Cast-in-place pile optical fiber monitoring system and method

A monitoring system and cast-in-place pile technology, which is applied to excavation, sheet pile walls, and measuring devices, can solve problems such as potential safety hazards in foundation pit construction, damage to optical fiber sensors, and failure to collect data, achieving small impact on the measurement environment and high monitoring efficiency Improve and monitor cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

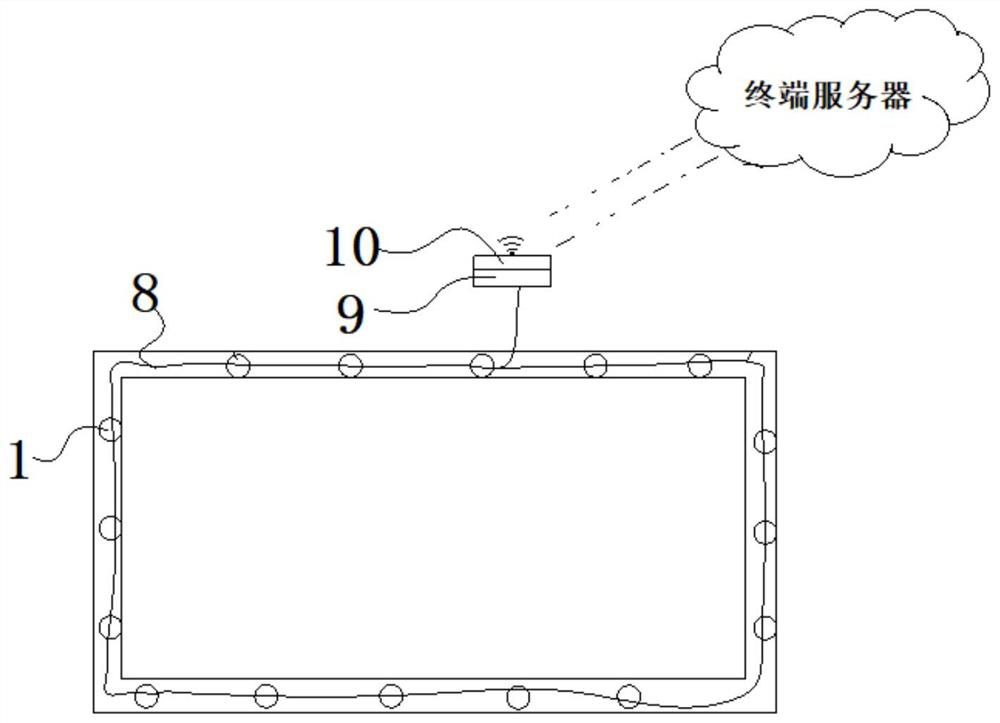

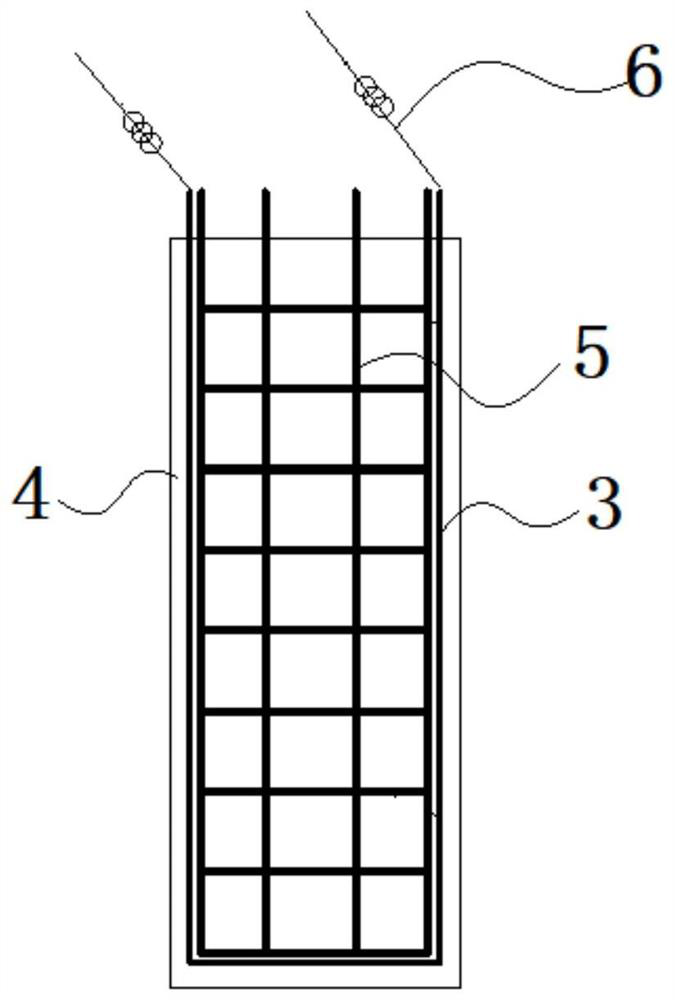

[0039] Such as Figure 1-6 As shown, the specific embodiment of the present invention is a fiber optic monitoring system for cast-in-situ piles. Each monitoring point 1 of cast-in-situ piles is equipped with an optical fiber sensor 2, and the optical fiber sensor 2 is installed on the cast-in-situ pile 4 through a protective fastener 3. The optical fiber sensor 2 is also connected to the main rib 5 of the optical fiber sensor 2 , and the optical fiber outgoing line 6 is connected to the detection module 7 . The optical fiber sensor is a fiber grating.

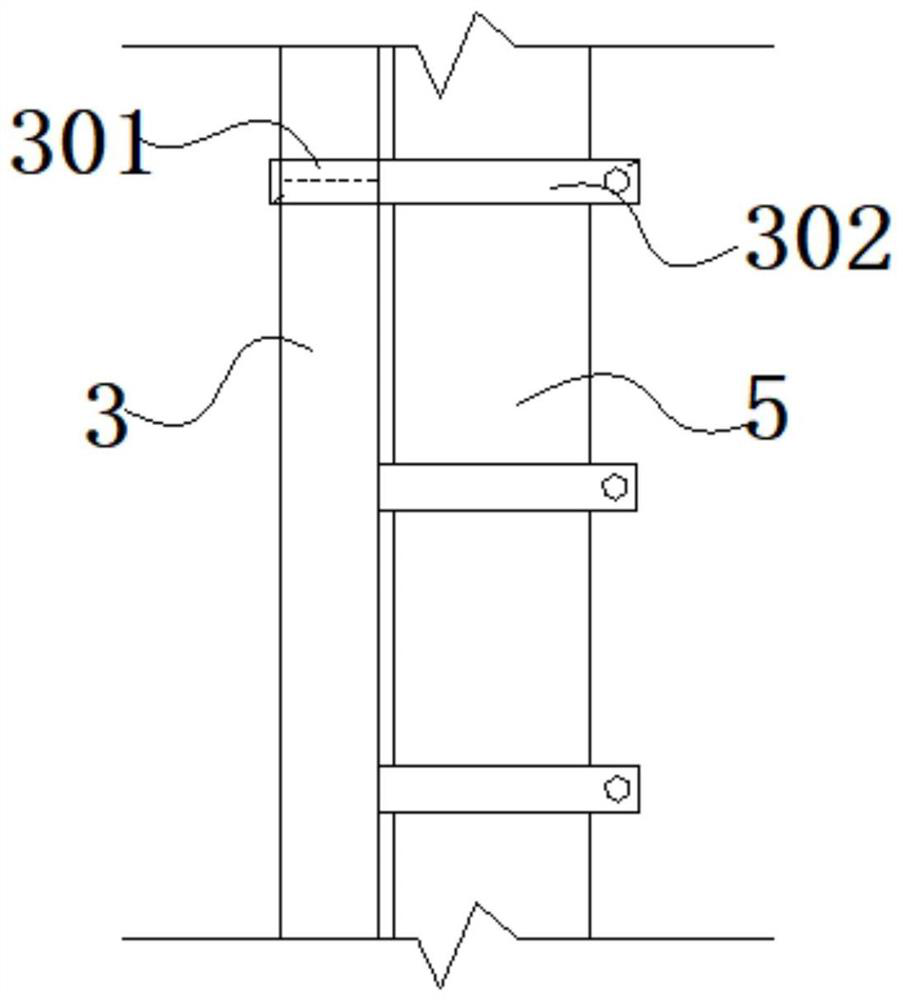

[0040] The protective fastener 3 includes a movable sleeve 301 and a buckle 302. The movable sleeve 301 is composed of a rotating shaft 303, a half-moon inner cover 304 and a half-moon outer cover 305. The half-moon outer cover 305 can rotate around the rotating shaft 303. open outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com