Cab design method based on cab sound reduction index analysis

A design method and cab technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as auditory system damage, hearing damage, deafness, etc., and achieve the goal of improving sealing performance, high sound insulation performance, and reducing internal noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

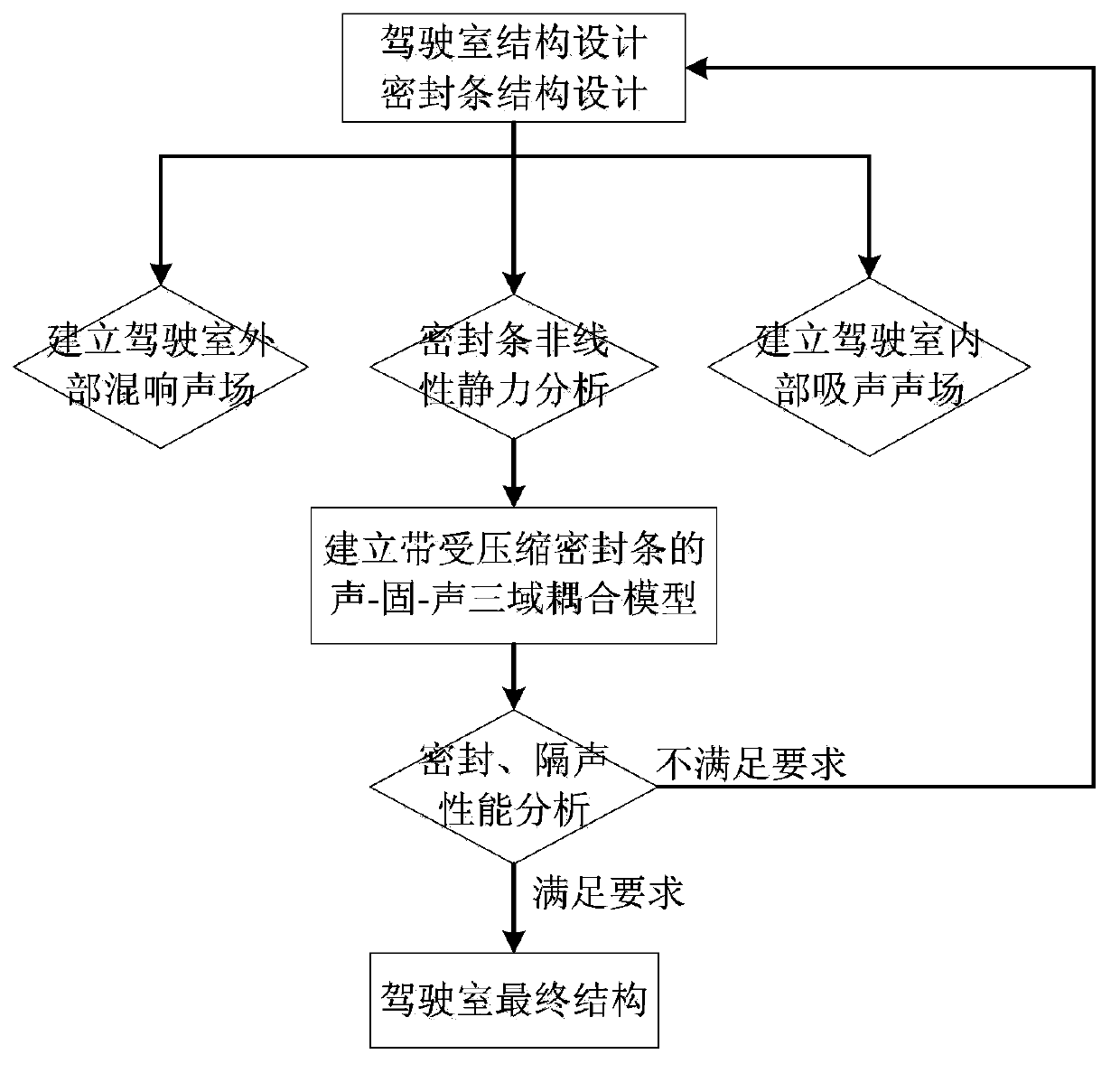

[0039] Such as figure 1 As shown, a cab design method based on cab sound insulation analysis, the cab includes a cab assembly and a sealing strip, and the design method specifically includes the following steps:

