Patents

Literature

38results about How to "Realize intelligent measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

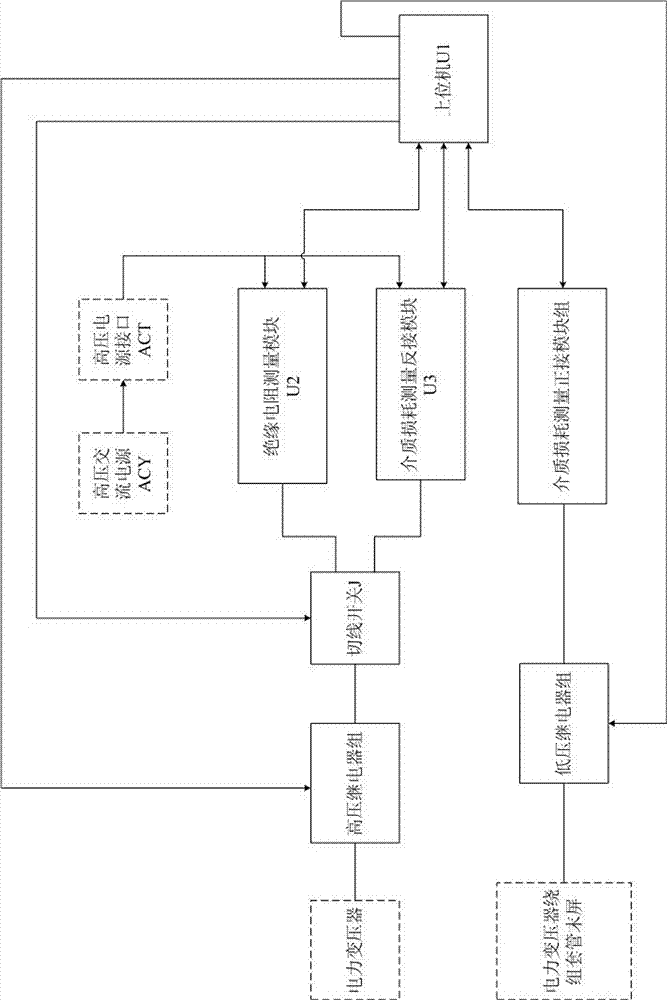

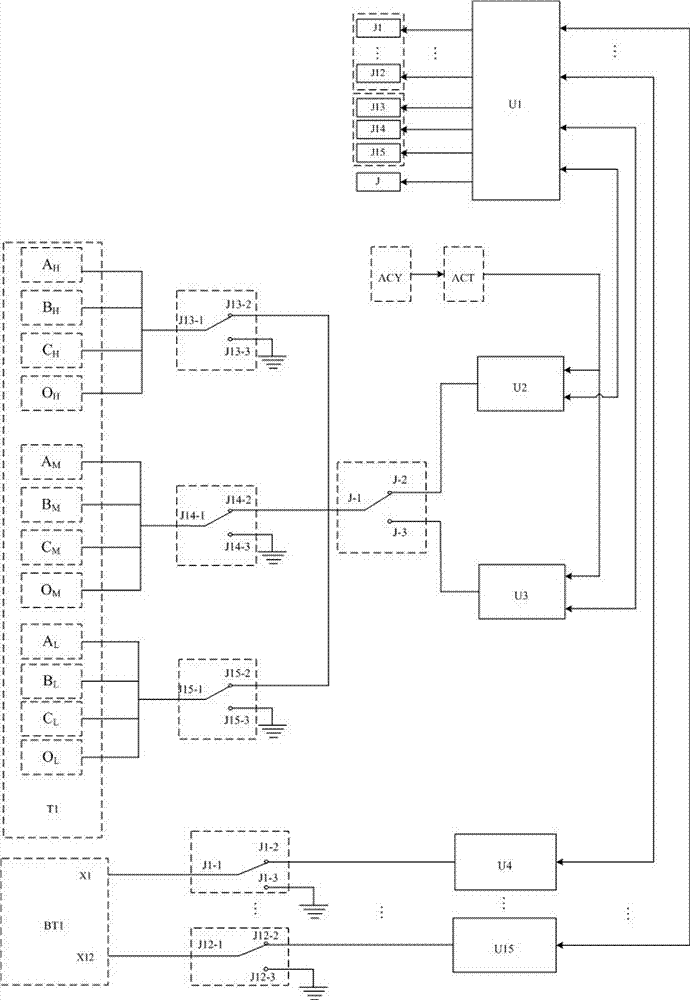

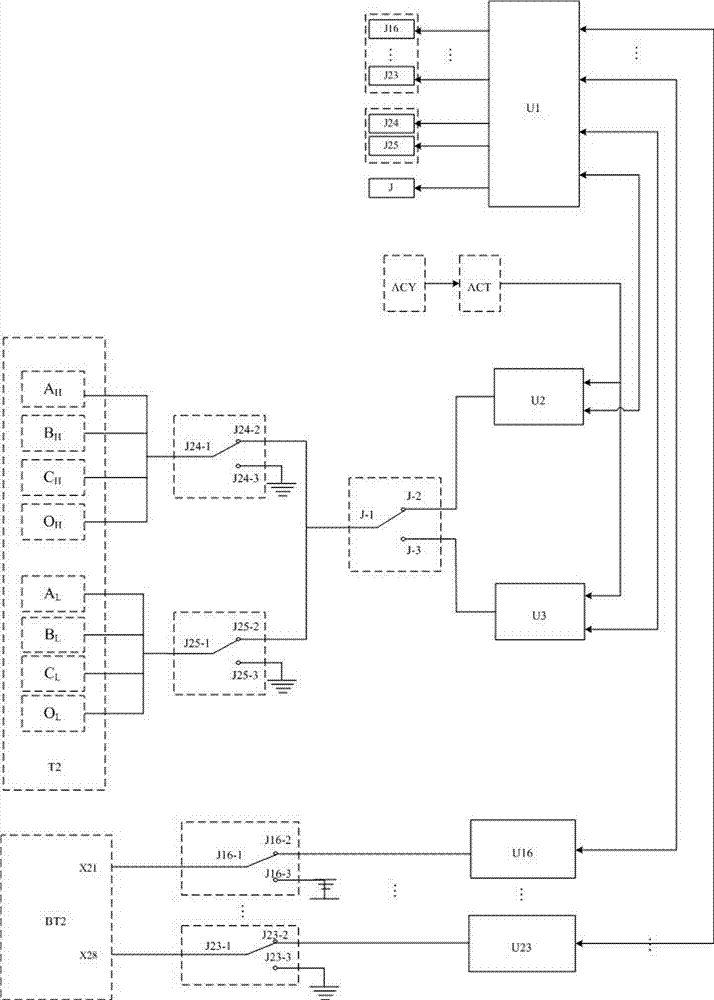

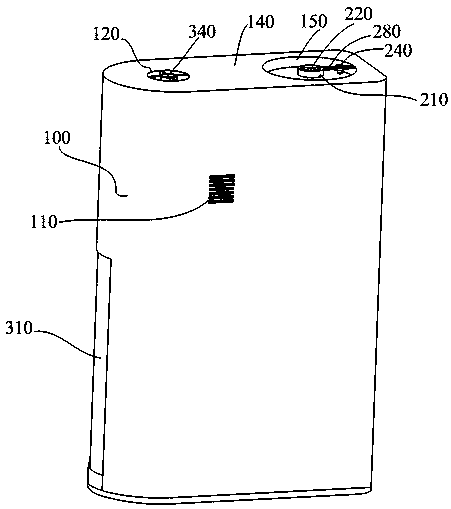

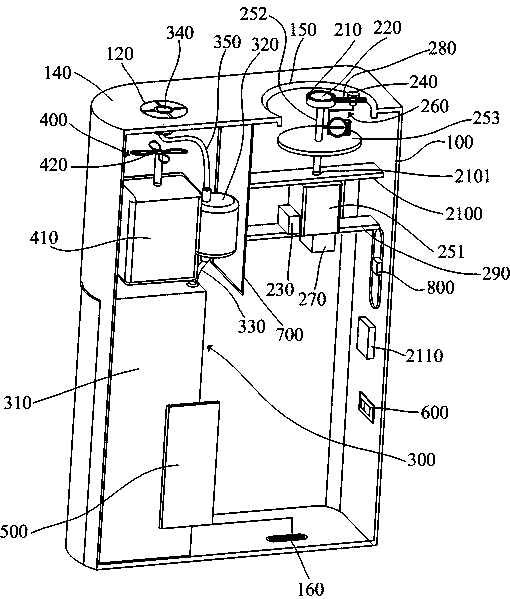

Intelligent device for measuring dielectric loss factor and insulation resistance of power transformer

InactiveCN103941100ARealize intelligent measurementReduce measurement errorResistance/reactance/impedenceElectrical resistance and conductanceDielectric loss factor

The invention relates to an intelligent device for measuring the dielectric loss factor and the insulation resistance of a power transformer. The intelligent device comprises an upper computer U1, an insulation resistance measuring module U2, a dielectric loss measuring reverse connection module U3, a dielectric loss measuring positive connection module set, a diverter switch J, a high-voltage relay set and a low-voltage relay set. The intelligent device has the following advantages that as long as connection lines are well connected at the beginning of a test, in the whole test process, the upper computer is used for controlling high-voltage relays, low-voltage relays and the diverter switch to select a winding state and a measurement project so as to replace manual line connecting, the winding state is automatically switched in the whole measurement process, manual intervention is not needed, measurement errors can be reduced, the working intensity can also be relieved, the working efficiency is improved, and intelligent measurement of the dielectric loss factor and the insulation resistance of the power transformer is achieved.

Owner:STATE GRID CORP OF CHINA +2

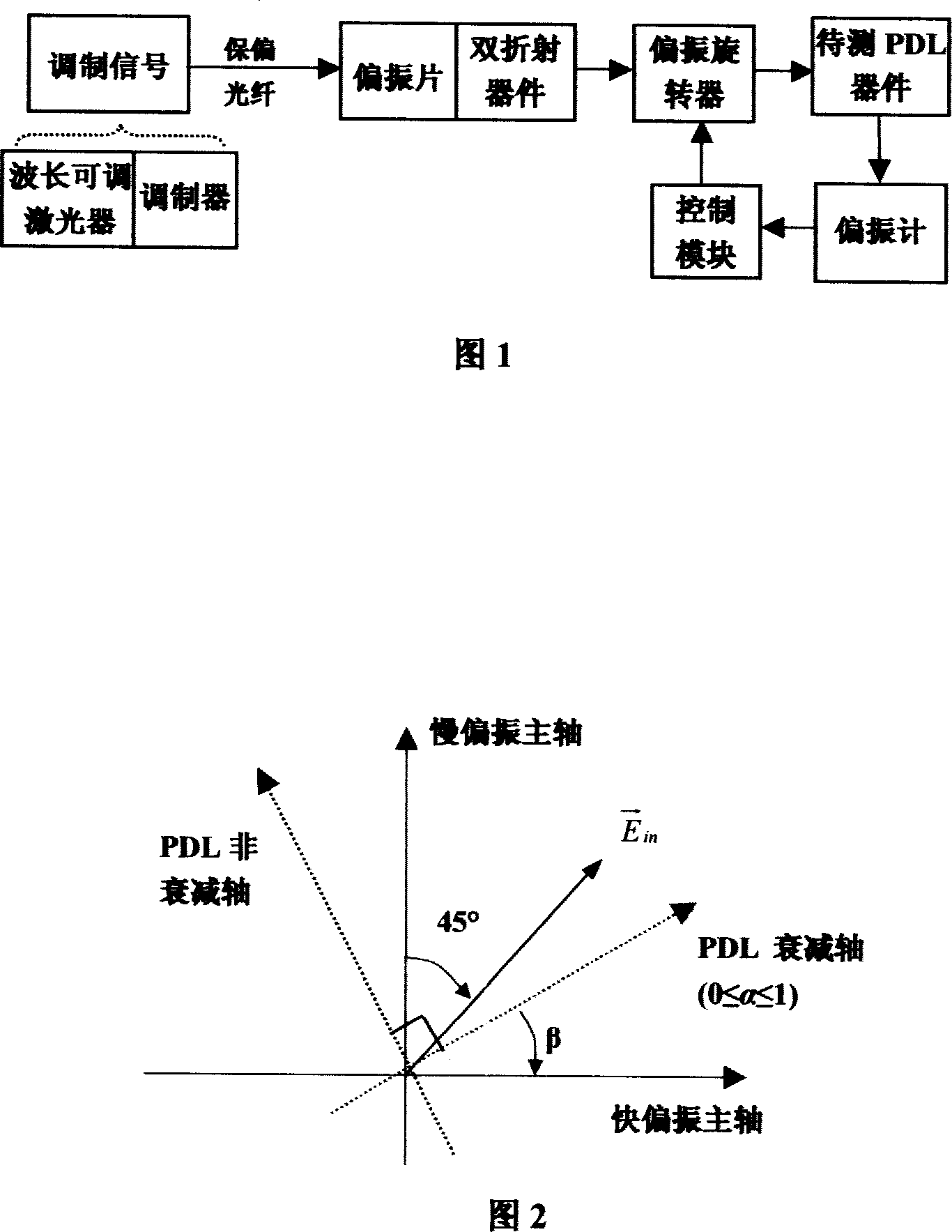

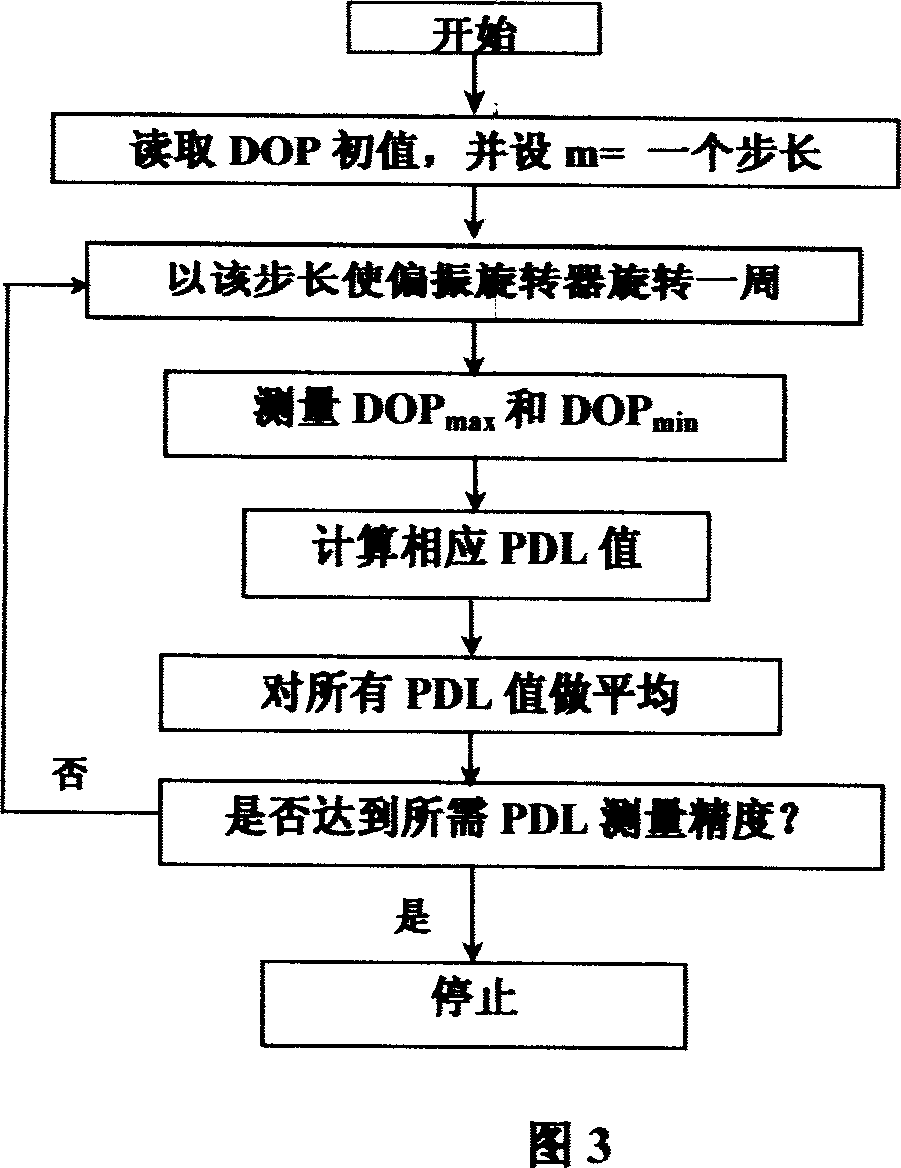

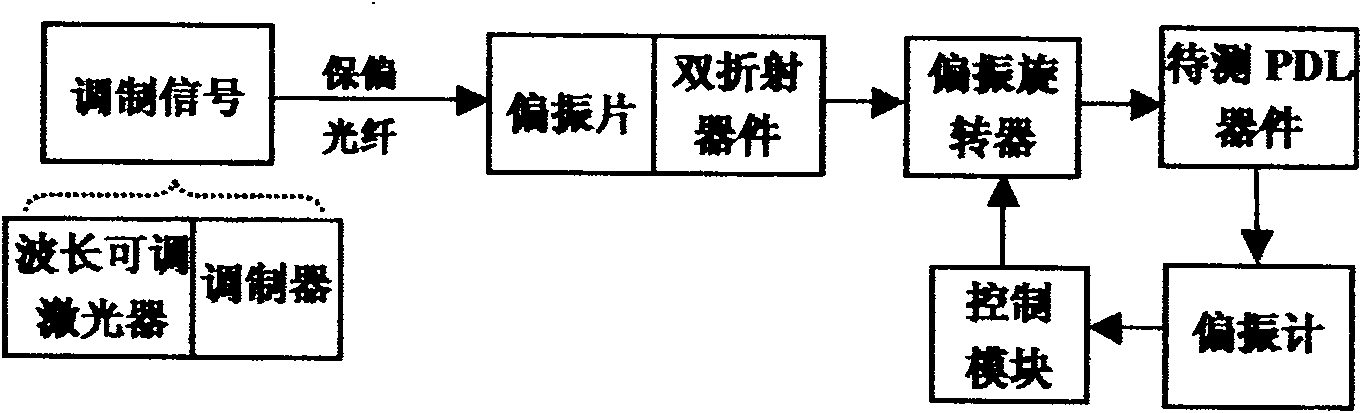

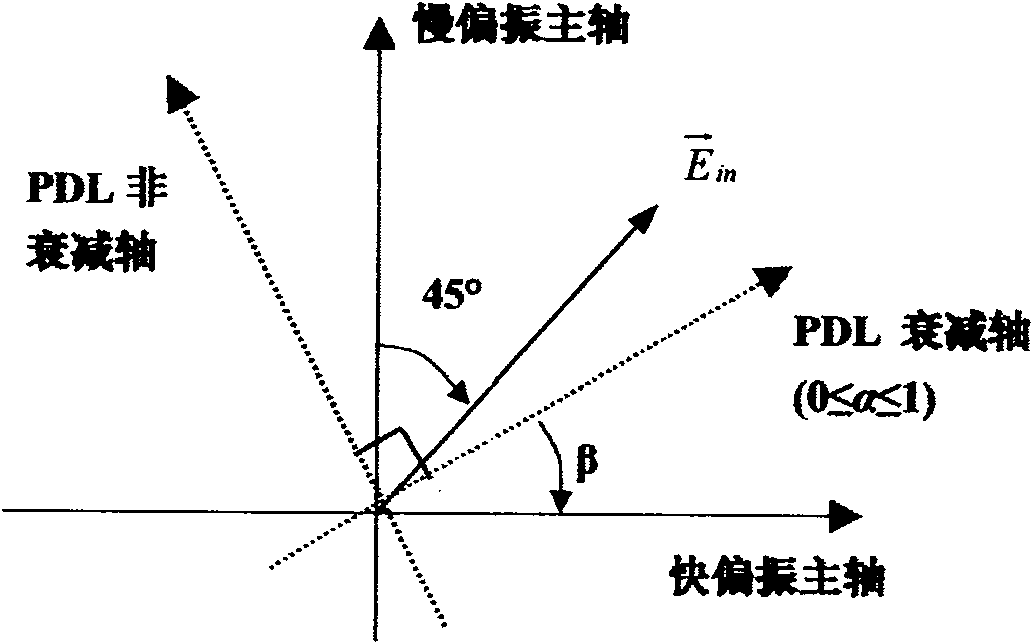

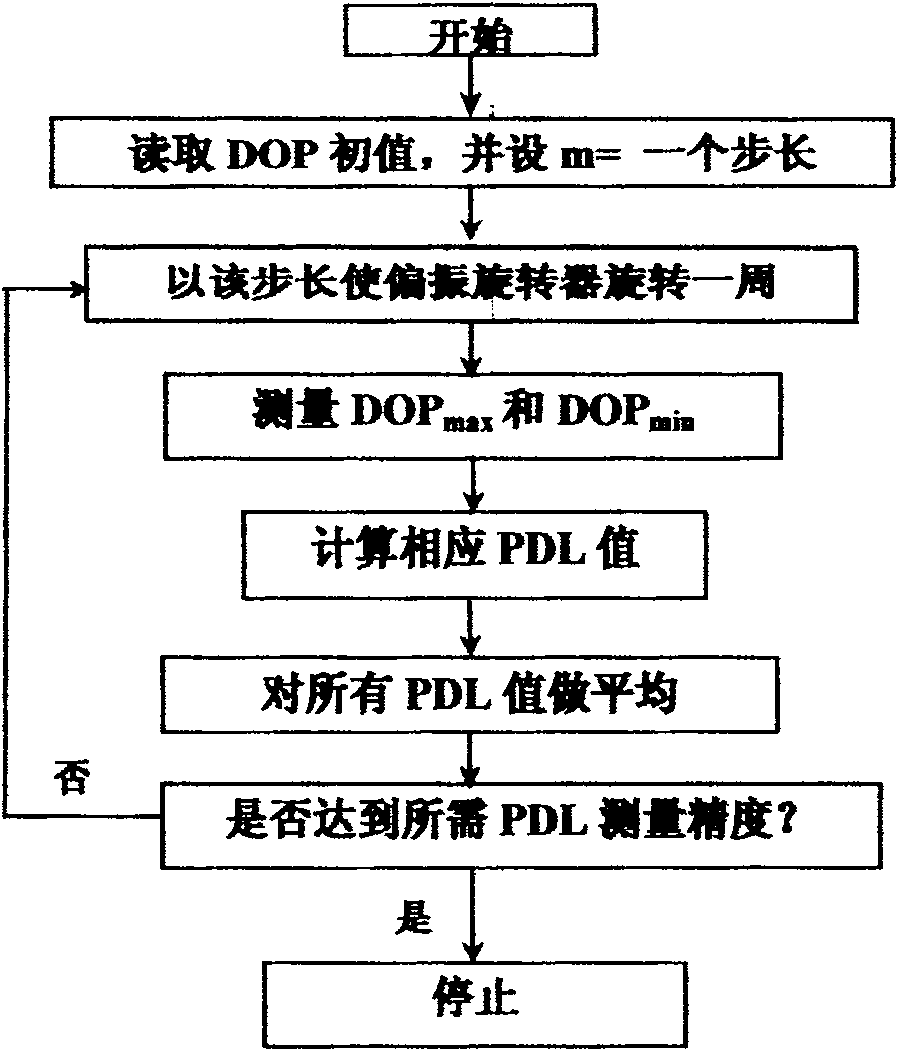

Measuring method for polarized dependent loss PDL

ActiveCN1988419ARealize intelligent measurementEfficient measurementElectromagnetic transmissionLength waveFeedback control

This invention relates to a measurement method for PDL characterizing that: an incident modulated optical signal enters into a dual-refraction device to pass through a polarization rotor, a PDL device to be tested and enters into a polarization meter finally to let the rotor rotate a circle axially to note down the appeared DOP maximum value and the minimum value and compute the PDL value of related device, which is advantaged that it can measure PDL value in optical devices or system under single wavelength or multiple wave lengths and realize intelligent measurement to PDL without monitor.

