an ethylene-ethyl acrylate copolymer, acetic acid ethenyl ester copolymer emulsion, trisopropanolamine, an adhesive, a dispersing agent, a tackifier, a cross-linking agent, a catalyst, a plasticizer, a flexibilizer, a foaming agent, a foaming regulator, a foam stabilizer, a curing agent, a degradation agent and a stabilizer. The sound-proof material is prepared by the steps of mixing, extruding and the like. The sound-proof material is applied to 3D (three dimensional) printing. The material is degradable, can be degraded completely after 267-283 days, and a sound reduction index is 25.36-29.51 dB which shows that the material has a good sound-proof effect.

Owner:广西丰达三维科技有限公司

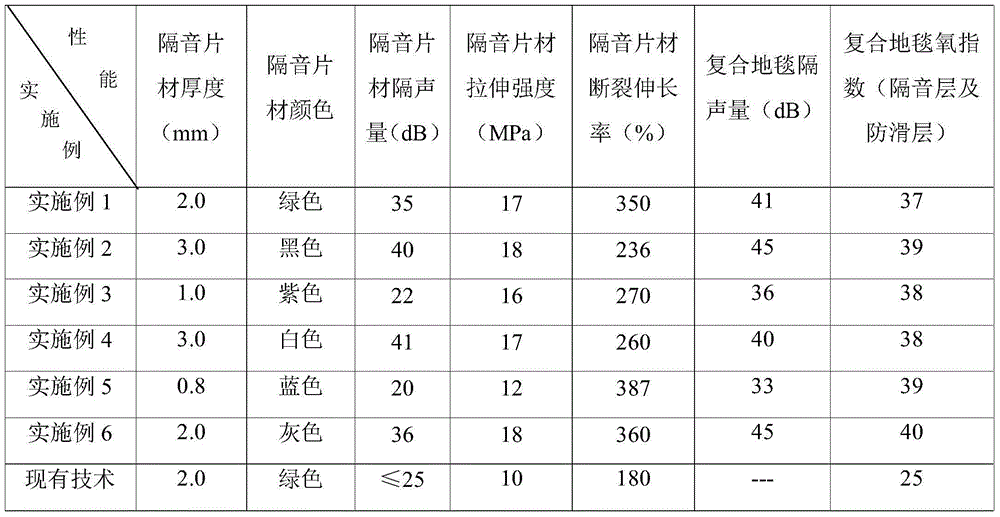

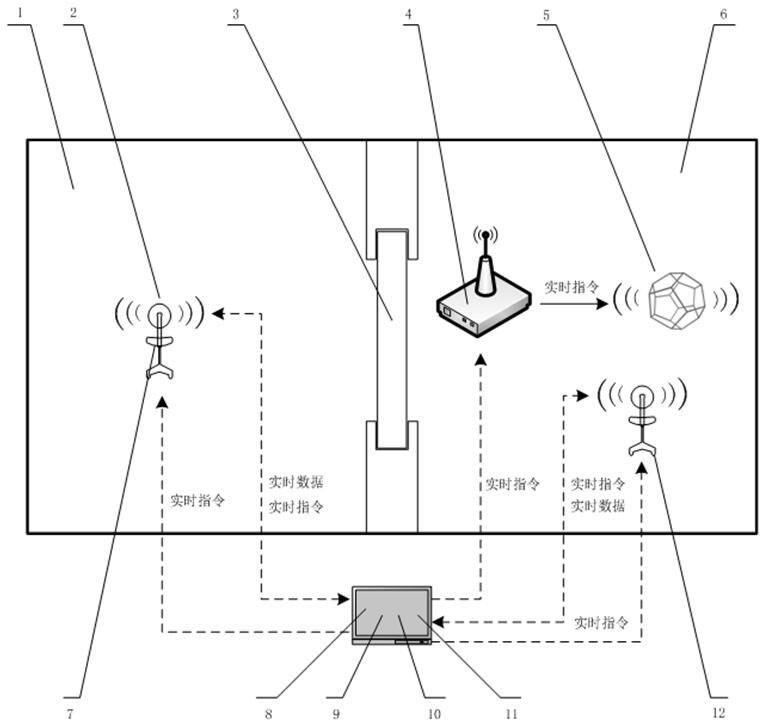

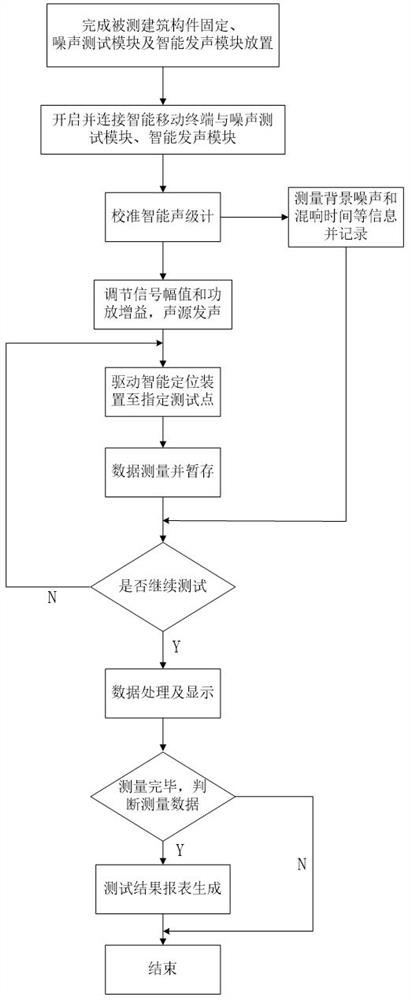

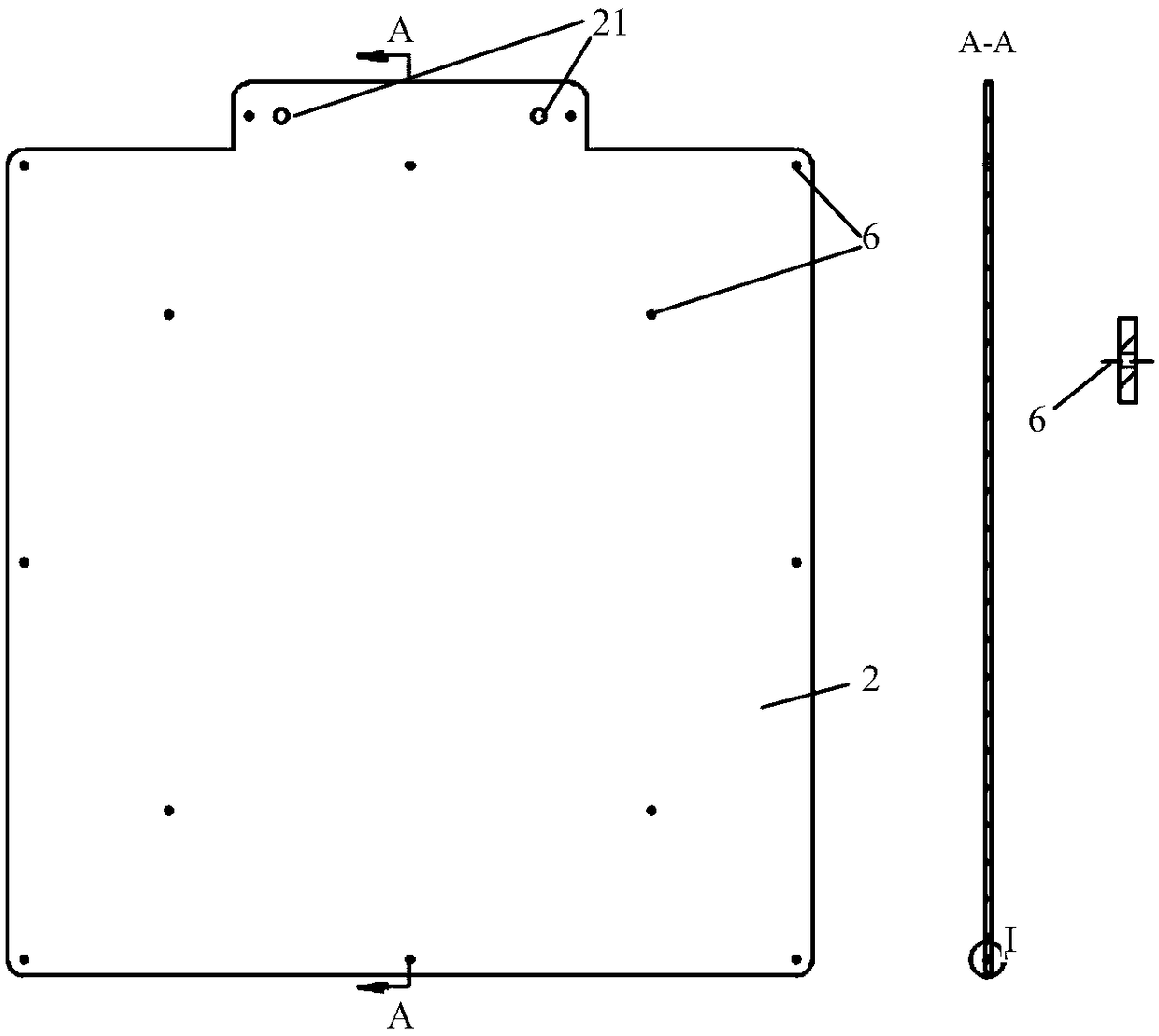

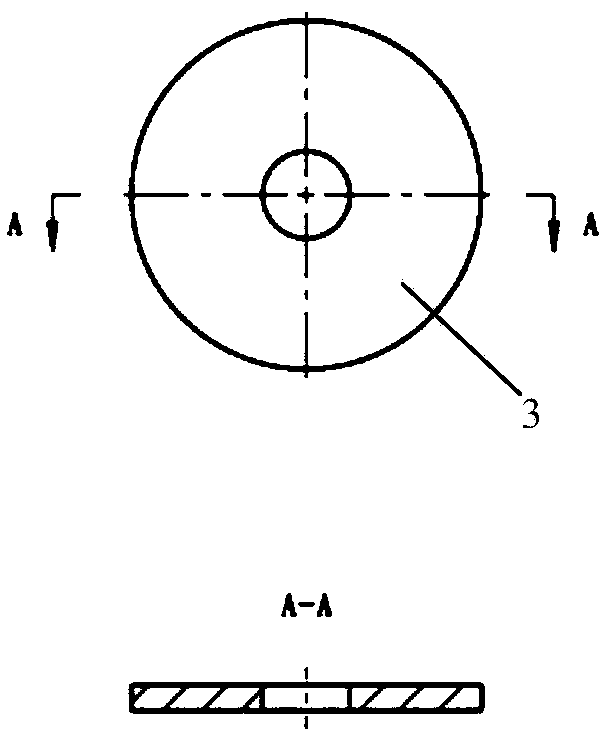

Intelligent laboratory measurement system for building component sound reduction index

