Hydromotive machine

A technology of hydraulic machinery and water turbines, applied in the field of hydraulic machinery, can solve the problems of uneconomical use of small turbines, and achieve the effects of facilitating transportation and equipment procurement, efficient and reliable assembly work, and reducing size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

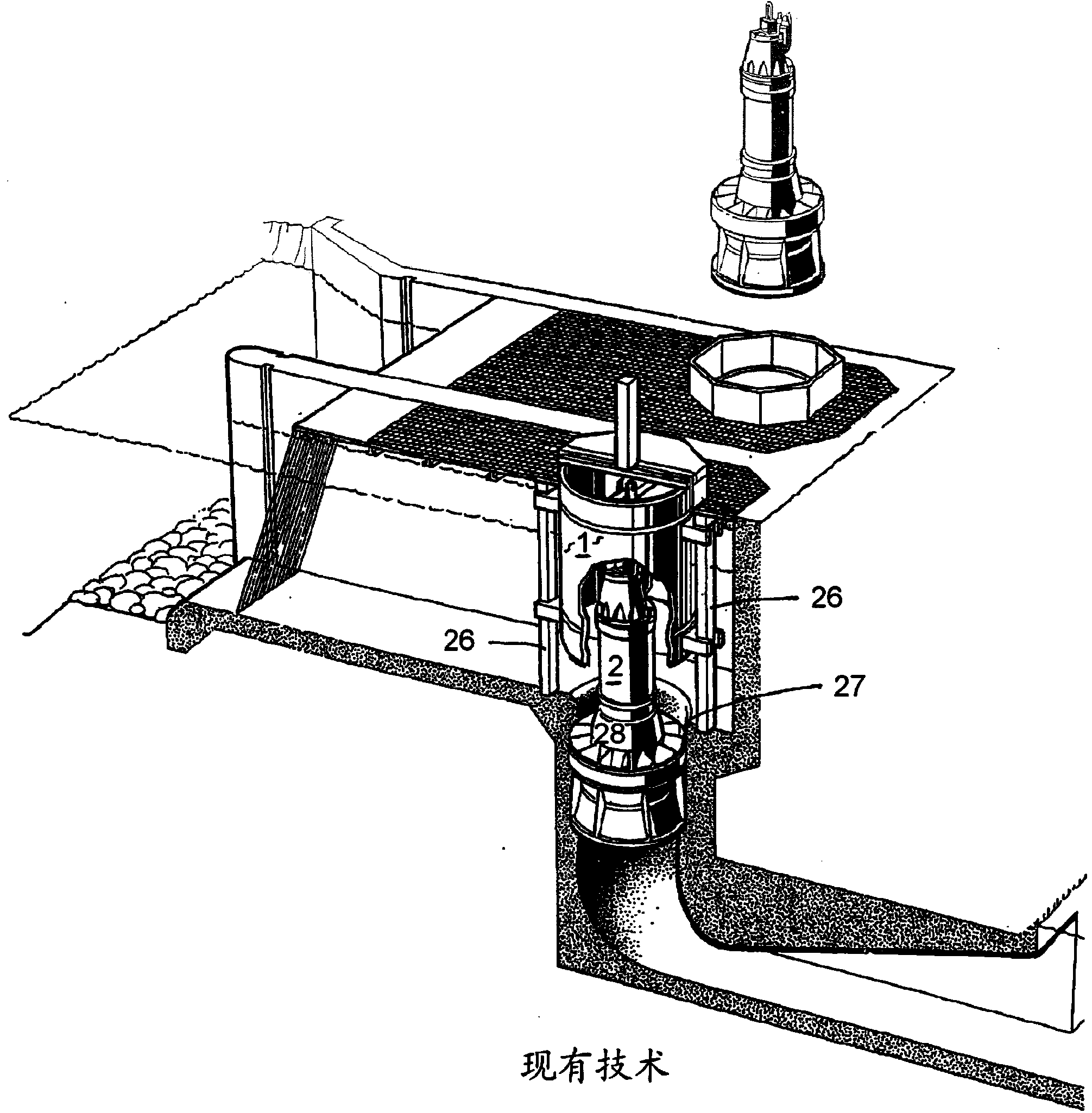

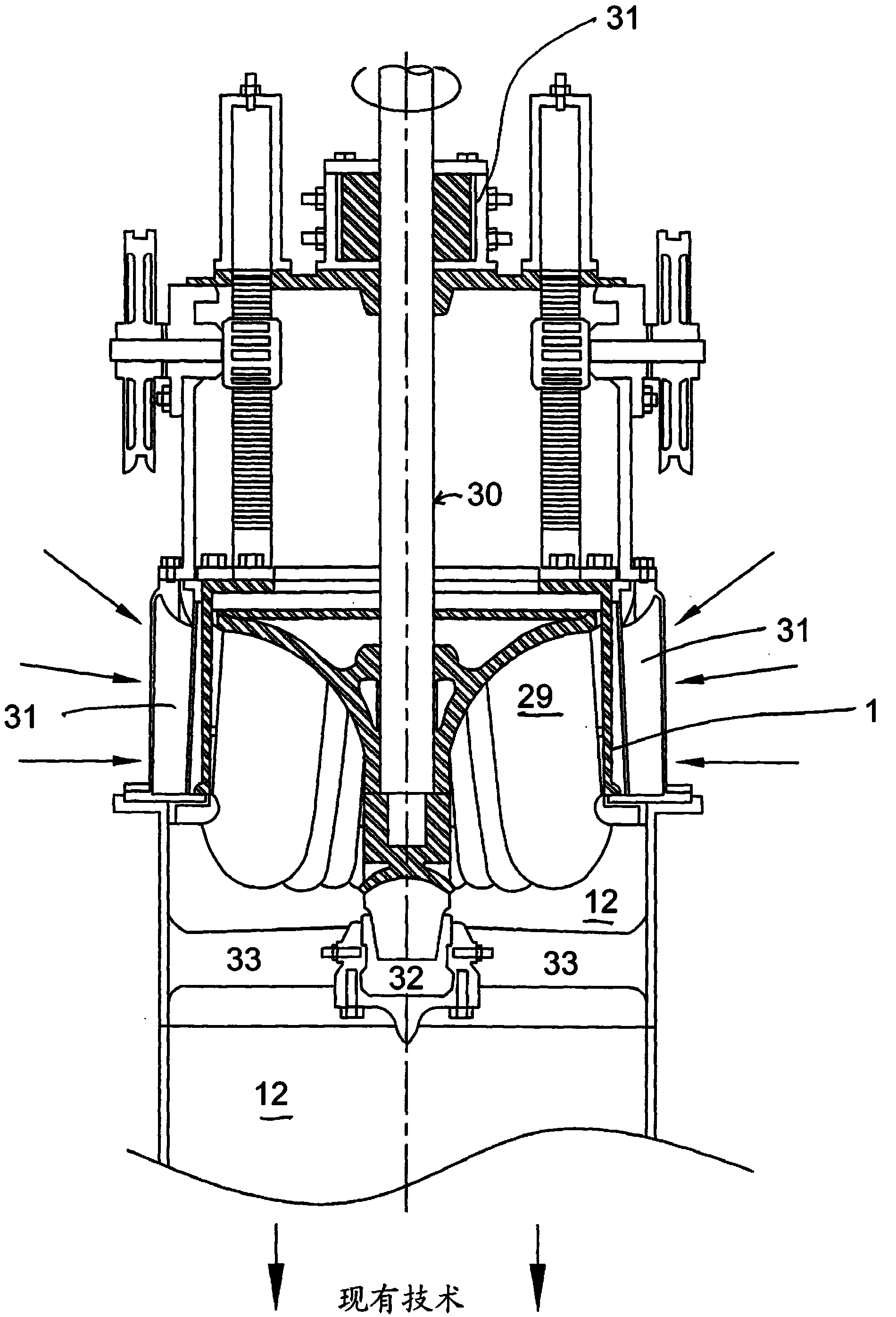

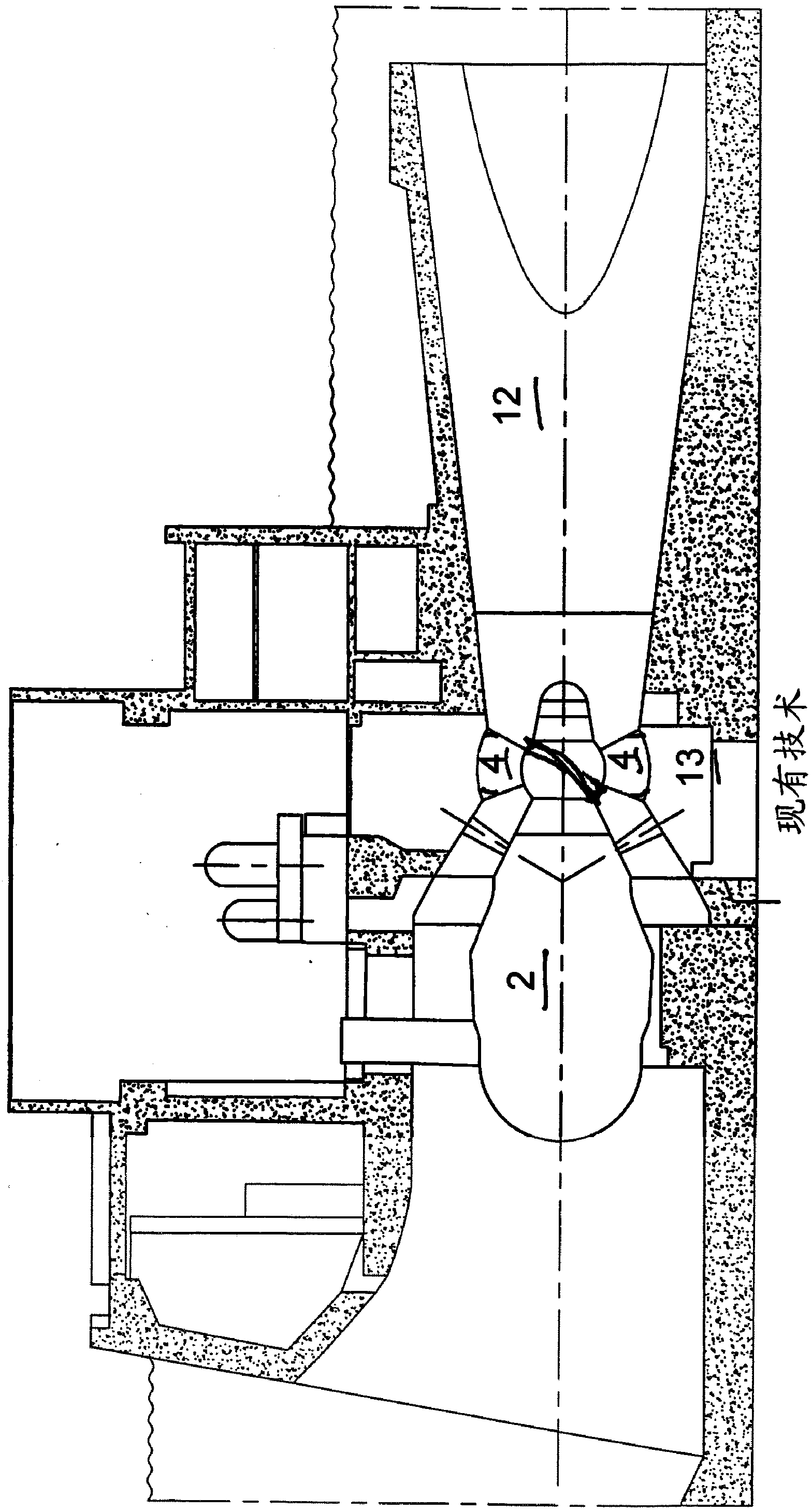

[0099] refer to figure 1 , shows a prior art turbine arrangement using a column gate. The dimensions of the illustrated prior art column gate 1 are large enough to allow complete removal of the turbine-generator unit through the closed column gate 1 . The large space between the cylindrical gate 1 and the outer diameter of the housing of the generator 2 limits the use of a vertical installation of such a cylindrical gate 1 extending above the water surface in its closed position. Furthermore, the configuration of the vertical rails 26 requires that they be placed radially away from the manifold inlet 27 so as not to cause unacceptable disturbances to the turbine input flow. The outer housing diameter of the illustrated generator 2 is too small for an economically designed direct drive generator, thus requiring a gear increaser 28 . The gear increaser 28 typically results in a shorter turbine generator life and lower reliability compared to direct drive alternatives.

[0100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com