Sound insulation material, composite carpet using the material and preparation method thereof

A technology of sound-insulating materials and carpets, which is applied in the field of high-sound-insulation composite carpets and its preparation, can solve the problems of poor sound wave reflection and blocking ability, difficulty in volume complementation and uniform distribution, and blocking of sound wave transmission, so as to simplify the production process, reduce production costs, The effect of good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

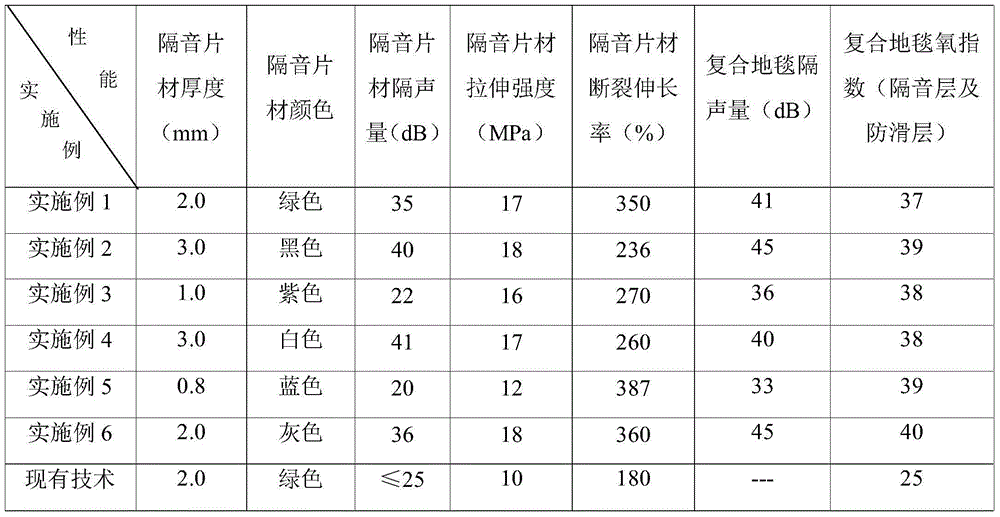

Examples

Embodiment 1

[0055] 1. Choose pure wool carpet as the surface carpet layer;

[0056] 2. Preparation of middle layer sound insulation layer:

[0057] Preparation of sound-insulating functional body particles: 10kg of calcium carbonate, 90kg of barium sulfate, choose non-smooth round particles, and the amount of particles with a particle size of about 0.5um, 1.0um and 2.0um is 5kg, 90kg and 5kg respectively , mix them well.

[0058] Sound insulation material ingredients: SG-1 type PVC resin 20kg, SG-3 type PVC resin 70kg, SG-5 type PVC resin 10kg, citrate plasticizer 20kg, calcium zinc composite stabilizer 3kg, zinc stannate flame retardant 2kg , Magnesium hydroxide-aluminum hydroxide-coupling agent flame retardant system 8kg, sound-proof functional particle 70kg, stearic acid 3kg, antioxidant 1010 0.5kg, antioxidant 168 0.5kg, UV-327 0.3kg, talcum powder 50kg, polyoxyethylene 2kg, green toner 0.8kg.

[0059] Sound insulation material preparation: (1) Mixing of raw materials: Zinc stannat...

Embodiment 2

[0065] 1. Choose polyester carpet as the surface carpet layer;

[0066] 2. Preparation of middle layer sound insulation layer:

[0067] Preparation of sound-proof functional body particles: 30kg of zinc carbonate, 25kg of magnesium hydroxide, 25kg of aluminum hydroxide, 20kg of titanium dioxide, choose non-smooth round particles, and the particle size is about 0.4um, 1.2um and 1.9um. The dosages are 15kg, 70kg and 15kg respectively, and they are fully mixed evenly.

[0068] Sound insulation material ingredients: SG-1 type PVC resin 10kg, SG-3 type PVC resin 80kg, SG-5 type PVC resin 10kg, citric acid ester plasticizer 10kg, calcium zinc composite stabilizer 5kg, magnesium hydroxide-aluminum hydroxide -Coupling agent (1:1.2:0.1) 15kg flame retardant, 70kg sound-proof functional particle, 1kg calcium stearate, 0.3kg antioxidant 1076, 0.4kg antioxidant 168, 1.3kg carbon black, 20kg calcium carbonate , Polyoxyethylene laurate ether 0.6kg.

[0069] Sound insulation material prepar...

Embodiment 3

[0075] 1. Choose acrylic carpet as the surface carpet layer;

[0076] 2. Preparation of middle layer sound insulation layer:

[0077] Preparation of sound-proof functional body particles: 12kg of barium sulfate, 45kg of magnesium hydroxide, 40kg of aluminum hydroxide, 3kg of zirconia, choose round particles with non-smooth surface, and the particle size is about 0.2um, 0.8um and 2.5um The dosage of granules is 10kg, 80kg and 10kg respectively, and they are fully mixed evenly.

[0078] Sound insulation material ingredients: SG-1 type PVC resin 40kg, SG-3 type PVC resin 45kg, SG-5 type PVC resin 15kg, citric acid ester plasticizer 50kg, calcium zinc composite stabilizer 6kg, sound insulation functional particle 30kg, poly Vinyl wax 2kg, calcium carbonate 60kg, antioxidant 1076 0.7kg, antioxidant 168 0.8kg, UV-326 0.3kg, purple toner 1kg.

[0079] Preparation of sound insulation materials: (1) Mixing of raw materials: Put PVC resin and calcium-zinc composite stabilizer in a hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com