Owner:GUANGXUN SCI & TECH WUHAN

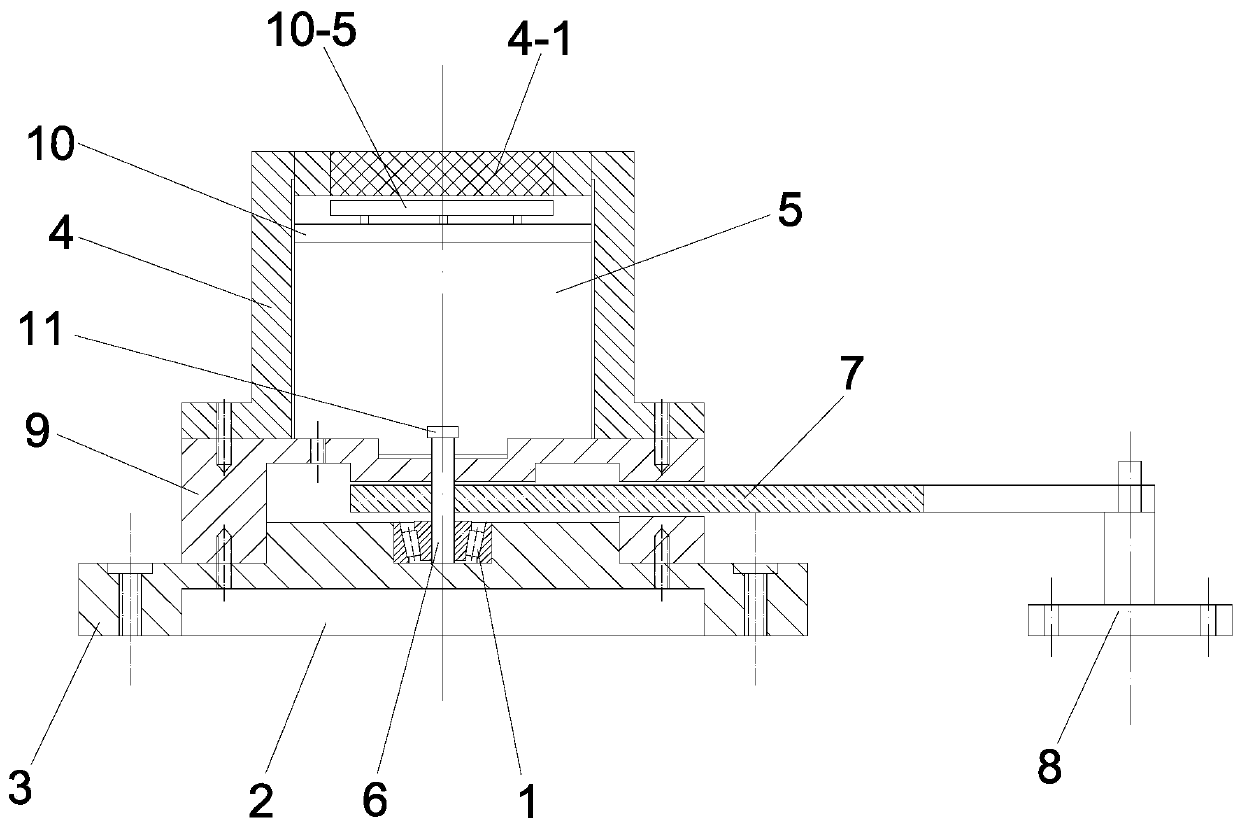

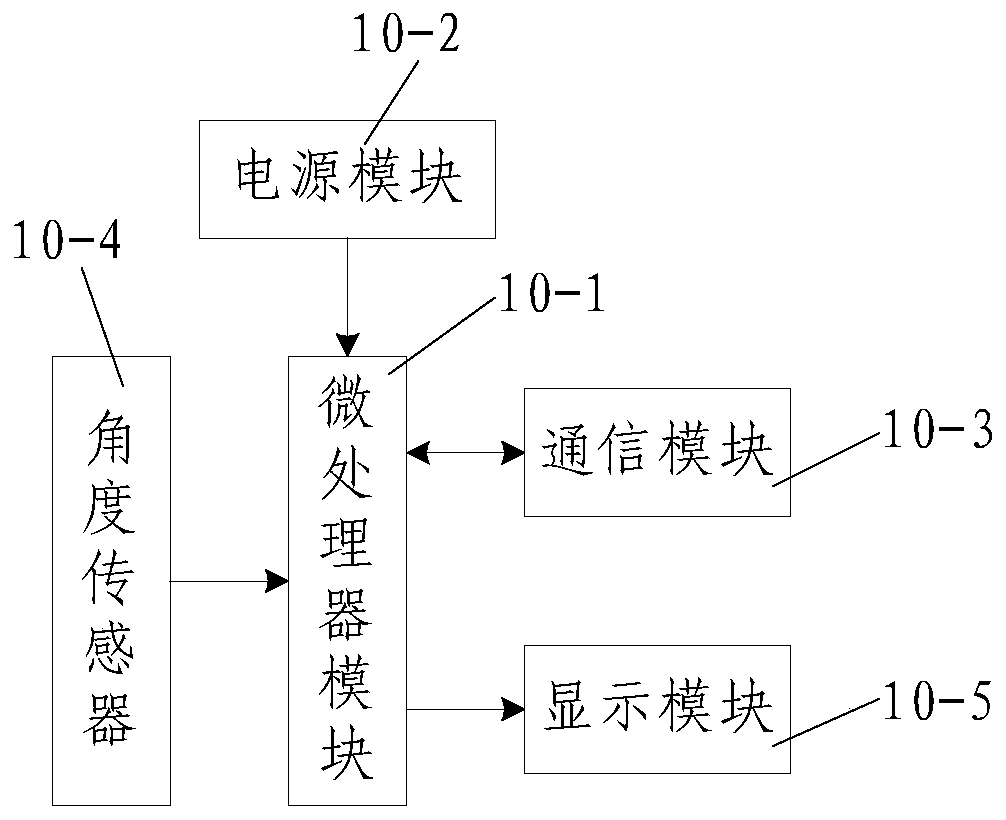

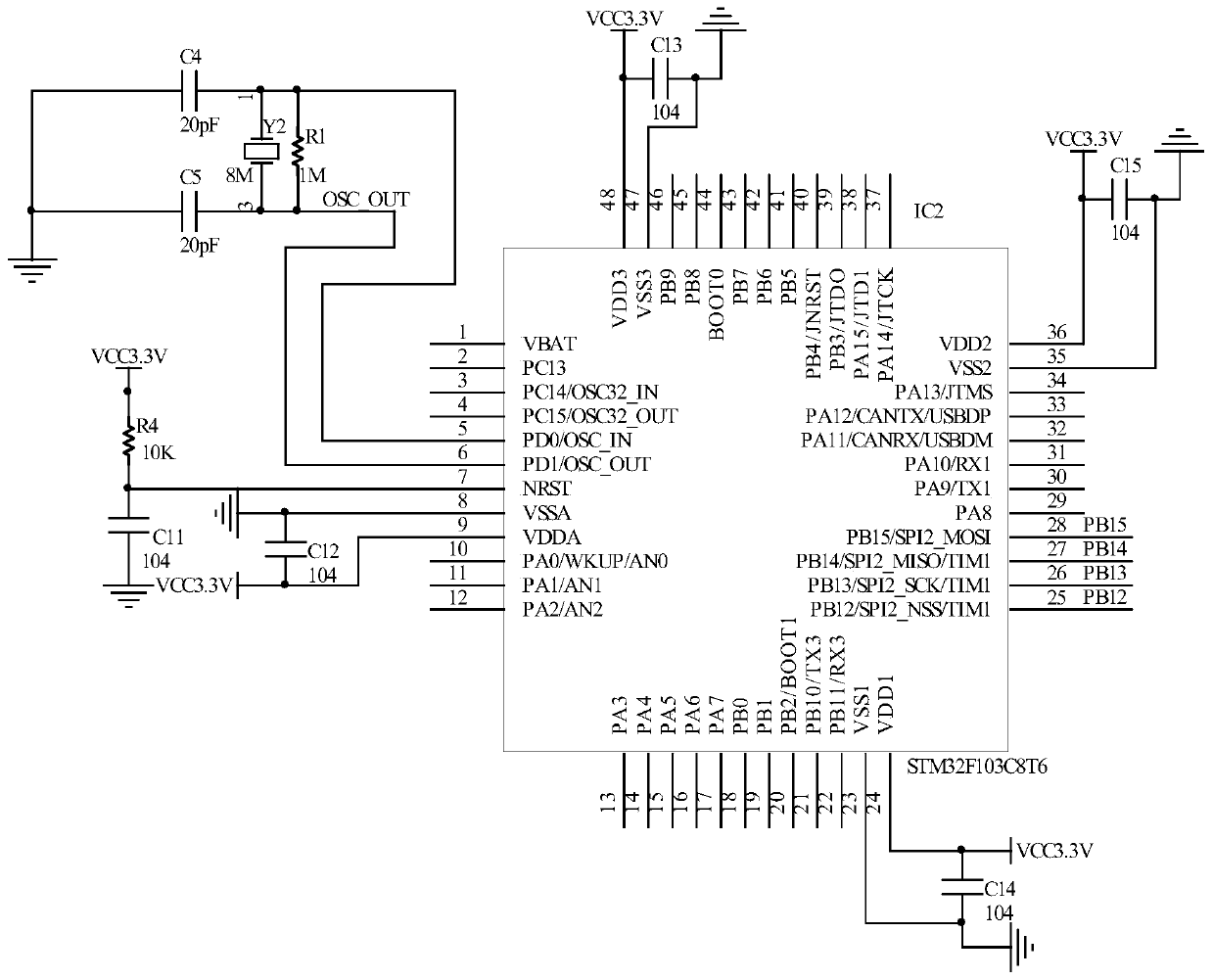

Detection sensor and detection method for angle of rocker arm of coal cutter

PendingCN109916295ASimple structureNovel and reasonable designSlitting machinesUsing electrical meansComputer moduleRocker arm

The invention discloses a detection sensor and a detection method for an angle of a rocker arm of a coal cutter. The sensor includes a base, a base top cover and a rocking bar; the base is connected with a revolving shaft, and the rocking bar is fixedly connected with the revolving shaft; one end of the rocking bar that is not fixedly connected with the revolving shaft is connected with a connection base; the top of the revolving shaft is provided with circular magnetic steel; the top of the base top cover is connected with a sensor protective shell; an inner cavity of the sensor protective shell is a circuit board installation cavity and a sensor circuit board is installed in the circuit board installation cavity; the sensor circuit board is integrated with a sensor circuit; and the sensor circuit includes a microprocessor module, a power supply module, a communication module, an angle sensor, and a display module. The method includes the following steps: 1. installing the sensor; and2. detecting the angle of the rocker arm of the coal cutter. The sensor is novel and reasonable in design, is convenient to implement, is good in work stability and reliability, is strong in anti-interference capability, is high in detection precision, provides guarantee for realization of automatic height adjustment of the coal cutter, is strong in practicability, and is convenient for popularization and usage.

Owner:XIAN UNIV OF SCI & TECH

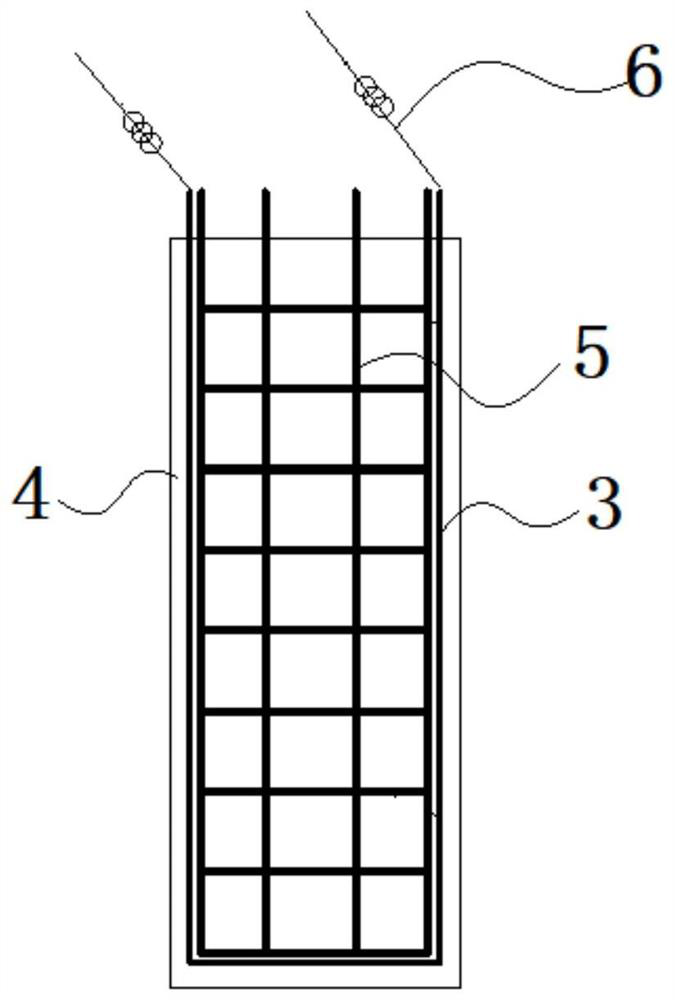

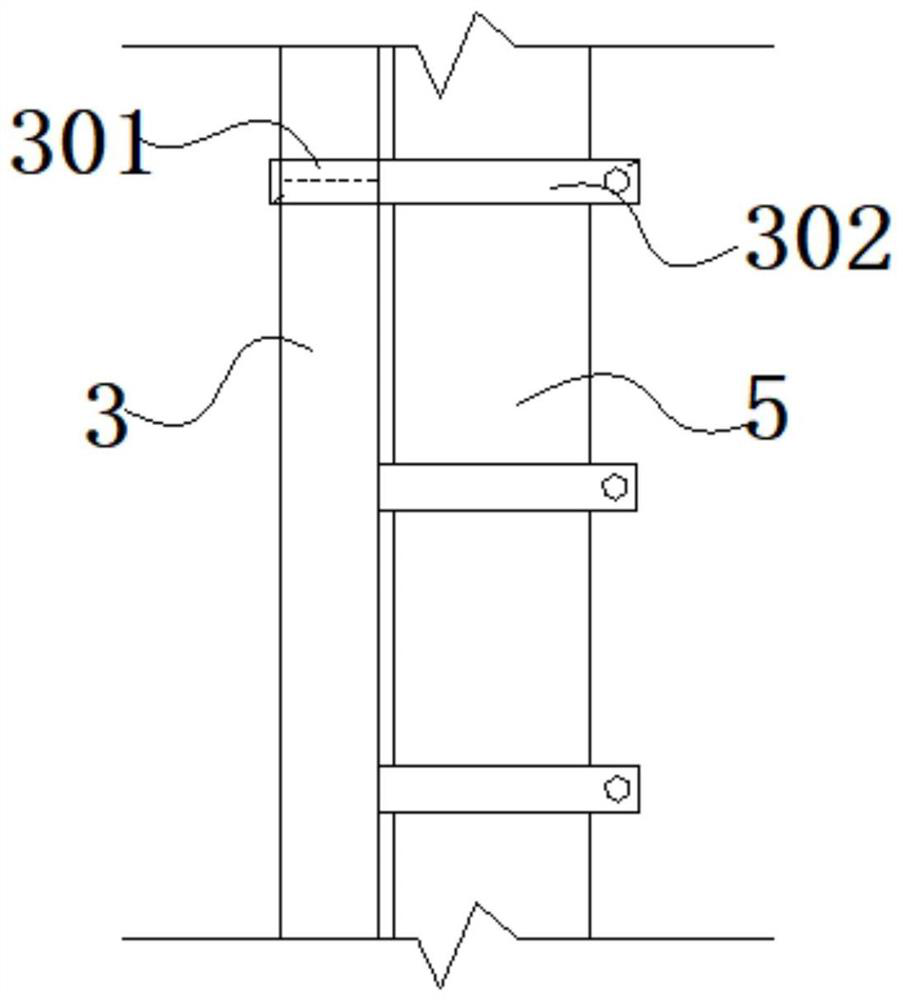

Cast-in-place pile optical fiber monitoring system and method

PendingCN112648931AEffective protectionAvoid destructionFoundation testingUsing optical meansMonitoring siteMonitoring system

The invention discloses a cast-in-place pile optical fiber monitoring system. An optical fiber sensor is arranged in each cast-in-place pile monitoring point; each optical fiber sensor is arranged on a main reinforcement of a cast-in-place pile a through protection fastener; the optical fiber sensor is connected with an optical fiber outgoing line; and the optical fiber outgoing line is communicated with a detection module. The system realizes a foundation pit deformation automatic monitoring function, has the advantages of convenient measurement, high measurement efficiency, small influence of a measurement environment, real-time early warning and the like, realizes an intelligent measurement function, and enables measurement to be informationized; the protection fastener can effectively protect the optical fiber sensor and prevent the optical fiber sensor from being damaged by construction, and is high in practicability; and meanwhile, the foundation pit monitoring of each construction site is realized by one optical fiber demodulator, problems caused by the condition that optical fiber demodulators are few and are expensive are solved; and field technicians do not need to be additionally dispatched for monitoring, the management is convenient, the monitoring efficiency is greatly improved, and the monitoring cost is greatly reduced.

Owner:中铁二十二局集团市政工程有限公司

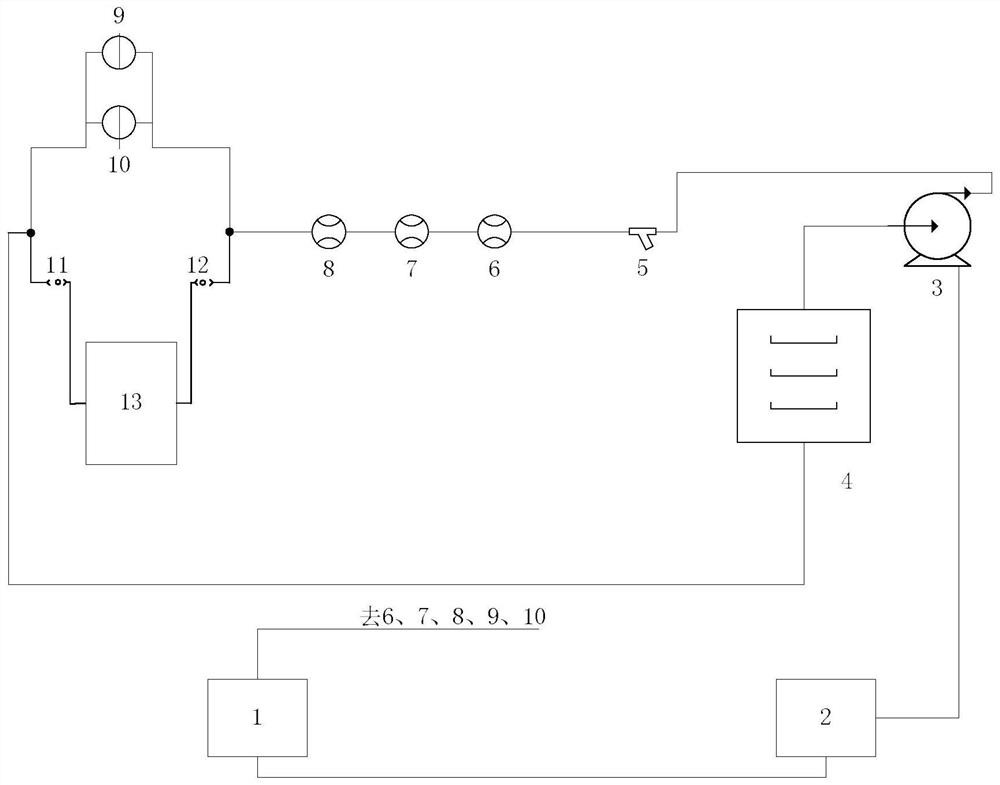

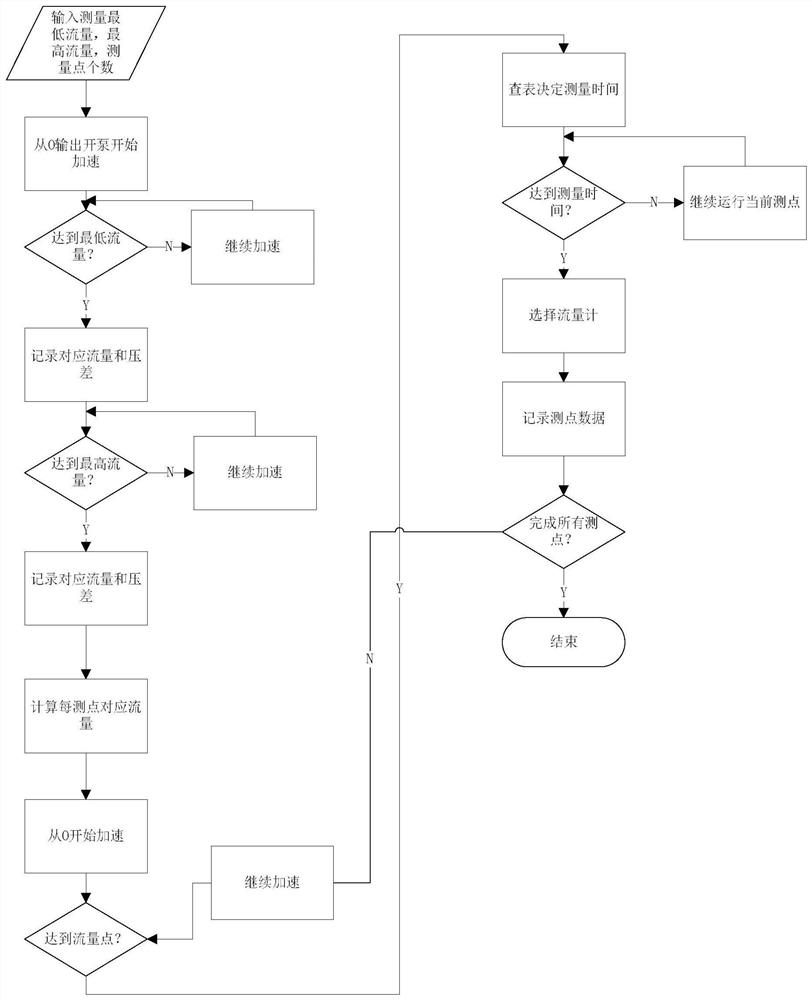

Automatic flow resistance control system for minimum flow

According to an automatic flow resistance control system for minimum flow, a small flow can be continuously measured in real time, and the measurement precision is high. According to the technical scheme, a positive displacement pump is communicated with a flow and flow resistance circulation loop formed by series flow pipes of a positive displacement flow meter, a differential pressure flow meter and an ultrasonic flow meter, and the flow and flow resistance circulation loop is connected with a PWM voltage converter through a single-chip microcomputer; and the single-chip microcomputer 1 realizes equal proportion conversion of a duty ratio PWM signal and a voltage signal through a PWM signal-to-analog signal module to form a direct current control voltage to drive a motor, the single-chip microcomputer selects a reading of a corresponding measuring range flow meter to directly drive a dual-mode PWM control circuit in a pump motor to adjust the rotating speed of the motor and a pump, the readings of the selected flow meter and the differential pressure sensor at the corresponding moment are collected at the tail of each time slice to form measuring points, then the measuring step length is automatically set according to the number of the input measuring points, and the measurement of the differential pressure and the flow in the measuring range is achieved.

Owner:10TH RES INST OF CETC

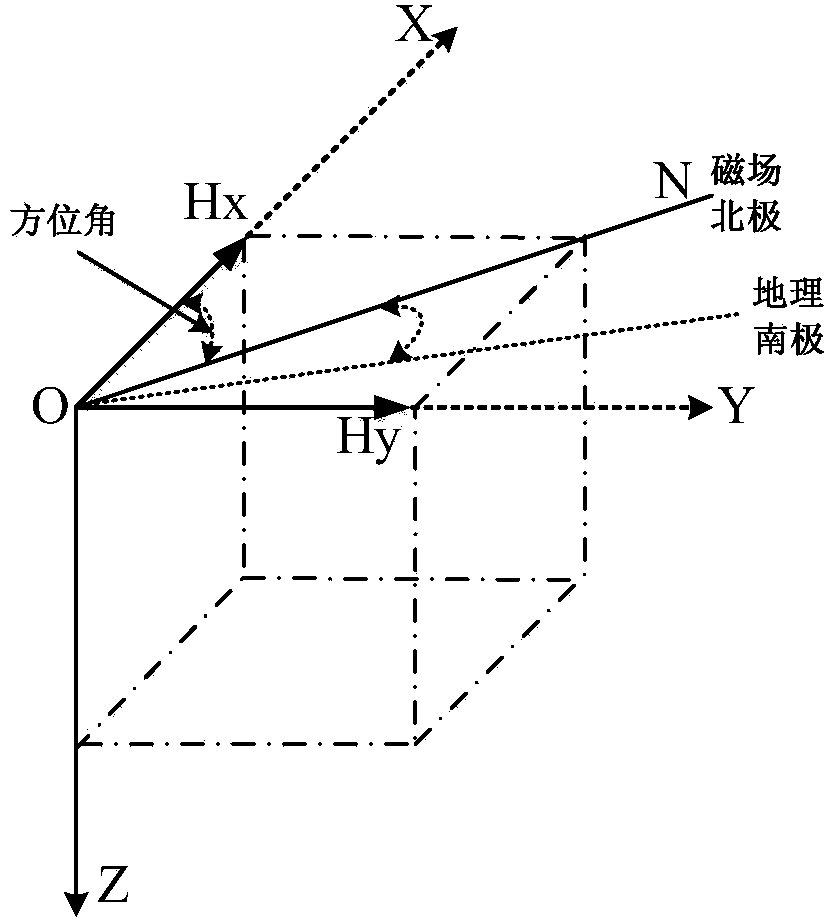

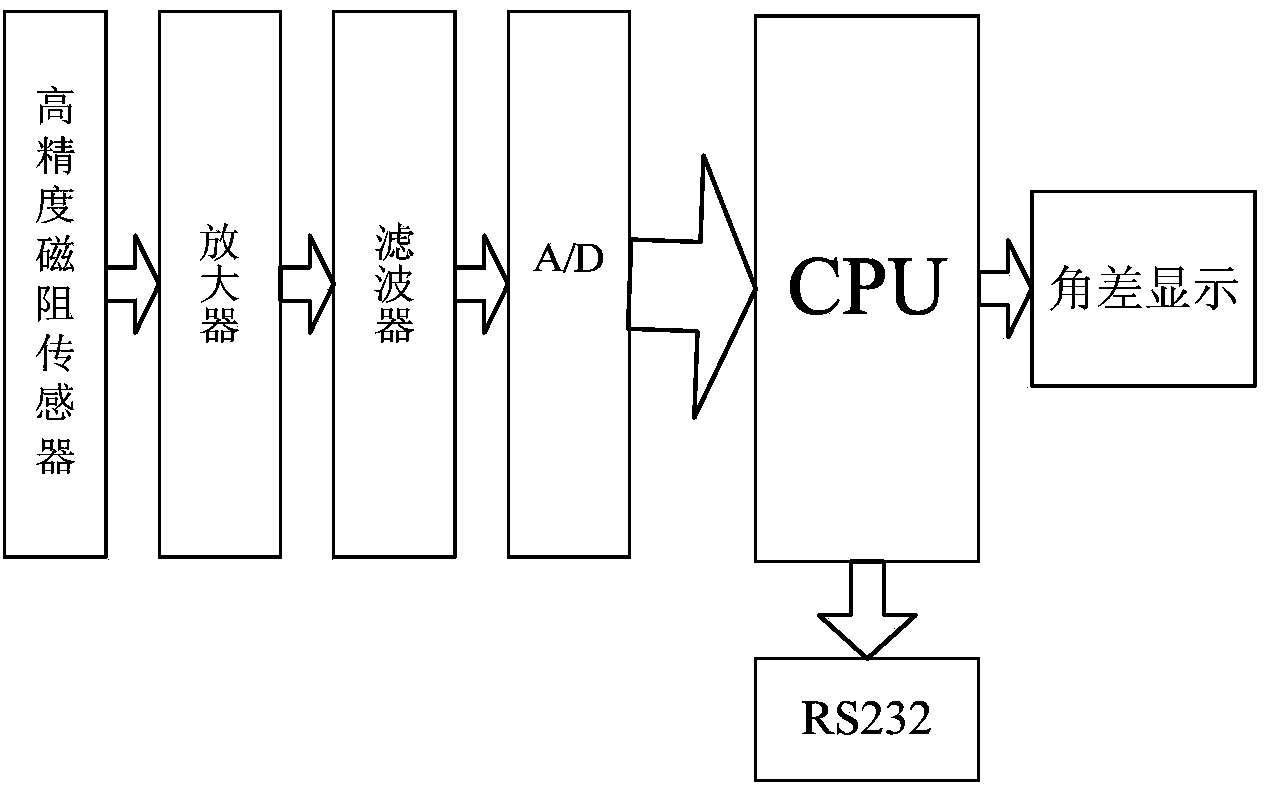

Intelligent drilling angular difference measurement device and angular different measurement method

ActiveCN104234697AHigh precisionRealize intelligent measurementSurveyMeasurement deviceEarth's magnetic field

The invention relates to an intelligent drilling angular difference measurement device and an angular difference measurement method. The measurement device comprises a geomagnetic field signal acquisition unit arranged in an annular cavity, wherein a level calibration unit for calibrating the geomagnetic field signal acquisition unit is also arranged in the annular cavity; the geomagnetic field signal acquisition unit is connected with a geomagnetic field signal preprocessing unit; the geomagnetic field signal preprocessing unit is connected with an angular difference measurement unit. According to the device and the method, the position of a starting point of a dial is regulated to be aligned with a zero point of MWD (measurement while drilling) or a zero point of a drilling tool, and an angular difference value is obtained by the steps of acquisition and preprocessing of a geomagnetic field signal, calculation and the like; a level gauge is arranged, so that an angular difference is only required to be measured twice under the condition of ensuring the levelness of the device, convenience in measurement is ensured, the number of measurement times is greatly reduced, the efficiency is improved, and measurement errors are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