PendingCN112684008ARealize intelligent measurementReduce human influenceAnalysing solids using sonic/ultrasonic/infrasonic wavesReverberation timeData displaySound sources

The invention relates to an intelligent laboratory measurement system for building component sound reduction index. The system mainly comprises an intelligent sound production module, a noise test module, an intelligent mobile terminal, a receiving chamber and a sound source chamber. The intelligent sound production module comprises an intelligent signal generator, a power amplifier all-in-one machine and a regular dodecahedron sound source. The noise test module comprises a support, an intelligent positioning device and an intelligent sound level meter. The intelligent mobile terminal comprises an intelligent positioning device control module, a sound source control module, a sound reduction index analysis module and a data display module. The noise test modules in the receiving chamber and the sound source chamber transmit data to the intelligent mobile terminal in a wireless manner, and the sound reduction index analysis module analyzes and processes the data to obtain the sound reduction index of each frequency band constructed by the tested building. According to the invention, a remote building component sound reduction index testing method can be realized, the human influence in the noise measurement process is reduced, and the obtained test data is more accurate, more credible and more authoritative.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

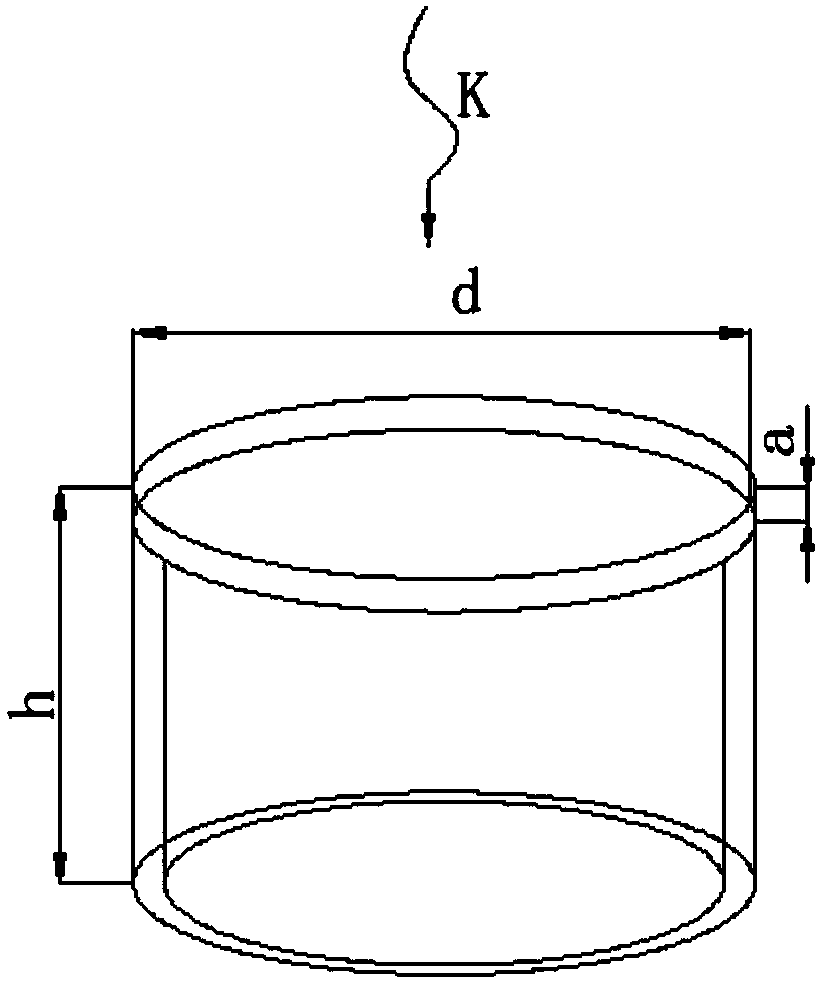

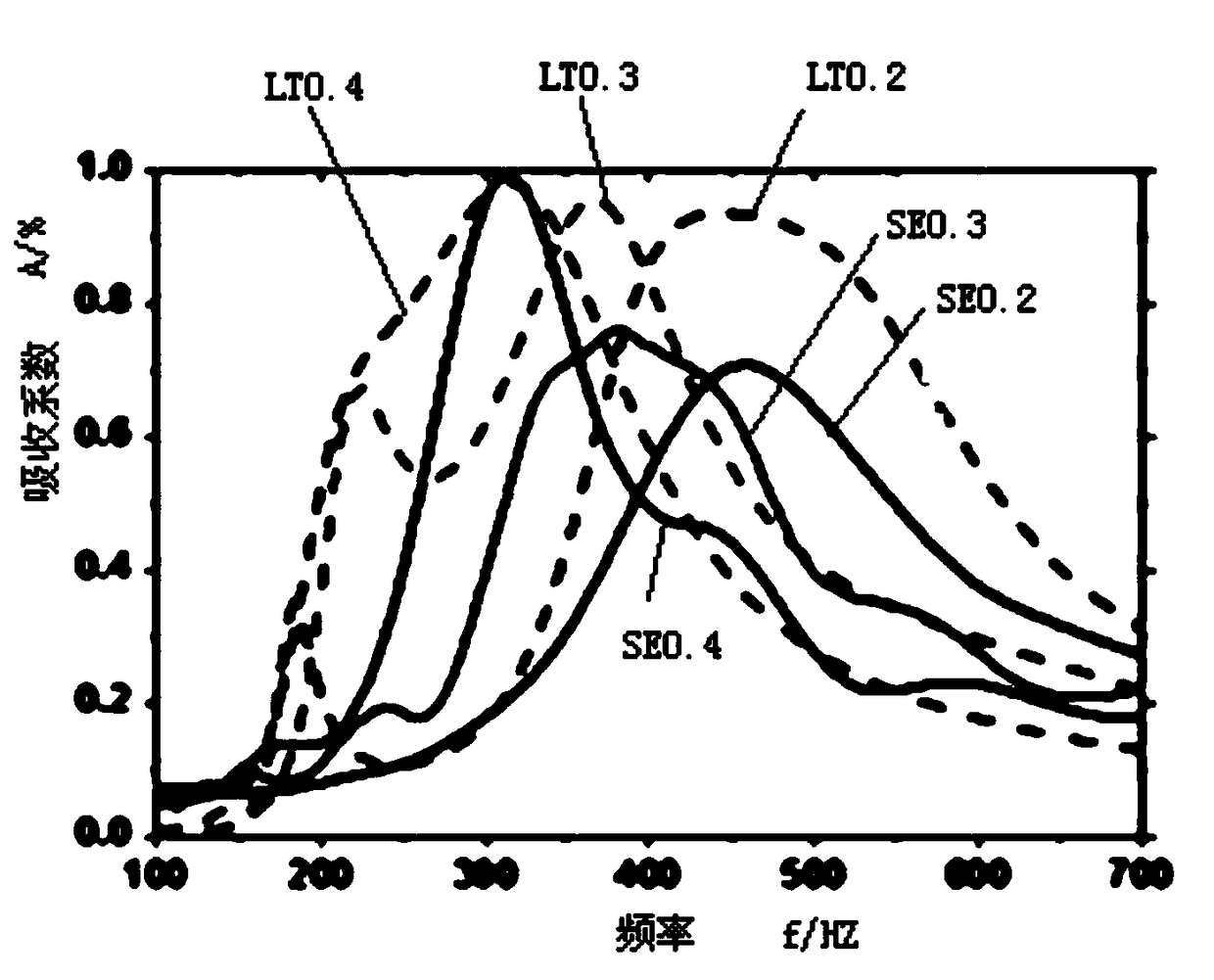

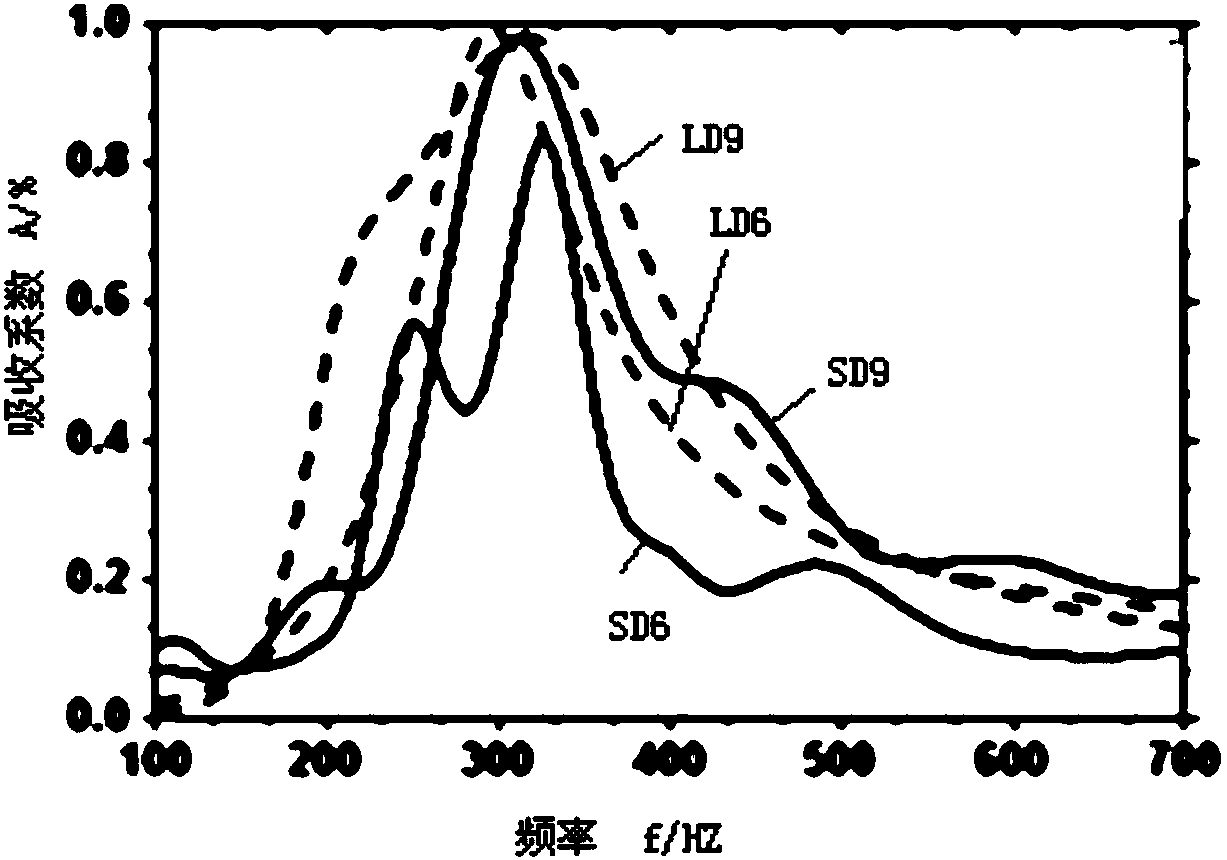

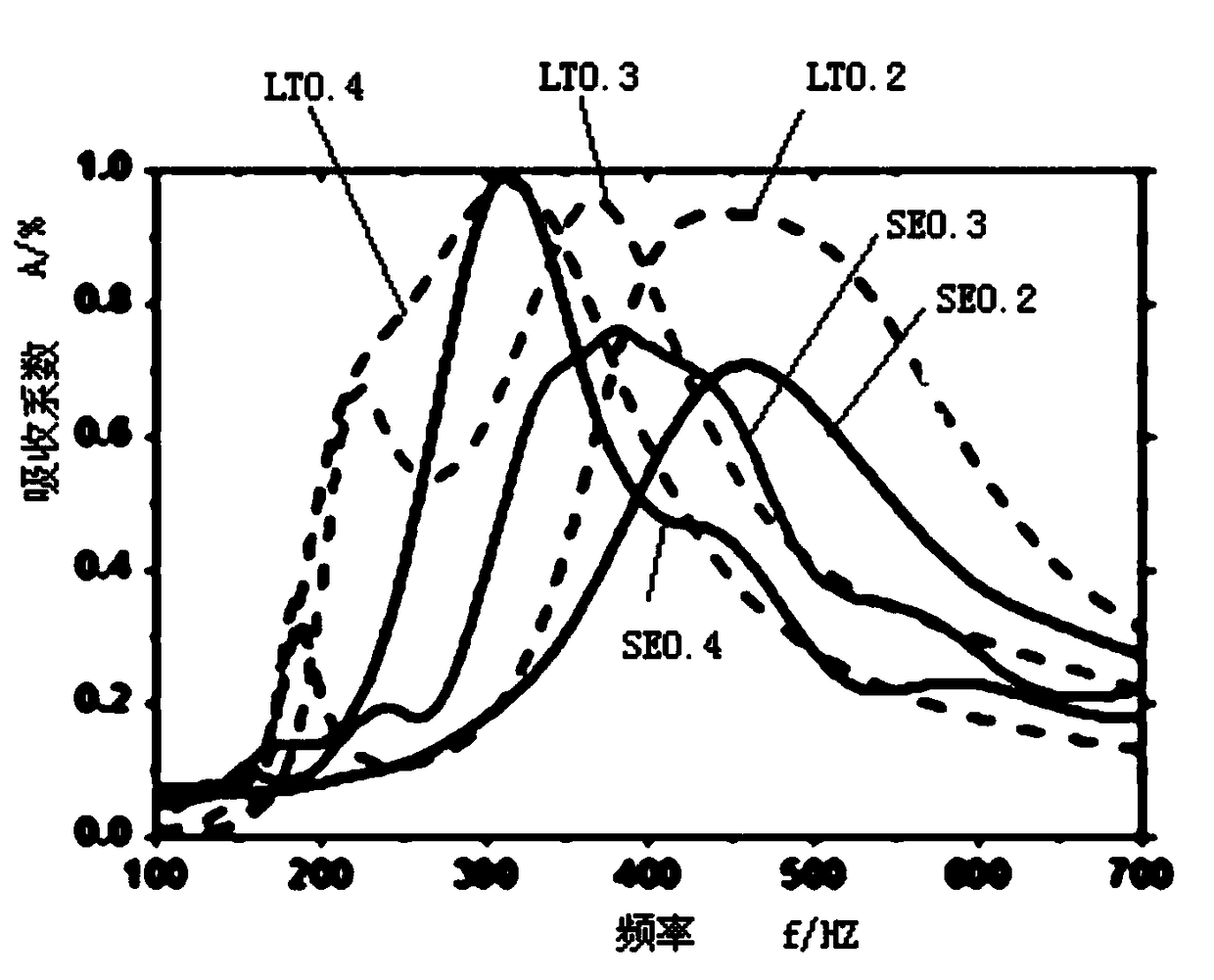

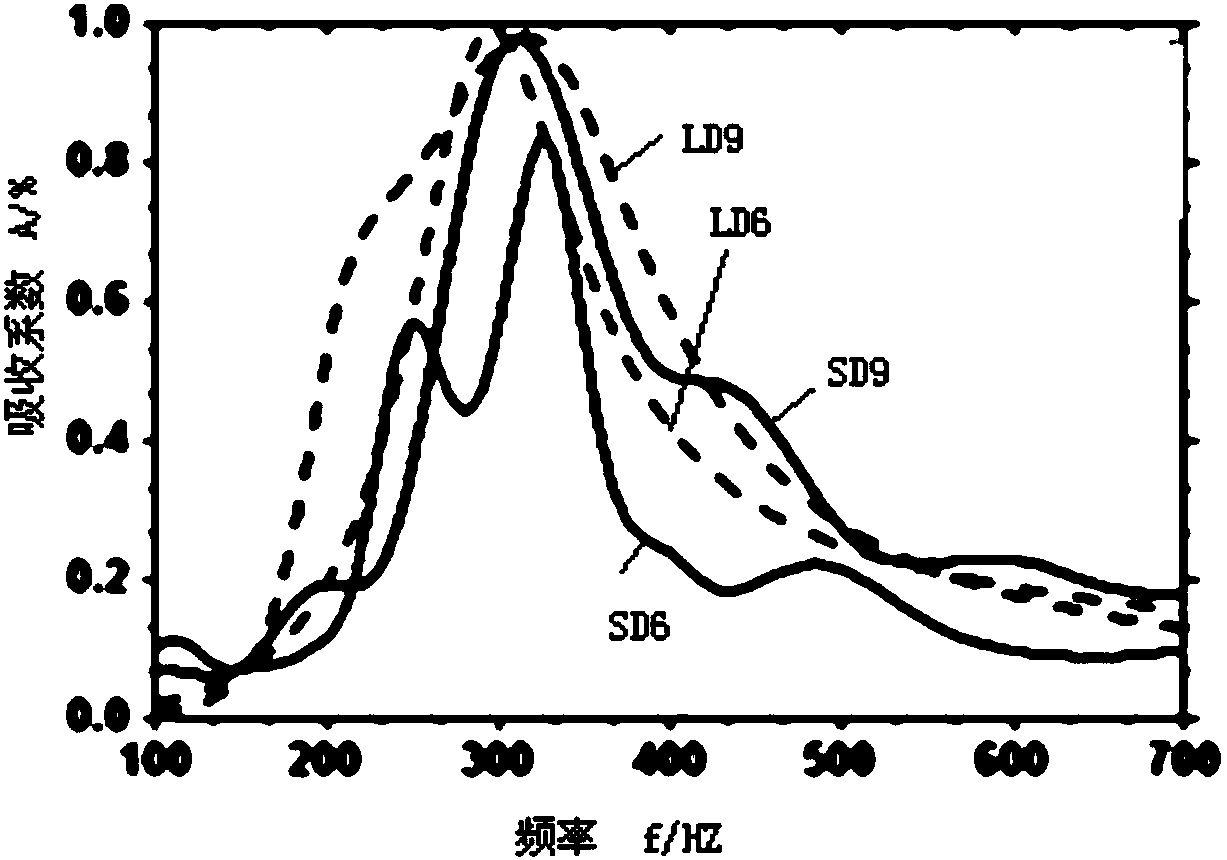

Research method for conducting low-frequency noise processing by using COMSOL and resonant cavity models

ActiveCN108344803ALow costAchieve specific absorptionAnalysing solids using sonic/ultrasonic/infrasonic wavesPeak valueStudy methods