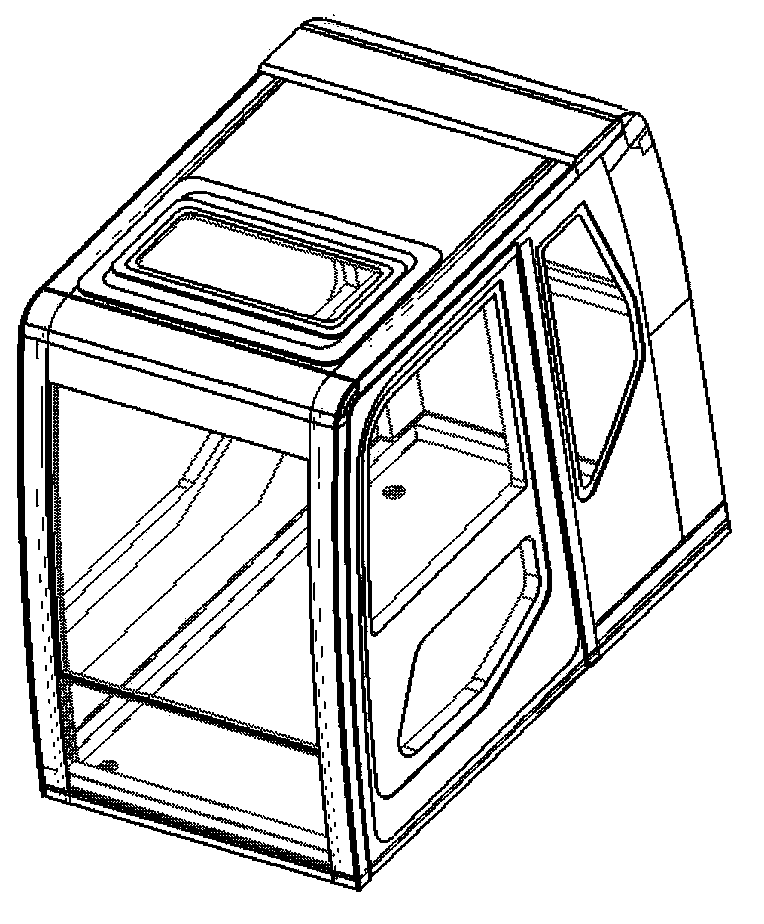

[0040] 1) Establish the CAD model of the cab assembly based on the design drawings of the cab by means of surveying, mapping, scanning point clouds, etc. A certain simplification is carried out locally, that is, local bosses and chamfers that have little influence on the results are ignored, and only the inner and outer layers of the cab part structure, door glass, side glass and front windshield glass are considered, such as figure 2 shown.

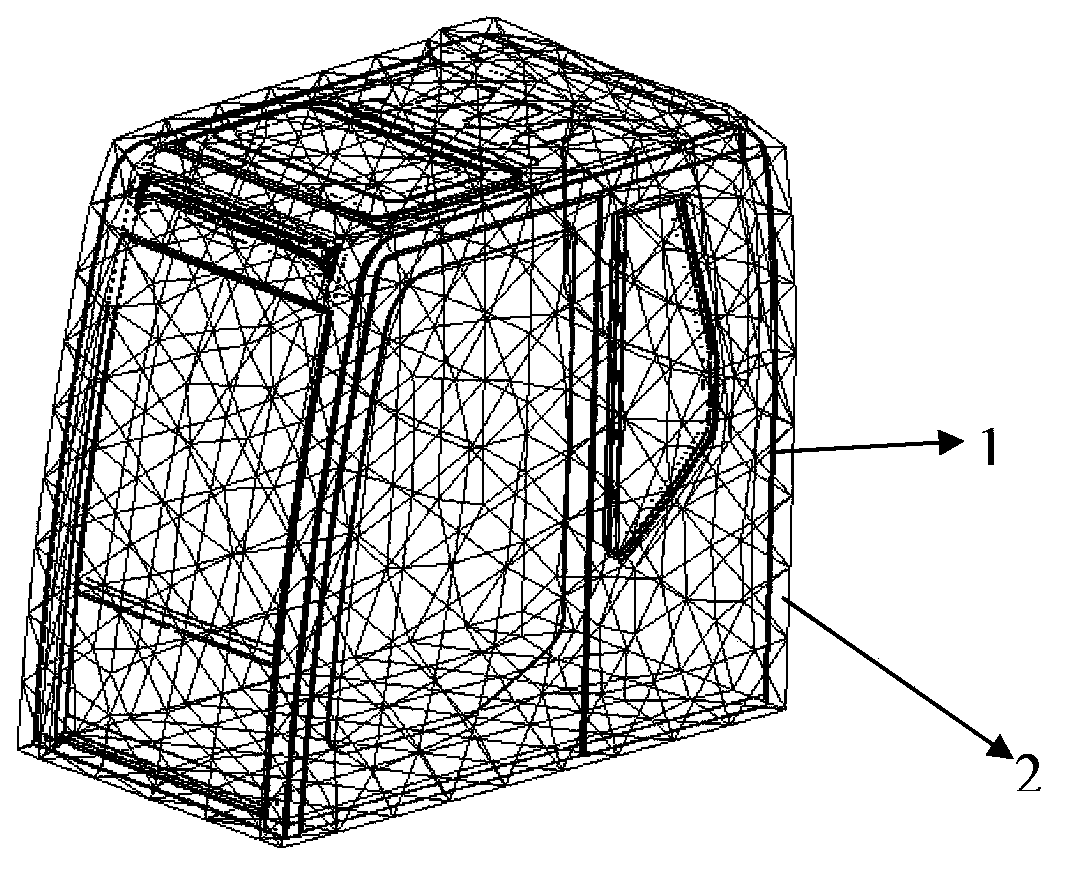

[0041] Then use the finite element pre-processing software Hypermesh to mesh the CAD model of the cab assembly, and establish the finite element model of the cab assembly. The model is mainly modeled by shell elements, CWELD is used for spot welding, and RBE2 is used for seam welding. simulation. The material parameters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com