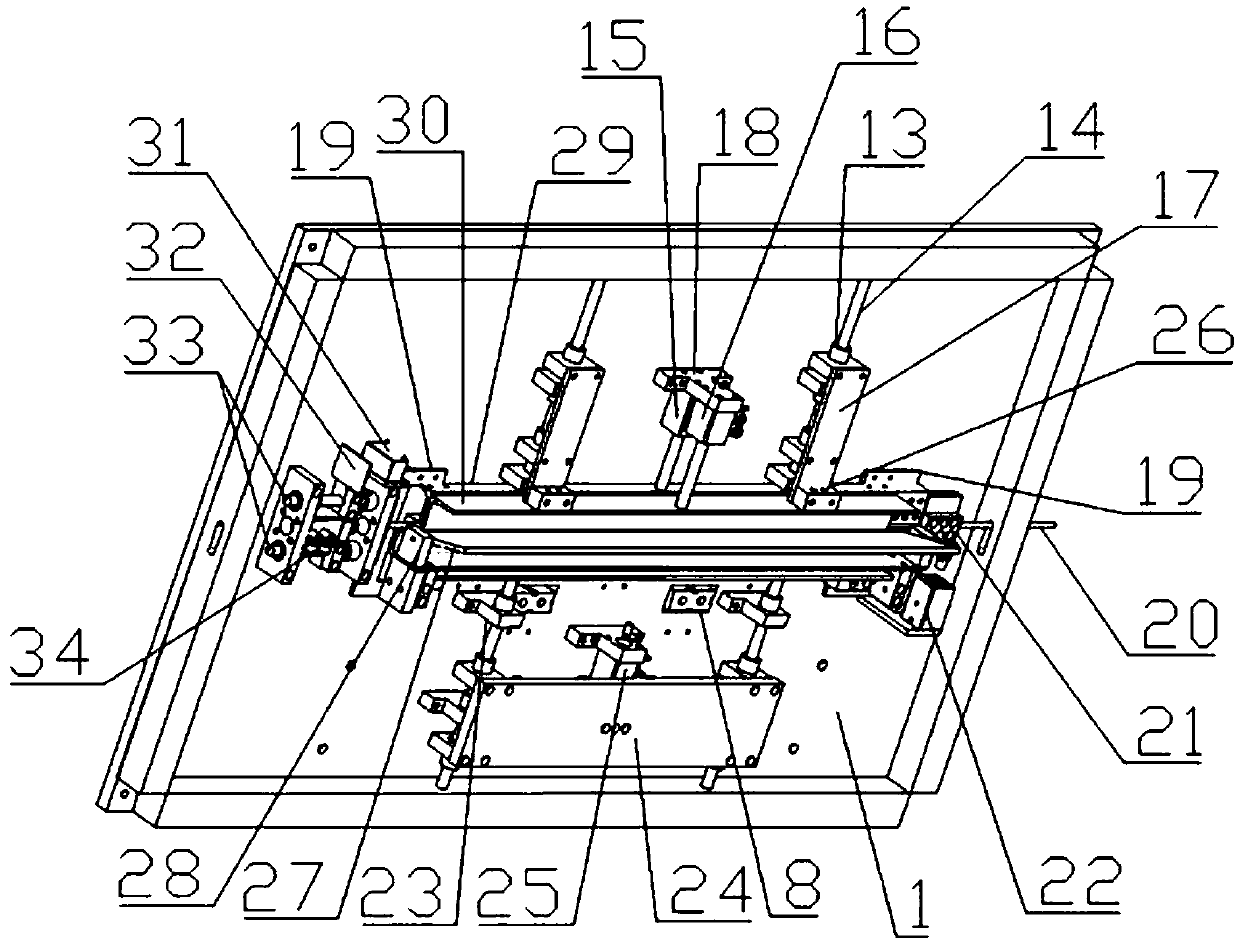

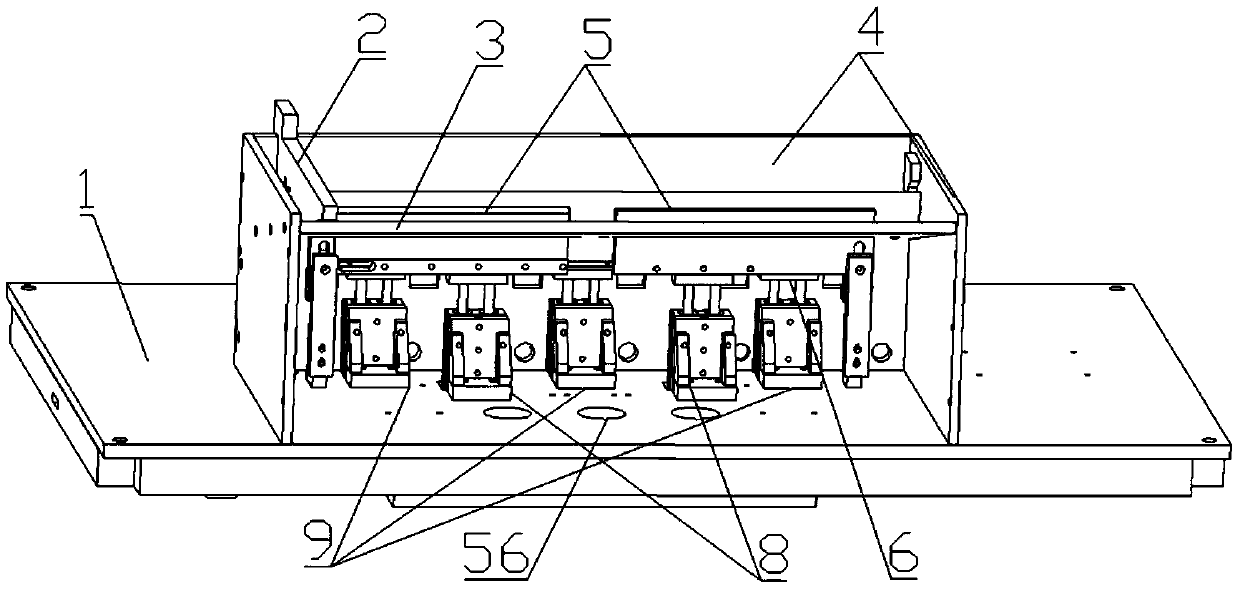

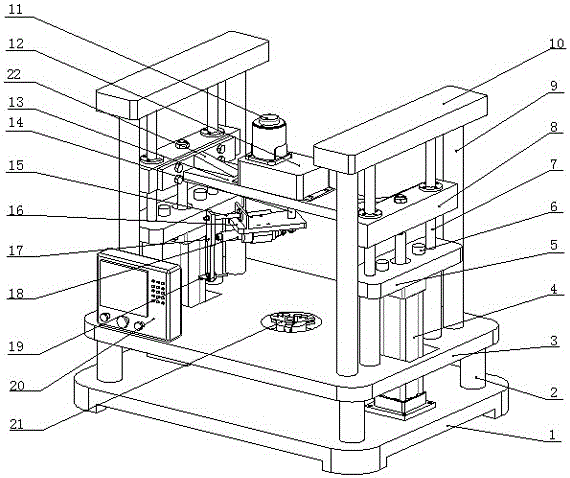

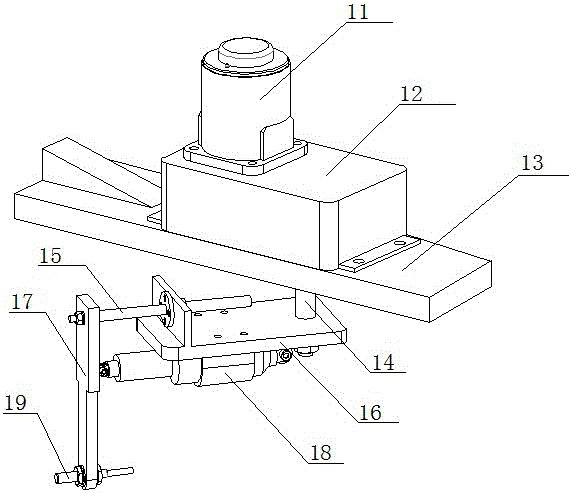

Pipe fitting length integrated detection device

PendingCN109622399ASolve the high error rate and poor accuracyThe solution process is cumbersomeSortingIndustrial engineeringProduction line

The invention relates to the technical field of pipe-like object length measuring, and provides a pipe fitting length integrated detection device. The pipe fitting length integrated detection device comprises a bearing platform, wherein a whole set of automatic detection device is mounted on the bearing platform. A feeding mechanism for normally and orderly controlling pipe fitting conveying is arranged on the bearing platform. A pipe fitting guide mechanism and a limiting and fixing mechanism are arranged on the bottom face of the bearing platform. A measuring mechanism for measuring the pipefitting length is further arranged on the bottom face of the bearing platform. According to the pipe fitting length integrated detection device, the pipe fitting length can be automatically detected,and pipe fittings conforming to the pipe length needed by production are screened; and the problems that when the pipe fitting length is measured by technicists, the error rate is high, and the precision is poor are solved, and the problem that due to the complex manual detection process, the detection efficiency of a whole production line is low is also solved.

Owner:重庆康世德源科技实业有限公司

Concrete carbonization depth detector and detection method

ActiveCN110658188AEasy to carryEasy to useMaterial analysis by observing effect on chemical indicatorUsing optical meansSprayerEngineering

The invention provides a concrete carbonization depth detector and a detection method. The concrete carbonization depth detector comprises a shell, a measuring device, a liquid spraying device and anair blowing device. The shell is provided with an air inlet, an air outlet and a display unit; a detection opening is formed in the plane part of the shell; and the diameter of the detection opening is larger than that of a to-be-detected hole in the surface of a concrete detection area. The measuring device consists of an annular lighting source, a visual sensor, a PLC, a laser displacement sensor, a rotation driving mechanism, a radial sliding driving mechanism, a data processor, a guide support and a fixing support. The liquid spraying device includes a reagent bottle, a low-pressure electric water pump, a liquid conveying pipe and a sprayer. And the air blowing device includes a motor and an impeller. According to the invention, the concrete carbonization depth detector integrating airblowing, liquid spraying and measuring functions can be carried and used conveniently; and because of automatic measurement and intelligent measurement of the carbonization depth of the laser displacement sensor, the measurement precision is greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

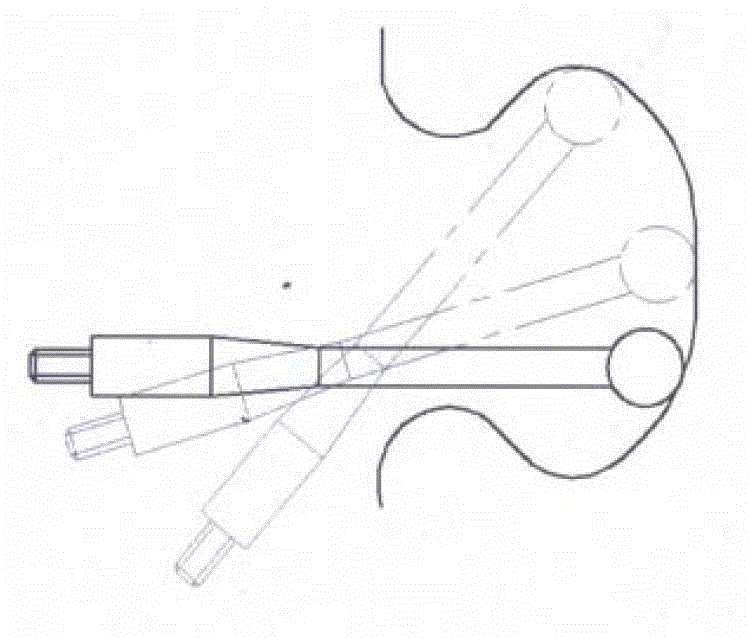

Lens component of intelligent image measurement instrument

InactiveCN110132148AIncrease coverage and flexibilityAchieving angular activity adjustmentUsing optical meansCamera lensEngineering

The invention discloses a lens component of an intelligent image measurement instrument. The lens component comprises a fixing structure, and a camera and a lens installed on the fixing structure; thelens is installed below the shooting position of the camera; the fixing structure comprises an installation rod and a placement board fixed at the lower part of the installation rod; the camera is rotationally installed on the placement board in a clamping and limiting manner. According to the lens component provided by the invention, the whole structure is fixedly or movably connected onto the detection structure via the installation rod, so that when the lens component is used for observing a detection sample, the observation detection angle position of the camera and lens can be controlledvia the installation rod, and thus intelligent measurement is achieved; when in rotating, the camera can elastically enter a blind hole through pressing limiting bumps by the limiting rod; when the camera is rotated for a certain angle, the limiting rod is positioned between the adjacent limiting bumps again, the limiting bumps are raised elastically, so that the rotation angle of the camera canbe limited, and thus the active adjustment on the angles of the camera and the lens can be achieved, and the shooting coverage and flexibility can be improved.

Owner:HENAN JIANYI TECH CO LTD

System and method for implementing gem identification based on Raman spectrum and OCT

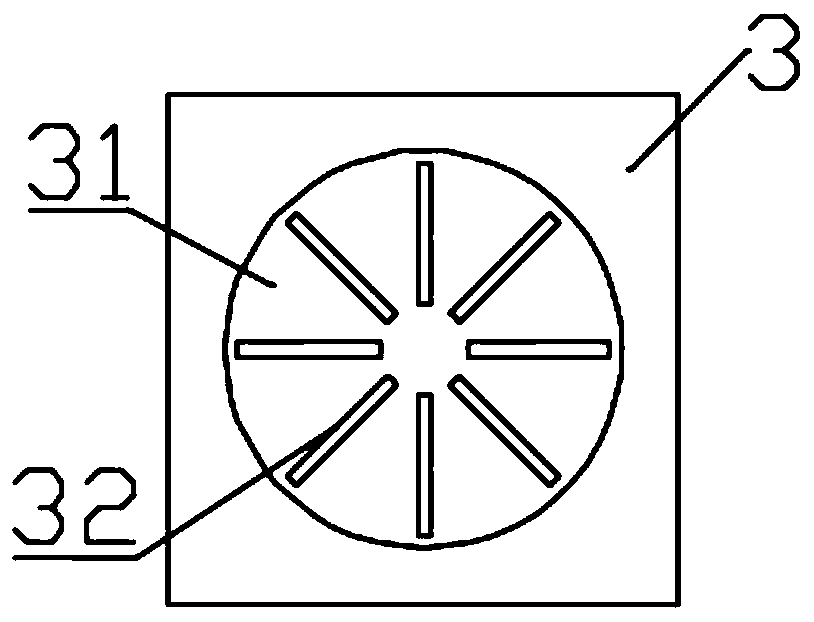

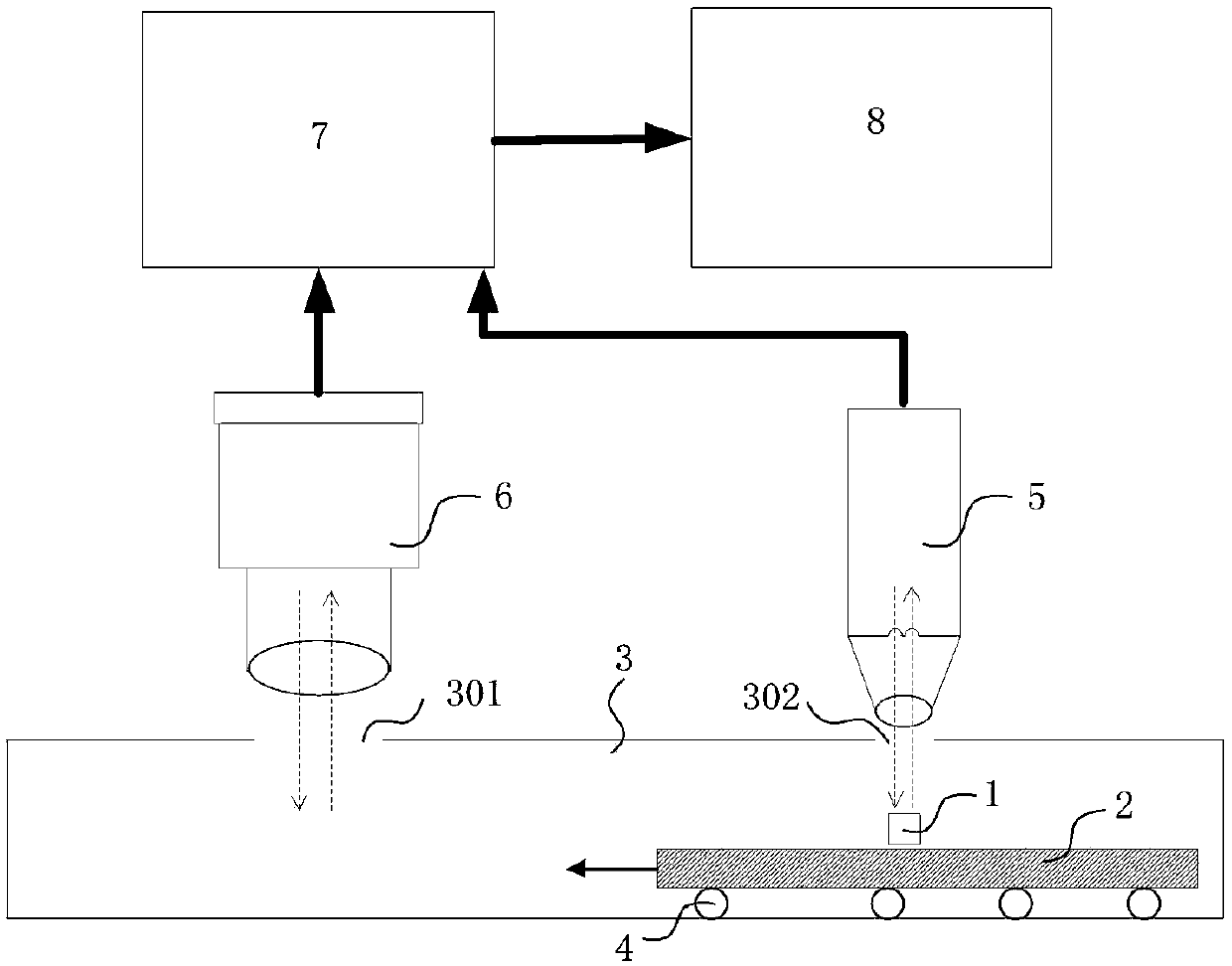

InactiveCN108918504AReduce operation unchangedReduce resource overlapPhase-affecting property measurementsRaman scatteringOptical pathOptical path length

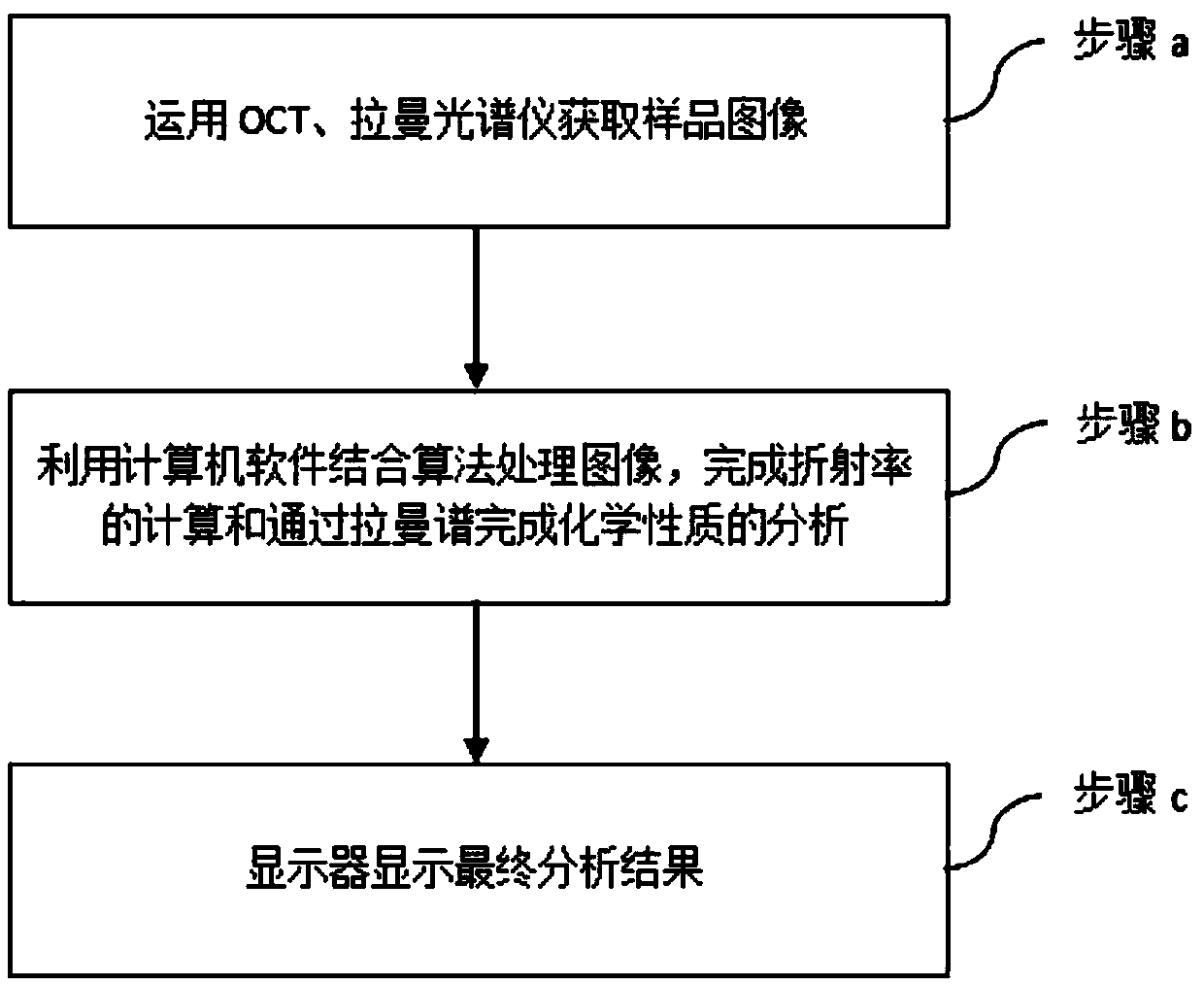

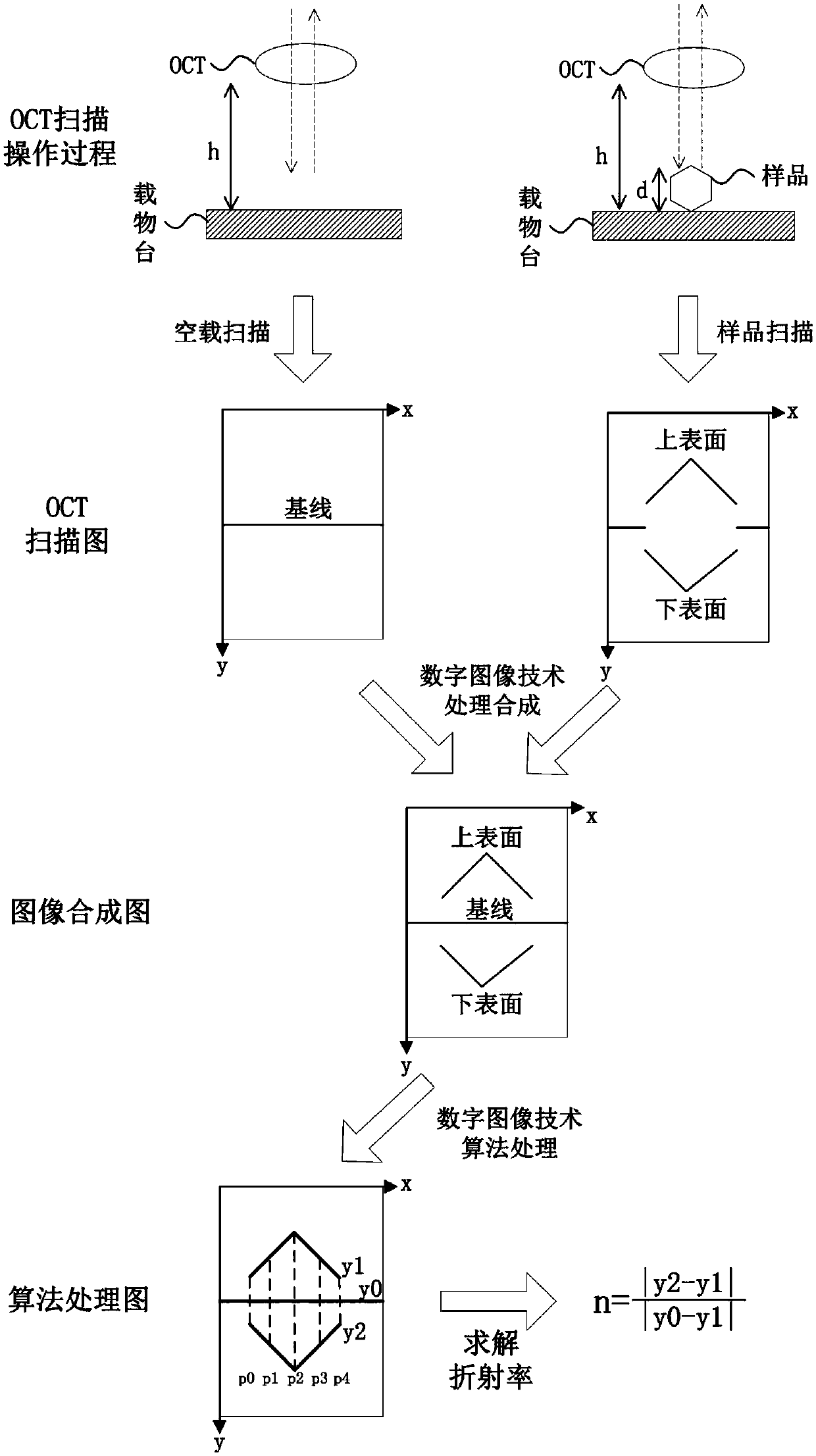

The invention discloses a system and a method for implementing gem identification based on Raman spectrum and optical coherence tomography (OCT). The system comprises a gem sample, a glass slide, a cassette, a mobile platform, a Raman spectrometer, an OCT, a data extraction and processing module and a display, wherein the cassette comprises two light holes. The method comprises the steps of firstly using OCT to acquire a no-load image via the light holes during no-load of the glass slide, and then separately using OCT and the Raman spectrometer to detect the sample on the glass slide, to acquire a sample spectrogram and an OCT image; using computer software to analyze the image to acquire boundary and distance information of the sample, completing the computation of a refractive index viaan optical path matching principle, and analyzing a Raman spectra to acquire a chemical property of the sample; and finally displaying a measurement result via the display. The system and method are simple in design, simple and convenient to operate, and achieve quick switching on measurement of the same sample; measurement and comprehensive analysis of multiple indexes such as physical property (optical refractive index) and chemical components of the irregular gem material are implemented; and meanwhile, the method achieves automation, digitization and intelligent measurement of optical refractive indexes of different faults of the gem.

