Intelligent operation staring and controlling visual management system

A management system and operation technology, applied in the direction of manufacturing computing system, data processing application, induction recording carrier, etc., can solve the problems of only viewing flat video images, processing pipelines that do not use big data technology, and ineffective monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

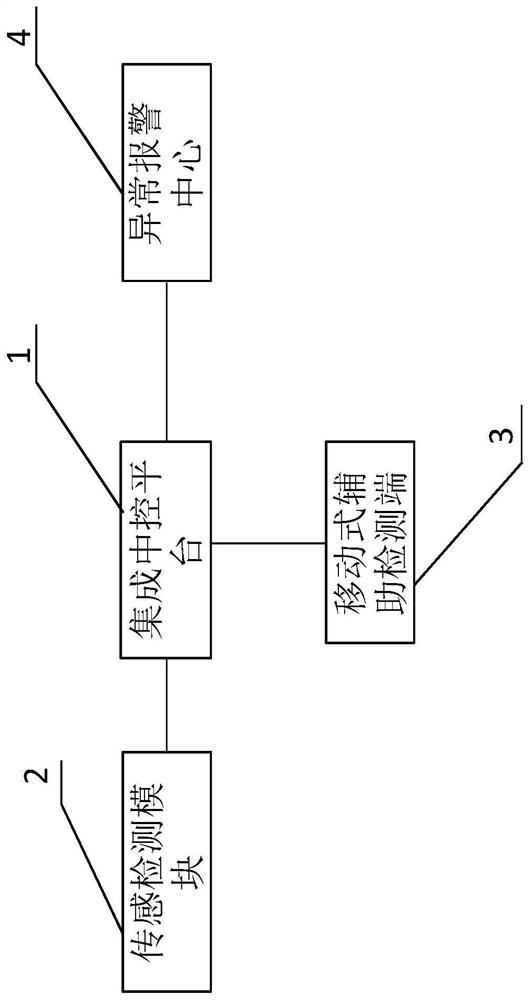

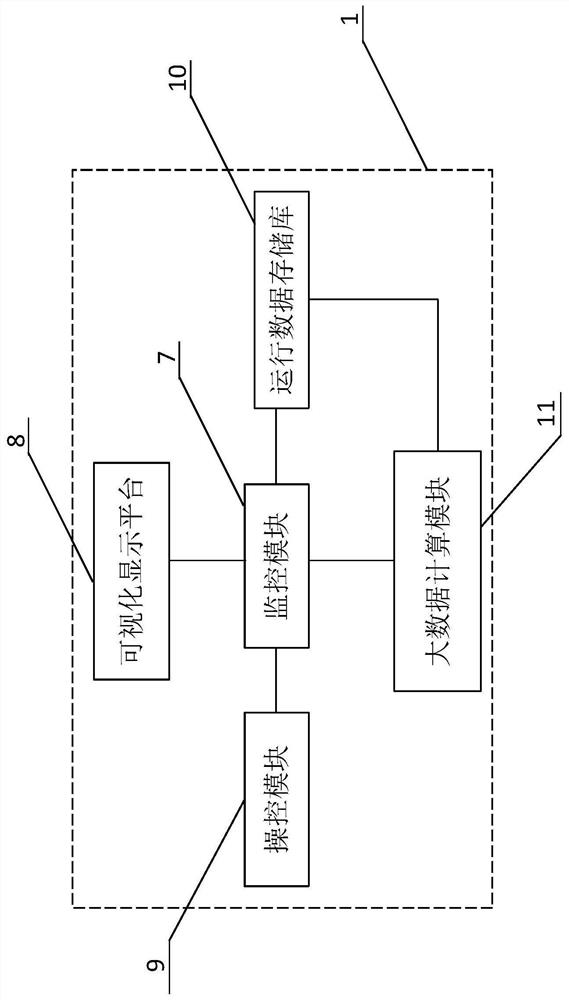

[0049] see figure 1 , the present invention provides a technical solution: an intelligent operation monitoring visual management system, which is applied to a processing line, including an integrated central control platform 1, a plurality of sensor detection modules 2, a mobile auxiliary detection terminal 3, and an abnormal alarm center 4; The integrated central control platform 1 is respectively connected with a plurality of sensing detection modules 2, a mobile auxiliary detection terminal 3, and an abnormal alarm center 4 through data communication, so as to realize data communication and manipulation control;