The invention relates to a research method for conducting low-frequency noise processing by using COMSOL and resonant cavity models. The method includes the steps that firstly, resonant cavity modelsof different specifications are made; secondly, first detection groups are placed in B&K type 4206 impedance tubes respectively for sound reduction index testing, and second detection groups are placed in B&K type 4206 impedance tubes respectively for sound reduction index testing; thirdly, theoretical simulation of resonant cavity sound absorption is conducted by using COMSOL software until theoretical data fitted by the COMSOL software is basically consistent with experimental data in the second step; fourthly, expansion simulation of resonant cavity sound absorption continues to be conducted through a control variable method by using the COMSOL software, and finally an influence curve of film thickness and diameter on the sound absorption effect is determined. According to the film typeresonant cavity with adjustable parameters, the absorption frequency and absorption coefficient of the peak value are adjusted by changing the size of the models and the thickness of elastic films, theoretical simulation is conducted by using the COMSOL software, and specific absorption at a specific frequency is realized with the least space, the minimum material consumption and the lowest cost.

Owner:CHONGQING UNIV

Design method for improving acoustic performance of anti-icing panel of turbo-propeller plane

The invention provides a design method for improving the acoustic performance of an anti-icing panel of a turbo-propeller plane. The method comprises the following steps: selecting the model of the anti-icing panel, selecting the model of an acoustic inner core, designing the aerodynamic shape of the anti-icing panel, meeting the environmental suitability design requirement and the anti-icing panel installing requirement. According to the method, an anti-icing panel structure with the characteristics of high sound reduction index, low aerodynamic noise, easiness in replacement, capacity of meeting the environment suitability and the like can be designed, and the performance requirements in two aspects of preventing a propeller from throwing ice so as to damage the body of the plane and improving the acoustic performance of the body structure of the plane are met under the condition that the structure of the plane is not changed.

