Device and method for measuring sound reduction index of acoustic material by adopting pulse method

A technology of acoustic materials and sound insulation, applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve cumbersome and unpopular problems, achieve the effects of improving measurement accuracy, overcoming influence, and avoiding secondary errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Describe the present invention below in conjunction with specific embodiment:

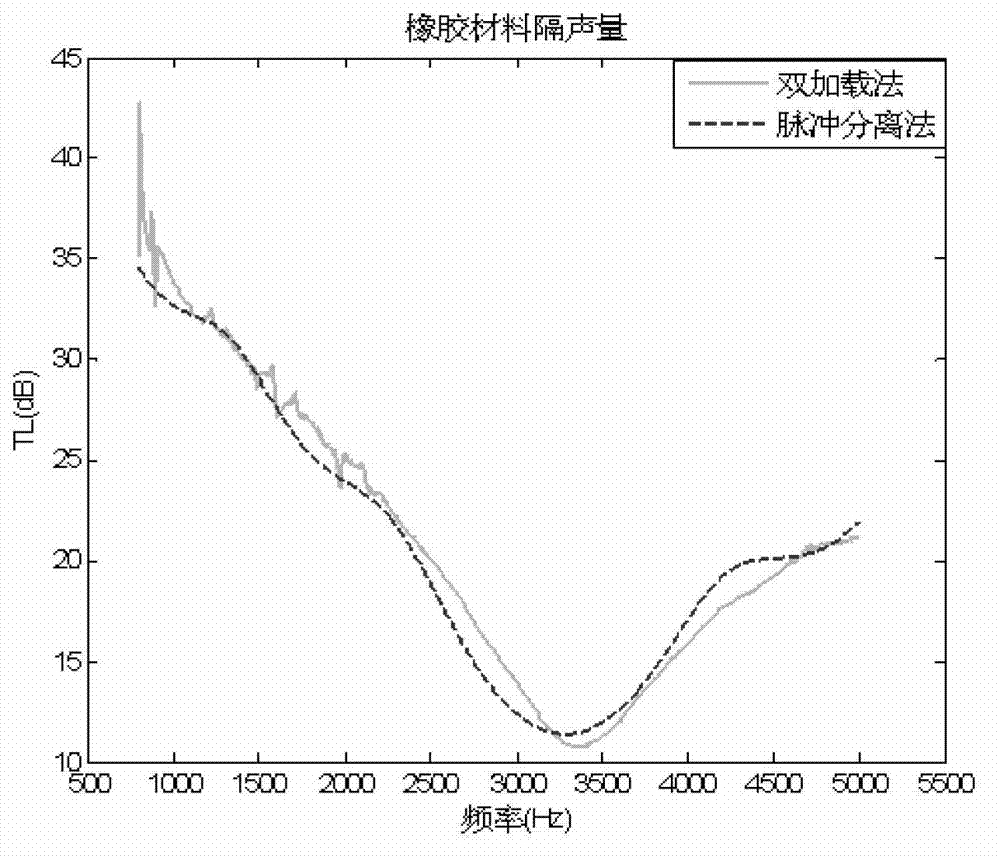

[0027] In this embodiment, a measurement experiment of sound insulation is carried out on a 3 cm rubber material.

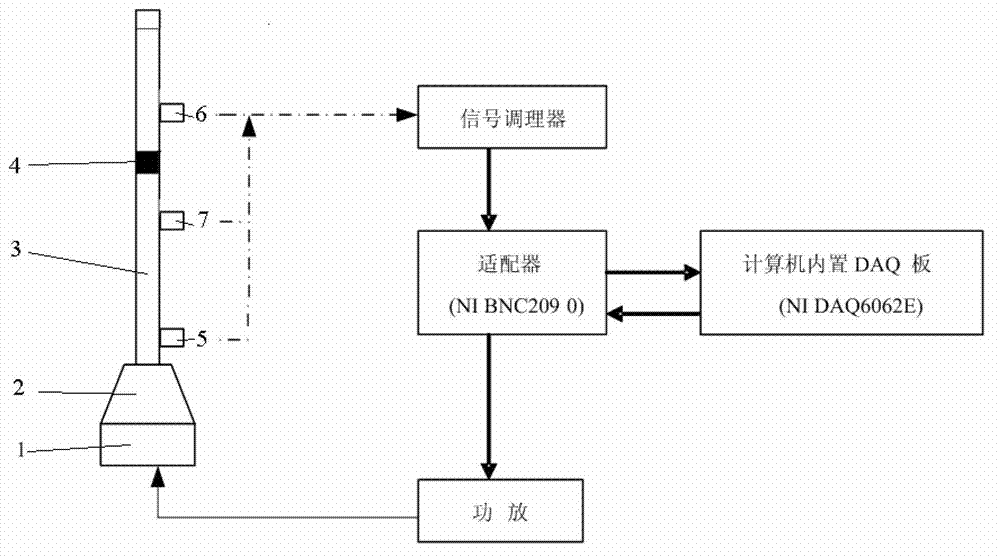

[0028] The measurement device used in this embodiment includes a sound tube, a pulse sound source, a microphone, a power amplifier, a signal conditioner, an adapter and a data acquisition device.

[0029] The sound tube is composed of a section of large-diameter cylindrical tube, conical tube and small-diameter cylindrical tube, which are connected coaxially in sequence. The material of the sound tube is made of steel. The length of the large-diameter cylindrical tube is 150mm, the length of the conical tube is 200mm, and the small-diameter cylindrical tube is The tube length is 1360mm. The inner diameter of the large-diameter cylindrical tube is the same as the diameter of the pulse sound source. The pulse sound source is installed in the large-diameter cylindrical tube. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com