Owner:GUANGZHOU MEDICAL UNIV

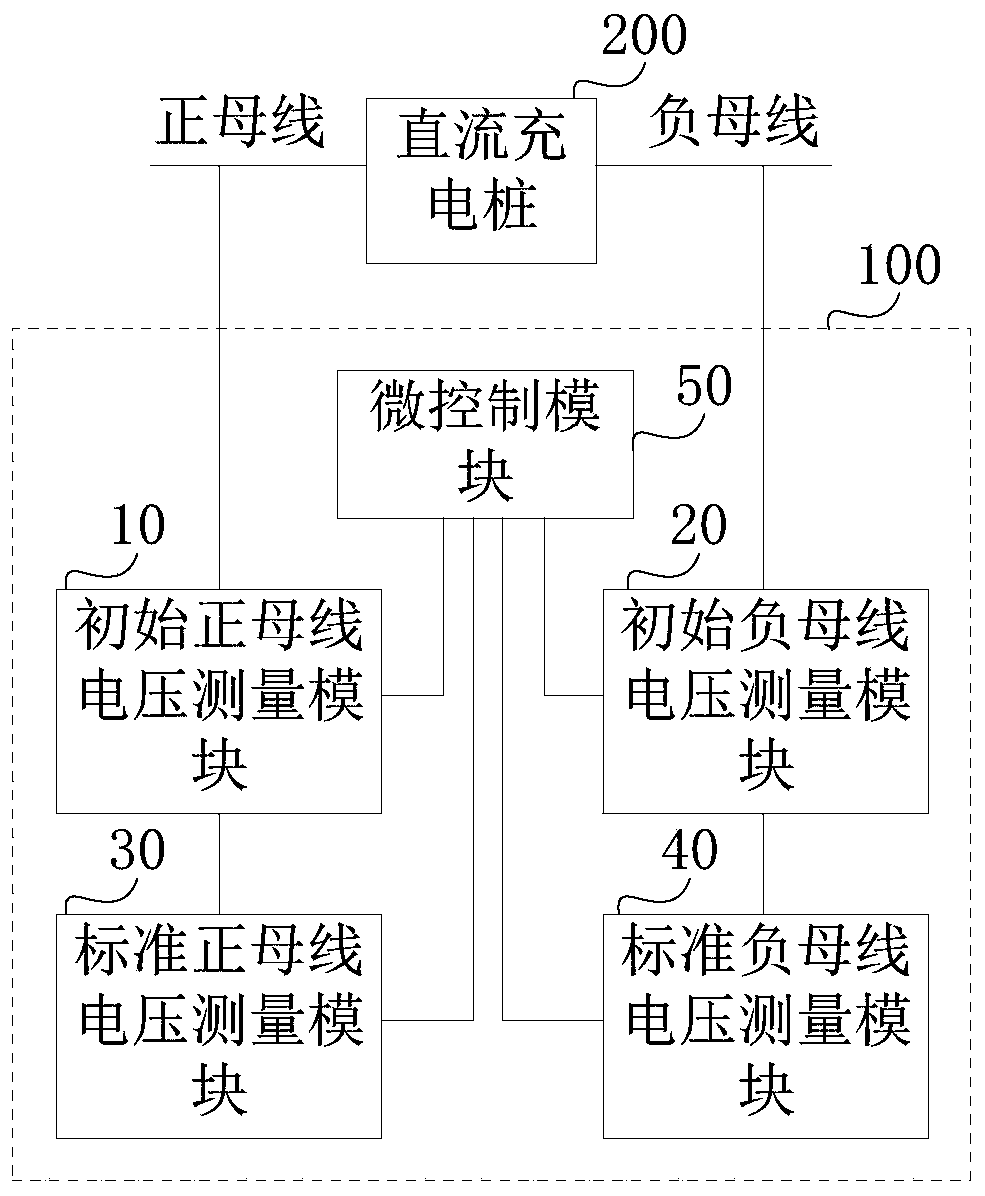

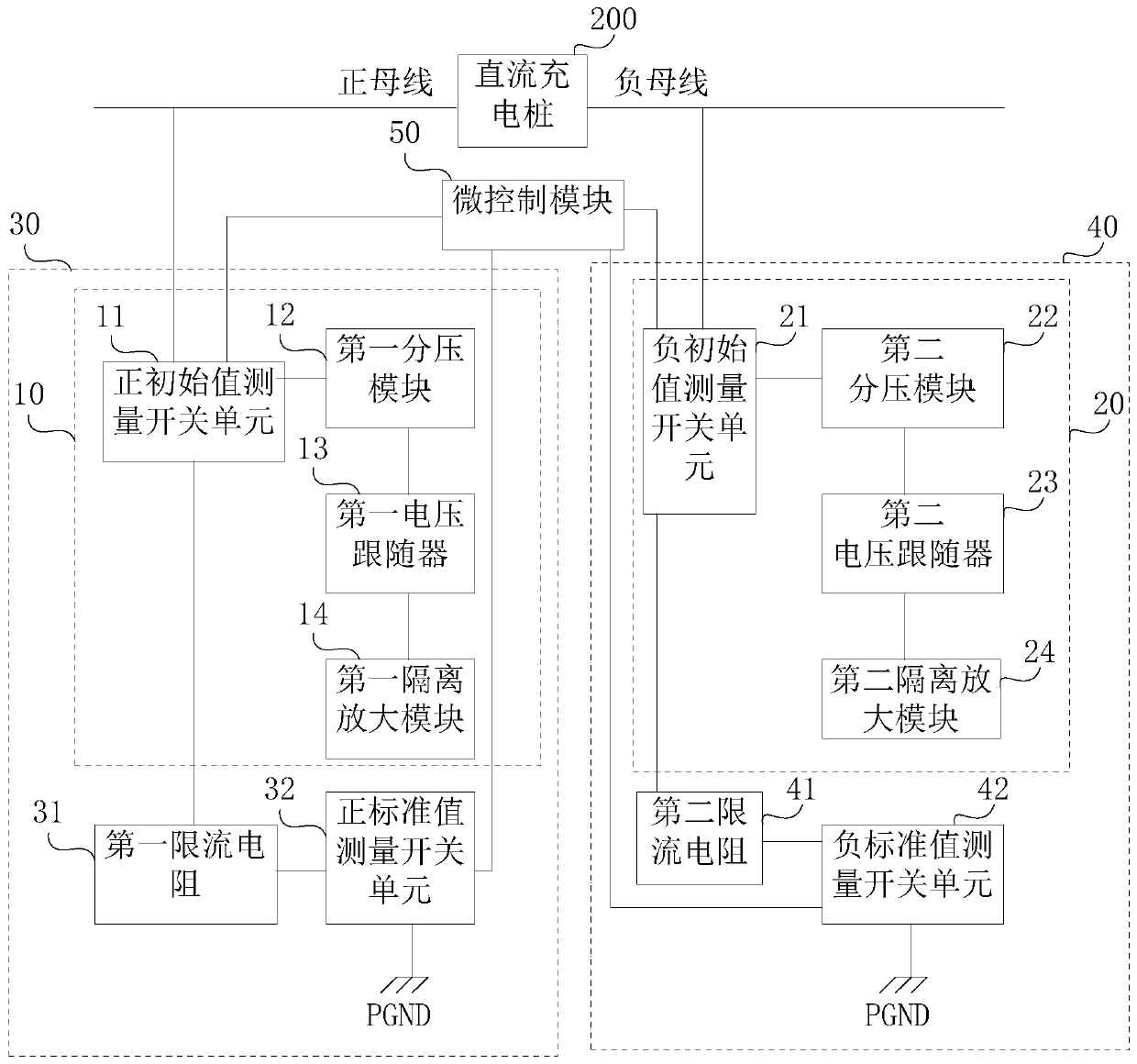

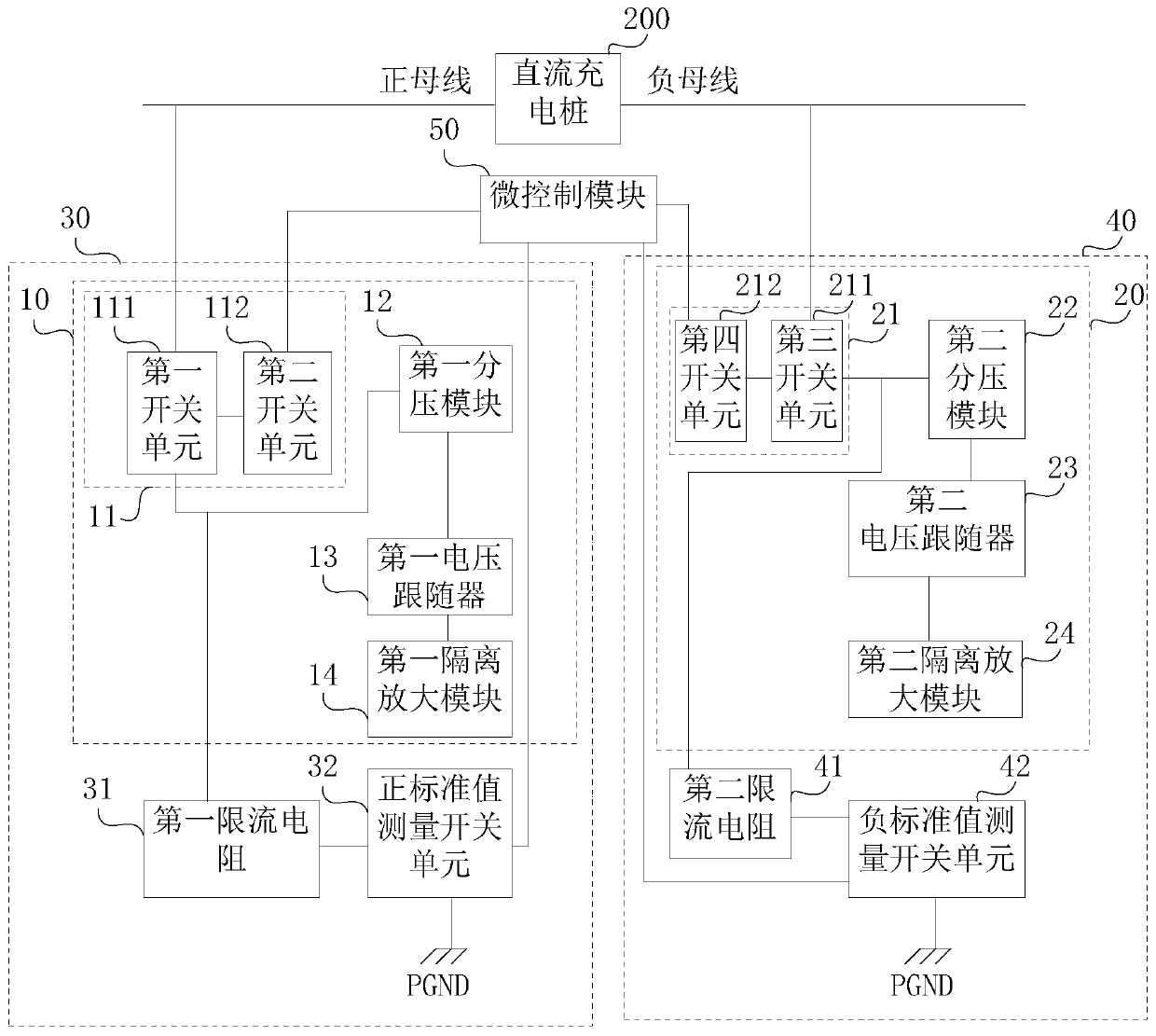

DC charging pile insulation monitoring circuit and method

ActiveCN111366785ARealize intelligent measurementRealize monitoringVery high resistance measurementsControl theoryBus

The invention relates to a DC charging pile insulation monitoring circuit and method. The circuit comprises an initial positive bus voltage measurement module, an initial negative bus voltage measurement module, a standard positive bus voltage measurement module, a standard negative bus voltage measurement module and a micro-control module. The micro-control module is used for sending a positive initial voltage signal, a negative initial voltage signal, a positive standard voltage signal and a negative standard voltage signal to the initial positive bus voltage measurement module, the initialnegative bus voltage measurement module, the standard positive bus voltage measurement module and the standard negative bus voltage measurement module. Positive / negative insulation resistance values of the positive bus and the negative bus to the ground are calculated based on the received positive initial voltage signal, negative initial voltage signal, positive standard voltage signal and negative standard voltage signal, and when it is judged that the positive / negative insulation resistance values exceed the corresponding threshold values, an alarm signal is sent out, so that the working safety of the direct-current charging pile is improved.

Owner:南方电网电动汽车服务有限公司 +1

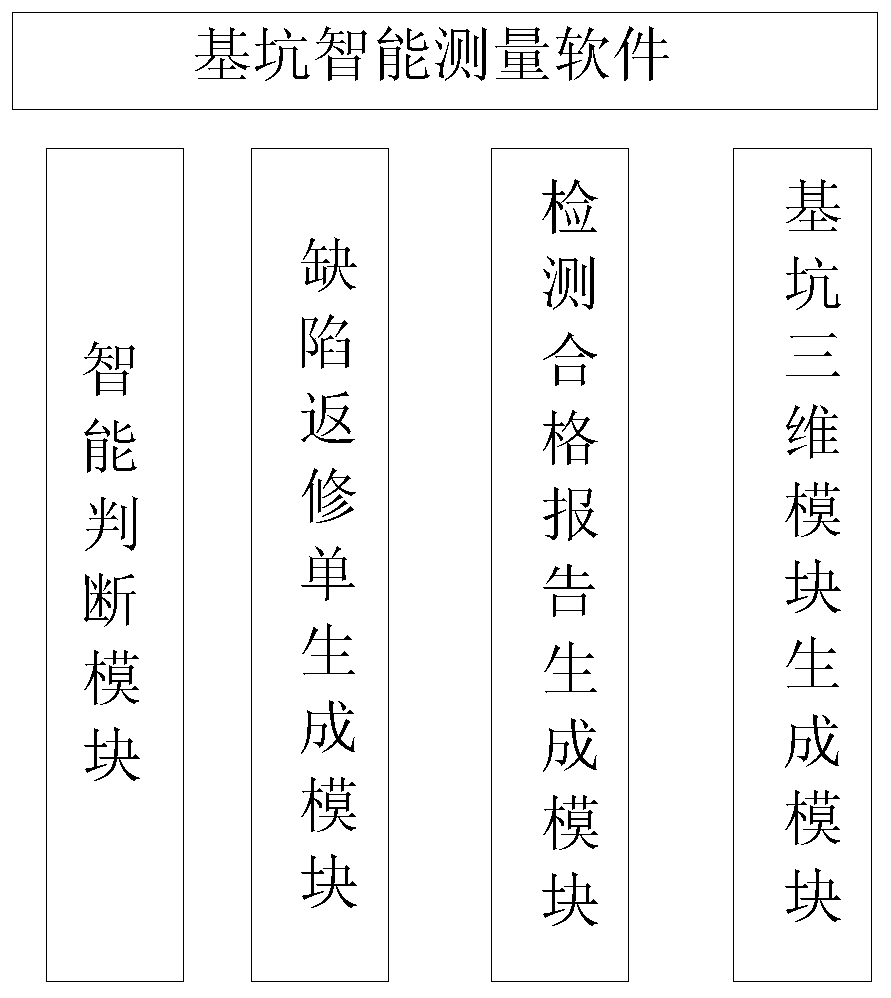

Intelligent foundation pit measurement system and method

The invention discloses an intelligent foundation pit measurement system and method. The system comprises a central processing unit and at least nine ranging units, wherein all the ranging units are communicably connected with the central processing unit; at least eight ranging units are horizontal-direction ranging units and at least one ranging unit is a vertical-direction ranging unit, the ranging direction of which is downward; the central processing unit is communicably connected with a ranging-end wireless communication module and a GPS positioning module; the ranging-end wireless communication module is used for being wirelessly and communicably connected with an intelligent mobile terminal; the intelligent mobile terminal is wirelessly and communicably connected with the central processing unit and a cloud data platform, and is provided with intelligent foundation pit measurement software; and the intelligent foundation pit measurement software comprises an intelligent judgement module, a defect repair list generation unit and a detection qualification report generation module. By utilizing the system and method, the intelligent control, measurement, acceptance inspection and acceptance inspection result generation of the foundation pits can be realized, so that the acceptance inspection efficiency and correctness of the foundation pits are effectively improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD QUZHOU POWER SUPPLY CO +1

An automatic radial runout measuring device

ActiveCN104515493BMeet the requirements of automatic radial runout detectionMeets measurement requirements for radial runout tolerancesMeasurement devicesEngineeringManipulator

The invention discloses an automatic radial run-out measuring device which comprises a frame body, a lifting mechanism, a measuring mechanism, a clamping mechanism and a controller. The automatic radial run-out measuring device has the advantages that workpiece automatic radial run-out measuring is achieved, workpiece clamping and measuring can be achieved, the whole process does not need manual interference, automatic production line online detection can be achieved by the device coordinating with a mechanical arm to perform feeding and discharging, the actions of each mechanism are controlled by the controller, measuring data is collected through the controller, and intelligent measuring is achieved; meanwhile, the automatic radial run-out detecting requirements of various types of workpieces can be satisfied, radial run-out of part elements relative to an excircle or an inner hole can be measured, and the device is wide in application range; during measuring, the space position of a measuring sensor can be set by a limit block and the measuring mechanism, and the radial run-outer tolerance measuring requirements of to-be-measured workpieces at different space positions can be satisfied.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

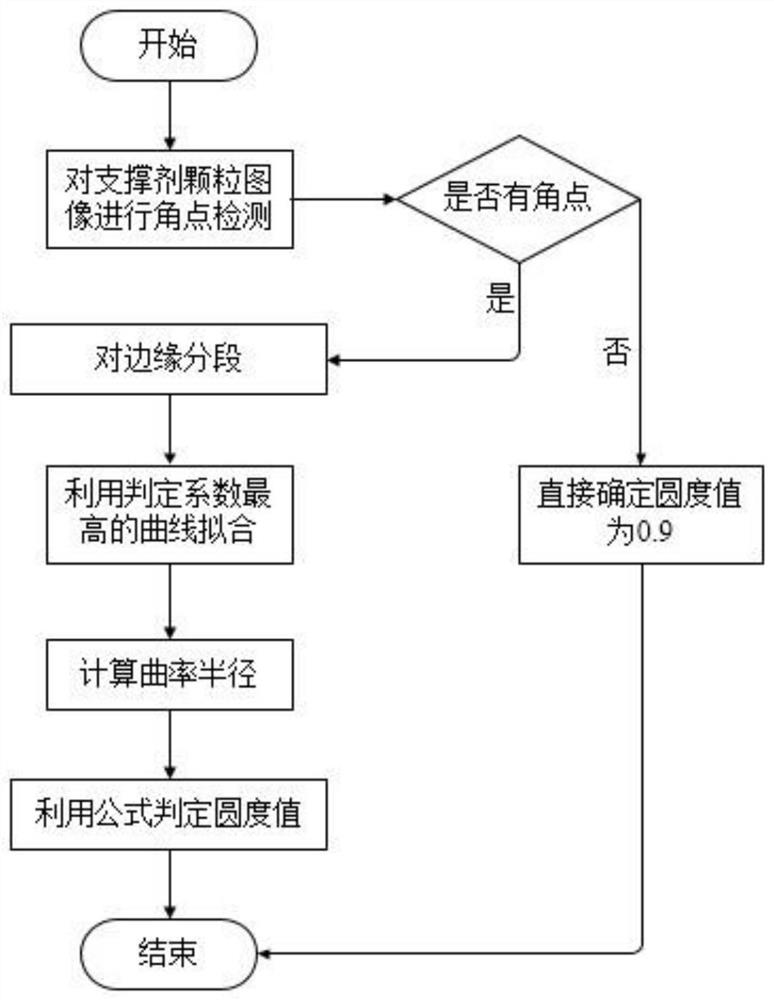

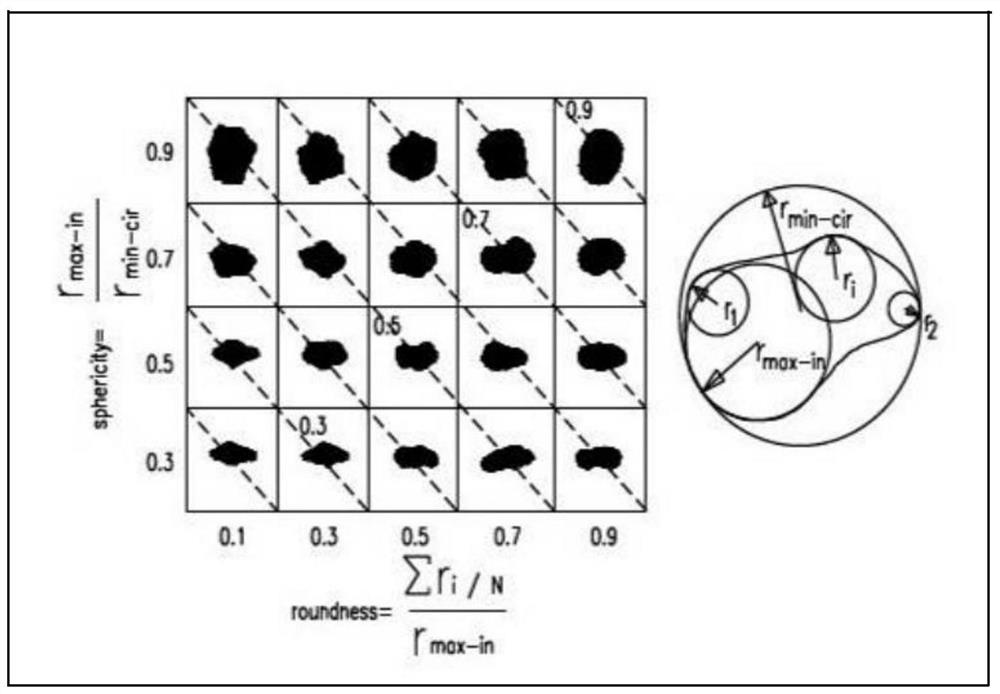

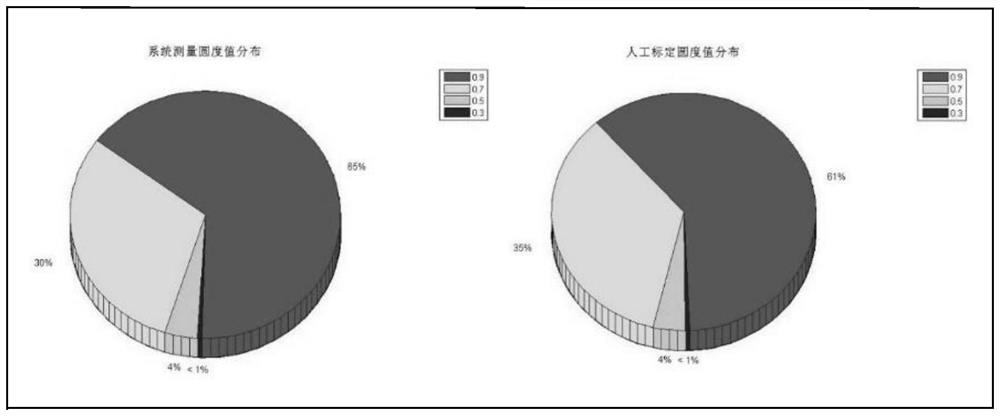

Fracturing propping agent roundness measuring method based on microscopic image processing

PendingCN114152211AAccurate measurementEfficient measurementImage analysisUsing optical meansMicroscopic imageMechanical engineering

The invention discloses a fracturing propping agent roundness measuring method based on microscopic image processing. The fracturing propping agent roundness measuring method comprises the following steps: carrying out angular point detection on each processed fracturing propping agent particle edge image; if no angular point is detected, the roundness of the fracturing propping agent particles is judged to be 0.9, and otherwise, the next operation is carried out; dividing the edge curve of each fracturing propping agent particle into a plurality of sections, and fitting each section of curve by using a high-order curve with the highest judgment coefficient to obtain a plurality of fitted curvilinear equations; and for the detected angular point, calculating the curvature radius of the angular point according to the serial number of the curve segment where the angular point is located, and obtaining the roundness value of each fracturing propping agent particle. According to the relationship between the angular point curvature radius and the maximum inscribed circle radius of the particles, the novel fracturing propping agent roundness measurement method is provided, the sphericity value measured by the method is accurate and effective, and intelligent measurement is achieved.