Owner:CHINA AIRPLANT STRENGTH RES INST

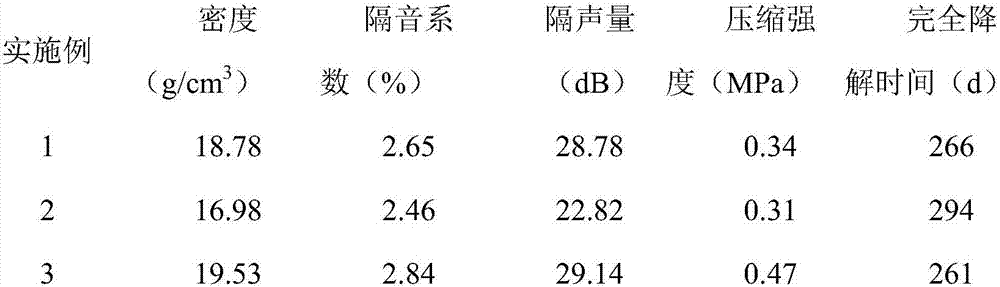

Foamed material, and applications thereof

The invention discloses a foamed material, and applications thereof. The foamed material is prepared from graphene, polyvinyl chloride, ethylene propylene rubber, polyoxypropylene triol, caprylic / capric triglyceride, a metacrylic acid ester polymer, chlorinated paraffin, ceramic fiber, maleic anhydride, ethylene-ethyl acrylate copolymer, vinyl acetate ethylene copolymerization emulsion, triisopropanolamine, an adhesive, a dispersant, a tackifier, a cross-linking agent, a catalyst, a plasticizer, a flexibilizer, an foaming agent, a foaming conditioning agent, a foam stabilizer, a curing agent, a degradation agent, and a stabilizing agent. The foamed material is obtained via steps including mixing and extrusion. The foamed material can be applied in 3D printing, is degradable, can be degraded completely in 261 to 294 days; the sound reduction index ranges from 22.8 to 29.14dB, and the sound insulation effect of the foamed material is excellent.

Owner:广西丰达三维科技有限公司

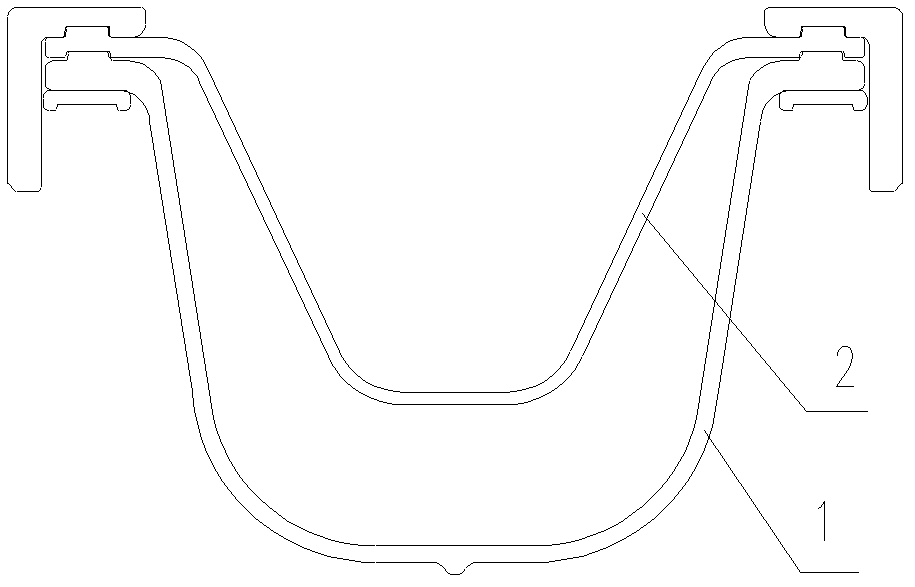

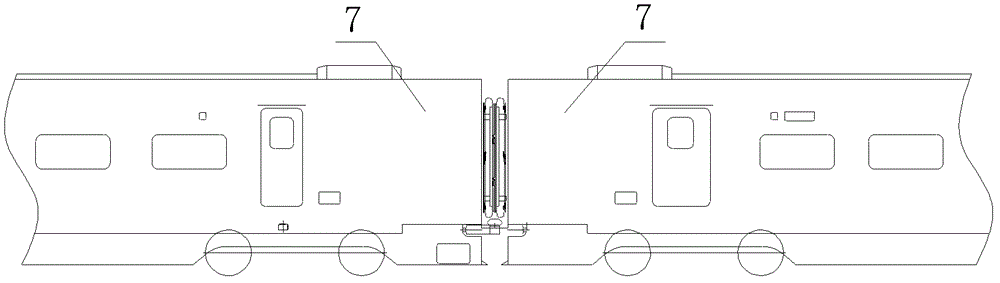

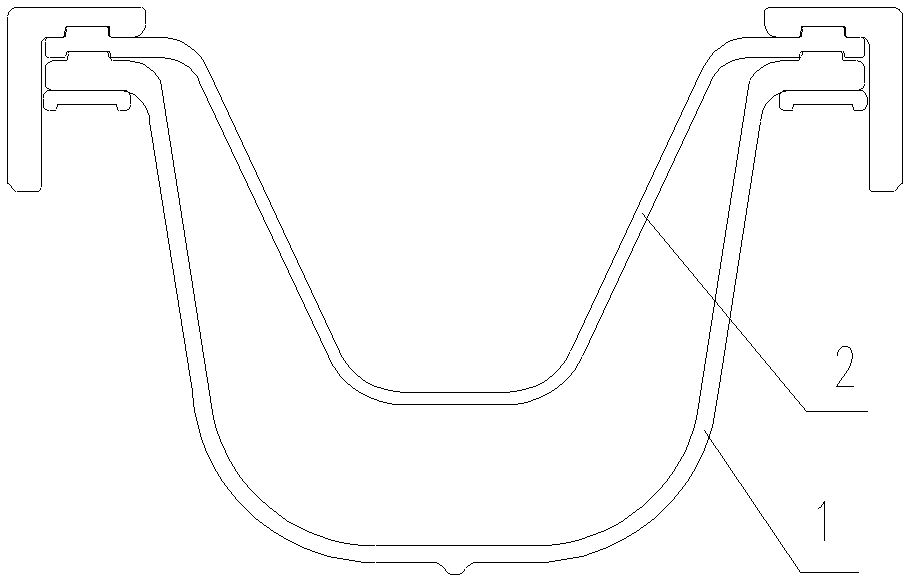

Railway vehicle end internal windshield and installation method thereof and usage method thereof

ActiveCN103129571ALarge displacementSmall degree of deformationAxle-box lubricationRailway bodiesNoise controlEngineering

The invention provides a railway vehicle end internal windshield and an installation method thereof and a usage method thereof. A complete double-layer closed capsule over-all structure is adopted, and capsules are connected with frames in a sliding mode. Not only can the sound reduction index of the internal windshield be improved, but also the problems that the capsule generates large deformation and is damaged when a train passes through curves are avoided. The internal windshield comprises a set of frames, the capsules, a top plate, a bottom transition plate and side protective plates, wherein the set of frames are longitudinally connected between the outer side of the end portion of a vehicle body and a nearby internal windshield, the capsules are arranged on the frames, and the side protective plates are arranged on two sides of the internal windshield. The capsules comprise outer layer capsules and inner layer capsules which are in overlapping joint with each other in an embedded mode and are connected into a whole. The outer layer capsules and the inner layer capsules form a complete double-layer closed sound insulation entire structure between one set of frames. The inner layer capsules are connected with the frames in a sliding mode. The internal windshield mainly plays a role of realizing noise reduction, and the double-layer capsules can substantially improve the entire sound reduction index, and enables noises of the vehicle end to be controlled within a standard range.

