Thermal resonance fusion engine

A technology of engines and fusion reactors, applied in the field of thermal resonance fusion engines, can solve the problems that electric motors cannot be used alone, high manufacturing, operation and maintenance costs, pollute the atmosphere and the environment, etc., and achieve low operation and maintenance, low total cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0155] When manufacturing a new engine, it must be designed and manufactured according to the specific index requirements of the engine and the requirements of the thermal resonance fusion engine, so as to meet the special performance requirements of the normal operation of the thermal resonance fusion engine. To achieve its excellent performance, for example, it only needs to input gaseous nuclear fuel to the reactor and under normal conditions, carbon-free and oxygen-free does not require complex systems, and low-cost long-term safe and stable normal operation can be achieved.

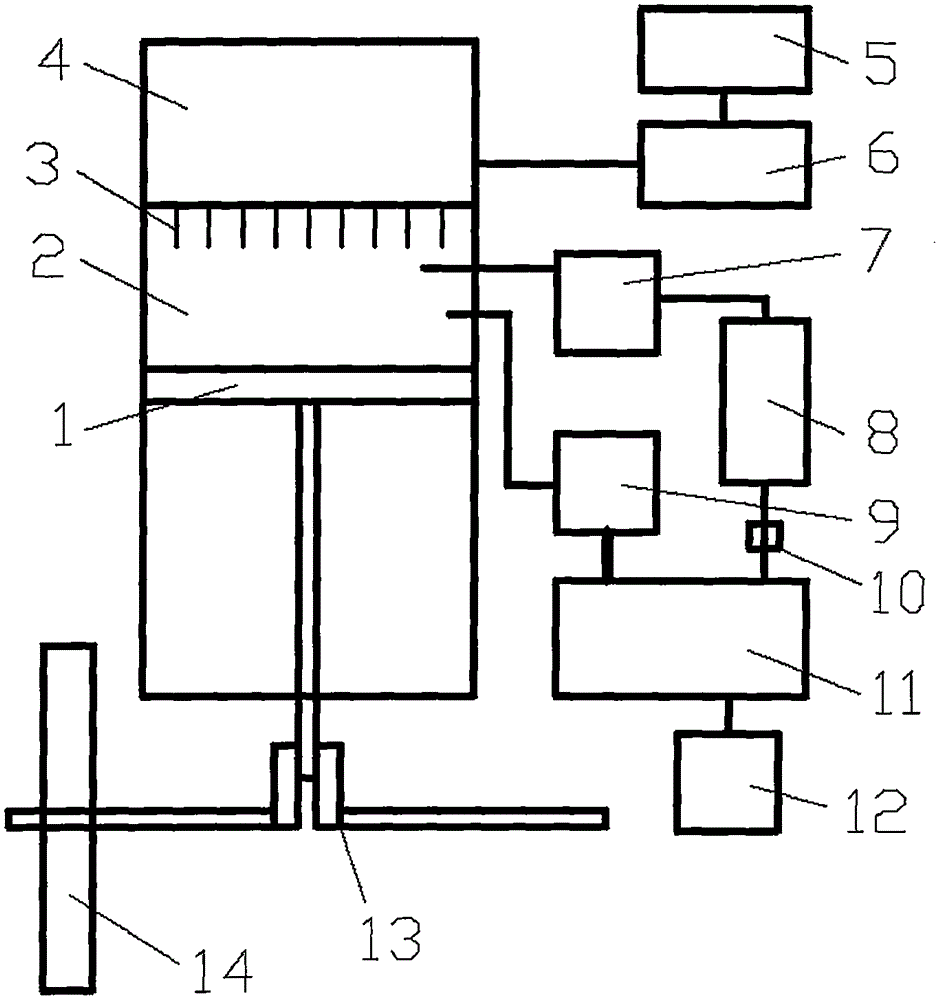

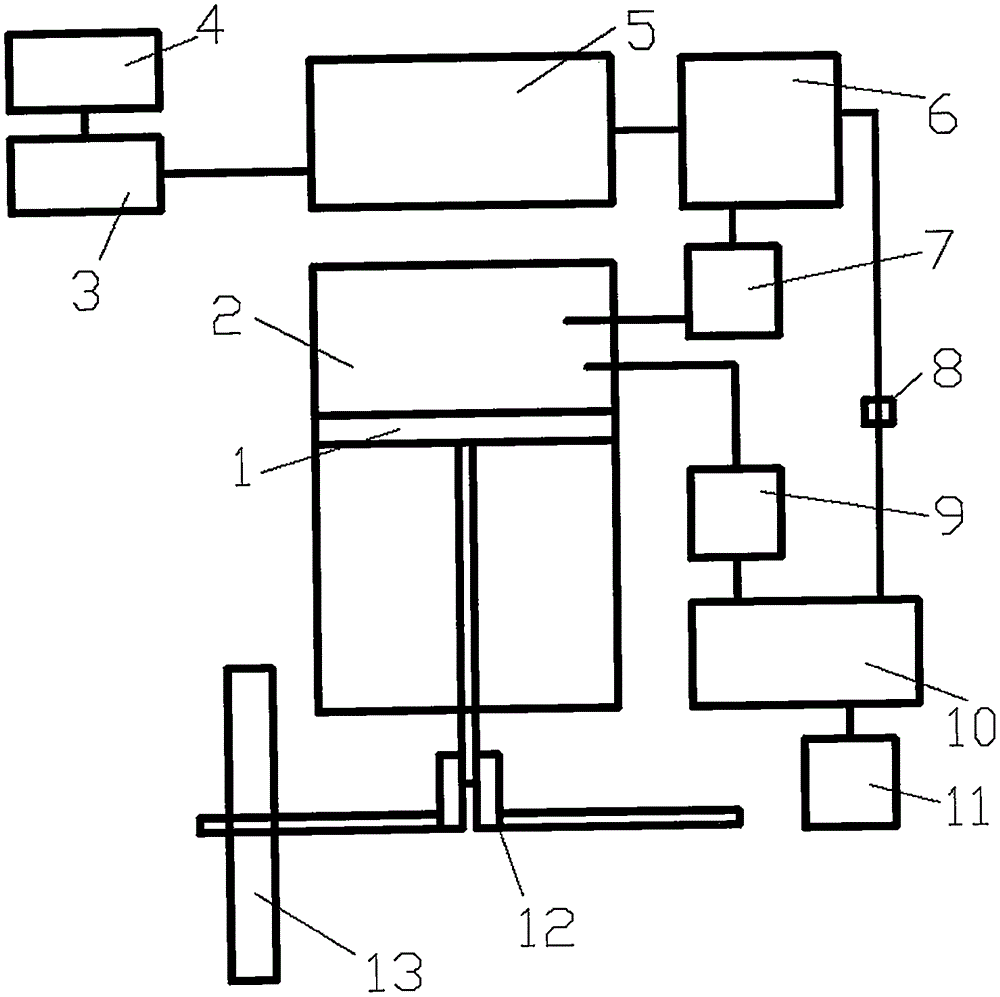

[0156] exist figure 1 Among them, the gas fusion fuel can be electrolytically produced by the heavy water storage electrolysis system (5) and then supplied to the gas storage tank system (6), and the gas fusion fuel enters the thermal resonance fusion reactor ( 4) A fusion reaction occurs in the interior, and the released heat energy is conducted to the heat exchanger of the heat exchanger system (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com