Owner:PETROCHINA CO LTD

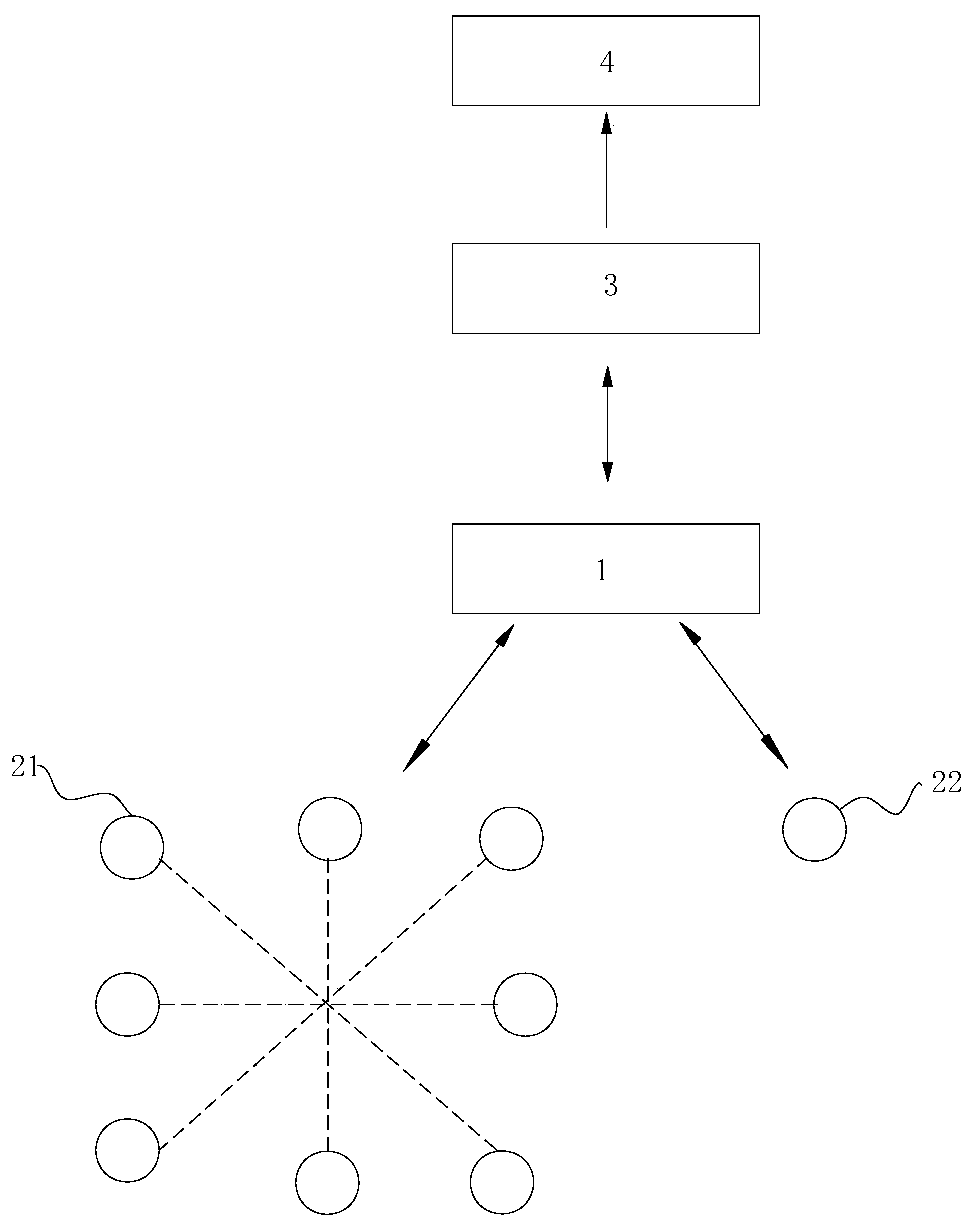

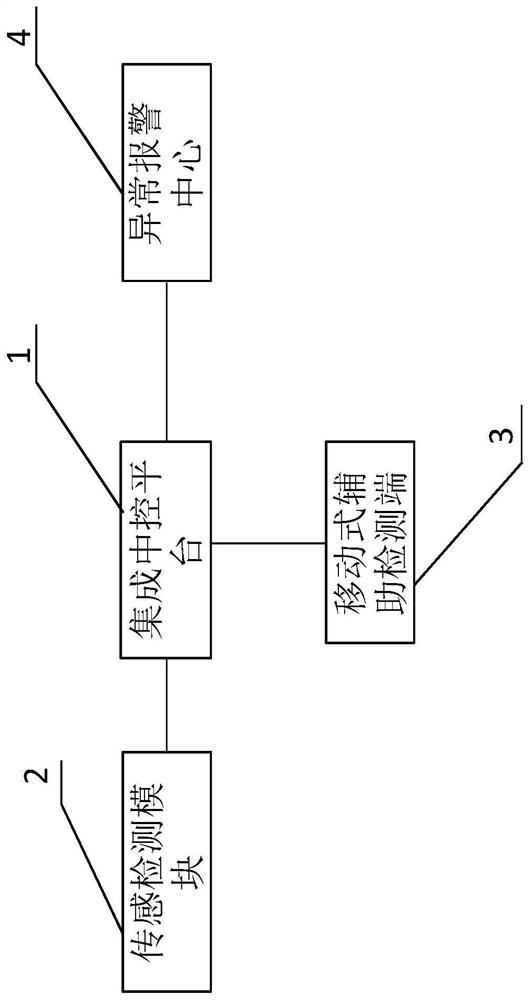

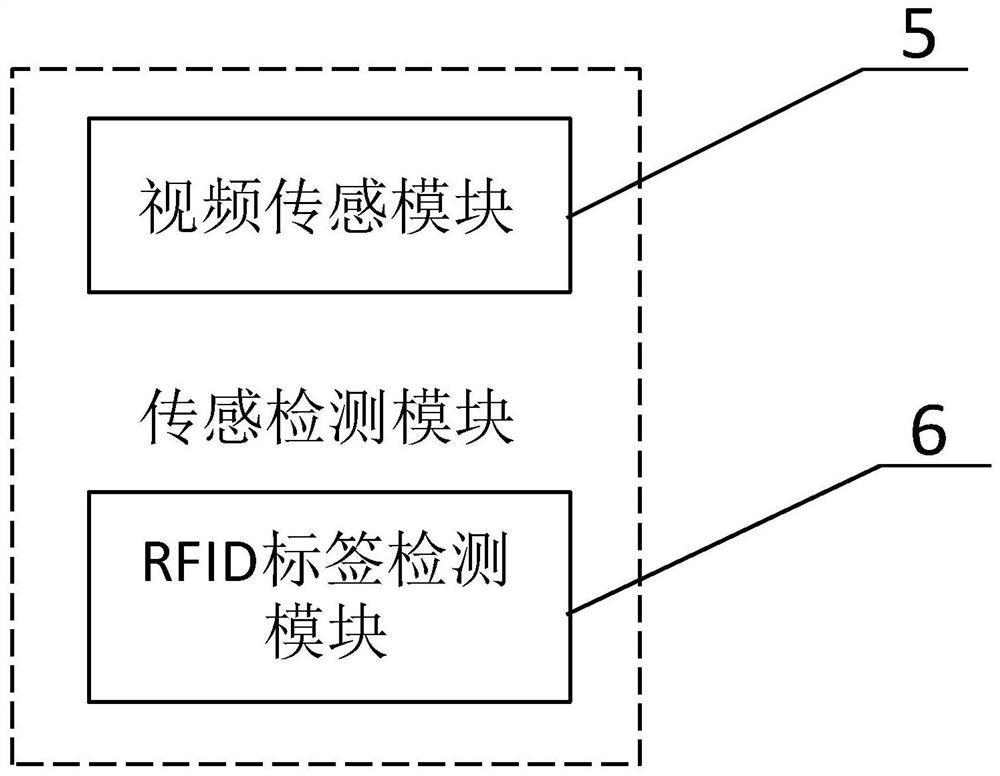

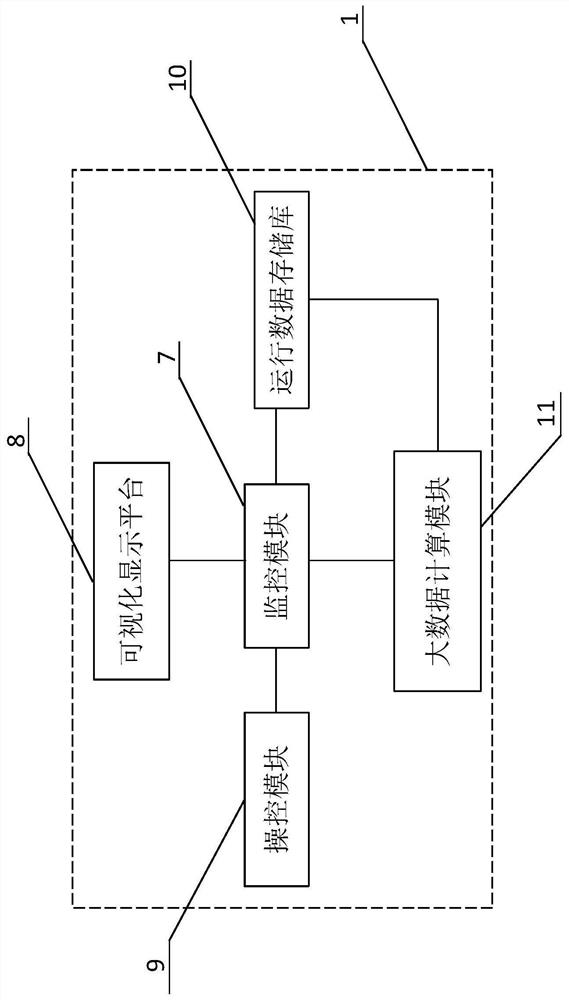

Intelligent operation staring and controlling visual management system

ActiveCN112818716AReduce layoutImprove efficiencyResourcesManufacturing computing systemsComputer hardwareIntelligent management

The invention discloses an intelligent work staring and control visual management system, which is applied to a processing assembly line and comprises an integrated central control platform (1), a plurality of sensing detection modules (2), a mobile auxiliary detection end (3) and an abnormity alarm center (4), the integrated central control platform (1) is respectively in data communication connection with the plurality of sensing detection modules (2), the mobile auxiliary detection terminal (3) and the abnormity alarm center (4) to realize data communication and manipulation control; according to the intelligent work staring and control visual management system and management method, a mode of combining big data calculation is adopted, key highlighting and key attention are performed, arrangement of monitoring sensing equipment can be reduced, and intelligent management efficiency and monitoring cost are improved.

Owner:深圳市宇航软件股份有限公司

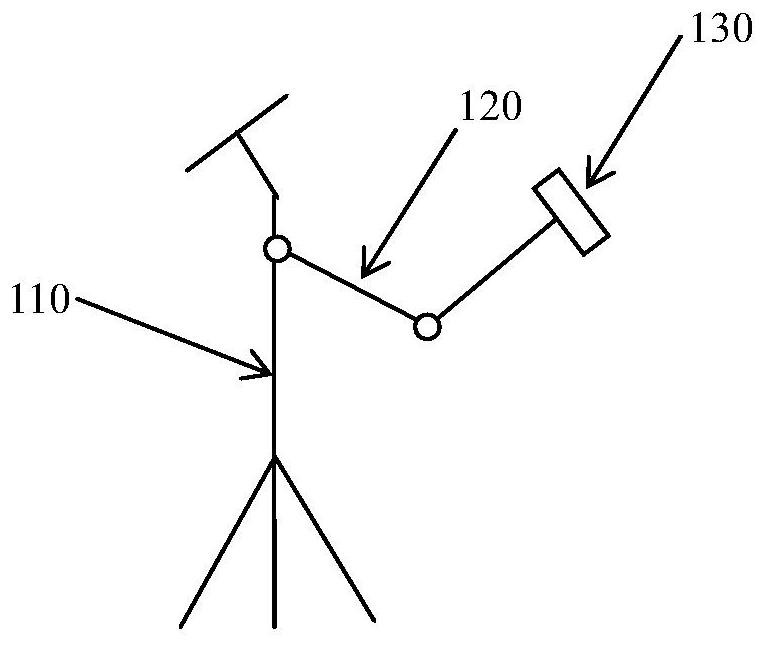

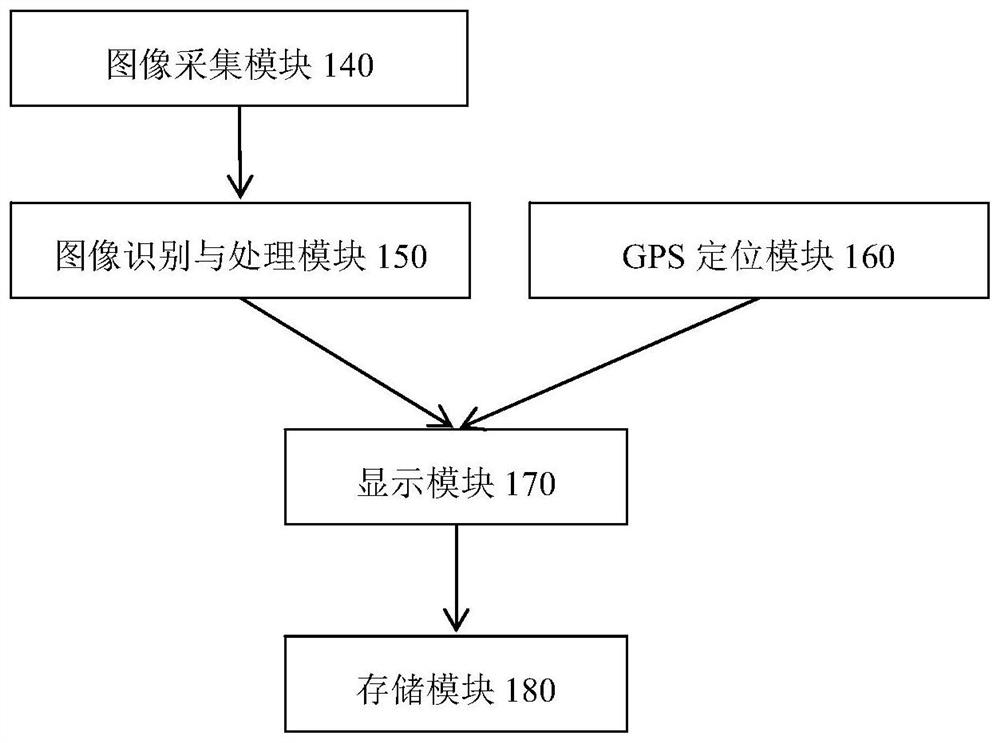

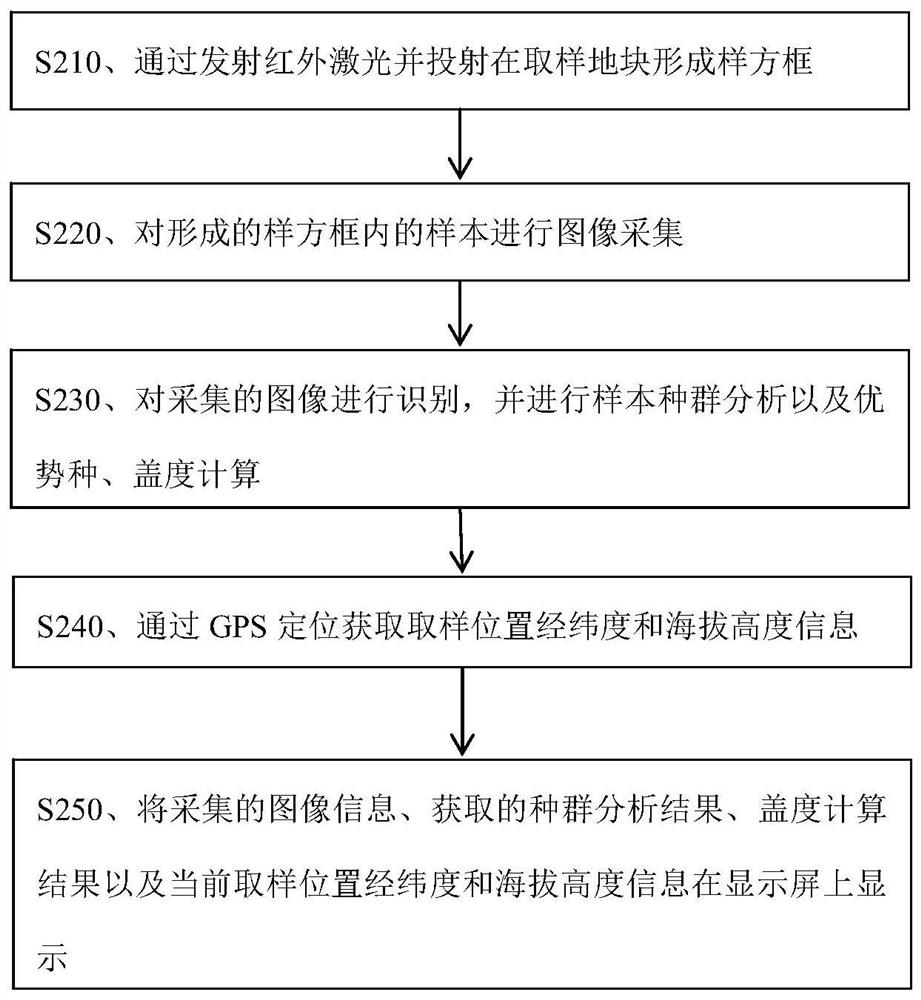

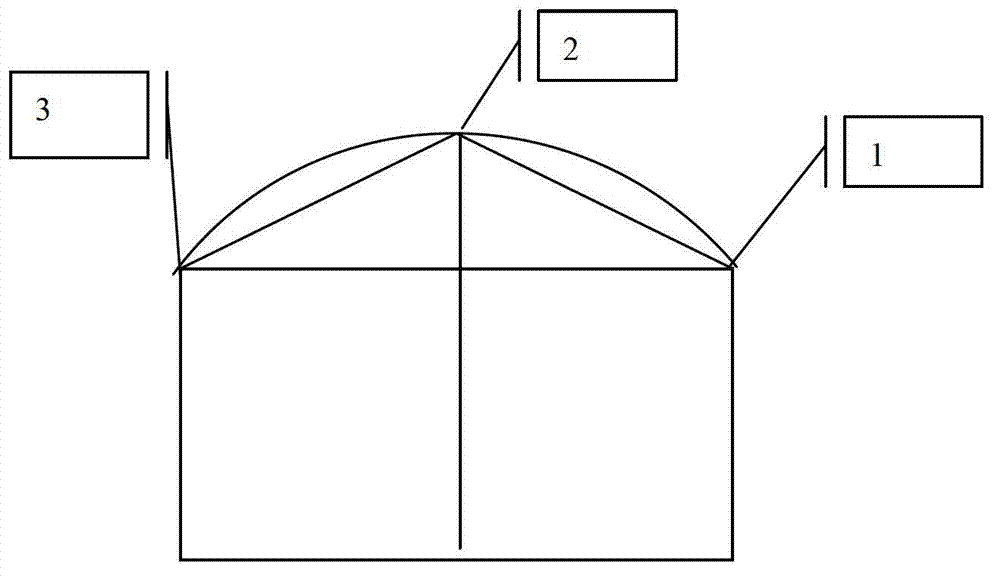

Infrared laser intelligent quadrat investigation device and method

PendingCN113933301ARealize intelligent measurementPowerfulMaterial analysis by optical meansSatellite radio beaconingSample plotIr laser

The embodiment of the invention discloses an infrared laser intelligent quadrat investigation device and method. The device comprises a bracket, an infrared laser projector, an image collection module, an image recognition and processing module, a GPS positioning module, and a display module. The method comprises: emitting infrared laser, and projecting on a sampling plot to form a quadrat frame; carrying out image collection on samples in the formed quadrat frame, identifying the collected images, carrying out sample population analysis and dominant species and coverage calculation, and obtaining latitude, longitude and altitude information of a sampling position through GPS positioning; and displaying the collected image information, the collected population analysis result, the coverage calculation result, the latitude and longitude of the current sampling position and the altitude information are displayed on a display screen. According to the invention, a quadrat frame is formed through infrared laser projection, a traditional quadrat frame does not need to be carried, intelligent measurement of the coverage and intelligent positioning of the sampling position can be achieved, and strength is increased for field scientific research.

Owner:青海省草原改良试验站

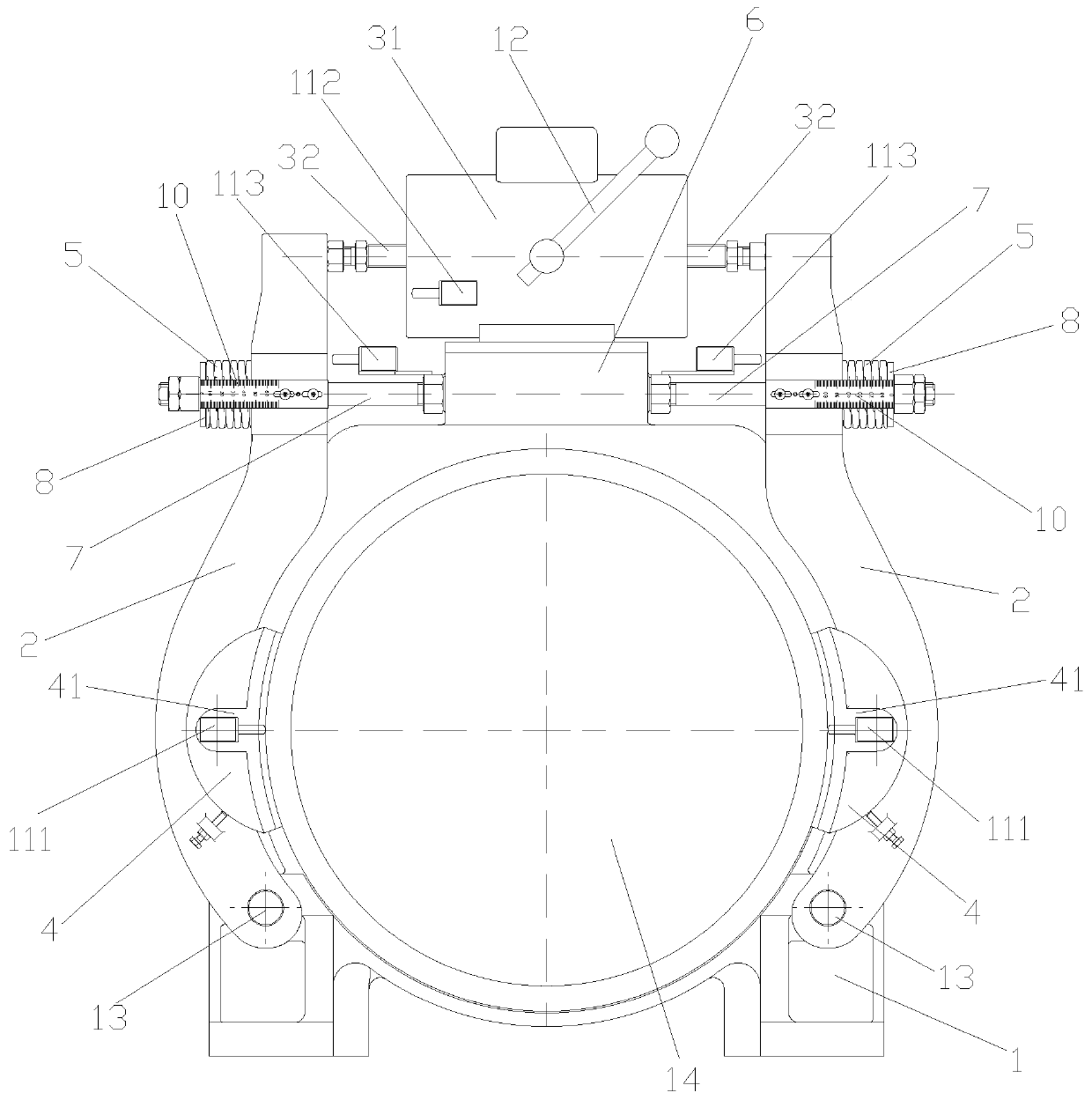

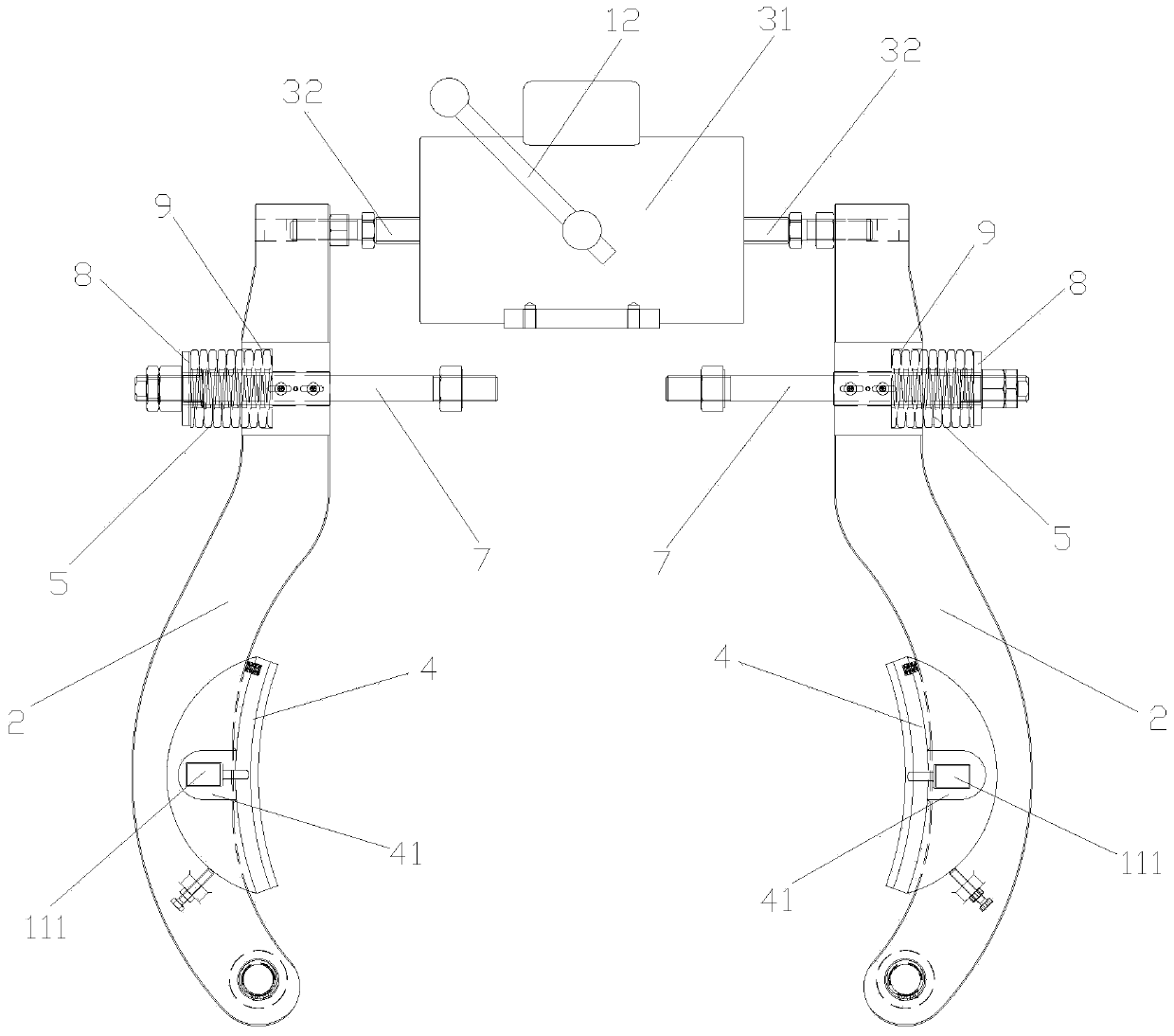

Traction machine brake

PendingCN111320095AAccurate measurementGuaranteed uptimeSlack adjustersHoisting equipmentsControl theoryBrake shoe

The invention discloses a traction machine brake. The traction machine brake comprises a brake state and a brake release state, wherein in the brake state, brake shoes make complete contact with brakesurfaces, and in the brake release state, the brake shoes are completely separated from the brake surfaces; the traction machine brake further comprises displacement measuring devices, the displacement measuring devices comprise first displacement sensors arranged on brake arms, the first displacement sensors are used for measuring the real-time brake release distances between the brake shoes andthe brake surfaces, the first displacement sensors are connected with control devices, and the first displacement sensors transmit the real-time brake release distances between the brake shoes and the brake surfaces in the brake release state to the control devices; and preset modules and comparison modules are arranged in the control devices, the minimum brake release distances between the brakeshoes and the brake surfaces are preset in the preset modules, the comparison modules are used for comparing the real-time brake release distances with the minimum brake release distances, and the control devices control brake release devices to act according to comparison results.

Owner:苏州江南嘉捷光机电技术有限公司

Bullet train rod piece measuring device based on artificial intelligence

InactiveCN111811409AEasy to useEasy to classifyUsing optical meansMechanical engineeringRail transit

The invention relates to the technical field of rail transit, and discloses a bullet train rod piece measuring device based on artificial intelligence. The bullet train rod piece measuring device comprises a base and a main control box, the top of the base is fixedly provided with a set of conveying belt of a circular structure through three sets of supporting legs arranged in a triangular shape.A plurality of groups of classified scanning tunnels are fixedly mounted on the upper side of the conveying belt at equal intervals; an air cylinder with the output end facing the center of the conveying belt and electrically connected with the main control box is fixedly installed on the belt edge of the conveying belt outside the rear side of the classified scanning tunnel, the inner side of thenotch is obliquely and downwards connected with a discharging channel, and the bottom of the discharging channel communicates with a rotary measuring groove fixed to the upper surface of the base. The device has the advantages of intelligent operation, automatic classification, automatic rotary measurement, high working efficiency and high use value.