Owner:CRRC QINGDAO SIFANG CO LTD

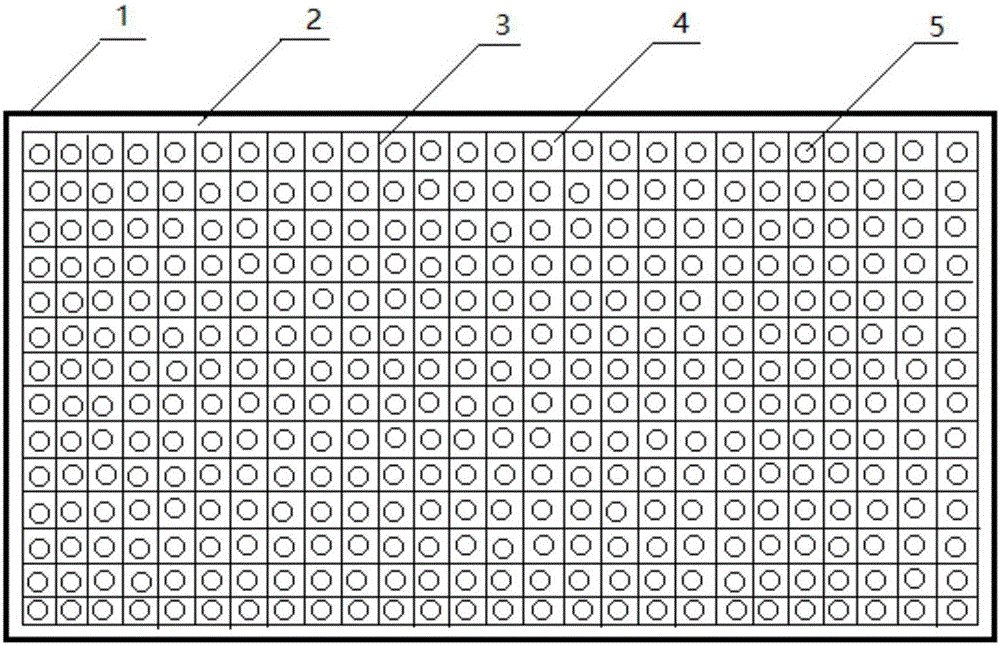

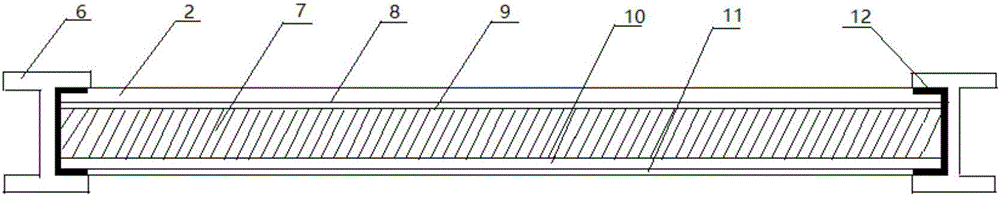

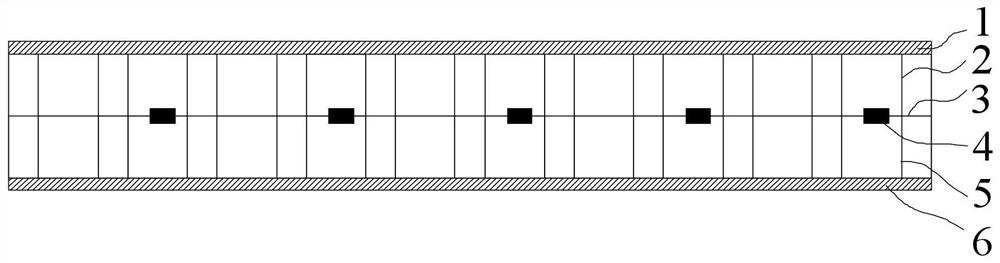

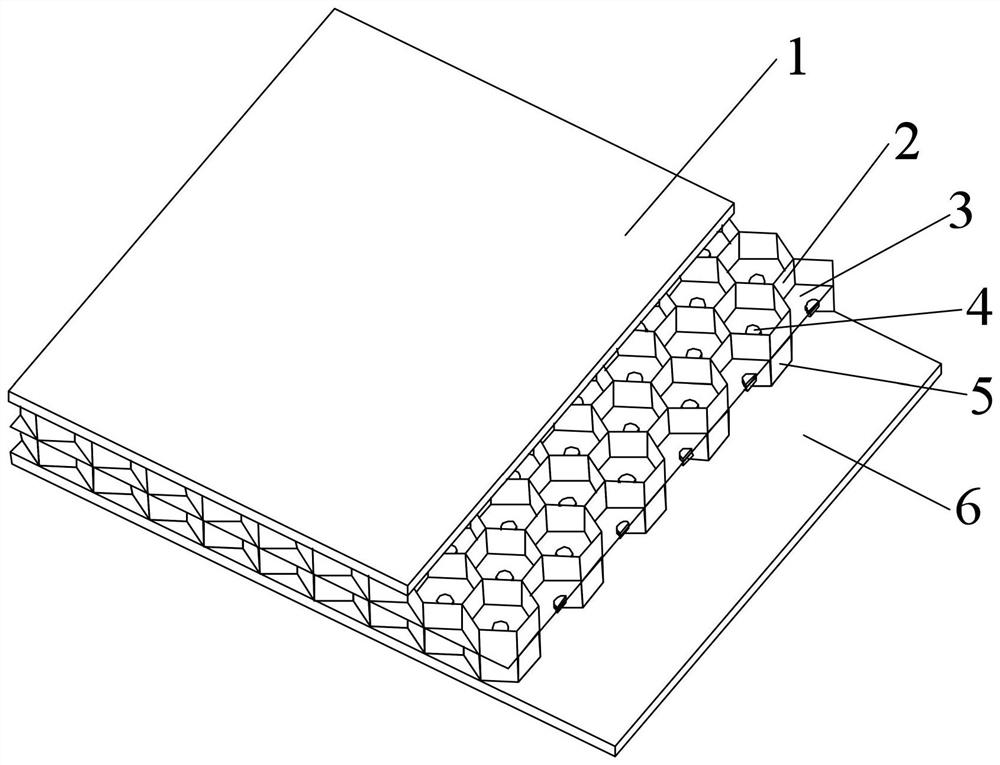

Low-frequency sound insulation cellular board

PendingCN112026296AGuaranteed lightweightExcellent low-frequency sound insulation performanceSynthetic resin layered productsPaper/cardboard layered productsThin membraneSound reduction index

The invention provides a low-frequency sound insulation cellular board. The low-frequency sound insulation cellular board is formed by sequentially bonding an upper panel, an upper cellular layer, anelastic film, a lower cellular layer and a lower panel, the elastic film is divided into a plurality of elastic units by honeycomb cells of the upper cellular layer and the lower cellularlayer, and mass oscillators are uniformly distributed on each elastic unit of the elastic film to form a mass oscillator array; the a mass oscillator arrays are formed; each mass oscillator and the corresponding elastic unit are adopted to form a miniature dynamic vibration absorber. According to the invention, the light weight of the plate is ensured, and the outstanding low-frequency sound insulation performance is ensured; according to the characteristics of a noise source, the sound reduction index characteristics of the board can be designed in a targeted manner.

Owner:HUNAN UNIV OF TECH

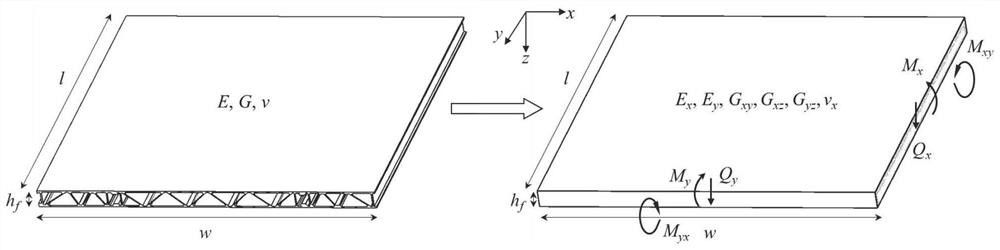

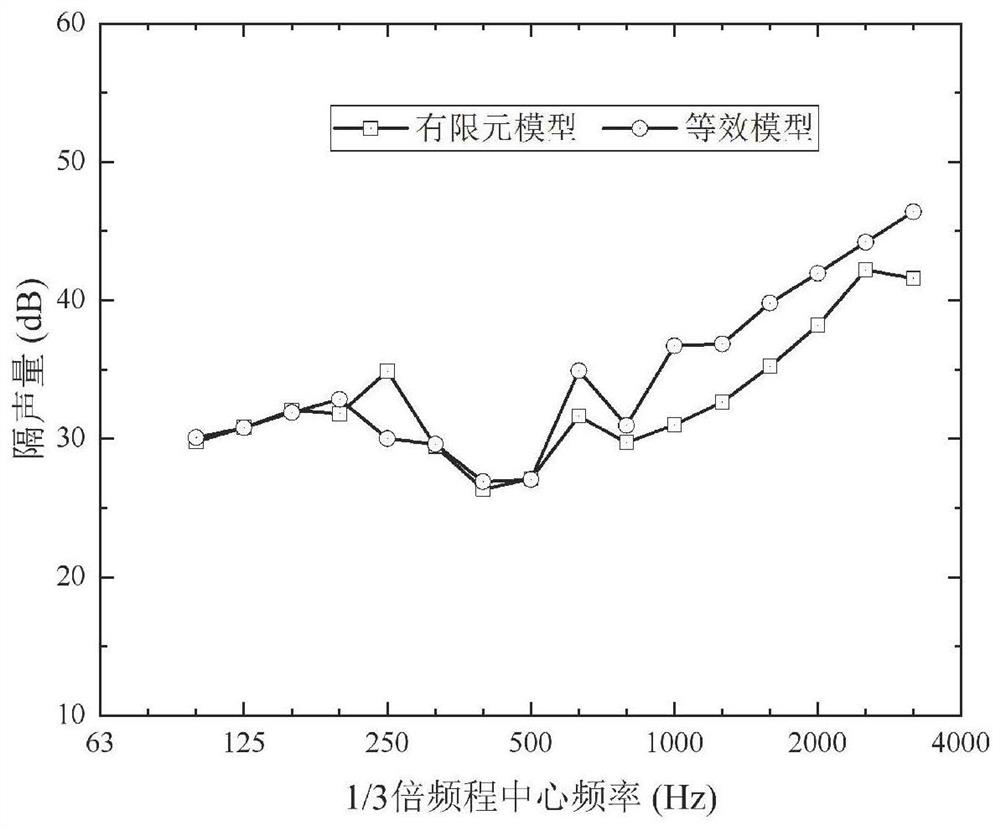

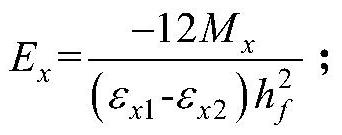

Acoustic vibration equivalent modeling method for rail vehicle body aluminum profile structure

ActiveCN112541289AImprove the efficiency of acoustic vibration performance researchAccurate calculationSustainable transportationDesign optimisation/simulationShear modulusElement model

The invention discloses an acoustic vibration equivalent modeling method for an aluminum profile structure of a railway vehicle body. The method comprises the following steps: S1, establishing a finite element model of the aluminum profile structure; S2, calculating an elastic modulus Ex and a Poisson's ratio vx; S3, calculating an elastic modulus Ey; S4, calculating a shear modulus Gxy; S5, calculating a shear modulus Gxz; S6, calculating a shear modulus Gyz; S7, calculating the equivalent density rho eq; and S8, establishing an acoustic vibration equivalent model; according to the modeling method, the acoustic vibration characteristics of the aluminum profile of the railway vehicle body can be rapidly and accurately simulated, the sound reduction index rules of the finite element model and the acoustic vibration equivalent model at 100-3150 Hz are consistent, the average error is only 1.6 dB, and compared with the finite element model, the acoustic vibration equivalent model can shorten the calculation time by 90%; therefore, the acoustic vibration performance research efficiency of the aluminum profile of the railway vehicle body is improved.

Owner:SOUTHWEST JIAOTONG UNIV

Method for carrying out low-frequency noise environmental governance by utilizing super sound absorber

ActiveCN108363872AAchieve specific absorptionSubsonic/sonic/ultrasonic wave measurementDesign optimisation/simulationResonant cavityEngineering

The invention relates to a method for carrying out low-frequency noise environmental governance by utilizing a super sound absorber. The method comprises the following steps of: 1, measuring a noise frequency of a low-frequency noise source; 2, determining a height of the super sound absorber according to a space distance between a cover of the low-frequency noise source and the low-frequency noise source; 3, manufacturing super sound absorber models in different specifications; 4, respectively putting a first detection group and a second detection group into a B&K type 4206 impedance tube tocarry out sound reduction index test; 5, carrying out theoretical simulation on resonant cavity sound absorption by utilizing COMSOL software until theoretical data fit by the COMSOL software is basically consistent with experimental data in the step 4; 6, carrying out extended simulation on the resonant cavity sound absorption by adoption of a control variable method by utilizing the COMSOL software and finally determining a film thickness and a diameter; and 7, manufacturing a plurality of super sound absorbers and fixed the bottoms of the super sound absorbers on the inner wall of the coverof the low-frequency noise source. According to the method, specificity absorption at specific frequencies is realized via minimum space and material and lowest cost.