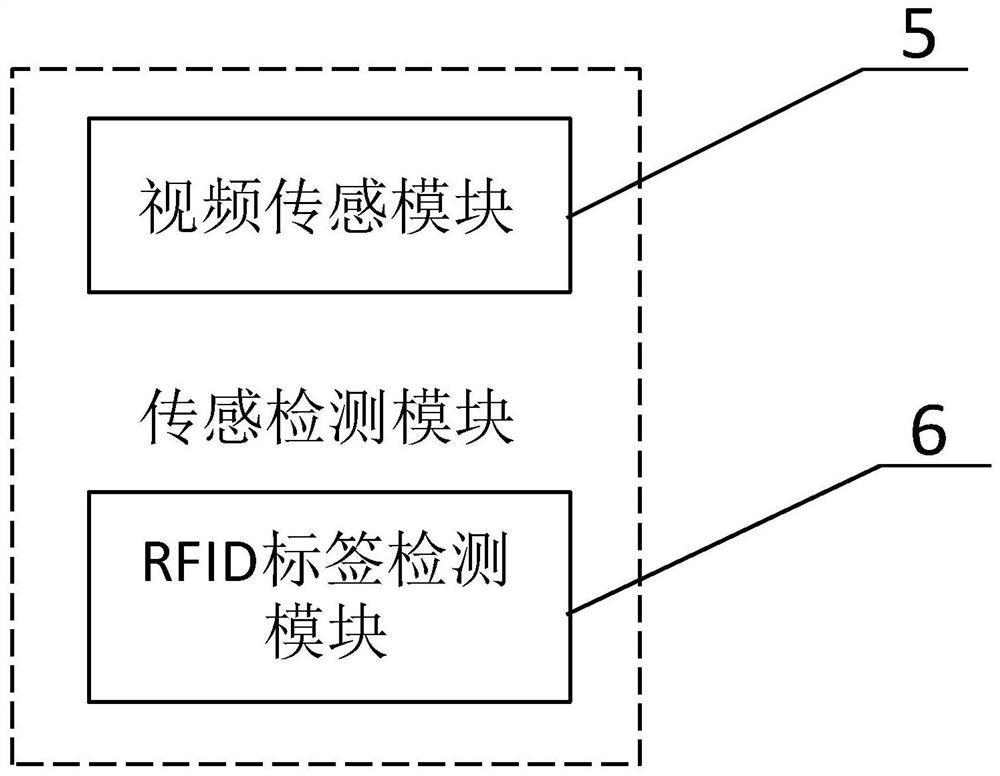

[0050] The sensing detection module 2 includes a video sensing module 5 and an RFID tag detection module 6; the video sensing module 5 is arranged at each assembly line processing point for keeping an eye on the working condition of the corresponding processing procedure; the RFID tag detection The modules 6 are arranged at the edge of the assembly line at interva...

specific Embodiment 2

[0063] Specific embodiment 2: On the other hand, this application also provides a visual management method for intelligent job monitoring, including a visual management system for intelligent job monitoring. The specific monitoring management method is as follows:

[0064] Step S1, initializing the intelligent operation monitoring visual management system, realizing normal data communication and control of each module of the management system;

[0065] Step S2, when the product enters the assembly line, an RFID tag is installed on the product, and it is assembled and displayed on the visual display platform 8. Every time a process is completed, a structural view is added to the product, and the visual display Platform 8 displays the virtual process installation diagram of the product, and the installation progress of the installed components;

[0066] Step S3, the big data calculation module 11 reads the historical operation data stored in the operation data storage library 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com