Owner:青岛海科虚拟现实研究院

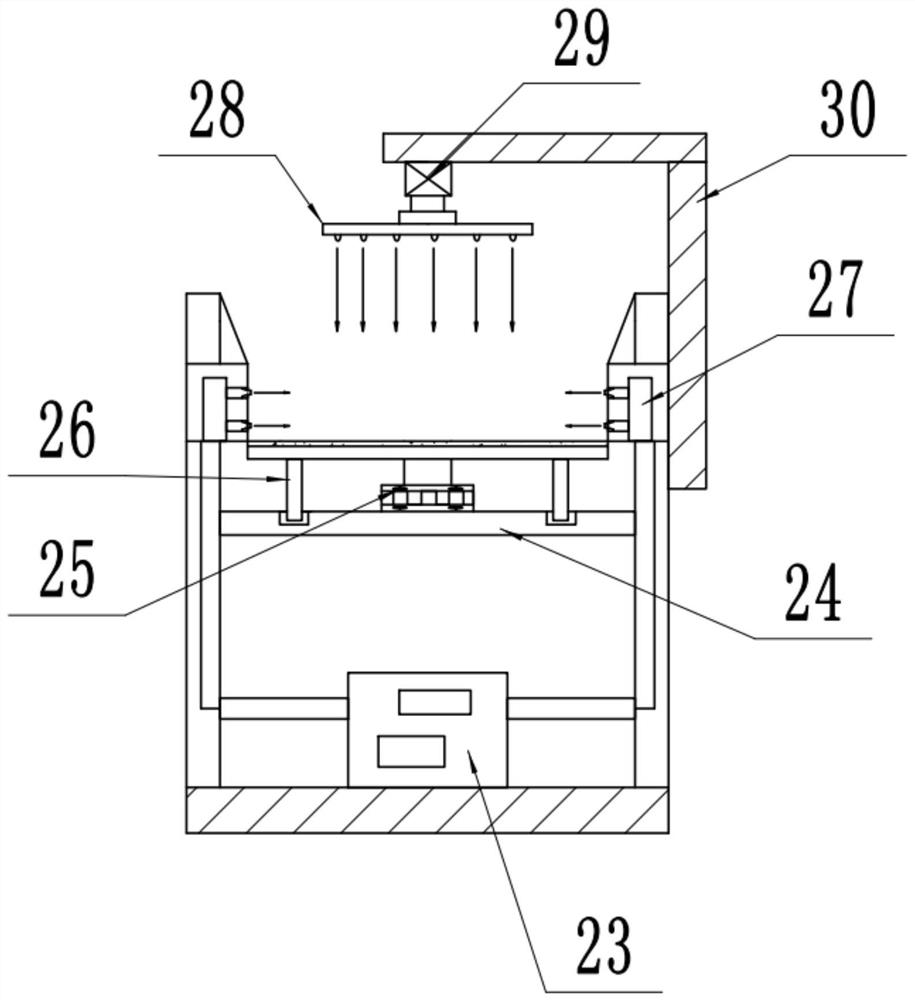

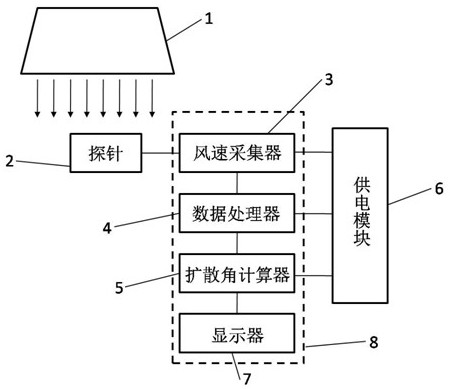

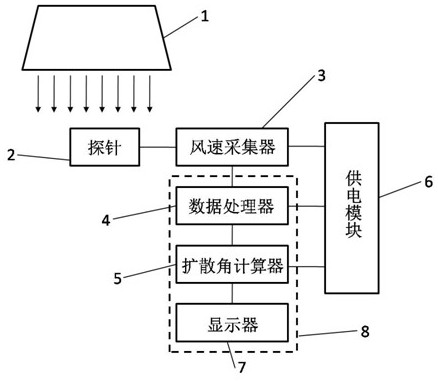

An Apparatus for Calculating Diffusion Angle of Air-conditioning Air Vent Using Fractal Dimension

ActiveCN109099557BRealize acquisitionEasy to adjustMechanical apparatusSpace heating and ventilation safety systemsAir velocityEngineering

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

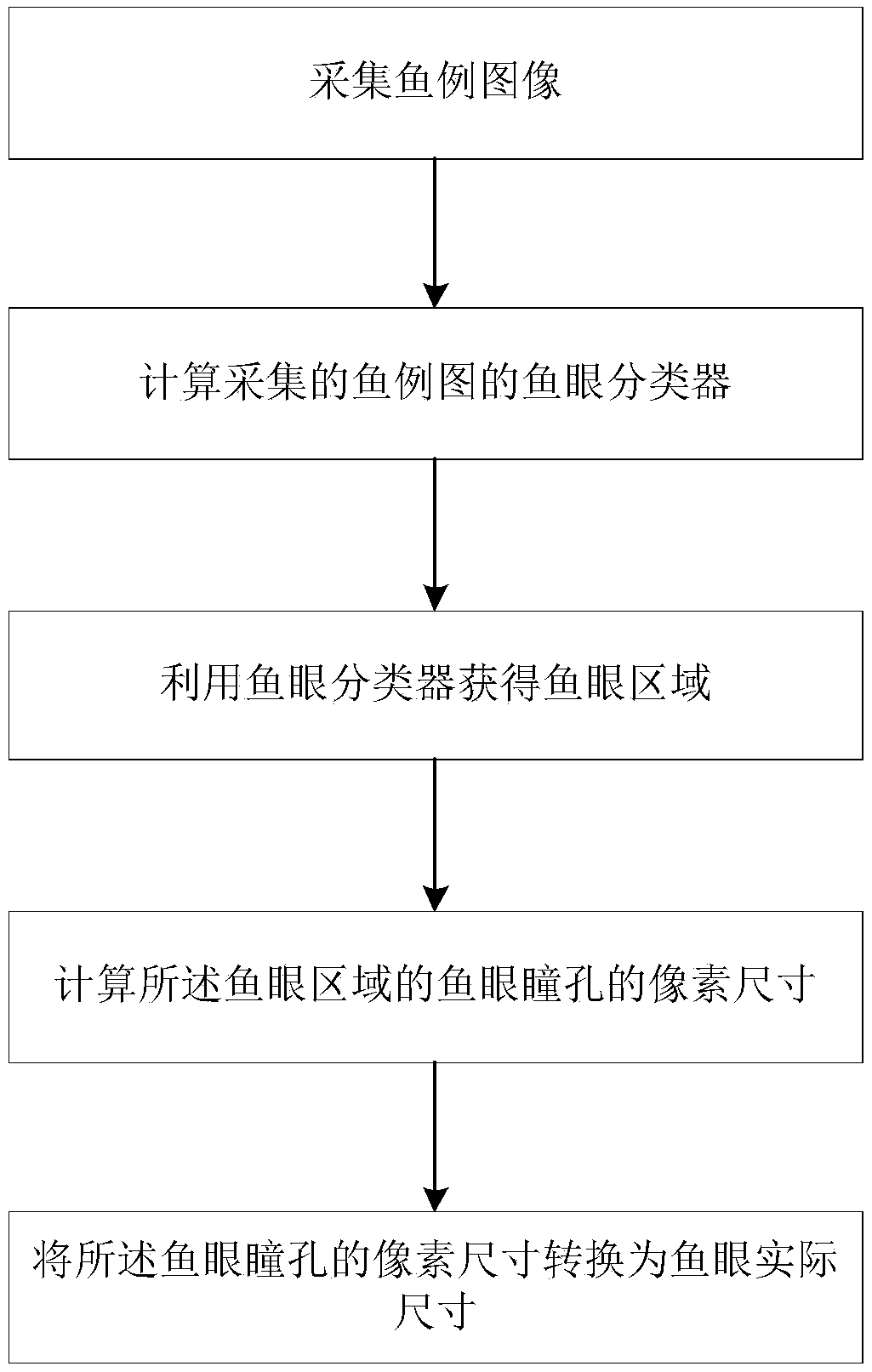

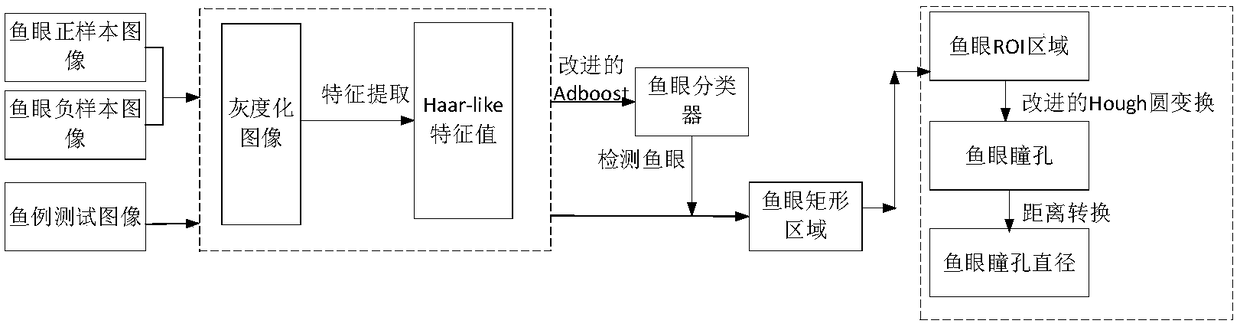

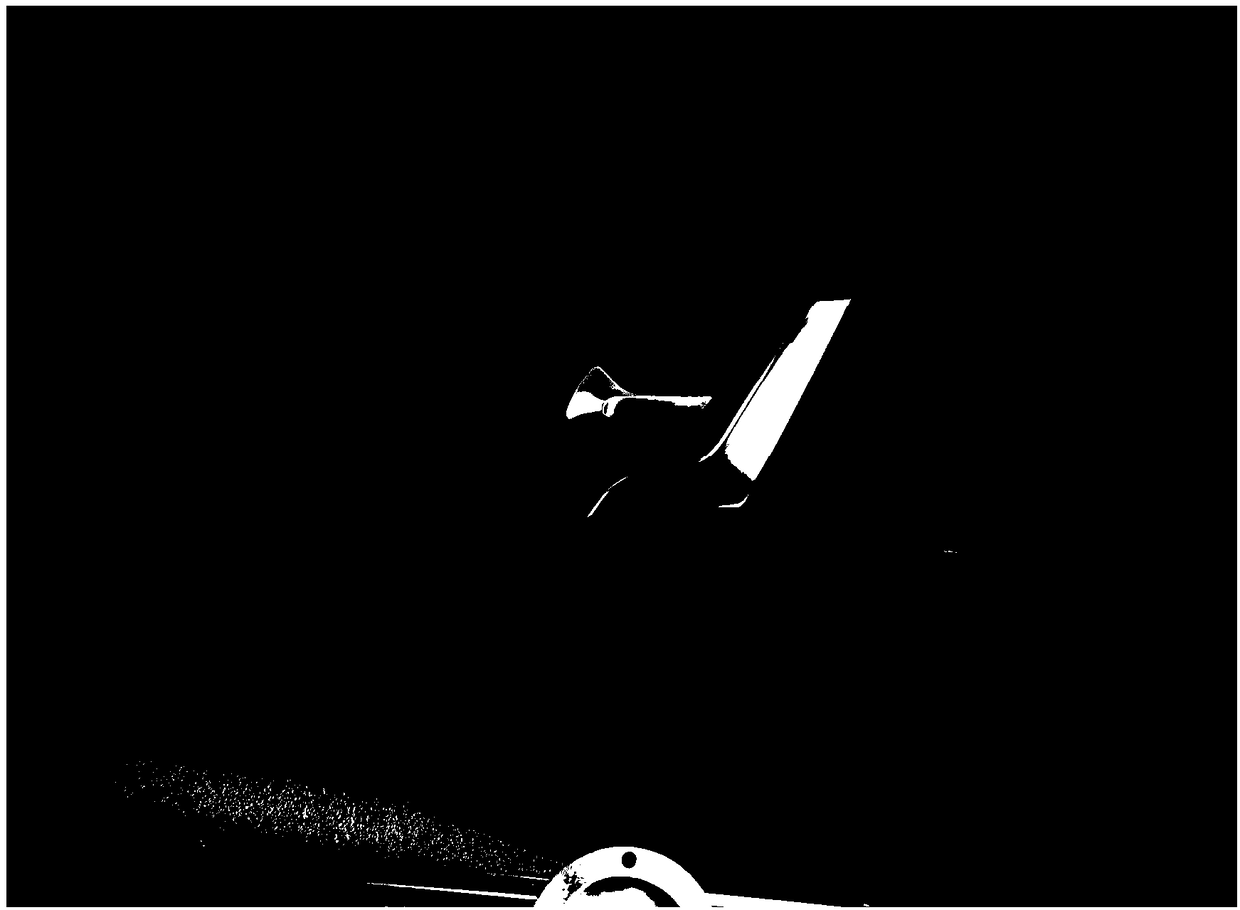

Fisheye pupil intelligent measurement method based on machine learning

ActiveCN108182380ARealize non-contactRealize non-destructive measurementClimate change adaptationAcquiring/recognising eyesImaging processingVisual technology

The invention relates to a fisheye pupil intelligent measurement method based on machine learning. The method comprises steps: a fish case image is acquired, a fisheye classifier for the acquired fishcase image is calculated, the fisheye classifier is used to acquire a fisheye area, the pixel size of the fisheye pupil in the fisheye area is calculated, and the pixel size of the fisheye pupil is converted to the actual fisheye size. According to the method provided in the invention, the fisheye classifier obtained through training by an AdaBoost-based machine learning method is used to accurately detect the fisheye area in the fish case image, non-contact intelligent measurement on the fisheye pupil can be realized in combination of a computer vision technology and an image processing technology, and while the precision and the stability of the measured data are ensured, the measurement efficiency and the measurement intelligence are improved.

Owner:TIANJIN UNIV

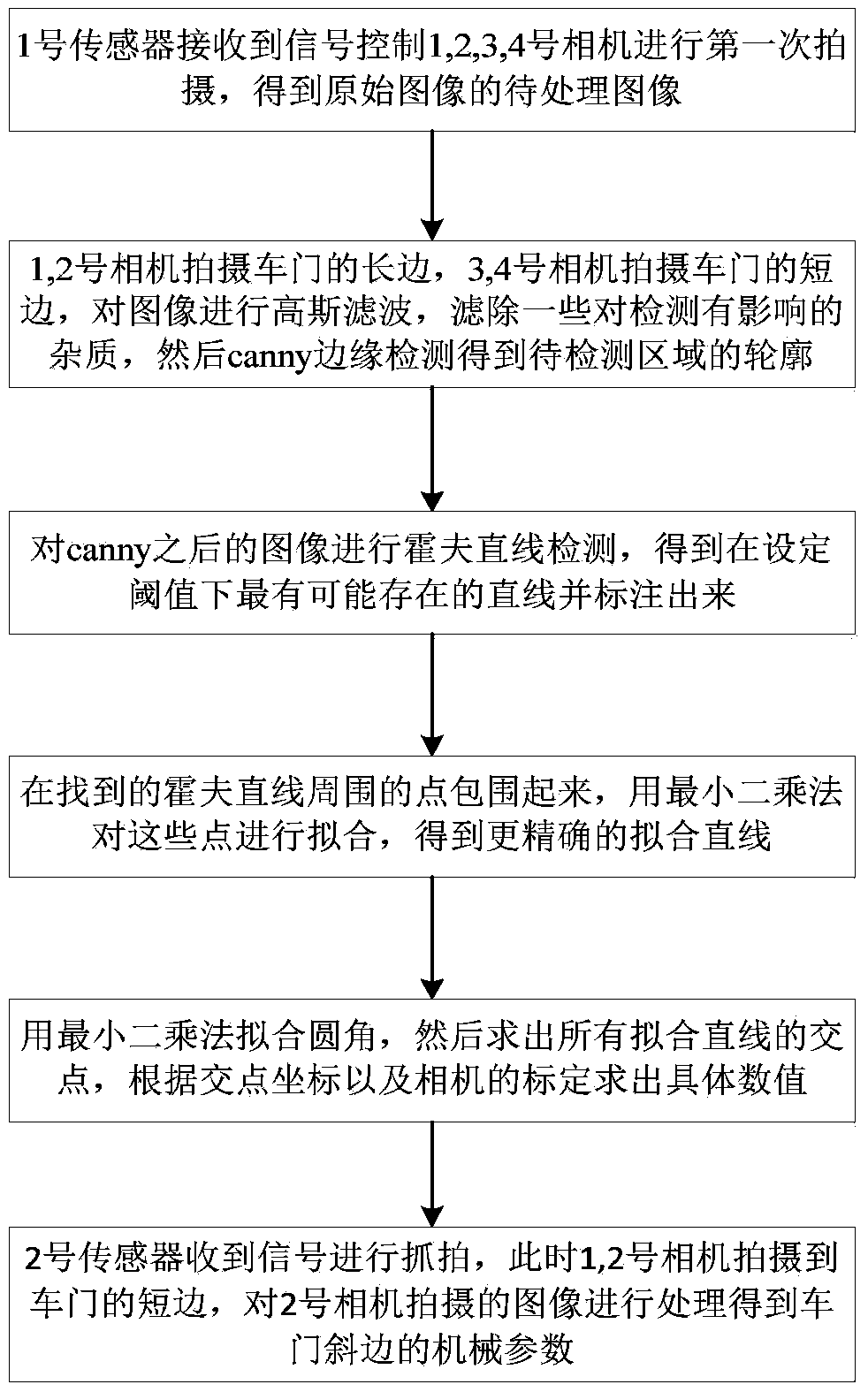

Device for intelligently measuring car door mechanical parameter based on machine vision

InactiveCN109186468AReduce the numberGuaranteed accuracyUsing optical meansMachine visionAssembly line

The invention discloses a device for intelligently measuring a car door mechanical parameter based on machine vision. The device capable of measuring car door size and diameter comprises an image collection device, an image measurement device, and a car door welding platform; the image collection device is mounted on the car door welding platform; the image measurement device receives an image sent from the image collection device and processes the same. An operation of dynamically measuring a precise mechanical parameter of the car door on an assembly line is realized, the precision is improved while satisfying the operation of intelligently measuring multiple car doors, the precision is improved, and the device can be great for improving the appearance and the safety performance of the car door.

Owner:天津安通林汽车饰件有限公司

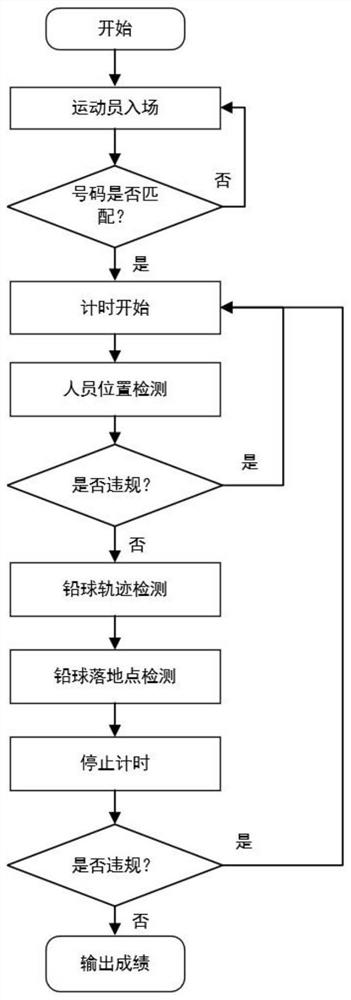

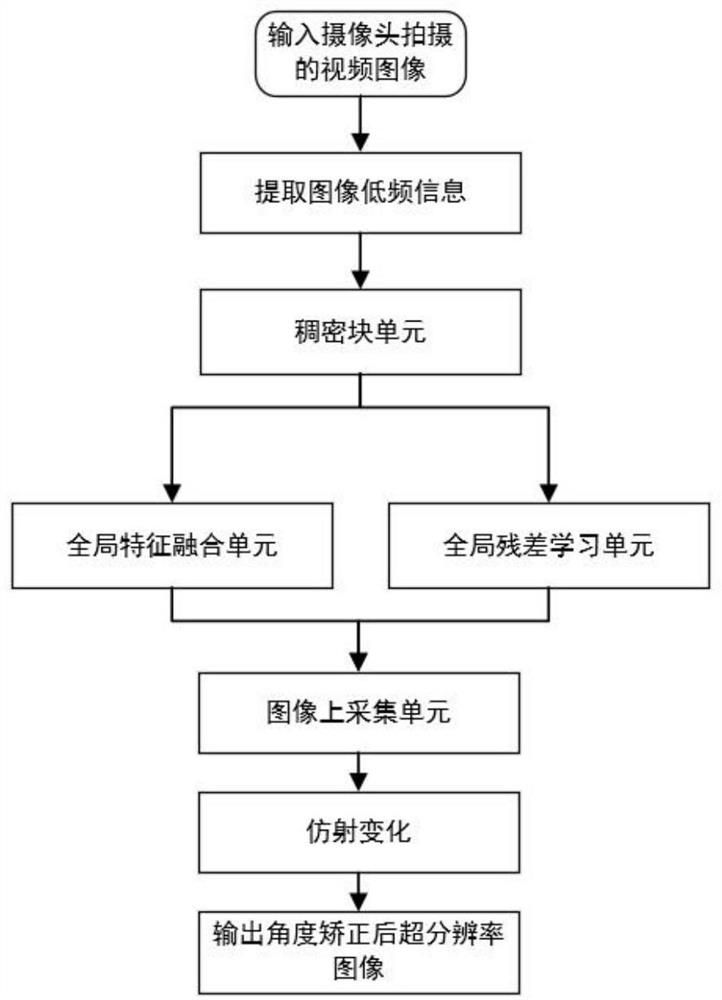

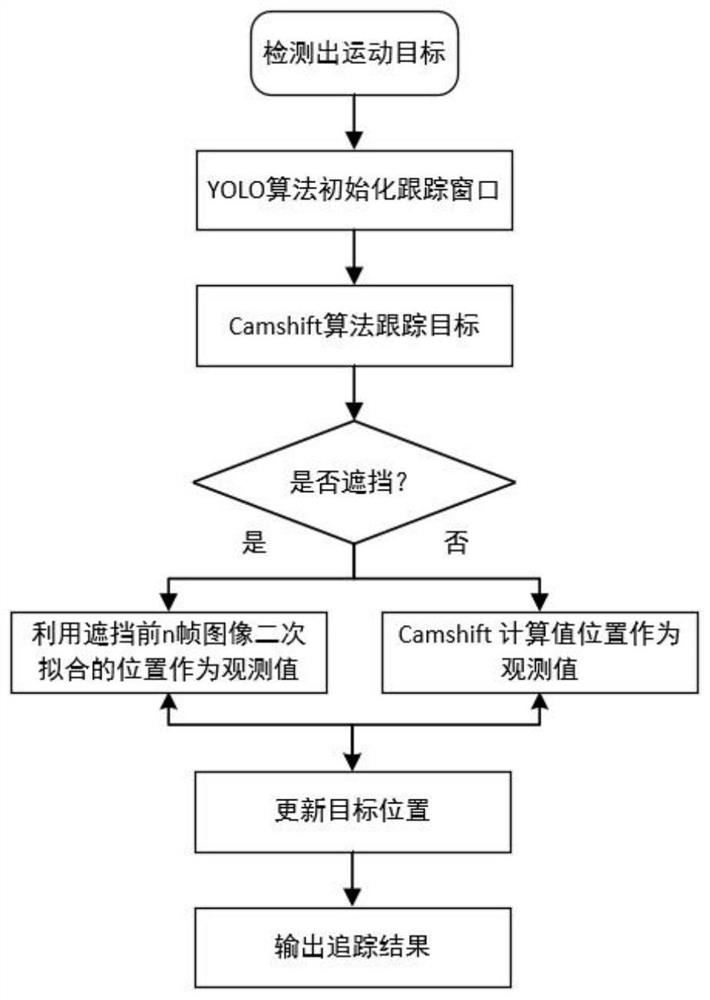

Shot put throwing score recording system based on artificial intelligence

PendingCN114187171ACorrection angleHigh-resolutionImage analysisGeometric image transformationAlgorithmData acquisition

The invention discloses a shot throwing score recording system based on artificial intelligence, which is characterized in that a preparation area and a score area are arranged in a throwing field, a throwing start line is arranged in the preparation area, and a camera is arranged in the throwing field; n athletes in the throwing field wear different number plates in sequence according to a departure sequence, and an industrial personal computer, a display screen and a loudspeaker are arranged on one side of the throwing field; the industrial personal computer is provided with a data acquisition module, a preprocessing module, a number matching module, a timing module, a personnel position detection module, a violation detection module, a track detection module, a landing point detection module and a score output module. According to the invention, intelligent measurement of the throwing distance is realized by using artificial intelligence, so that the accuracy and fairness of measurement are improved.