Owner:CHONGQING UNIV

Environmentally-friendly macromolecule foam material

InactiveCN106893165AImprove sound insulationAdditive manufacturing apparatusCross-linkPolymer science

The invention discloses an environmentally-friendly macromolecule foam material. The environmentally-friendly macromolecule foam material is prepared from the following raw materials: graphene, polyolefin polymer, rubber, polyoxypropylene triol, caprylic / capric triglyceride, methacrylate polymer, polyethylene wax, polyamide fiber, maleic anhydride, ethylene-ethyl acrylate copolymer, an acetic acid vinyl ester and ethylene copolymer emulsion, tri-isopropanolamine, an adhesive, a dispersing agent, a tackifier, a cross-linking agent, a catalyst, a plasticizer, a flexibilizer, a foaming agent, a foam modifier, a foam stabilizer, a curing agent, a degradation agent and stabilizer. The material disclosed by the invention is degradable, and is completely degraded 265 to 295 days later; the sound reduction index is 22.65 to 29.01 dB, so that the material disclosed by the invention is good in sound insulation effect.

Owner:广西丰达三维科技有限公司

Pressure-resistant acoustic filter for truncation parametric array and design method

ActiveCN109036360AMeet pressure requirementsBlock high-frequency initial wavesSound producing devicesFrequency waveParametric array

The invention discloses a pressure-resistant acoustic filter for a truncation parametric array and a design method. The acoustic filter comprises a front plate, a rear plate, a connecting piece and abolt. The design method comprises the following steps of S1, determining the density and the sound velocity of a front plate material and a rear plate material, S2, determining the frequency ranges and the sound reduction indexes of a high-frequency band and a low-frequency band; S3, calculating the thickness and the spacing of the front and rear plates; S4, determining the surface dimensions of the front and rear plates; and S5, designing a installation structure. Since all parts, except the position of the connecting piece, between the front and rear plates communicate with the outside, anda formed cavity structure having a certain spacing does not change under different water depths, the acoustic performance of the acoustic filter does not vary with pressure, thereby solving the problem of pressure resistance. Moreover, since the acoustic filter design method can be customized according to the use frequency requirements of different truncation parametric arrays, high-frequency initial waves can be blocked and low-frequency difference frequency waves can be transmitted. The method is simple and convenient.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

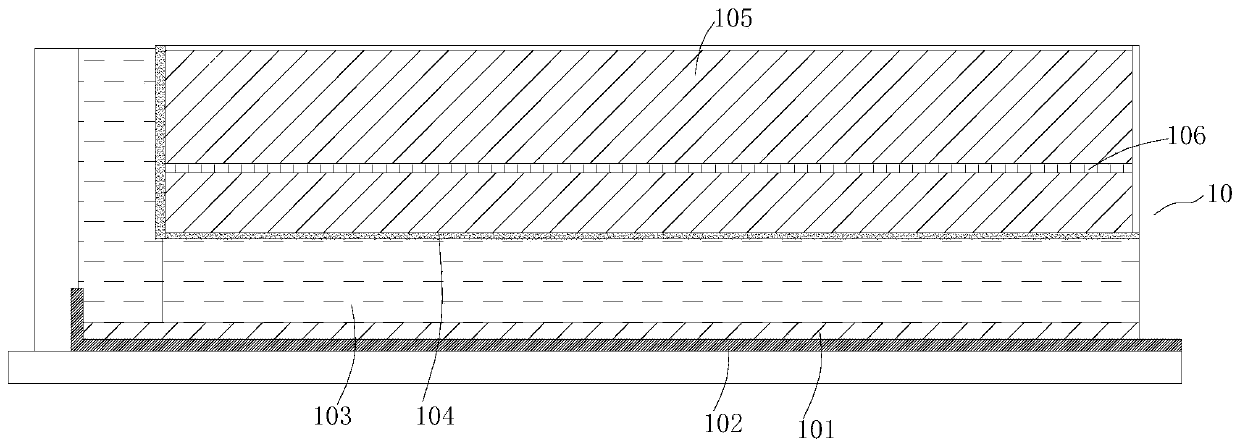

Method for testing simulated sound reduction index of large wallboard component based on low-temperature test box device

ActiveCN110045025ASimple structureEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesTemperature controlReduced size

The invention discloses a method for testing a simulated sound reduction index of a large wallboard component based on a low-temperature test box device, and belongs to the field of testing methods for sound insulation performance of materials in a low-temperature state. According to the method, an ultra-low temperature small test box with a refrigeration function is used in combination with an anechoic chamber, so that a standard sound-proof chamber with high temperature control cost is simulated and replaced; meanwhile, the large-scale wallboard part required to be tested is cut into a rectangular small-size sample plate part with a reduced size, so that a standard test window in the standard sound-proof chamber is simulated by utilizing a rectangular simulation test window arranged on the ultralow-temperature small test box, and thus the interior of the small test box body is simulated as a sounding chamber in the standard sound-proof chamber, the silent environment of the anechoicchamber outside the small test box body is simulated as a sound receiving chamber in the standard sound-proof chamber, and acoustic measurement of the simulated sound reduction index of the small-sizesample plate part is completed. The low-temperature test box device is simple and practical in structure and easy to operate, and the method for testing the simulated sound reduction index based on the device is low in cost.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD +1

Multilayer composite material for floors of high-speed trains and bullet trains

InactiveCN105966412AIncreased acoustic impedance ratioEffective reflectionSynthetic resin layered productsAxle-box lubricationFiberAcoustic wave

The invention discloses a multilayer composite material for floors of high-speed trains and bullet trains. The multilayer composite material is characterized in that the inner layer of the multilayer composite material is a phenolic aldehyde composite material having the thickness being 10-12mm, the phenolic aldehyde composite material is formed by processing thermosetting resin and reinforcing fiber through the special technology, the compression strength of the phenolic aldehyde composite material is 10-20MPa, the sound reduction index is 30-50dB, the thermal conductivity coefficient is 0.02-0.04 W / m.k, and the phenolic aldehyde composite material can be simply composited as well as 3-D formed; the outer layer is a novel sound insulation composite material having the thickness being 2-3mm, and is formed by alternatively arraying foaming layers and unfoamed layers through the micro-layer extrusion technology, the single-layer thickness of the sound insulation composite material is 1-1.5mu, the number of layers is 2000-3000, and effective reflection of sound waves by the layered interface is realized. Compared with the rubber floor applied to the high-speed trains and bullet trains at present, the multilayer composite material has the advantages of low density (being less than or equal to 1300kg / m<3>) or less, good sound insulation performance (being greater than or equal to 29dB), long service life, flame retardance, environmental protection and the like, and can be applied to rail transit vehicles, such as high-speed bullet trains, subways, trams, light railways and rail flaw detection vehicles.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Lightweight sandstone and production technology thereof

The invention discloses lightweight sandstone. The lightweight sandstone is characterized by comprising the following components in percentage by weight: 70-90% of silica sand, 8-21% of organic adhesive and 6-16% of inorganic flame-retardant powder. A production method of the lightweight sandstone is further provided, and comprises the following steps: (1) weighing the components, mixing the weighed inorganic flame-retardant powder and the weighed organic adhesive in a container, and stirring the weighed inorganic flame-retardant powder and the weighed organic adhesive evenly; (2) then addinga catalyst and a curing agent for even stirring; (3) after the silica sand is weighed and is ground to be 30-60 meshes, adding ground silica sand into a mixture in the step (1), and conducting stirring for 10-20 minutes; (4) pouring an obtained mixture into a mould, and conducting compaction and smoothing; and (5) after the mould is placed in a drying tunnel for drying, conducting demoulding. No waste or harmful gas is generated in the production process, no pollution is generated, and waste is turned into wealth; the average sound reduction index of a lightweight sandstone slab is above 30 dB, a sound absorption and reduction coefficient is larger than 0.7, both the average sound reduction index and the sound absorption and reduction coefficient exceed the national standard, and the mechanical performance is good, so that the lightweight sandstone slab is an ideal outdoor acoustic sound absorption material; and the fireproof performance reaches an A grade.