Owner:安徽一视科技有限公司

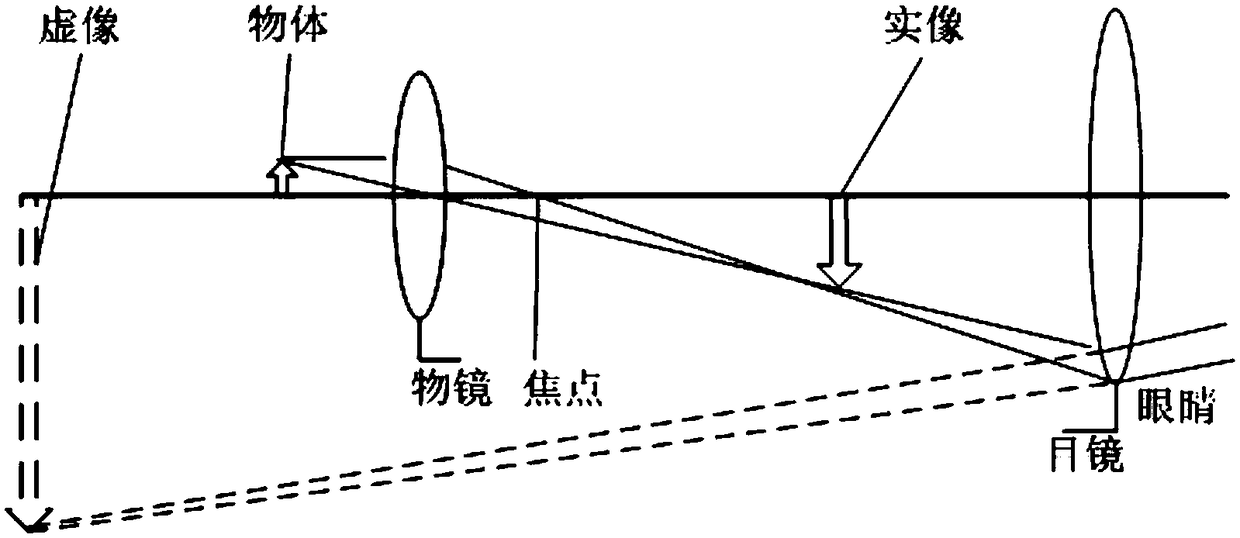

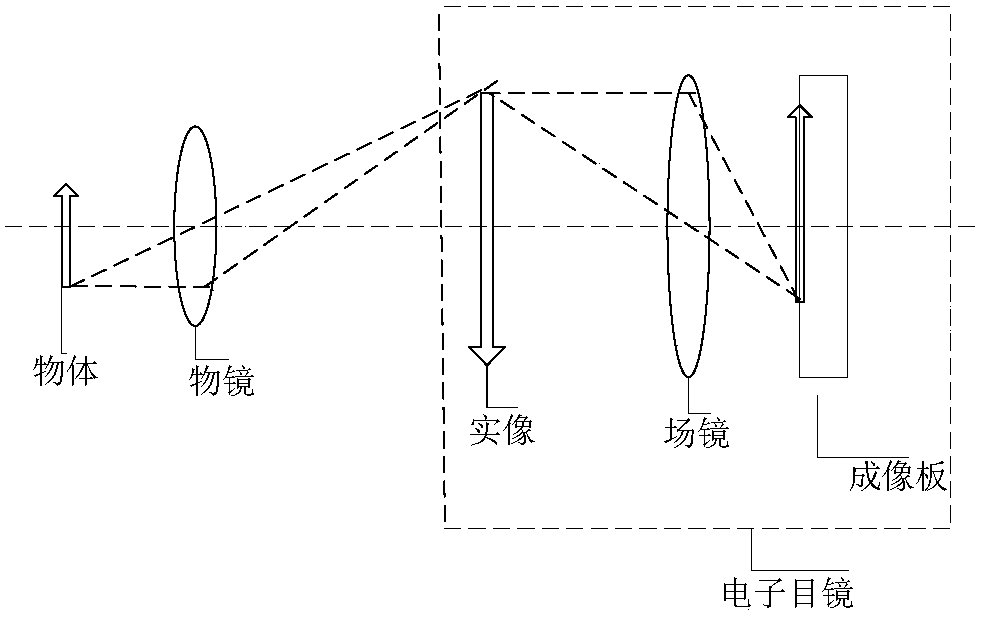

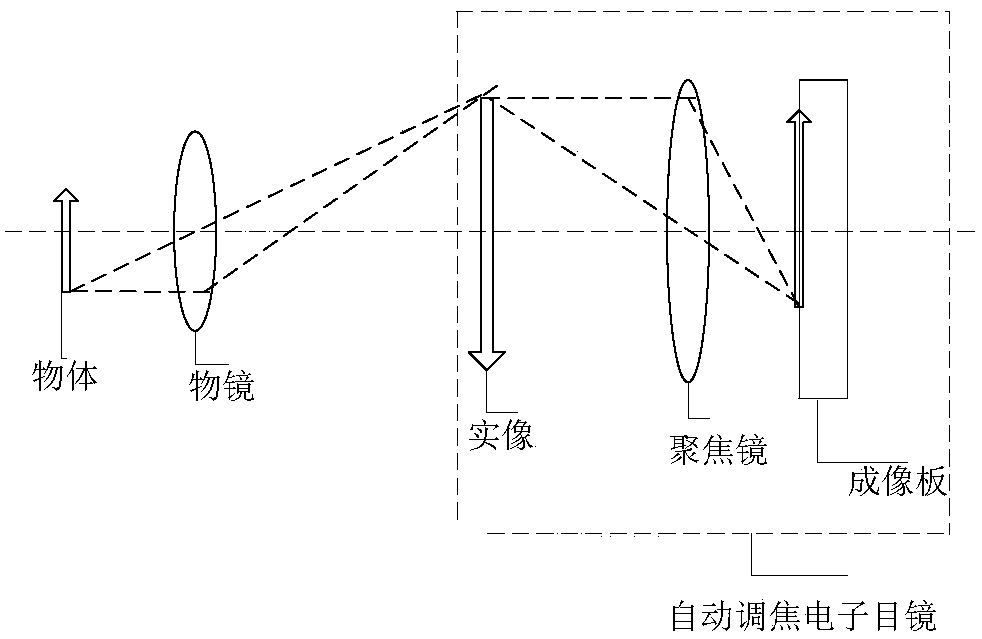

An automatic focusing electronic eyepiece and system

ActiveCN106210520BImprove focusing efficiencyReduce focusing timeTelevision system detailsColor television detailsCamera lensEyepiece

The invention relates to an automatic focusing electronic eyepiece and a system. Including: lens, Sensor board, main control unit, interface unit, the lens receives the image of the measured target once formed by the front-end optical system, which includes the focusing lens group, focusing motor and lens group position detection unit, the Sensor board realizes photoelectric conversion, and the The optical signal through the lens is converted into an image signal and then output to the main control unit; the main control unit outputs a control signal to control the focus motor to drive the movement of the focus lens group, and integrates the focus lens group and the corresponding control circuit into the electronic Inside the eyepiece, the main control unit inside the electronic eyepiece executes the focus search algorithm, controls the movement of the focusing lens group, and realizes automatic focusing by adjusting the image distance. Through the present invention, automatic focusing can be realized without moving or changing the front-end optical system (including not limited to microscopes, telescopes, etc.), improving focusing efficiency and shortening focusing time.

Owner:TAGYE TECH HANGZHOU CO LTD

Measuring method for polarized dependent loss PDL

ActiveCN100547953CRealize intelligent measurementEfficient measurementElectromagnetic transmissionLength waveFeedback control

This invention relates to a measurement method for PDL characterizing that: an incident modulated optical signal enters into a dual-refraction device to pass through a polarization rotor, a PDL device to be tested and enters into a polarization meter finally to let the rotor rotate a circle axially to note down the appeared DOP maximum value and the minimum value and compute the PDL value of related device, which is advantaged that it can measure PDL value in optical devices or system under single wavelength or multiple wave lengths and realize intelligent measurement to PDL without monitor.

Owner:GUANGXUN SCI & TECH WUHAN

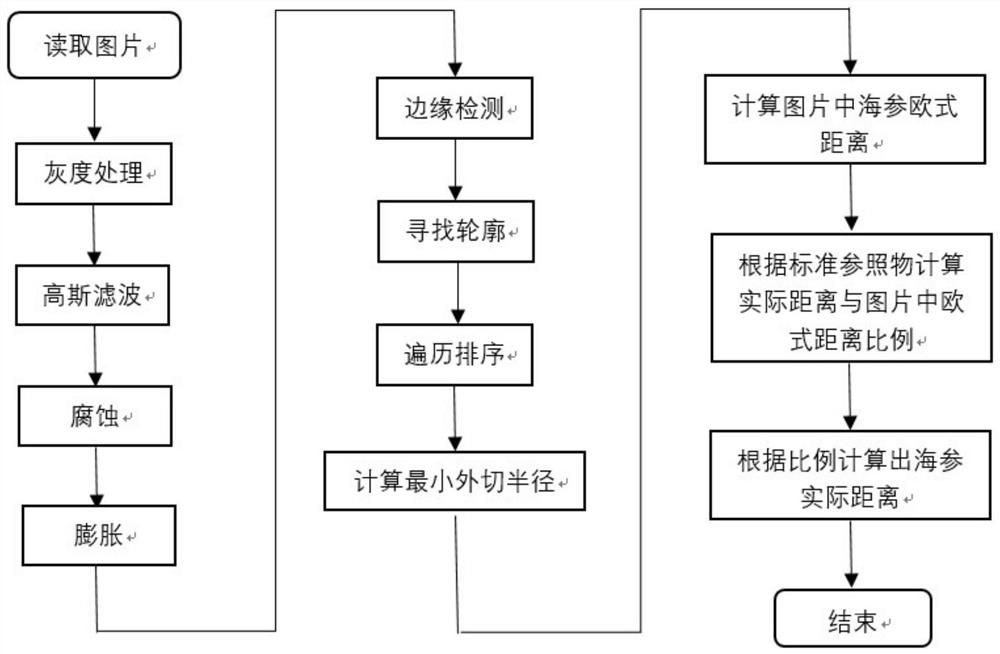

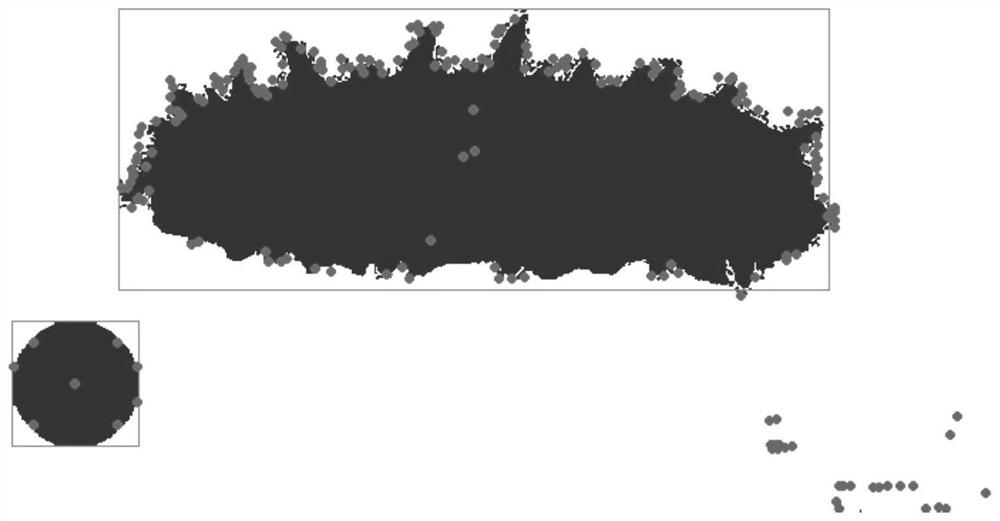

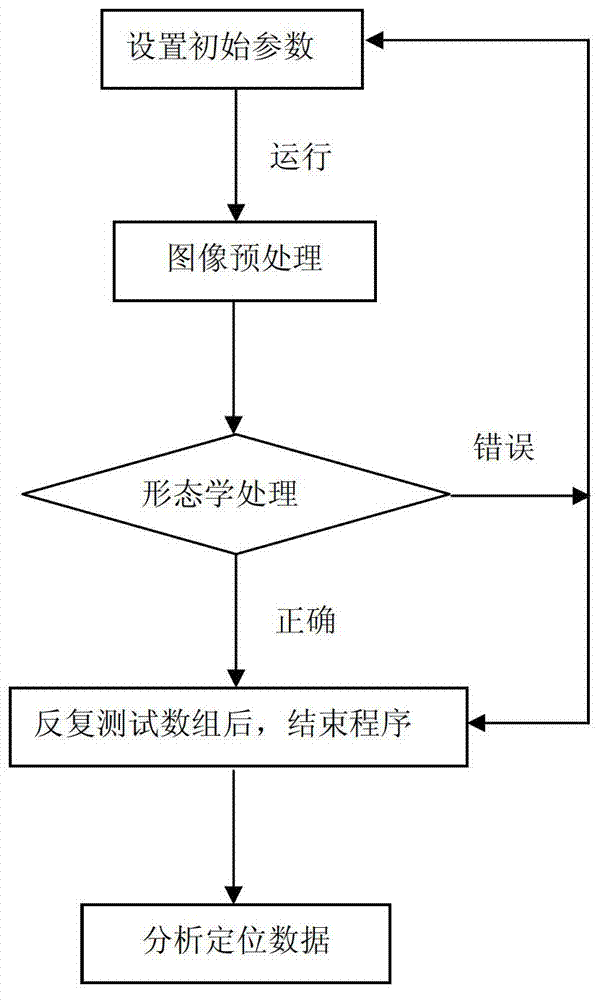

Holothurian size screening method adopting computer vision

InactiveCN112077018ARealize intelligent measurementLabor savingSortingMonocular cameraComputer graphics (images)

The invention discloses a holothurian size screening method adopting computer vision. The method mainly comprises the following steps of acquiring a holothurian image through a monocular camera, and performing binarization, Gaussian filtering, morphological processing and the like on the holothurian image to obtain a processed image. The minimum circumscribed rectangle of the holothurian and a reference object is drawn by extracting the contours of the holothurian and the reference object in an edge image, the Euclidean distance between the holothurian and the reference object in the image iscalculated according to the vertex of the circumscribed rectangle, and the actual distance of the holothurian is calculated according to the ratio of the Euclidean distance of the standard reference object to the actual distance. The holothurian screening method solves the problems of low working efficiency, inaccurate screening and the like in manual screening, and solves the problems that a screen is blocked in screen screening, inaccurate screening is easily caused, the holothurians are scratched by the screen and the like.

Owner:HARBIN ENG UNIV

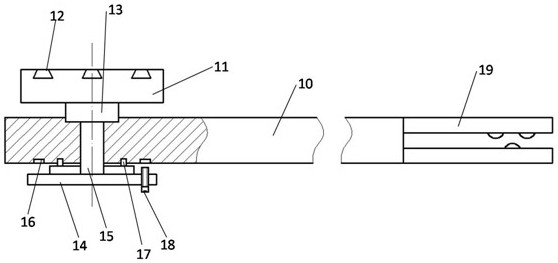

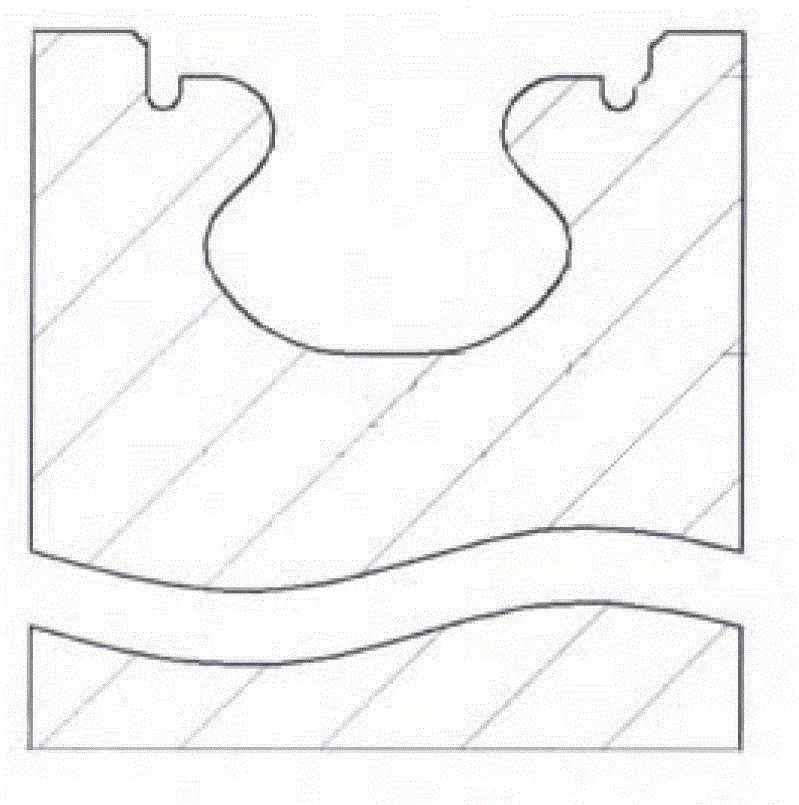

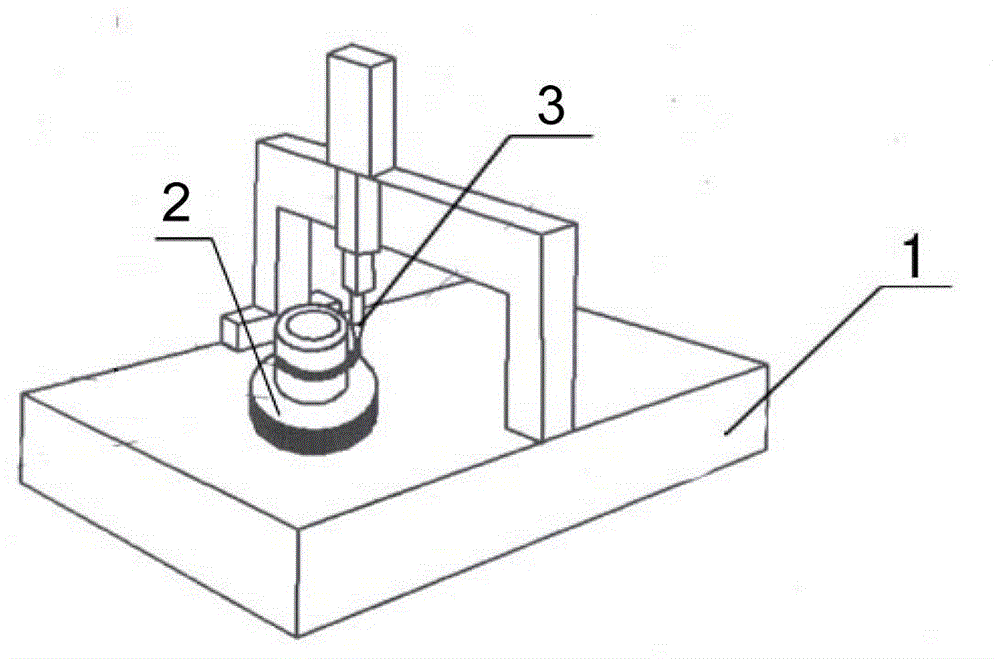

Device and method for measuring profile tolerance of annular dovetail groove of any axial section

ActiveCN102944163BImprove the accuracy of contour measurementFully automatedMechanical counters/curvatures measurementsCoordinate-measuring machineEngineering

The invention discloses a device and a method for measuring the profile tolerance of an annular dovetail groove of any axial section, belonging to the technical field of machining. The device comprises a three-coordinate measuring machine, a survey probe mechanism and a rotating table, wherein the survey probe mechanism comprises a lengthening bar, a survey probe central seat, a survey probe joint and a corner piece survey probe; the lengthening bar of the survey probe mechanism is connected with one end of the survey probe joint through the survey probe central seat; the other end of the survey probe joint is connected with the corner piece survey probe; the rotating table is arranged on a workbench of the three-coordinate measuring machine; a tested workpiece is arranged on the rotating table; the lengthening bar of the survey probe mechanism is connected with the three-coordinate measuring machine through a sucking disk; and the corner piece survey probe of the survey probe mechanism is contacted with the inner molding surface of the annular dovetail groove. Due to the adoption of the device and the method, the aim of improving the processing quality and detection efficiency of the dovetail groove is fulfilled.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

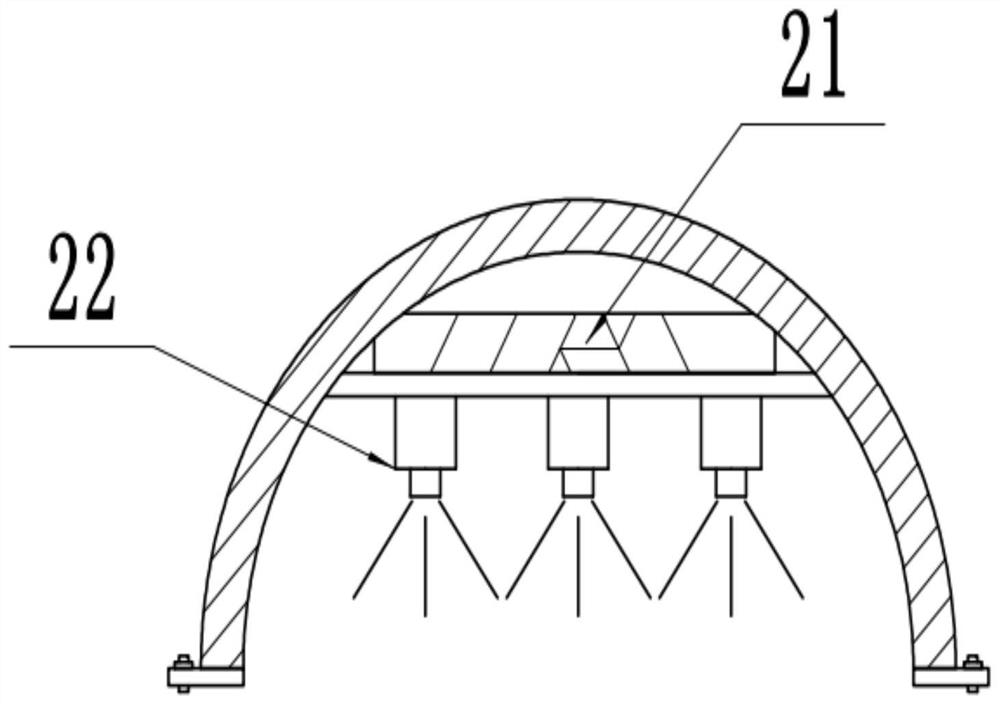

Tunnel surrounding rock deformation detection method adopting digital camera technique

The invention discloses a tunnel surrounding rock deformation detection method adopting a digital camera technique under the remote control of a computer. The method is characterized by arranging a plurality of observation points on the section of the tunnel surrounding rock, shooting the observation points by utilizing digital imaging equipment, transmitting the acquired images to a monitoring computer by utilizing a wireless network and processing the monitored images by the monitoring computer to obtain the measurement data of surrounding rock deformation. The method has the following advantages: by shooting the plurality of observation points on the section of the tunnel surrounding rock, utilizing research methods such as image enhancement, image pre-processing, image recognition and the like and adopting multistage image processing, the contrast is improved, the target margin is sharpened, and the observation points on the surrounding rock become clearer, thus effectively separating the key recognized targets from the tunnel background and then carrying out coordinate positioning and contrast on the processed images; and measurement and early warning can be carried out on surrounding rock deformation quickly, safely and automatically.

Owner:CHANGAN UNIV

Method for measuring concentricity of copper-coated steel grounding bodies

InactiveCN106643620ARealize intelligent measurementImprove efficiencyMeasurement devicesProduction lineMeasuring instrument

The invention discloses a method for measuring the concentricity of copper-coated steel grounding bodies. The method includes the steps of A, performing ultrasonic cleaning on the grounding bodies; B, placing the cleaned grounding bodies on a material placing device, wherein the grounding bodies do not contact with one another; C, by a control system, controlling a mechanical arm to grab one of the grounding bodies to place the same above a production line, wherein the grounding body is suspended; D, arranging at least three non-contact type thickness measuring instrument annularly arranged, allowing each thickness measuring instrument to aim at one testing point on the surface of the grounding body, wherein the testing points are located on the same circumference; E, allowing the thickness measuring instruments to work, transmitting the measured data to the control system, and calculating and analyzing to obtain a result; F, by the mechanical arm, conveying the measured grounding body to a storage device. The method for measuring the concentricity of the copper-coated steel grounding bodies has the advantages that intelligent measuring of the concentricity can be achieved through the grabbing by the mechanical arm and the measuring by the thickness measuring instruments, and efficiency is increased greatly as compared with that of the prior art.

Owner:江苏金合益复合新材料有限公司

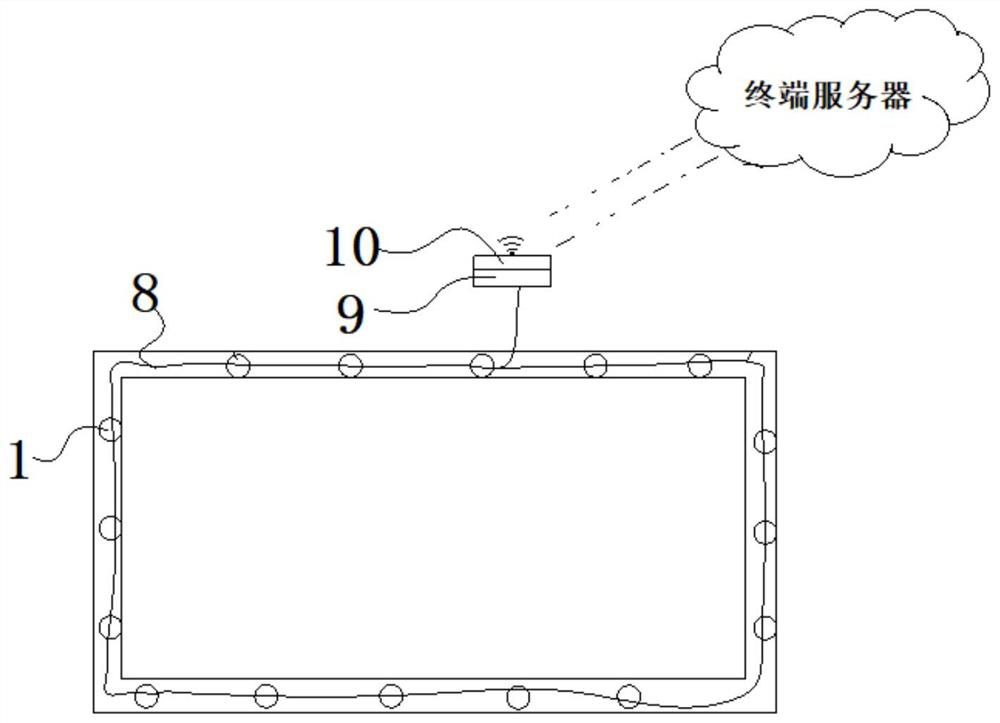

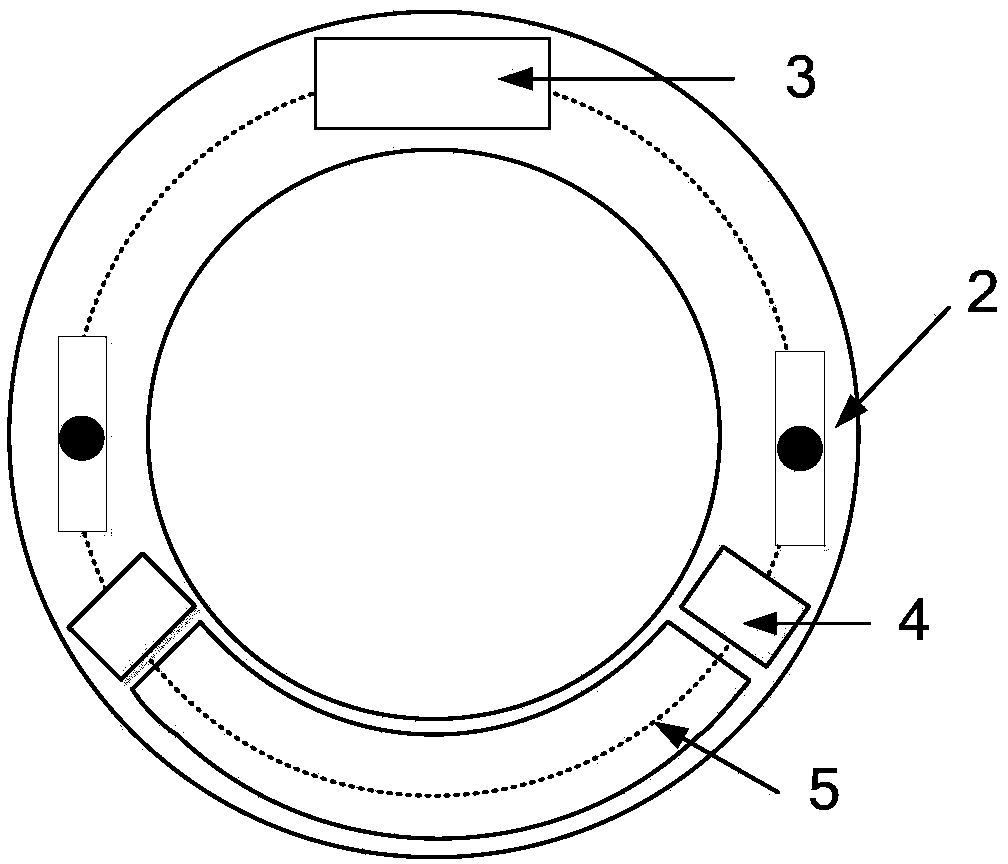

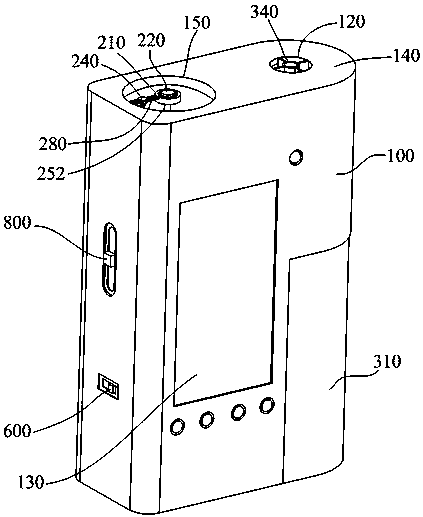

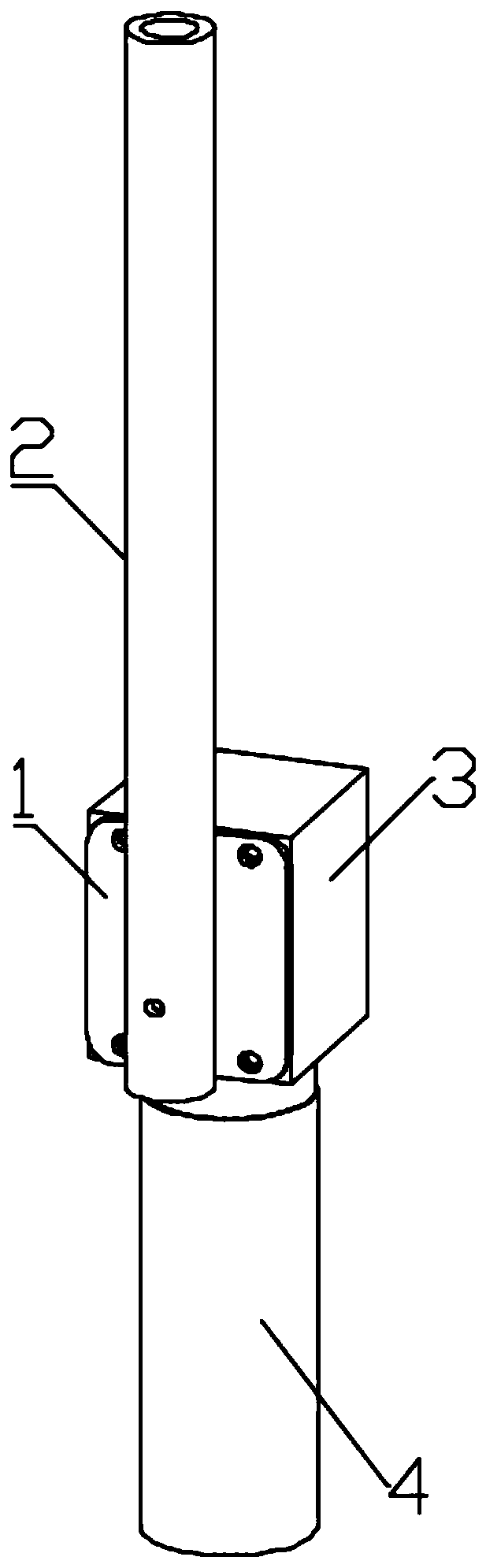

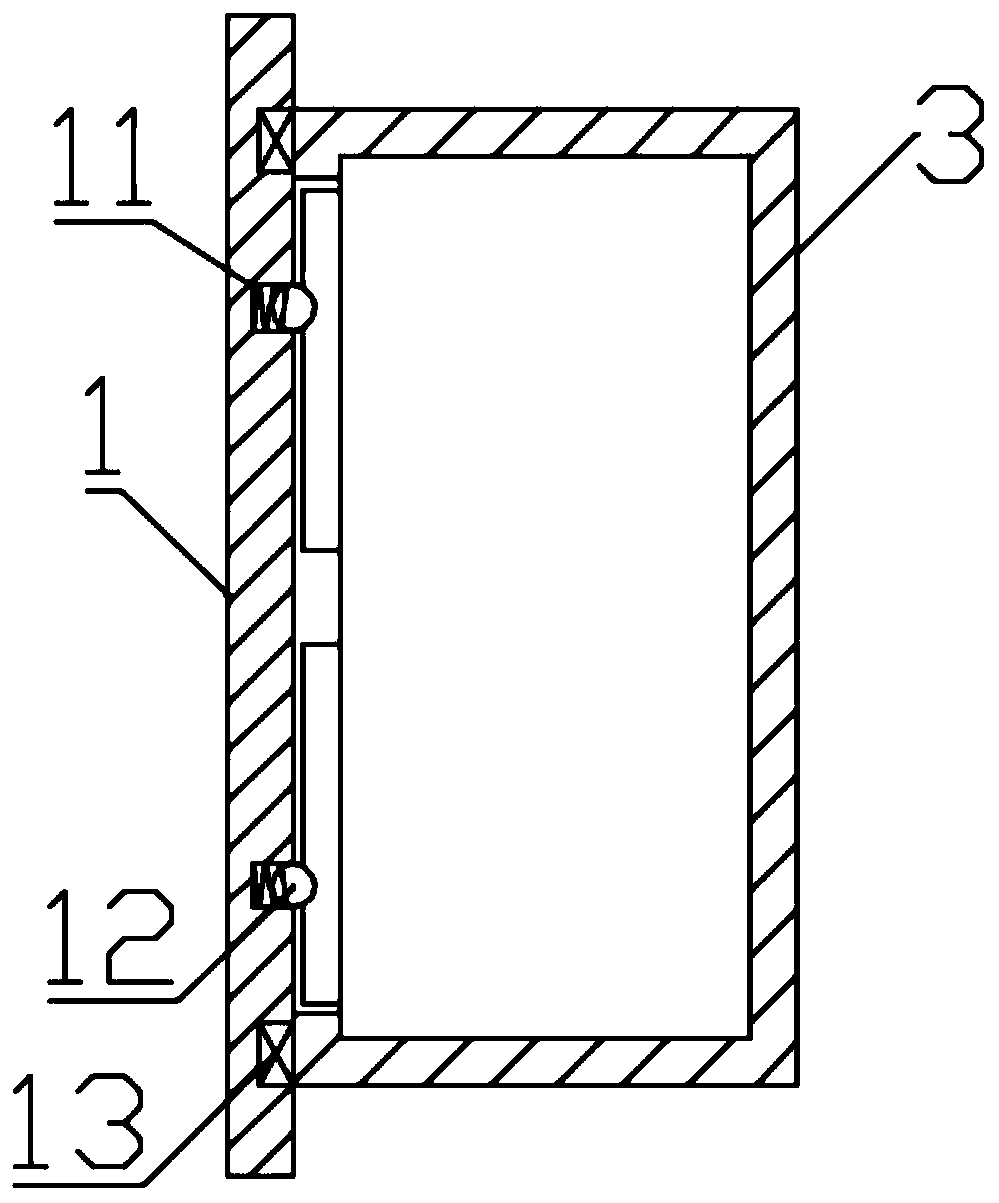

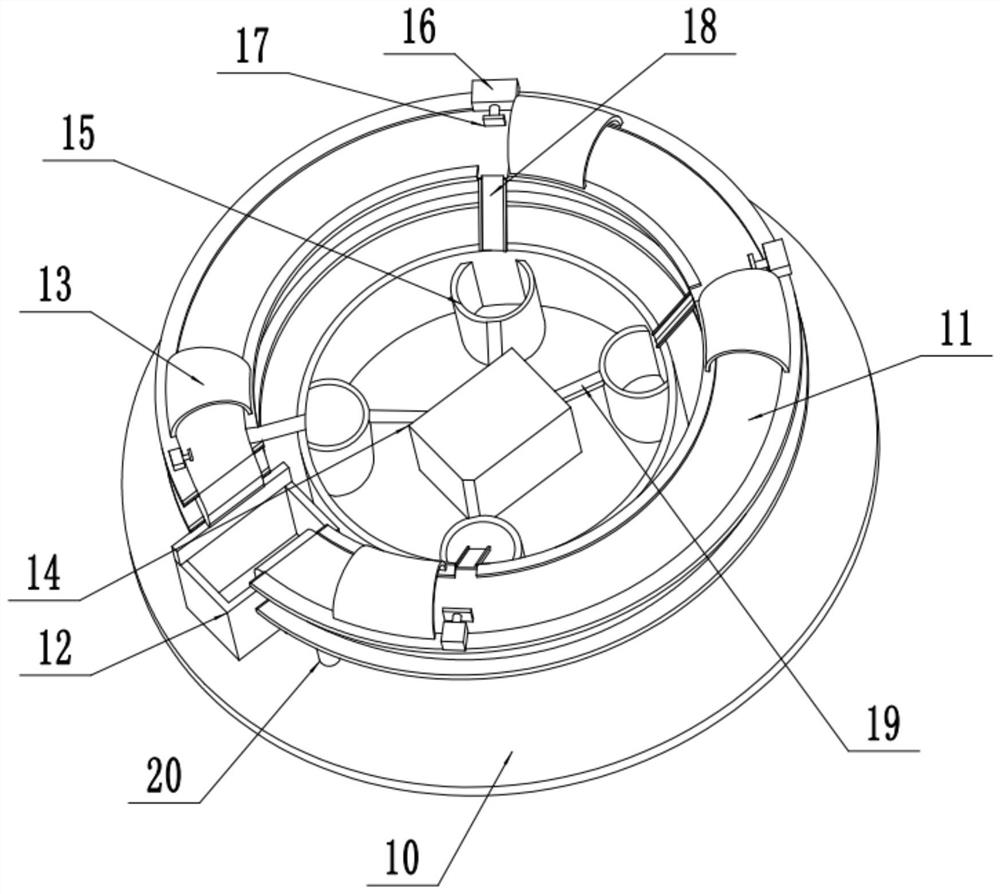

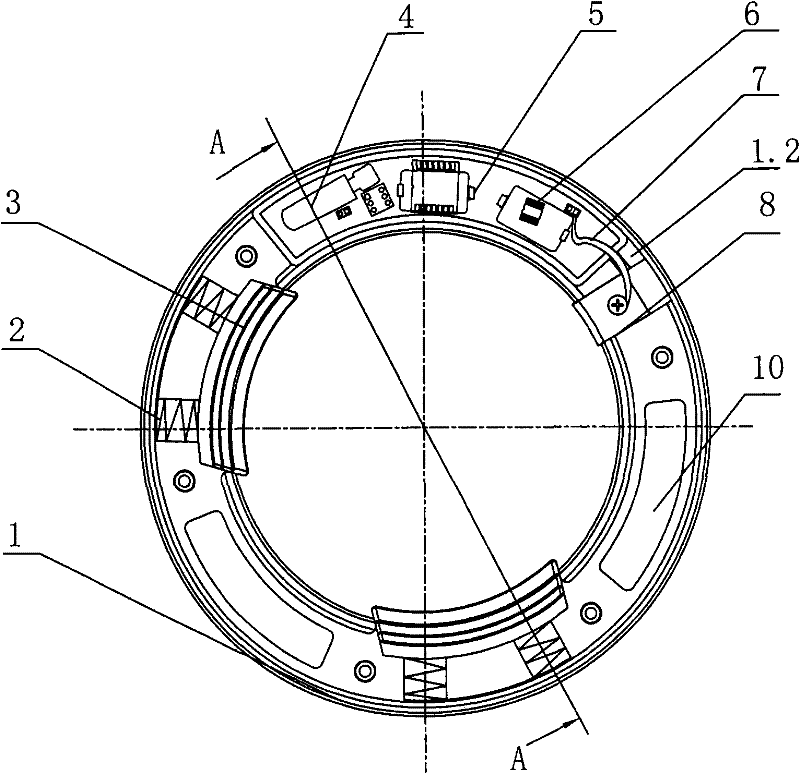

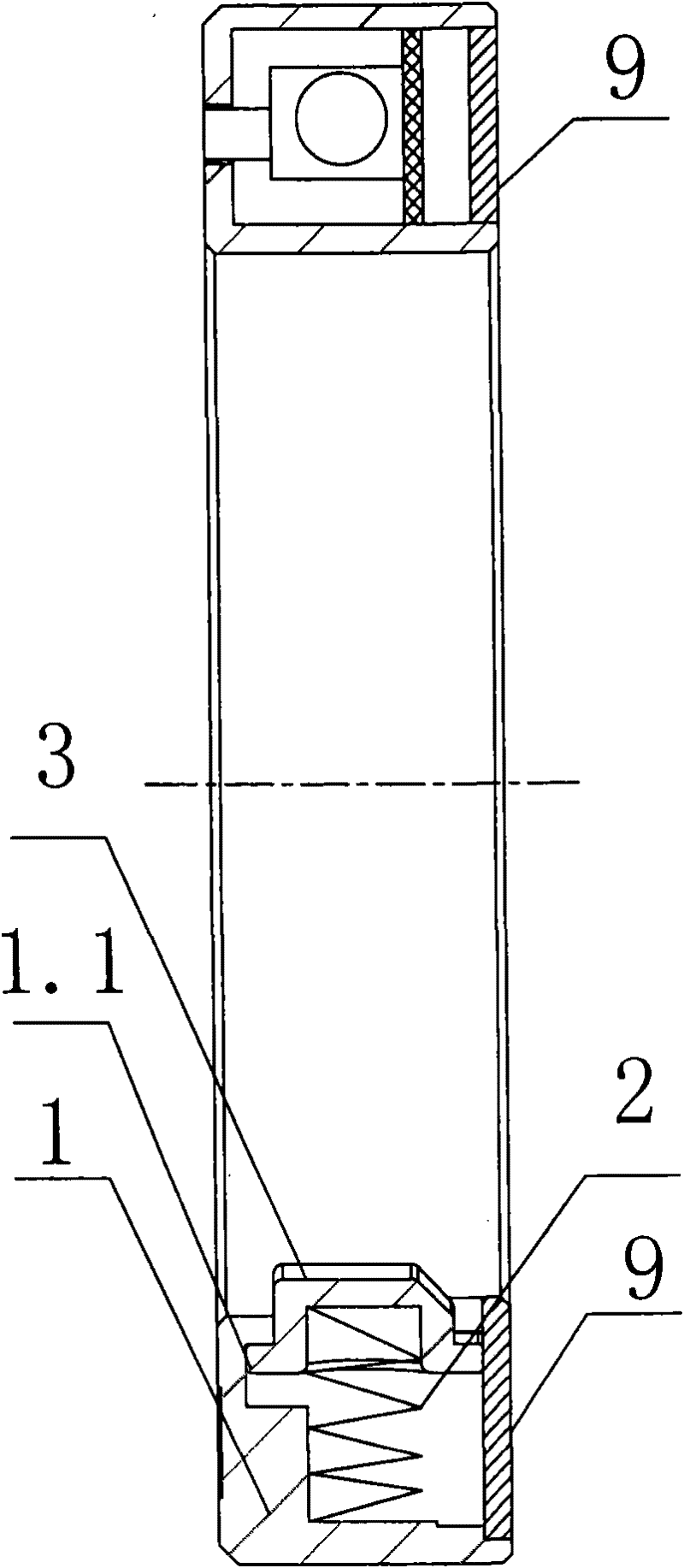

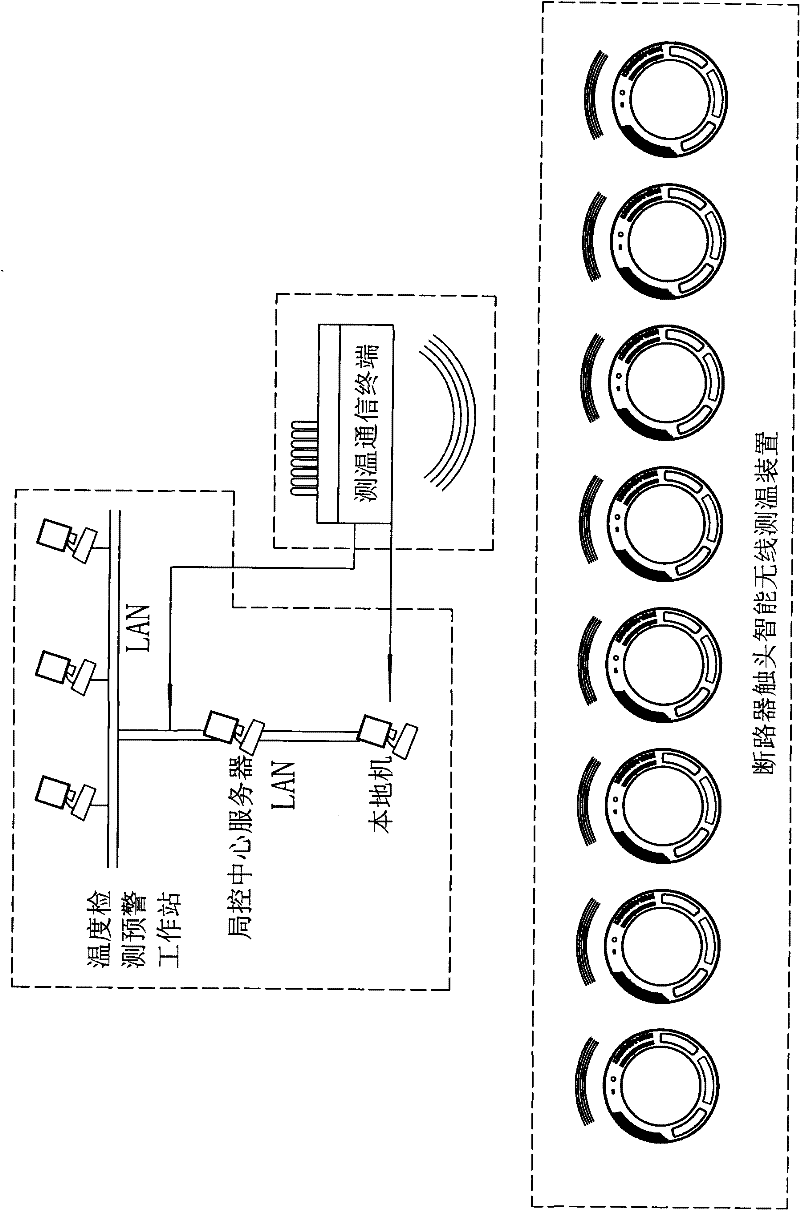

Intelligent wireless temperature-detecting device for breaker contact

ActiveCN101975617BRealize temperature measurementFixed tightlyThermometer detailsTransmission systemsHeat conductingComputer module

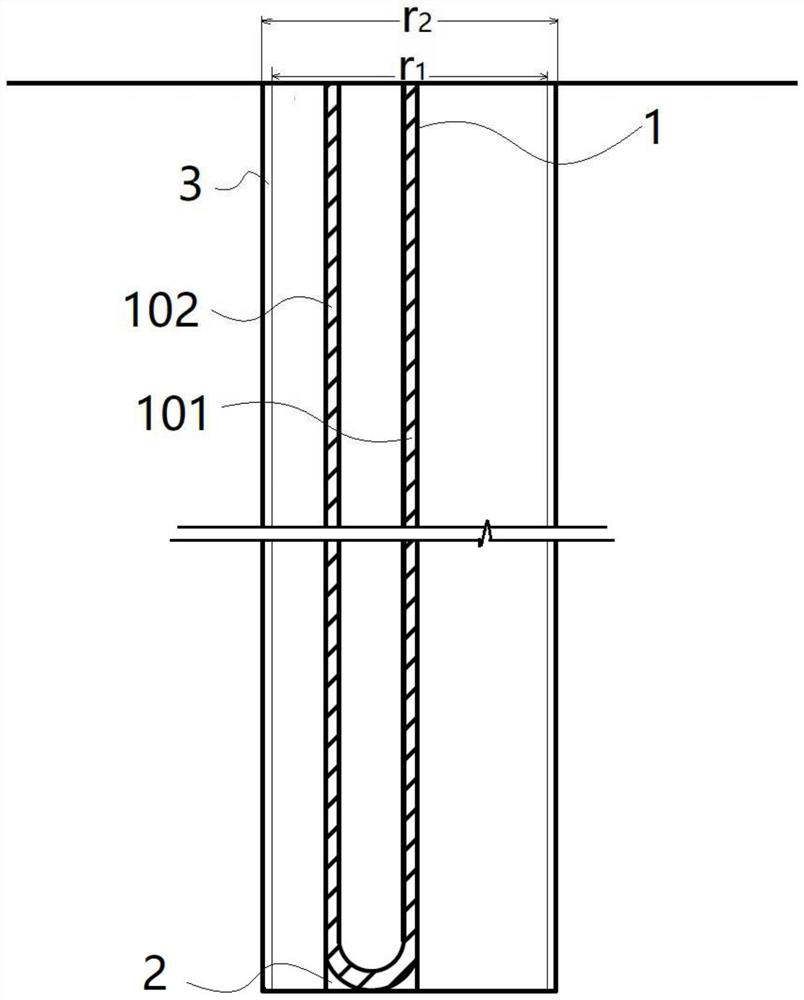

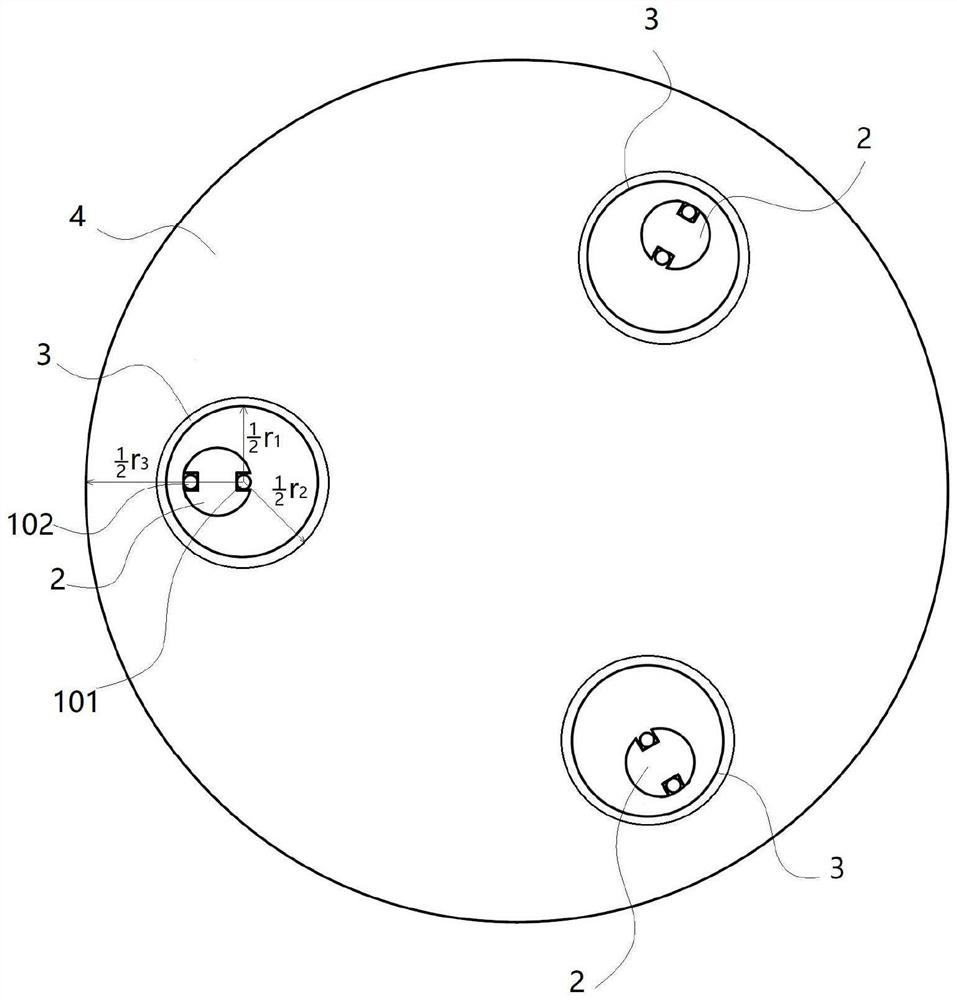

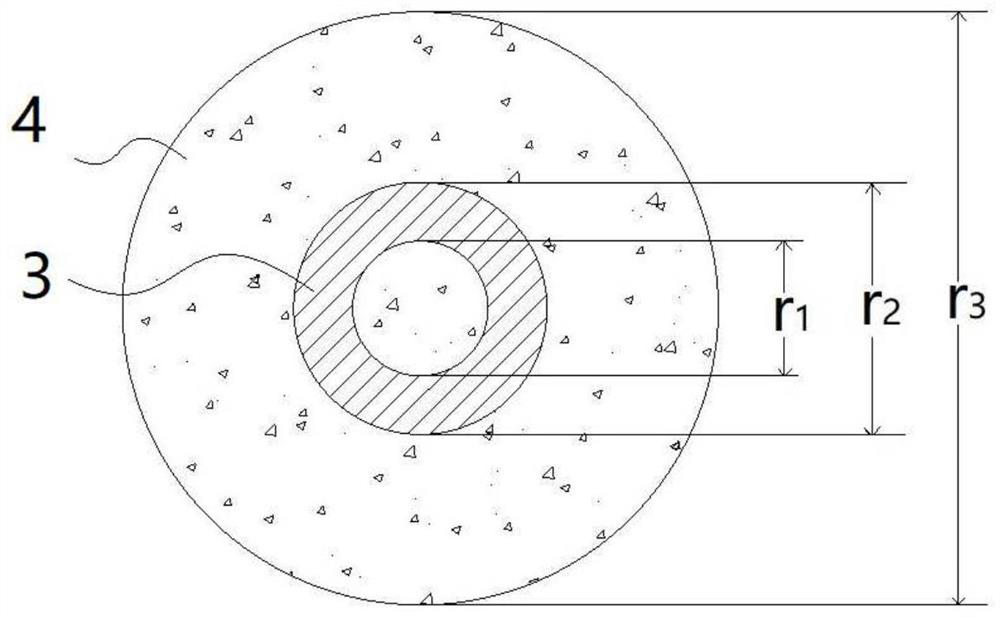

The invention relates to an intelligent wireless temperature-detecting device for a breaker contact. The device is of ring shape and comprises a base (1) and a rear cover (9) in matching connection with the base (1), wherein the interior of the base (1) is a cavity; a slot (1.1) is arranged on an annular inner wall; the number of the slot (1.1) is at least three; one slot (1.1) is provided with aheat conducting plate (8); two slots (1.1) are provided with an eccentric positioning tile (3); the front end of the eccentric positioning tile (3) is extended out of the slot (1.1) while the rear end thereof is arranged in the cavity of the base (1); a compression spring (2) is mounted in the cavity of the base (1) and is arranged on the tail end of the eccentric positioning tile (3); the front end of the heat conducting plate (8) is extended out of the slot (1.1) while the rear end thereof is connected to one end of a sensor (7); the other end of the sensor (7) is connected to one end of a MCU control unit (6); and the other end of the MCU control unit (6) is connected to a RF wireless data transmission module (4). The device can be mounted on a static contact of the high-pressure shafts, has long service life and can precisely detect the temperature of the contact.

Owner:JIANGSU LIDE INTELLIGENT MONITORING TECH CO LTD

Post-loading monitoring method for composite pile

PendingCN114486018AHigh sensitivityImprove performanceFoundation testingForce measurement by measuring optical property variationArchitectural engineeringStructural engineering

The invention discloses a back-mounted monitoring method for a composite pile. Distributed optical fibers are fixed to the designated position of a PVC pipe; the PVC pipes are bonded and combined into the specified length, then the PVC pipes are inserted into the sounding pipe of the first cast-in-place pile, then the PVC pipes with the distributed optical fibers are inserted into the sounding pipe of the next cast-in-place pile, and the PVC pipes are fixed through grouting of pipe openings of the PVC pipes; and the distributed optical fibers are connected to an optical fiber demodulator, and the stress change in the cast-in-place pile is measured in real time. According to the method, the distributed optical fibers are adopted, the sensitivity is high, the performance is stable, meanwhile, the installation process is simple and easy to implement, new measuring pipes do not need to be additionally arranged, and existing sounding holes in the cast-in-place pile are fully utilized for installation; the method can realize automatic and real-time detection of deformation of a plurality of combined cast-in-place piles, has the advantages of convenience in measurement, high measurement efficiency, small influence of a measurement environment, real-time early warning and the like, realizes an intelligent measurement function, and realizes measurement informatization.

Owner:中铁二十二局集团市政工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com