Owner:广东天戈声学科技有限公司 +1

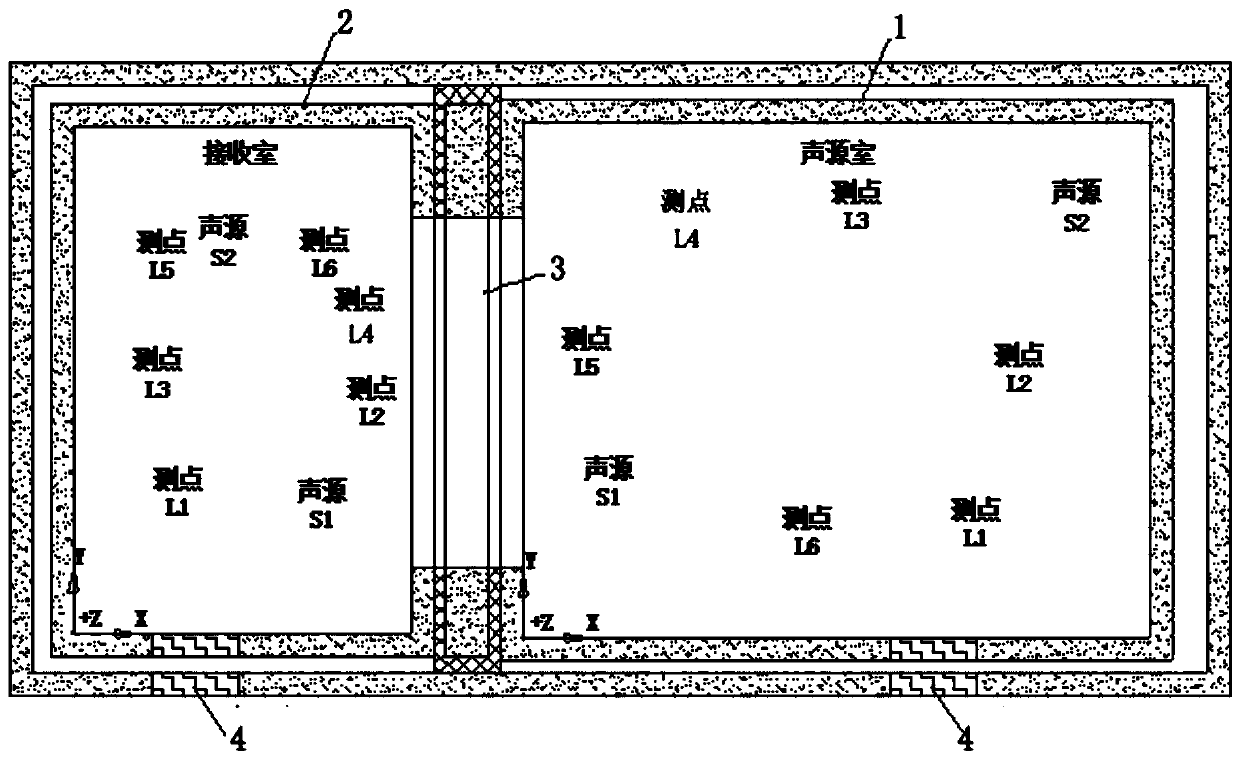

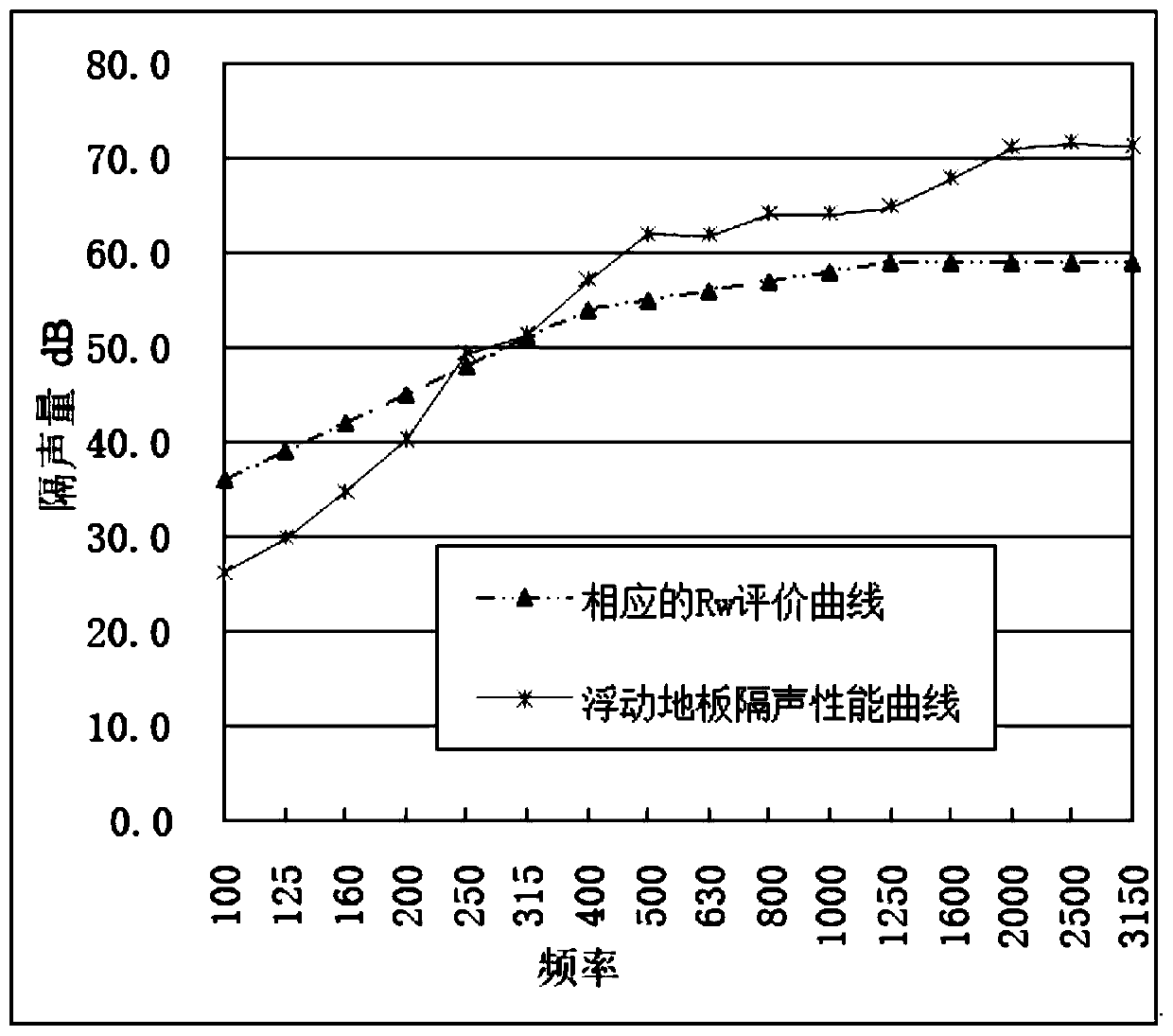

Floating floor air sound insulation detection method

PendingCN111595951ACoordinate digital precisionHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesEngineering

The invention relates to a floating floor air sound insulation detection method which comprises the following steps: step a, establishing a laboratory which comprises a sound source chamber and a receiving chamber that are communicated through a test hole and are respectively provided with sound insulation doors; step b, carrying out measuring point and sound source arrangement; to be specific, arranging a plurality of sound sources and a plurality of measuring points in the sound source chamber and the receiving chamber, determining coordinate positions of the sound sources and the measuringpoints, and installing test pieces at the positions of the measuring points; and step c, calculating an average sound reduction index of the test pieces. According to the sound insulation detection method, the sound insulation index of the floating floor is detected by arranging the plurality of sound sources and the plurality of measuring points in the sound source chamber and the receiving chamber, and the sound insulation index of the floating floor is obtained by calculating the average sound insulation index of the plurality of measuring points.

Owner:湖北一特新材料科技有限公司

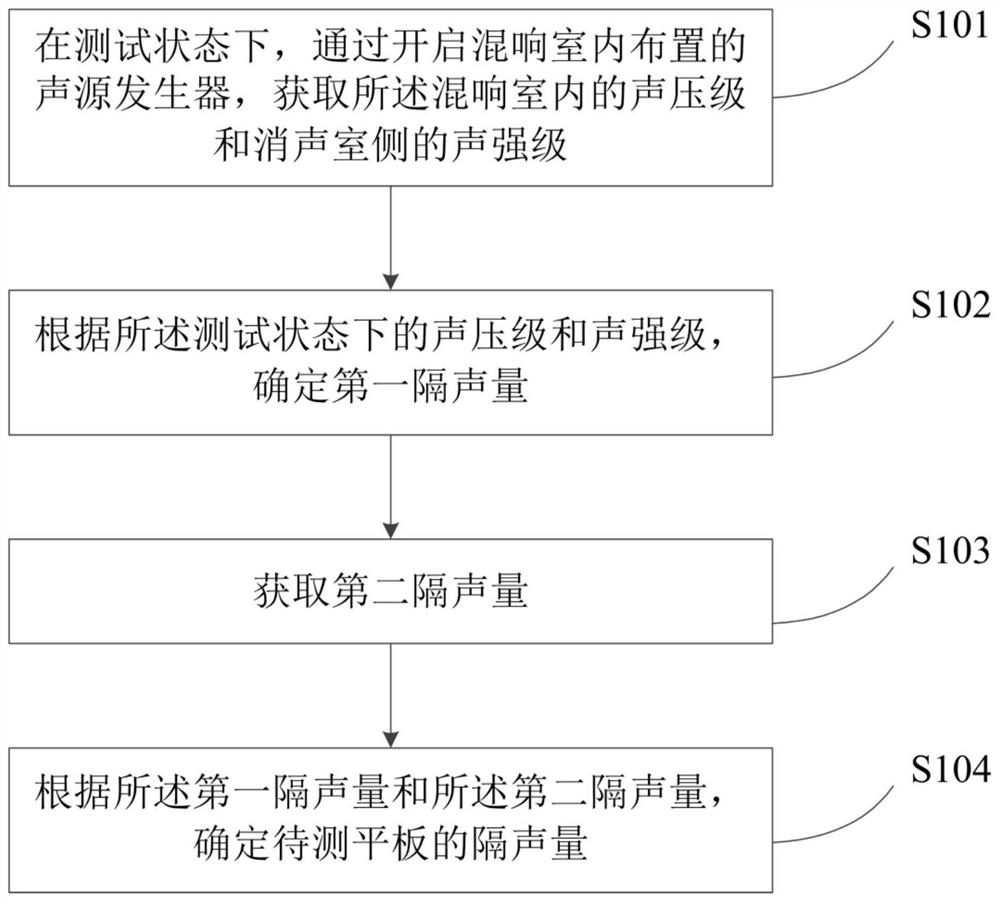

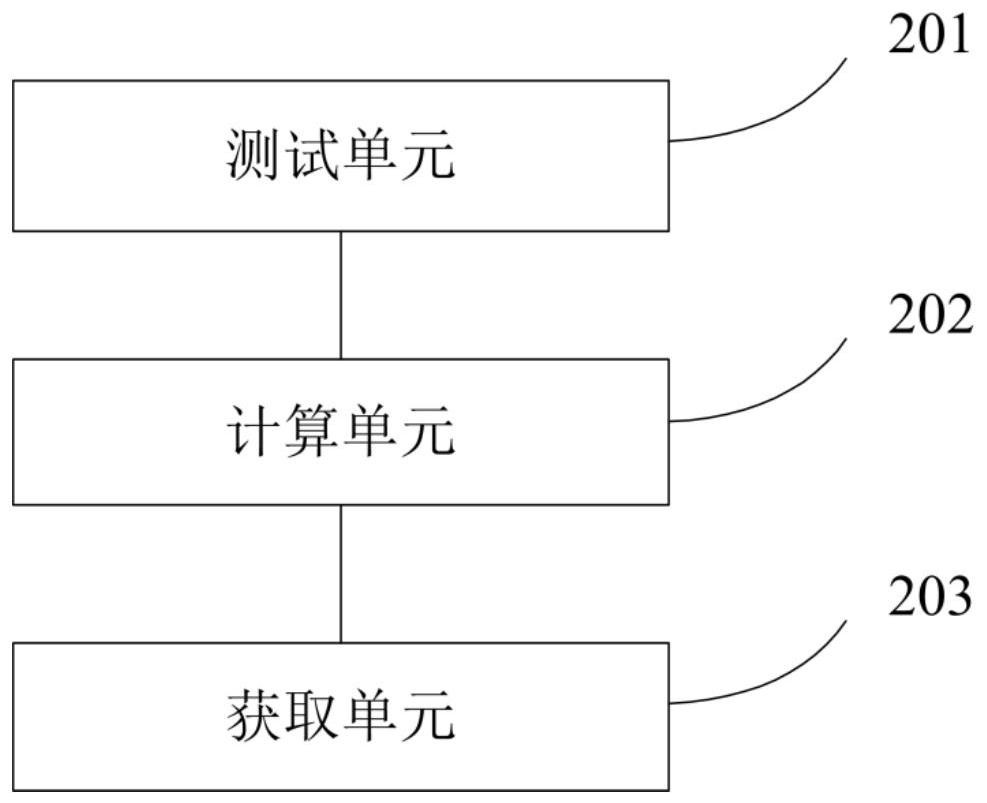

Method and device for testing sound insulation performance of flat plate

PendingCN114414665AEliminate errorsImprove accuracyVehicle testingAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesAnechoic chamber

The embodiment of the invention discloses a flat plate sound insulation performance testing method and device, and the method comprises the steps: obtaining the sound pressure level in a reverberation chamber and the sound intensity level of an anechoic chamber side through starting a sound source generator disposed in the reverberation chamber in a testing state, and determining a first sound insulation index according to the sound pressure level and the sound intensity level in the testing state; and obtaining a second sound reduction index, and determining the sound reduction index of the to-be-detected flat plate according to the first sound reduction index and the second sound reduction index. Wherein the second sound reduction index is determined according to the sound pressure level and the sound intensity level in the through hole state after the sound source generator is started in the through hole state. The test method in the through hole state is designed for the test process of the sound insulation performance of the flat plate, test result errors caused by a sound insulation test tool are eliminated, and the accuracy of the sound insulation performance test result of the flat plate is improved.

Owner:SAIC MOTOR

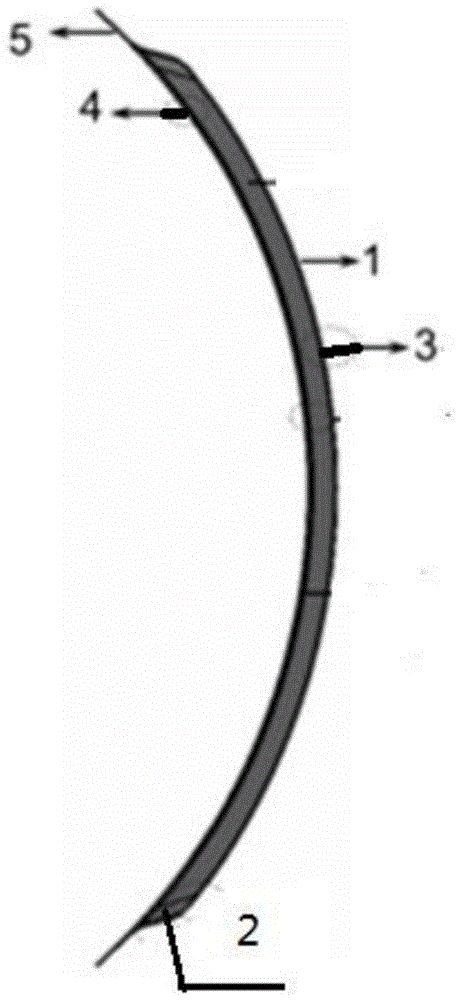

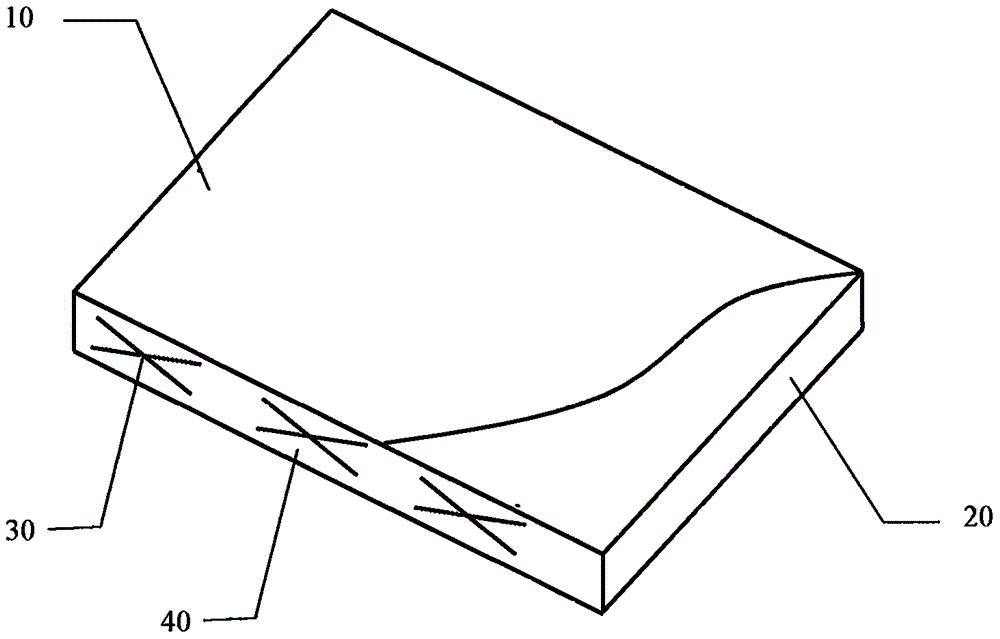

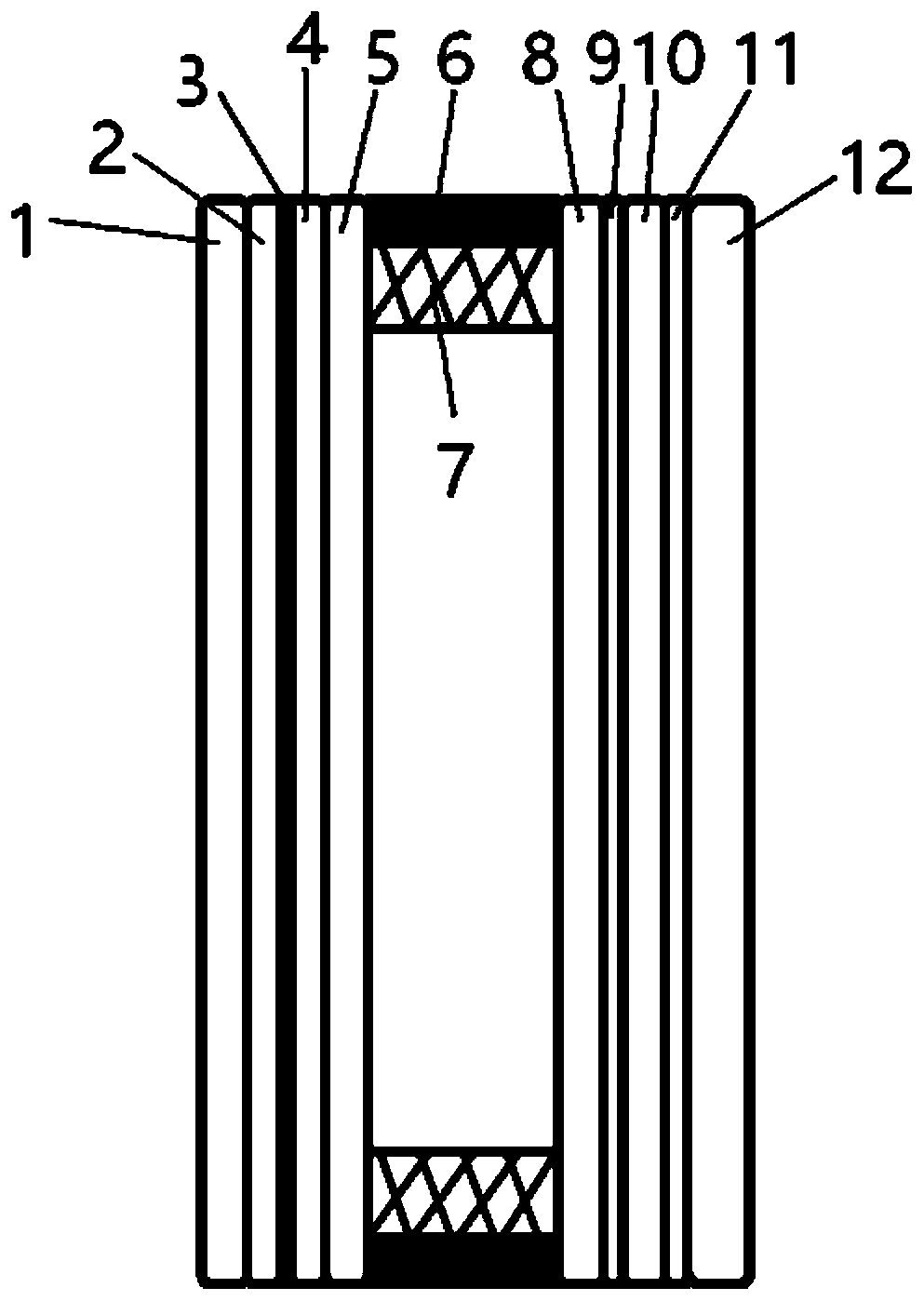

Lightweight train window for high-speed train and manufacturing method of lightweight train window

PendingCN110588102AStrong impactGood sound and heat insulationSynthetic resin layered productsLaminationThermal insulationEngineering

The invention relates to a lightweight train window for a high-speed train and a manufacturing method of the lightweight train window. The train window is of a hollow structure, a sandwich structure on the inner side comprises a first glass layer (1), a first film layer (2), a PET film (3), a second film layer (4) and a second glass layer (5) from indoor to outdoor sequentially; a sandwich structure on the outer side comprises a third glass layer (8), a third film layer (9), a fourth glass layer (10), a fourth film layer (11) and a fifth glass layer (12); the first glass layer (1) and the second glass layer (5) are chemically strengthened glass, and the thicknesses are 1.8 mm-2.0 mm; the first film layer (2) is low frequency sound insulation PVB, and the thickness is 0.38 mm; and the second film layer (4) is high frequency sound insulation PVB, and the thickness is 0.76 mm. The sound and thermal insulation performance of the train window is good. Weighting sound reduction index (Rw) isnot lower than 46 dB, the heat transfer coefficient (K) is smaller than 1.0 W / (m<2>.K), and the weight is only 70% of traditional high-speed train side window glass.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com